Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

MADE IN

Shop online at

User’s Guide

HHP360 Series

Precision Absolute Manometer

Page 2

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WAR NING: These products are not designed for use in, and should not be used for, human applications.

Page 3

USER MANUAL

PRECISION ABSOLUTE MANOMETER

The Precision Absolute Manometer is a microprocessor based

pressure sensing device used to directly measure pressure

relative to absolute zero. Model HHP360-A measures pressure

from 0 – 17.403 PSIA and model HHP360-B measures

pressure from 0 – 38.674 PSIA. Pressure can be displayed in a

variety of English and S.I. engineering units. All HHP360s

include a Tare function, a Min/Max function, selectable damp

rates and altitude displayed in feet or meters. The HHP360

can also display barometric pressure corrected to sea level.

1 of 32

Page 4

Table of Contents

User Interface ......................................................................................3

1. Keypad Functions ....................................................................3

ON/OFF & BACK

MIN/MAX & UP KEY .............................................................3

TARE & DOWN KEY..............................................................3

PRGM & ENTER KEY ............................................

BACKLIGHT KEY.......................................................................4

2. Zeroing the Manometer ...........................................................5

3. Program Mode........................................................................10

Units Select ..................................................................................11

Displaying Altitude (US Standard Atmosphere 1962) ..............12

Display User Defined Altitude....................................................12

Pressure Corrected to Sea Level ..................

Damp Rate Select ........................................................................17

User Info Select ...........................................................................18

Auto Shut-Off ..............................................................................19

Lockout Select .............................................................................20

Header Name .........................................................

Contrast Select .............................................................................22

Data Logging ............................................. 23

Leak Test......................................................................................24

Re-Calibration ...................................................................................25

RE-CALIBRATION – 1 Point EDIT and START ....................26

RE-CALIBRATION – 5 Point EDIT .........................................27

RE-CALIBRATION – 5 Point START............ ..........................27

RE-CALIBRATION – Restore Factory Defaults ......................29

Specifications ....................................................................................30

Certification/Safety/Warnings ..........................................................31

Changing the Batteries......................................................................31

KEY

............................................................3

...............................15

......................21

..................................

................3

2 of 32

Page 5

User Interface

1. Keypad Functions

ON/OFF & BACK ▲ KEY

Turns the manometer on and enters the unit into the Mea sur e

Mode. Pressing the key while in the Measure Mode turns the unit

off. It also serves as a backspace key when editing in the Program

Mod e. The key takes the user out of a programmable register

without changing the previous setting. Pressing this key repeatedly

will return the user to the Measure Mode and then shut off the

manometer.

MIN/MAX & UP ▲ KEY

In the Measure Mode activates the Min/Ma x function of the

manometer. When activated the minimum value is displayed on the

upper left of the display and the maximum value on the upper

right. This key also deactivates and resets this function. The key

is used to scroll through the programmable registers when the unit

is in the Program Mode. Once a programmable register is selected

▲

the key can be used to edit that register.

TARE & DOWN KEY

In the Measure Mode toggles on/off the Tare function. The Tare

function is designed to set the display value to “0”. With Tare

activated, the letter “T” appears in the lower left of the display.

▲

The key is used to scroll through programmable registers with

the unit in the Program Mode. Once a programmable register is

selected the key can be used to edit that register.

PRGM & ENTER KEY

Puts the manometer into the Program Mode from the Me asure

Mode. When in the Program Mode, pressing this key selects the

programmable register to be edited (with prompt for password if

Lockout is set). After the register has been edited, pressing the

▲

▲

▲

▲

3 of 32

Page 6

PRG M key enters the new setting into the manometer’s nonvolatile memory. This key also acts as a forward space key when

editing user input such as the header name and user units.

BACKLIGHT KEY

The BACKLIGHT key, represented by the standard light bulb

symbol, toggles the display backlight between green and off.

▲

4 of 32

Page 7

2. Zeroing the Manometer

The HHP360 is a stable and precise instrument. However, on

occasion the handheld should have a new zero taken. This is done

to remove zero drift that can occur since it was last zeroed. The

HHP360 can be zeroed only if the new applied zero is within ± 1%

FS of the original factory calibration zero. This prevents

accidental zeroing at atmospheric pressure or other relatively high

pressures. If outside this limit a “ZERO RANGE ERROR”

message appears and the manometer will not zero.

The HHP360 provides three mechanisms for re-zeroing:

1. Referenced to Absolute Zero: This traditional and

preferred method takes a “snapshot” of the measured pressure

when a vacuum of less than 100 microns Absolute is applied

to the sensor.

2. Factory Zero: This method restores the calibration curve to

the original zero taken at the factory. Note that this feature is

intended for comparison purposes, and should not be used for

real pressure measurement, as any zero-drift will not be

compensated.

3. User-Adjusted Zero: This method allows the user to enter

any pressure value when a known reference is applied (for

example, the local barometer). The manometer will compare

its actual measured value with the entered value, and calculate

a new zero reference based on the offset.

1. To zero the manometer using Referenced to Absolute

Zero, start with the unit turned OFF and use the following

keystroke sequence:

