Page 1

User’s Guide

omega.com

®

www.omega.com

e-mail: info@omega.com

™

HHP-401 Series

Digital Manometer

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 6418405 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: Rudé armády 1868, 733 01 Karviná

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free in Czech Rep.: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621400 FAX: +33 (0)130 699120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 3017 FAX: +49 (0)7056 8540

Toll Free in Germany: 0800 TC-OMEGA

SM

e-mail: germany@omega.com

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in the United Kingdom: 0800 488 488

e-mail: sales@omega.co.uk

omega.comomega.com

OMEGAnet®On-Line Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

®

™

Page 3

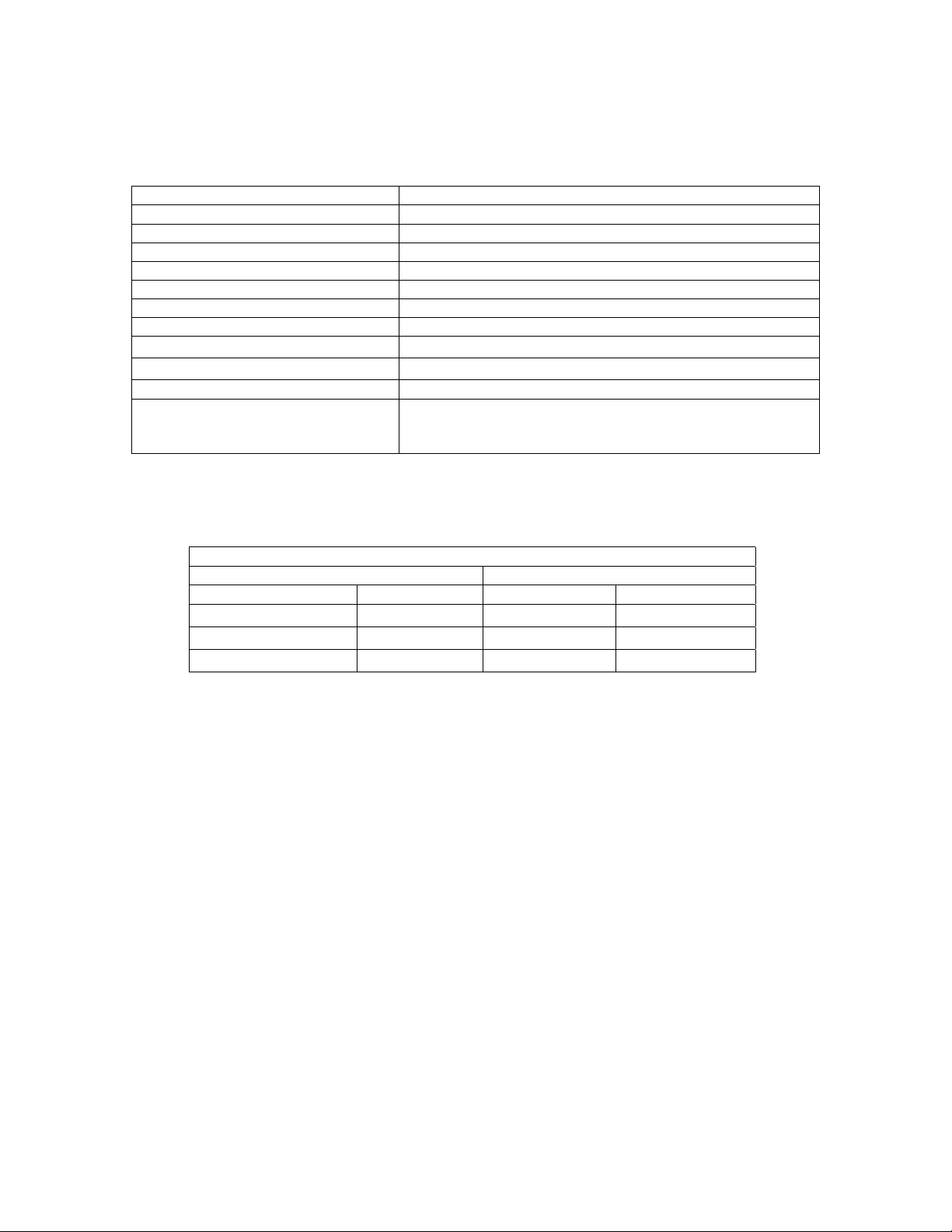

DIGITAL MANOMETER, HHP-401 Series

Specifications

Ranges, in inches of water column : .1", .2", .5", 1.0", 2.0", 5.0", 10.0"

Accurracy +/- 1% of range plus 1 digit

Resolution .001" for ranges to 1.0", .01" for ranges from 2.0" to 10.0"

Connections Metal fittings for 3/32" or 3/16" flexible tubing

Display LCD, .5" digit height

Low battery indicator The symbol "BAT" appears on display

Battery One 9 Volts, alkaline

Battery life 200 hours

Operating temperature range0o

Storage temperature

Standard accessories 9V batter y

Optional accessories Carrying case with two lengths of rubber tubing, one

Warning: This device is for use with air or non corrosive, non explosive gases only.

