Page 1

Q-43

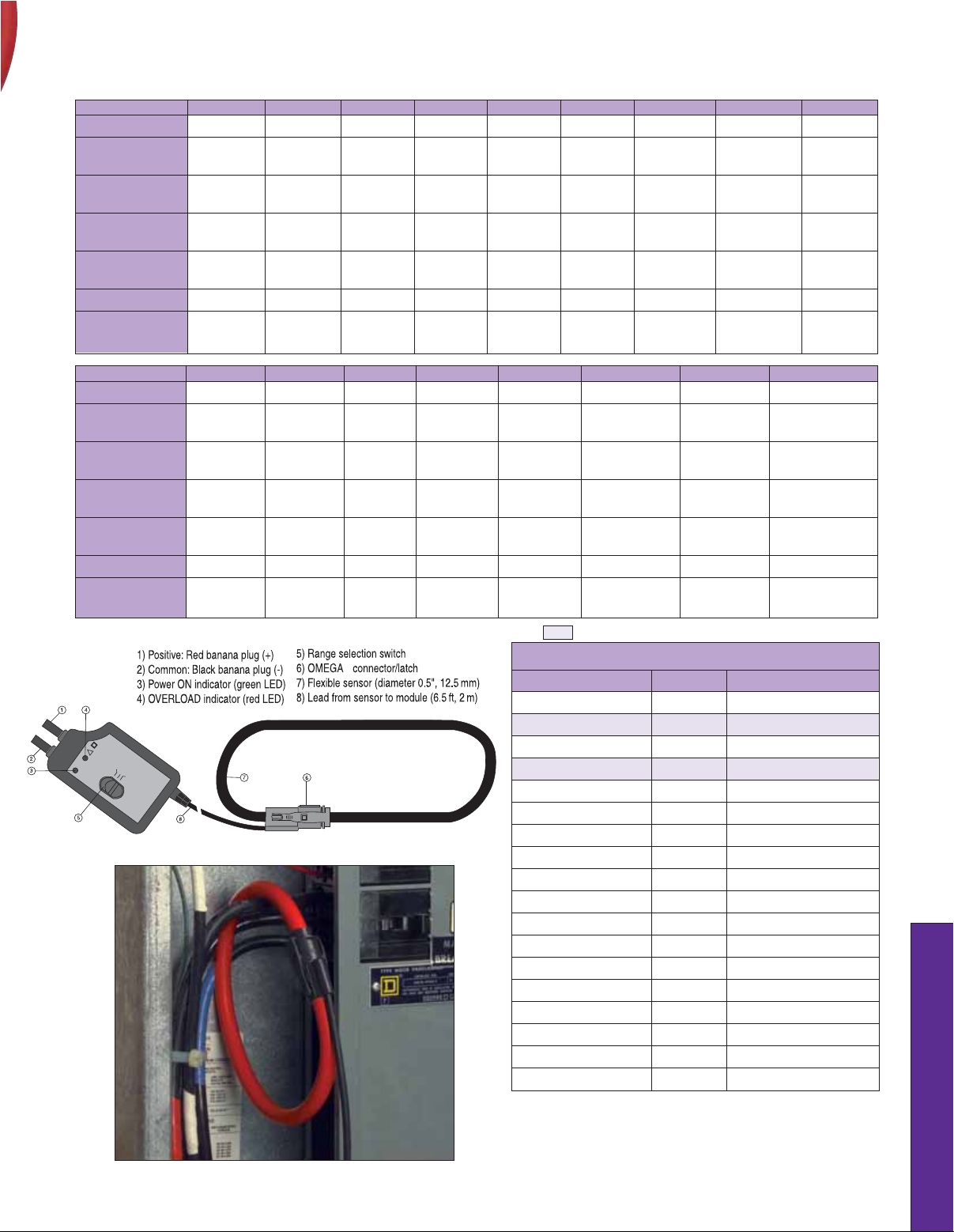

sensors. The HHM800 Series is

lightweight and does not use

magnetic cores like standard

transformers.

The transformation principle is based

on an air core. It presents virtually no

load to the system under test, has low

phase shift and excellent frequency

response and cannot be damaged by

current overloads. The sensor

assembly is waterproof and insulated

for 1000 V working voltage. The

HHM800 Series has an mV output

proportional to the current measured

for direct readings on DMM’s,

loggers, oscilloscopes and power or

harmonic meters. The length of the

flexible sensor can be selected from

610 mm (24") to 1520 mm (60").