5 of 32

Page 8

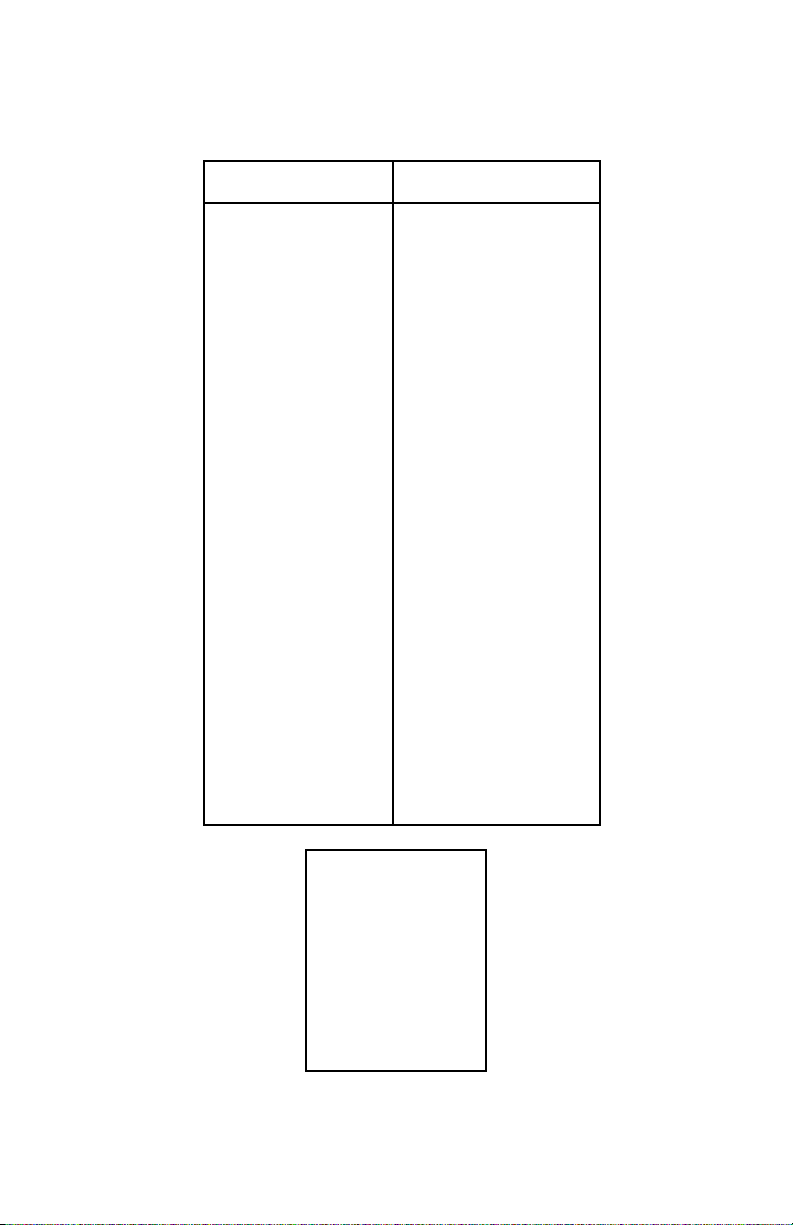

Keystroke

Display

1. Press ON/OF button.

The display briefly shows

the header name and full

scale range of the unit in the

last engineering units

selected. The manometer

then goes into the Measure

Mode where the applied

pressure and engineering

unit of measure are

displayed.

2. Connect the HHP360

to a vacuum source

capable of a vacuum of

100 microns absolute

pressure or less.

3. Pull a full vacuum.

Display should read close to

zero. (See note on next

page)

4. Press MIN/MAX and

TARE keys at the same

time. (See figure 1

below.)

Top line of display reads

“ZEROING SOURCE:”

Bottom line of display reads

“REF TO ABS ZERO”

5. Press the PRGM key.

Top line of display reads

“ZERO IN PROGRESS”

while bottom line counts

down from 9. Zeroing is

complete when unit returns

to Measure Mode.

Figure 1

6 of 32

Page 9

2. To zero the manometer using Factory Zero, start with the

unit turn ON and in Measure Mode and use the following

keystroke sequence:

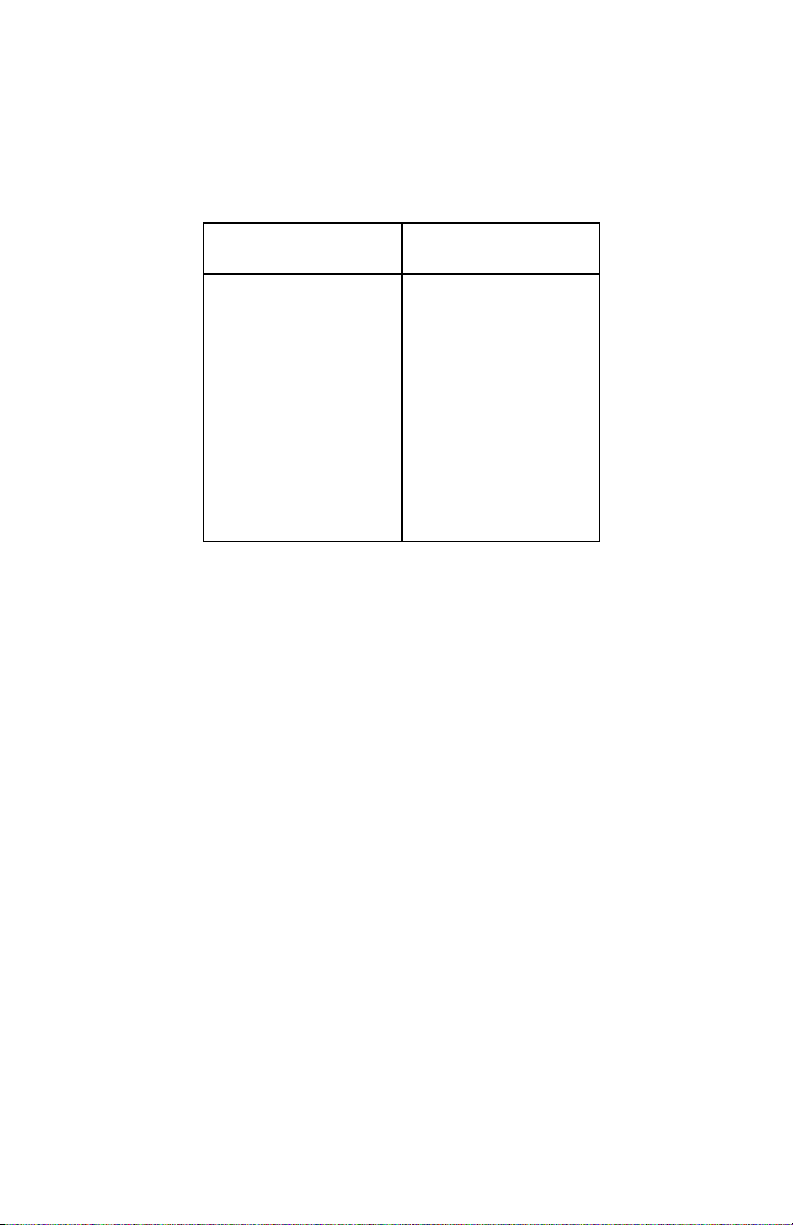

Keystroke Display

1. Press MIN/MAX and

TARE keys at the

same time. (See

figure 1 above.)

2. Press or arrow

key until desired zero

function is shown on

the bottom line.

3. Press the PRGM key.

NOTE: The HHP360 can be zeroed only if the new applied

zero is within ± 1% FS of the original factory calibration zero.

If outside this limit a “ZERO RANGE ERROR” message

appears and the manometer will not zero. Contact the factory

for support in this case.

3. To zero the manometer using User-Adjusted Zero, start

with the unit turn ON and in Measure Mode and use the

following keystroke sequence:

▲

▲

Top line of display reads

“ZEROING SOURCE:”

Bottom line of display

reads “REF TO ABS

ZERO”

Bottom line of display

reads “FACTORY ZERO”

Zeroing is complete when

unit returns to Measure

Mode.

7 of 32

Page 10

Keystroke Display

1. Apply a known,

accurate pressure

source. This may be

true atmospheric

pressure, with known

reference defined by a

local barometer.

2. Press MIN/MAX and

TARE keys at the

same time. (See

figure 1 above.)

3. Press or arrow

key until desired zero

function is shown on

the bottom line.

4. Press the PRGM key. Top line of display shows

5. Press any of or

arrow key or the

PRGM key to begin

editing.

Example: set current

pressure value to 29.5

In Hg @ 0º C.

▲

▲

▲

Top line of display reads

“ZEROING SOURCE:”

Bottom line of display

reads “REF TO ABS

ZERO”

Bottom line of display

reads “USER ADJ.

ZERO”

the current non-zero

compensated pressure

value. Bottom line of

display shows the same

value, along with the

engineering unit.

▲

Top line of display

continuously updates.

Bottom line of display data

is ready for editing; the

first digit is blinking.

8 of 32

Page 11

6. Press the or arrow

key to set the first

digit to 0.

Using the UP arrow

key the character

sequence is 0 - 9, (-)

negative, (.) decimal

point. The (-) sign is

used if your location

is below sea level.

▲

▲

Current: xxx.xx

0xx.xx INHG

7. When the digit is

correct press the

PRGM key.

If an error is made use

the back space

to move the cursor

back to the incorrect

digit. Press the UP

or DOWN arrow

keys to display the

correct value.

8. Continue this process

until the display reads

as shown at right.

9. Press the PRGM key

to enter the final

digit.

Note that the User Adjusted Zero feature will not accept

entries in altitude units (FEET or METERS). When the current

engineering unit is FEET, the User Adjusted Zero function

will automatically prompt for an entry in Inches of Mercury @

0º C. When the current engineering unit is METERS, the User

Adjusted Zero function will automatically prompt for an entry

in Millimeters of Mercury @ 0º C.

key

▲

Cursor flashes to the right

of “0”.

▲

Current: xxx.xx

029.50 INHG

Zeroing is complete when

unit returns to Measure

Mode.

9 of 32

Page 12

3. Program Mode

The program mode is used to configure the manometer for

Measure Mode operation. After the P R G M key is pressed in

Measure Mode, the top line of the display reads “PROGRAM

MODE”. The bottom line reads “UNITS SELECT”. Press the or

▲

arrow keys to scroll through the Program Mode to the desired

register. The configurable registers found in the Program Mode

are Units Select, Damp Rate Select, User Info Select, Contrast

Select, Sea Level Select, Data Logging, Leak Test and Exit.

Press the PRGM key to select any of these configurable registers.

The manometer can be put into Program Mode at any time during

Measure Mode operation by pressing the PRGM key. If Lockout

is set, the correct code must be entered when prompted (see the

User Info / Lockout section of this manual for more information on

Lockout).

▲

10 of 32

Page 13

Units Select

The standard engineering units available on the HHP360 Precision

Absolute Manometer are:

inches of Mercury at 0° C (in Hg @ 0° C)

millimeters of Mercury at 0° C (mm Hg @ 0° C)

PSI

milliBars (mBar)

Bars

kPa

Torr

Feet (Altitude displays)

Meters (Altitude displays)

To change the engineering units the manometer should be “ON”

and in Measure Mode. Then follow these steps:

Keystroke

1. Press the PRGM key.

2. Press the PRGM key.

3. Press the or arrow

key until desired engineering unit is displayed.

4. Press the PRGM key to

select the engineering unit.

5. Press the arrow key.

6. Press the PRGM key. Display returns to Measure

▲

▲

▲

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Top line reads “UNITS

SELECT” and bottom line

shows current engineering

units.

Engineering units on bottom

line of display change.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line reads “EXIT”.

Mode in new engineering unit.

Display

11 of 32

Page 14

Displaying Altitude (US Standard Atmosphere 1962)

3. Press the or arrow

Top line reads “UNITS

The model HHP360 is capable of displaying altitude in feet or

meters based on U.S. Standard Atmosphere1962 tables. To set the

unit to read out referenced to this altitude standard use the

following steps:

Keystroke

1. Press the PRGM key.

2. Press the PRGM key.

3. Press the or arrow

key until “USER UNIT

SELECT” is displayed.