Warning: Care should be taken not to exceed the maximum overpressure.

Maximum Safe Momentary Overpressure Table

Range Overpressure

English Metric English Metric

0.100 - 1.00" H2O 25 to 250 Pa 8" H2O2 kPa

2.00 - 10.0" H2O 0.5 to 2.5 kPa 5 psid 35 kPa

11.00" H2O - 5 psid 2.7 to 35 kPa 20 psid 140 kPa

C to +50oC (+32oF to +122oF)

-20oC to +70oC (-4oF to +160oF)

insertion tube, two static pressure tips, one 6 " insertion

length Pitot tube. Longer Pitot tubes to 60" are available

General instructions

1) Turn manometer on.

2) If low battery signal is displayed, replace battery located in compartment on back of

manometer.

3) Turn zero adjustment thumbwheel until display indicates zero.

4) Manometer is now ready to operate. Use as follows:

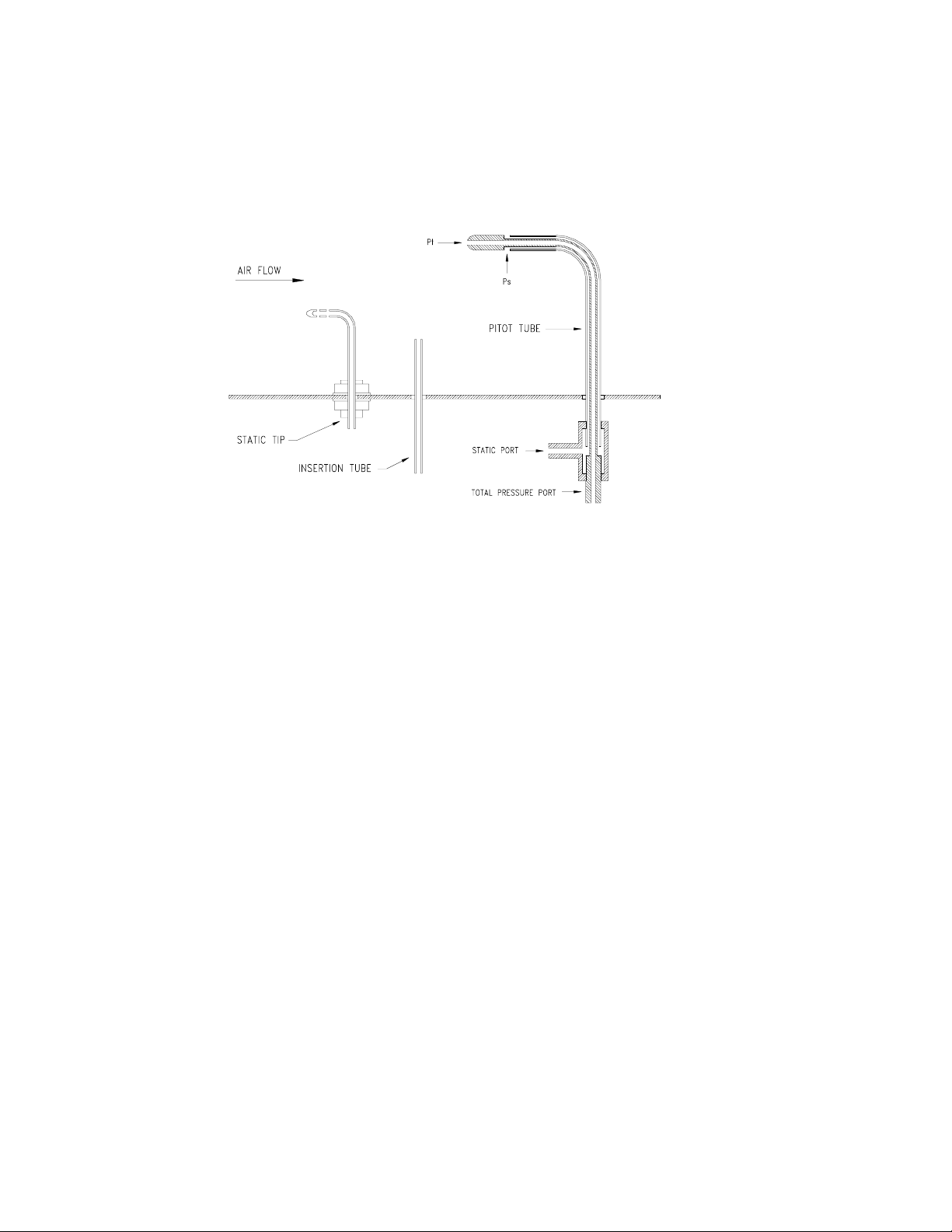

Static pressure

For measurements of static pressure in d ucts, it is recommended that a static pressure t ip or the

static connection of a Pitot tube be used (see f ig.1). Run tubing from stat ic tip to high pressure

port of manometer. A positive readin g i ndica tes pr es sur e a bov e atm os pheric pr ess ur e; a neg ativ e

reading, a pressure below atmospheric pressure.