4. Press the PRGM key.

5. Press the PRGM key.

6. Press the key.

Display User Defined Altitude

User Defined Altitude is useful in determining elevation change

from a map elevation reference or from a survey trig marker

elevation. To set up the HHP360 to display altitude based on user

entered information, use the following steps:

Keystroke

1. Press the PRGM key.

2. Press the PRGM key.

▲

▲

▲

▲

▲

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Top line reads “UNITS

SELECT” and bottom line

shows current engineering

unit.

Top line reads “UNITS

SELECT”

Bottom line reads “FEET or

METERS”.

Top line reads “ALTITUDE

SELECT”. Bottom line reads

“STANDARD”.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Manometer returns to Measure

Mode. Displays altitude

referenced to US Standard

Atmosphere 1962.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Top line reads “UNITS

SELECT” and bottom line

shows current engineering

unit.

Display

Display

12 of 32

Page 15

key until “FEET” or

“METERS” is displayed.

4. Press the PRGM key.

5. Press the arrow key

once.

6. Press the PRGM key.

7. If the value shown in

step 6 is the correct

altitude, press the PRGM

key to accept and the

key to return to Measure

Mode.

If the value shown in step

6 is not the correct

altitude, press the key

8. Press the PRGM key.

Example: set altitude to

685 feet above sea level.

9. Press the or keys to

set the first digit to “6”.

Using the key the

provides the character

sequence 0 - 9, ( - )

negative, and (.) decimal

point. The ( - ) sign is used

if your location is below

sea level.

▲

- OR -

▲

▲

▲

▲

▲

SELECT”

Bottom line reads “FEET or

METERS”.

Top line reads “ALTITUDE

SELECT”. Bottom line reads

“STANDARD”.

Top line reads “ALTITUDE

SELECT”. Bottom line reads

“REF. TO USER”.

Top line reads “VALUE=:

00000000”. Bottom line reads

“CHANGE?: NO”.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Top line reads “VALUE=:

00000000”. Bottom line reads

“CHANGE?: YES”.

Top line reads “USER MODEFEET”. Bottom line reads

“00000000”.

Top line reads “USER MODEFEET”. Bottom line reads

“60000000”.

10. When the digit is

correct press the PRGM

key.

If an error is made use the

back space key to move

the cursor back to the

incorrect digit. Press the

or arrow keys to display

the correct value.

▲

▲

Cursor flashes to the right of

the “6”. Example: “60000000”.

▲

13 of 32

Page 16

11. Continue the process

until the display reads as

shown at right.

12. Press the PRGM key

to enter the final value.

13. Press the key to

return to Measure Mode.

To set the unit to read in meters, select METERS from the UNITS

SELECT menu. Then follow the same steps as outlined above.

Because the local barometer varies with weather conditions, the

USER DEFINED ALTITUDE must be reentered each time the

HHP360 is to be used in this mode. To adjust the unit to the

current barometric pressure without changing the base altitude,

select “NO” in step 6 in the table above by pressing the PRGM

key. The HHP360 will display the current altitude referenced to

prevailing local barometric pressure. To maximize accuracy the

local altitude should be reset whenever better altitude information

is available.

▲

Top line reads “USER MODEFEET”. Bottom line reads

“685.0000”.

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Top line reads “altitude

referenced to 685”. Bottom line

reads “U 685 FEET”.

14 of 32

Page 17

Pressure Corrected to Sea Level

Pressure reduction to Sea Level is required so that barometric

readings can be compared at different elevations. The correction to

sea level is done using a “hypsometric equation”. This equation

simulates a “fictitious column of air” which extends downward

from the instruments location to sea level. This fictitious column is

assumed to be similar to the actual air column over nearby lower

elevations. Some properties are related to observed conditions

while others must be assumed. Barometric pressures given by the

National Weather Service and used at airports are always corrected

to sea level.

To set the unit to display pressure corrected to sea level:

Keystroke

1. Determine the elevation of

the instrument above sea

level, in meters. 700 meters

will be used as an example.

2. From Measure Mode press

the PRGM key.

3. Press the or key

▲

▲

until “SEA LEVEL

SELECT” is displayed.

4. Press the PRGM key.

5. Press the or key to

indicate the correction to

sea level status.

6. To turn on the correction,

set ENABLED on the 2

line & press the PRGM key.

▲

▲

nd

-OR-

To turn off the correction, set

DISABLED on the 2

and skip ahead to step 12 .

7. To change the value press

▲

the key to toggle the

nd

line

display to “YES”.

Display

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Top line reads “PROGRAM

MODE”. Bottom line reads

“SEA LEVEL SELECT”.

Top line reads “SEA

LEVEL SELECT”. Bottom

line reads either “ENABLE”

or “DISABLED”.

Bottom line toggles between

“ENABLE” and

“DISABLED”.

Top line reads “VALUE=:

00000000”. Bottom line

reads “CHANGE?:

NO”.

Top line reads “VALUE=:

00000000”. Bottom line

reads “CHANGE?:

YES”.

15 of 32

Page 18

8. Press the PRGM key.

9. Press the or arrow

keys to set the correct value

in the first digit.

10. When the value is correct

press the PRGM key.

11. Repeat steps 9 and 10

above until the correct

elevation is entered.

▲

▲

12. Press the PRGM key to

continue moving the cursor

to the right. When the last

digit is entered the unit will

leave the sea level select

mode and return to the

Program Mode.

13. Press the key. The

▲

display will return to the

Measure Mode. When the

Correction to Sea Level is

ENABLED, the display will

have the letter “S” at the

beginning of the 2

nd

line.

Top line reads “SEA Top

line reads “SEA

LEVEL METERS”. Bottom

line reads “00000000”.

Top line reads “SEA

LEVEL METERS”. Bottom

line reads “70000000”.

Cursor moves over to the

next digit.

Top line reads “SEA

LEVEL METERS”. Bottom

line reads “700.0000”.

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Display reads;

“S 803.1 TORR”

16 of 32

Page 19

Damp Rate Select

Adjustable exponential type damping is available to steady the

display when measuring pulsating pressures. The HHP360 has a

range of damping rates; 0.1, 0.2, 0.5, 1, 2, 5, 10, or 25 seconds.

Damping is done by averaging new data from the pressure sensor

against previously collected data. The microprocessor collects data

from the sensor every 0.1 seconds. The display updates every 0.5

seconds, showing the current 0.1 second pressure reading. When set

at 25 seconds, the display updates every 0.5 seconds with the

average of the previous 25 seconds readings. Therefore, it takes up

to 25 seconds from the time pressure is applied until the manometer

displays the full scale applied pressure. Min/Max display updates

every 0.1 seconds.

To set the damp rate:

Keystroke

1. Enter Program Mode by

pressing the PRGM key.

2. Press the key.

3. Press the PRGM key.

4. Press the or keys until

the desire damp rate is

displayed on the bottom line.

5. Press the PRGM key.

6. Press the key.

7. Press the PRGM key. Returns to Measure Mode.

▲

▲

▲

▲

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Bottom line reads “DAMP

RATE SELECT”.

Top line reads “DAMP

RATE SELECT”. Bottom

line shows current value.

Bottom line shows damp

rate settings in seconds.

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Bottom line reads “EXIT”.

Display

17 of 32

Page 20

User Info Select

The User Info Select registers are designed to provide the user with

information on the hardware and software in the manometer. This

register provides read only information on the sensor’s serial

number, software version and date of manufacture. It also allows

the user to edit the Auto Shut-Off, Lockout and Start-Up Header

Name features.

To access the User Info Select registers, follow the steps below. To

configure a User Info Select register, follow the steps shown on the

following page.

Keystroke

1. From the Measure Mode

press the PRGM key.

2. Press the arrow key

twice

3. Press the PRGM key.

4. Press the arrow key.

5. Press the arrow key.

6. Press the arrow key.

See instructions to set

AUTO SHUT-OFF later in

this manual.

7. Press the arrow key.

See instructions for using

LOCKOUT later in this

manual.

8. Press the arrow key.

See instructions for editing

the Header later in this

manual.

9. Press the arrow key

to go back to “USER

INFO SELECT” screen.

▲

▲

▲

▲

▲

▲

▲

Display

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

Bottom line changes to

“USER INFO SELECT”.

Bottom line shows serial

number.

Software version number

shown.

Manufacture date shown.

Top line reads “AUTO SHUT

OFF” and bottom line reads

“ENTER TO SELECT”.

Top line reads “LOCKOUT

CODE” and bottom line reads

“ENTER TO SELECT”.

Top line reads “HEADER

NAME” and bottom line

reads “text”. The cursor

flashes at bottom left.

Top line reads “PROGRAM

MODE” and bottom line

reads “USER INFO

SELECT”.

18 of 32

Page 21

Auto Shut-Off

Keystroke

Display

1. Follow steps 1-6 in the

User Info Select table.

Top line reads “AUTO SHUTOFF” and bottom line reads

“ENTER TO SELECT”.

2. Press the PRGM key,

then the up or down

arrow keys until the

desired shut-off time is

shown.

Top line reads “AUTO SHUTOFF” and bottom line toggles to

“DISABLED”, “10”, “20”,

“30”, “45” and “60” minutes .

3. Press the PRGM key.

Desired Auto Shut-Off time is

selected, top line reads “AUTO

SHUT-OFF” and bottom line

reads “ENTER TO SELECT”.

4. Press the left arrow

key three times.

Returns to Measure Mode.

Enabling the Auto Shut-Off feature allows the manometer to turn

itself off after a user selected period of keypad inactivity.

Selectable options include DISABLED, 10 Minutes (which is the

factory shipped default), 20 Minutes, 30 Minutes, 45 Minutes and

60 Minutes. Disabling this feature limits the manometer to being

turned off by using the ON/OFF key only.

To configure auto shut-off follow these steps:

Note: The “Auto Shut-Off” timer is suspended during Data

Logging and Leak Test sessions to prevent accidental loss of

information. Auto Shut-Off is re-instated after completion of Data-

Logging or Leak Test sessions.

19 of 32

Page 22

Lockout Select

Keystroke

Display

1. From the Measure

Mode press the PRGM

key. If the Lockout is set,

enter the correct

“password” when

prompted.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

2. Press the up arrow key

twice.

Bottom line reads “USER

INFO SELECT”.

3. Press the right arrow

key then the up arrow key

four times.

Top line reads “LOCKOUT

CODE” and bottom line reads

“ENTER TO SELECT”.

4. Press the right arrow

key, then press the up or

down arrow keys to

change the first digit.

Press the right arrow key

to proceed.

Bottom line shows the old

Lockout Code. The cursor

flashes at the first position

while the value is changed, the

cursor moves to the right

position once the right arrow

key is pressed.

5. Press the right arrow

key when the desired code

is set. Lockout is

activated.

Top line reads “LOCKOUT

CODE” and bottom line reads

“ENTER TO SELECT”.

6. Press the left arrow

key twice.

Returns to Measure Mode.

Enabling the Lockout feature prevents unauthorized users from

making changes to the configuration of the manometer. To enter

the Program Mode, the user must first enter the “password” (two-

digit Lockout Code) within approximately 40 seconds when

prompted. Failure to enter the correct two digit code within

approximately 40 seconds will return the unit to Measure Mode.

Any two-digit numeric code can be programmed. The factory

Lockout Code of 00 (which is the default as shipped from the

factory) disables the Lockout.

To set the Lockout Code follow these steps:

20 of 32

Page 23

Header Name

Keystroke

Display

1. From the Measure Mode

press the PRGM key.

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

2. Press the up arrow key

twice.