Insertion tube

The insertion tube may be used to measure static pressure wher e flow is re latively s low, smooth

and without turbulence. The op eni ng of th e tu be must be perpendicular to the direc ti on of t he f low

(see fig.1). If turbulenc e exists, impingement, aspir ation or unequal distribut ion of moving air at

the opening can reduce accuracy of readings significantly.

Air filter test

Connect manometer diff erentially across filter w ith static tips pointin g upstream to eliminat e the

possibility of error due t o air velocity. Connect the tubing fr om the static tip downstream of the

HHP-401 M-3490 / 0899

Page 4

filter to the low pressure port of the manometer and the tu bing from t he static tip u pstream of the

filter to the high pressure port of the manometer.

Figure 1

Air velocity measurement

1) Connect total pressure port (Pt) of Pi tot tube to high pressure por t of manometer and static

port (Ps) to low pressure port to read velocity pressure.

2) Insert Pitot tube in duct with tip pointing upstream and make a traverse according to fig. 2.

Refer to chart of fig. 3 to determine air velocity for each traverse point at standard conditions

70oF and 29.92 inches of mercury barometric pressure with a resulting density of .075

Lb/cu.ft) or use following formulas to compute air velocity at conditions other than standard.

The velocities are then averaged.

Note - For very small r ound pipes, a center reading is freque ntly sufficient to o btain reasonable

accuracy. For ducts 6 to 10 inches in dia meter an d average v elocities of 1000 t o 3000 f t/min, the

center velocity pressur e r e ading may be mu ltiplied by .81 to obtain the average velocity pr es sur e.

This method is not recommended for either accurate results or very high (or low) velocities.

HHP-401 M-3490 / 0899

Page 5

Note - Install a straightener at 6 duct diameters downstream from the beginning of straight portion

of duct and take velocity pressure reading 7 1/2 duct diameters downs-tream from the beginning of

this straight portion to insure correct P itot tube readings.

Air velocity = 1096.2 Pv where Pv = velocity pressure, in inches of water

D D = air density, in Lb/cu.ft

Air density = 1.325 Pb where Pb = barometric pressure in inches of mercury

460 +

To determine air flow : Q = AV where Q = flow, in cu.ft. per min.

o

F

o

F = temperature in degrees Farenheit

A = duct area, in square ft.

V = velocity, in ft. per min.

Note - For rectangular ducts, divide up the total area into a large number of small equal areas and

take a velocity pressure reading in the center of each small area. The number o f readin gs should

not be less than 16 and need not be more than 64. When less than 64 read ings are taken, the

number of equal spaces shou ld be such t hat the ce nters of the areas ar e not mor e than 6 inc hes

apart.

VELOCITY PRESSURE, Inches of water

0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09

400 566 694 801 896 981 1060 1133 1202

.0 .1 .2 .3 .4 .5 .6 .7 .8 .9

0

1

2

3

4

5

6

7

8

9

10

4003 4198 4385 4564 4736 4902 5063 5219 5370 5517

5661 5801 5937 6070 6201 6329 6454 6577 6698 6816

6933 7048 7160 7271 7381 7488 7595 7699 7803 7905

8006 8105 8203 8300 8396 8491 8585 8678 8770 8860

8950 9039 9128 9215 9302 9387 9472 9556 9640 9723

9805 9886 9967 10047 10126 10205 10283 10361 10438 10514

10590 10666 10741 10815 10889 10962 11035 11107 11179 11251

11322 11392 11462 11532 11601 11670 11738 11806 11874 11941

12008 12075 12141 12207 12272 12337 12402 12467 12531 12594

12658 12721 12784 12846 12909 12970 13032 13093 13154 13215

1266 1790 2192 2532 2830 3101 3349 3580 3707

Figure 3 – Velocities (ft/min) for dry air at various pressures

o

@70

F and 29.92 inches of Hg barometric pressure

HHP-401 M-3490 / 0899

Page 6

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s Warranty adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner .

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

MADE IN

Page 7

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

HHP-401 Series M3490 / 0899

Loading...

Loading...