Bottom line changes to

“USER INFO SELECT”.

3. Press the PRGM key.

Bottom line shows serial

number.

4. Press the up arrow key

five times.

Top line reads “HEADER

NAME” and bottom line

reads “text”. The cursor

flashes at bottom left.

5. If header is correct press

backspace key. If editing is

desired proceed to step 7.

Top line reads “PROGRAM

MODE” and bottom line

reads “USER INFO

SELECT”.

6. Press the left arrow key.

Returns to Measure Mode.

7. Press the up or down

arrow keys to set the

correct alpha-numeric

value.

Displays a number between 0

and 9, a letter from A to Z, /

or a blank space.

8. Press the right arrow key

to accept entry.

Cursor advances one space to

right.

9. Repeat steps 8 and 9

until the desired Header is

shown.

10. If an error is made press

the back arrow key until the

cursor is over the incorrect

value. Follow step 8 to

correct. Press the right

arrow key to advance the

cursor without changing

values.

11. When the Header is

complete press the PRGM

key until header accepted.

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

12. Press the left arrow

key.

Returns to Measure Mode.

Follow the steps below to edit the Header Name.

21 of 32

Page 24

Contrast Select

The Contrast Select register allows the user to adjust the character

contrast of the LCD display to provide the best visibility for the

ambient light conditions.

To adjust the contrast, follow these steps:

Keystroke

1. From the Measure Mode

press the PRGM key.

2. Press the key three

times.

3. Press the PRGM key.

4. Press the or keys to

increase or decrease the

contrast value. A low

number gives maximum

contrast and a high number

gives minimum contrast.

5. Press the PRGM key.

6. Press the key.

If an error is made during the contrast adjustment, pressing the key

returns the display to the previous contrast setting.

▲

▲

▲

▲

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

Bottom line reads

“CONTRAST SELECT”.

Top line reads “CONTRAST

SELECT”. Bottom line shows

a numerical value.

LCD lightens or darkens

depending on the value set.

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

Returns to Measure Mode.

Display

▲

22 of 32

Page 25

Data Logging

Data Logging can be used to record pressure measurements. Two

record modes are supported: automatic and manual. In automatic

mode, a pressure value is captured every 5 seconds for 20 minutes,

resulting in 240 stored values. In manual mode, a pressure value is

captured each time the PRGM key is pressed up to 240 values. The

data collected during a logging session can be viewed upon

completion.

1. From the Measure Mode

press the PRGM key.

2. Press the up arrow key

five times.

3. Press the PRGM key.

4. Press the PRGM key.

5. Press the PRGM key at

AUTO to start automatic

logging or at MANUAL to

start manual logging mode.

6. To stop recording values

at any time, press the key.

7. To access recorded

values, press the key.

8. To view recorded values,

press the PRGM key.

9. Press the key 3 times.

Keystroke

▲

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

Bottom line reads “DATA

LOGGING”.

Top line reads “DATA

LOGGING” and bottom line

reads “RECORD”.

Top line reads “RECORD

MODE” and bottom line

reads “AUTO” or

“MANUAL”.

Top line reads

“RECORDING X” and

bottom line reads “XX.XX

UNITS”. AUTO records

value every 5 seconds.

Manual records value each

time PRGM key is pressed.

Top line reads “DATA

LOGGING” and bottom line

reads “RECORD”.

Top line reads “DATA

LOGGING” and bottom line

reads “VIEW”.

Top line reads “DATA LOG:

1” and bottom line displays

the value. Continue pressing

the key to view all values.

▲

Returns to Measure Mode.

Display

The “Auto Shut-Off” timer is disabled for Data Logging sessions.

Be sure to end the session to re-enable the Auto Shut-Off timer.

23 of 32

Page 26

Leak Test

Keystroke

Display

1. From the Measure Mode

press the PRGM key.

Top line reads “PROGRAM

MODE” and bottom line

reads “UNITS SELECT”.

2. Press the down arrow key

twice.

Bottom line reads “LEAK

TEST”

3. Press the PRGM key.

Top line reads “LEAK

TEST” and bottom line reads

“CONFIGURE”.

4. Press the PRGM key.

Top line reads “Leak Test

Period” & bottom “X.X

MIN”.

5. Use the up, down & right

keys to input test period

Bottom line reads desired

period; Ex. “ 20.0 MIN”.

6. Press the PRGM key.

Top line reads “LEAK

TEST” and bottom line reads

“CONFIGURE”.

7. Press the up arrow key

once.

Top line reads “LEAK

TEST” and bottom line reads

“PRGM TO START”.

8. Press the PRGM key.

Top line displays MIN/MAX

pressure values at left/right.

Bottom line reads the current

pressure value and units.

At end of test period, top line

displays the leak rate in units

per minute. Bottom line

shows the current pressure

reading.

9. Press the PRGM key to

exit the Leak Test

Returns to Measure Mode

The Leak Test feature allows the user to determine the leak rate in

the pneumatic system being monitored. Once configured, Leak

Test monitors the measured pressure over time and displays the

leak rate in the pressure units per minute at the conclusion of the

test. The maximum configurable leak test period is 1440 min (1

day). Pressing any key during the leak test will abort the test.

To enable Leak Test follow these steps:

The “Auto Shut-Off” timer is disabled for Leak Test sessions. Be sure to end

the session to re-enable the Auto Shut-Off timer.

24 of 32

Page 27

Re-Calibration

The HHP360 can be re-calibrated in the field for zero, span, and

linearity. The proper primary standards must be available prior to

calibrating the unit. These standards should meet the accuracy

requirements for your company or industry. The factory follows

guidelines established by ANSI / NCSL Z540-1-1994 which

requires that the primary standard be 4 times more accurate than

the unit under test.

The re-calibration is not intended to replace the Factory Lab

Calibration Procedure. It is intended to correct the curve fit if the

actual sensor characteristics change slightly over time.

For sensors up to 200 PSI, a ±0.0015% of reading deadweight

tester is recommended.

1-point (within upper 50% of Full Scale), 5-point (nominal values

of 0%, 25%, 50%, 75% & 100% of Full Scale), and restore factory

default re-calibration options are offered. For the 5-Point re-

calibration, points 2, 3 and 4 can be adjusted within ±1% of

reading around the nominal values. Point #5 can be adjusted within

-1% of reading around nominal. Point #1 is fixed.

For example: for a 2000 inH2O sensor, Point # 2 (25%) can be

edited form 495 to 505 inH2O. Point #5 (100%) can be edited

from 1980 to 2000 inH2O.

The unit can only be re-calibrated if the calibration points are

within 5 times the accuracy of the original factory calibration (e.g.

@ 0.05% accuracy, the point limit is ±0.25% of Full Scale). If the

re-calibration procedure generates a new value outside this limit

the procedure will fail. In this case the unit would need to be

returned to the factory for service.

Once a re-calibration has been performed (either 1-point or 5-

point) the unit will continue to allow future re-calibrations only

with that type of re-calibration. In order to enable the other re-

calibration type, the user must first restore the re-calibration data to

the factory defaults.

25 of 32

Page 28

RE-CALIBRATION – 1 Point EDIT and START

Keystroke

Display

1. With unit OFF, press and

hold the MIN/MAX key,

turn the unit on by pressing

the ON/OFF key, then

release MIN/MAX.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

2. Press the up arrow key

until “START” is displayed

on the bottom line.

Top line reads “RE-CAL”.

Bottom line reads “START”.

3. Press the PRGM key.

Top line reads “RE-CAL

START”.

Bottom line reads “1POINT”.

4. Press the PRGM key.

Top line reads “CAL

POINT” and bottom line

displays the cal point value.

5. Press the up/down arrow

keys to edit the selected

digit. Use the left/right arrow

keys to change the cursor

position. Value entered must

be 50-100% of FS.

Bottom line displays the cal

point value. The cursor

flashes at the first position

while the value is changed,

then moves to the right

position when the right

arrow key is pressed.

6. Press the right arrow key

while on the right most digit

to proceed.

Top line reads “APPLY:”

Bottom line displays the

“CAL POINT” value.

7. Apply the input pressure

indicated using an

appropriate reference

standard; press PRGM key.

Top line reads “RE-CAL”.

Bottom line reads “START”,

Manometer has been

recalibrated.

8. Press the left arrow key.

Returns to Measure Mode

To perform a 1-point re-calibration, apply a pressure between 50%

and 100% of Full Scale and then follow these steps:

26 of 32

Page 29

RE-CALIBRATION – 5 Point EDIT

Keystroke

Display

1. With unit OFF, press and

hold the MIN/MAX key,

turn the unit on using the

ON/OFF key, then release

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

2. Press the PRGM key.

Top line reads “CAL POINT

1”. Bottom line displays the

cal point value.

3. Press the up/down arrow

keys to edit the selected

digit. Use the left/right

arrow keys to change the

cursor position. Note: For

0% go directly to step 4.

Bottom line displays the cal

point value. The cursor

flashes at the first position

while the value is changed,

then moves to the right

position when the right arrow

key is pressed.

4. Press the right arrow key

while on the right most digit

to proceed.

Top line reads “CAL POINT

2”. Bottom line displays the

cal point value.

5. Repeat steps 3 and 4 for

CAL POINTS 2, 3, 4 and 5.

Top line reads “CAL POINT

2/3/4/5”. Bottom line

displays the cal point value.

6. After editing CAL

POINT 5 press the right

arrow key while on the right

most digit to proceed.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

7. To perform the 5-point

re-cal, press the up arrow

key until START is

displayed on the bottom

line.

OR

To exit without

performing the 5-point recal press the left arrow key

Top line reads “RE-CAL”.

Bottom line, “START”.

Continue with 5-Point Recalibration procedure at step

3 on next page.

OR

Returns to Measure Mode.

To edit the calibration points for a 5 Point re-calibration follow the

steps below.

NOTE: If the factory default values are acceptable, skip this

section and proceed to the re-calibration 5-Point START

procedure.

RE-CALIBRATION – 5 Point START

To begin the 5-point re-calibration procedure, turn the unit OFF

and follow the steps below.

27 of 32

Page 30

Keystroke

Display

1. Press and hold the

MIN/MAX key. Turn unit

on using the ON/OFF key.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

2. Press the up arrow key

until “START” is displayed

on the bottom line.

Top line reads “RE-CAL”.

Bottom line reads “START”.

3. Press the PRGM key.

Top line reads “RE-CAL

Bottom line reads “1POINT”.

4. Press the up arrow key

until “5-POINT” is

displayed on the bottom

line.

Top line reads “RE-CAL

START”.

Bottom line reads “5POINT”.

5. Press the PRGM key.

Top line reads “POINT 1 –

ZERO:”

Bottom line displays live

applied pressure.

6. Vent P1 and P2 ports to

atmosphere and

simultaneously press the

MIN/MAX and HOLD

keys, then release.

Unit takes new zero. Top line

reads “ POINT 1 - ZERO:”

Bottom line displays live

applied pressure. POINT 1

has been taken.

7. Press the right arrow key

while on the right most

digit to proceed.

Top line reads “POINT 2 APPLY:”.

Bottom line displays the cal

point value to apply.

8. Apply the indicated

calibration point pressure

using external pressure

standards. After pressure is

stable, press the right arrow

key.

Top line reads “POINT 3 APPLY:”.

Bottom line displays the cal

point value to apply.

9. Repeat step 8 for CAL

POINTS 4 and 5.

Top line reads “POINT 4/5 APPLY”

Bottom line displays the cal

point value.

10. Use up or down arrow

keys to select NO or YES

when asked “Save?” the

Re-Calibration data.

Top line reads “SAVE?”.

Bottom line reads “NO” or

“YES”.

11. Press the PRGM key at

YES to save the ReCalibration data or at NO to

exit without saving.

Top line reads “RE-CAL”.

Bottom line reads “START”.

Re-cal is complete.

12. Press the left arrow

key.

Returns to Measure Mode.

28 of 32

Page 31

Keystroke

Display

1. With unit OFF, press and

hold the MIN/MAX key,

turn the unit on using the

ON/OFF key, then release.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

2. Press the up arrow key

twice.

Top line reads “RE-CAL”.

Bottom line reads

“RESTORE DEFAULTS”.

3. Press the PRGM key.

Top line reads “RESTORE

DEFAULTS”.

Bottom reads “YES” or

“NO”.

4. Use the up and down

arrow keys to select YES or

NO when asked to restore

defaults.

Top line reads “RESTORE

DEFAULTS”.

Bottom reads “YES” or

“NO”.

5. Press the PRGM key at

YES to restore the Factory

Default Calibration data or

at NO to exit without

restoring.

Top line reads “RE-CAL”.

Bottom line reads

“RESTORE DEFAULTS”.

Factory defaults have been

restored.

6. Press the left arrow key.

Returns to Measure Mode.

RE-CALIBRATION – Restore Factory Defaults

To restore the re-calibration data to the factory defaults, follow

these steps:

29 of 32

Page 32

Specifications

Type, Range and Display Resolution:

HHP360-A: 0 - 17.403 psia (0 - 900.00 mmHg)

HHP360-B: 0 - 38.674 psia (0 - 2000.0 mmHg)

Accuracy:

HHP360-A: 0017: ±0.02 % F.S. (F.S. = 900 mm Hg)

HHP360-B: 0038: ±0.015 % F.S.* from 0-1000 mm Hg

Temperature:

Media Compatibility:

Pressure Limits:

Connection:

Battery Operation:

Enclosure: (6.9" x 3.8" x 2.3") Polycarbonate, Permanently

Static Dissipative, ESD Protection

±0.025% F.S.* from 1000-2000 mm Hg

*F.S. = 2000 mm Hg Absolute

Includes the combined effects of temperature, linearity,

repeatability, hysteresis and resolution.

Warm up time = 5 minutes.

Storage = -40°C to +60°C (-40°F to +140°F)

Operating = -20°C to +50°C (-4°F to +122°F)

AI: Absolute pressure sensors for use with gases and liquids

compatible with 316L SS

AI units: 77 PSIA (4000 mm Hg Abs)

1/8” female NPT, 316L SS. P1 is the pressure connection.

P2 is not accessible (factory plugged with metal disc)

User must use a wrench on the pressure manifold when

installing user’s 1/8” NPT fitting. Do not tighten the

fitting without using a wrench on the pressure

manifold. Failure to use a wrench on the manifold will

damage the plastic enclosure and void warranty No

torque should be applied to the manifold with respect

to plastic enclosure.

>100 hours continuous use, 1 year shelf life, auto power off

programmable at Disabled, 10, 20, 30, 60 or 90 minutes

Enclosure with Boot: (7.2" x 4.2" x 2.5")

30 of 32

Page 33

Certification/Safety/Warnings

The HHP360 is for general purpose use only.

Note the following WARNINGS and requirements:

• Substitution of components may impair operation

• Do not use or service in the presence of explosive

atmospheres.

• Do not replace batteries in the presence of explosive

atmospheres.

• User must use a wrench on the pressure manifold when

installing user’s 1/8” NPT fitting. Do not tighten the fitting

without using a wrench on the pressure manifold. Failure to

use a wrench on the manifold will damage the plastic

enclosure and void warranty No torque should be applied to

the to the plastic enclosure while installing 1/8” NPT fittings.

Changing the Batteries

Adherence to the Specifications and Certification/Safety/Warnings

sections of this manual shall be enforced when changing batteries.

The manometer is powered by four, 1.5 volt AA size batteries.

When the output of the batteries under load drops, the display will

alternate between “LOW POWER DETECT” and “REPLACE

BATTERY”. Low power may affect performance. The unit should

not be used to measure pressure in this condition. All four batteries

should be replaced.

To replace the battery locate the battery compartment at the bottom

rear of the manometer, as shown here.

Remove the two screws on either side of the battery cover by

turning them counterclockwise until the fully disengaged from the

manometer base. Lift the cover from the back of the unit.

Remove the batteries by pulling the positive side first straight out

31 of 32

Page 34

of the battery compartment. Note the positive (+) and negative (-)

battery polarity markings at the bottom of the compartment, as

shown here.

To install the four batteries: 1) Make sure polarity of battery

matches the markings in the compartment. 2) 1st place the (+) end

of the battery into the bottom of the battery slot. 3) Then push in

(-) end of the battery until it is seated in the bottom of the battery

slot. The battery compartment has stand offs molded into the side

of the compartment. When a battery is installed with the polarity

reversed, the stand offs prevent the negative battery terminal from

contacting the positive terminal in the battery compartment. The

unit will not power up when a battery is installed this way. Should

this happen, simply reverse the battery to align the polarity.

With the batteries secured in the battery compartment, replace the

compartment cover. The cover has only one correct alignment.

The “WARNING

statement on the battery cover must be visible and aligned in the

middle of the manometer case. To secure the cover, torque the

screws clockwise to 1.6-1.8 in-lbs. Do not over tighten.

DO NOT OPEN IN EXPLOSIVE ATMOSPHERE”

32 of 32

Page 35

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds

an additional one (1) month grace period to the normal one (1) year product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by the company will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1)

as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or

activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or

with any nuclear installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from

any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of theproduct, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2010 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 36

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

SM

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Data Logging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M4928/0610

Manual 9R68M-IR EO 6816 Jun. 2010

Loading...

Loading...