HHM800 Series

Starts at

$

299

Models Ranging

from 30 Amp RMS

to 30,000 Amp RMS

Accuracy 1% of Reading

True rms Measurement

When Connected to

a True RMS Instrument

No Core Saturation

or Damage if Overloaded

Overrange LED for

Measurement Circuitry

1000 V IEC 1010

Cat III, CE Mark

Waterproof Sensor

9 V Battery for Typical

150 Hour Continuous

Operation

Custom Pre-Shaping

of Sensor Before Use

(No Drooping)

Very High Frequency

Response

Low Phase Shift for

Power Measurements

Insensitive to DC,

Measures Only AC

Component on DC+AC

Signals

Excellent Linearity

Lightweight Design

Flexible AC Current Probes

Common Specifications

Accuracy: 1% of reading

Frequency Range:10 to 20,000 Hz

Working Voltage: 1000 V IEC-1010 Cat.III

Safety Standards: Designed to

IEC 1010 and CE mark

CE Markings: 1997

Operating Temperature and % RH:

-20 to 55°C (sensor to 90°C),

0 to 90% RH (@ 50°C)

Minimum Bend Radius: 19 mm (0.75")

Water and Dustproofing: Sensor IP65

(NEMA 4X), Module IP40

Battery and Battery Life: 9 V alkaline

(included), approx 150 hr of continuous use

Good Battery Indication: Green LED

Electronic Overload Indication: Red LED

Output:

3

⁄4" spaced banana jacks, optional

banana plug to BNC adaptor available, 2 m

(6.5') lead from sensor to module

The HHM800 Series flexible ac

current probes are composed of a

flexible sensor and an electronic

module. The flexible sensor permits

measurements on conductors where

standard clamp-on probes cannot

be used.

In particular, it can be installed in

tight spaces, around cable bundles,

around wide or large bus bars or

even wrapped around irregularly

shaped objects. Probe design

enables the user to pre-shape the

sensor before inserting it between or

around conductors. This feature

facilitates positioning the sensor

around the conductor, enhances user

safety and alleviates the drooping

effect associated with other flexible

HHM802, $299, shown

smaller than actual size.

Page 2

Q-44

Q

Model No. HHM801 HHM802 HHM803 HHM804 HHM805 HHM806 HHM807 HHM808 HHM809

Operating Range 0.5 to 30 A 0.5 to 200 A 0.5 to 300 A 0.5 to 300 A 0.5 to 300 A 0.5 to 500 A 0.5 to 500 A 0.5 to 1000 A 0.5 to 1000 A

Measurement 5 to 30 A 5 to 200 A 5 to 300 A 5 to 300 A 5 to 300 A 5 to 500 A 5 to 500 A 5 to 1000 A 5 to 1000 A

Range

Output Signal 100 mVac/A 1 mVac/A 10 mVac/A 1 mVac/A 100 mVac/A 1 mVac/A 10 mVac/A 1 mVac/A 10 mVac/A

10 mVac/A 1 mVac/A 1 mVac/A

Crest Factor 3.0 >10 3.0 >10 3.0 >10 >10 9.0 9.0

(mid-range)

Phase Shift 1° 0.5° 0.5° 0.5° 1° 0.5° 0.5° 0.5° 0.5

@ 50/60 Hz

Residual Noise 200 mA 200 mA 200 mA 200 mA 200 mA 200 mA 200 mA 200 mA 200 mA

DC Offset 50 mV 2 mV 5 mV 2 mV 50 mV 2 mV 5 mV 2 mV 5 mV

5 mV 2 mV 2 mV

Model No. HHM810 HHM811 HHM812 HHM813 HHM814 HHM815 HHM816 HHM817

Operating Range 0.5 to 3000 A 0.5 to 3000 A 0.5 to 6000 A 0.5 to 6000 A 0.5 to 10,000 A 0.5 to 10, 000 A 0.5 to 30,000 A 0.5 to 30,000 A

Measurement 5 to 3000 A 5 to 3000 A 5 to 6000 A 5 to 6000 A 5 to 10,000 A 5 to 10,000 A 5 to 30,000 A 5 to 30,0000 A

Range

Output Signal 1 mVac/A 10 mVac/A 0.1 mVac/A 1 mVac/A 0.1 mVac/A 1 mVac/A 0.1 mVac/A 1 mVac/A

1 mVac/A 0.1 mVac/A 0.1 mVac/A 0.1 mVac/A

Crest Factor 3.0 3.0 >10 >10 9.0 9.0 3.0 3.0

(mid-range)

Phase Shift 0.5° 0.5° 0.3° 0.3° 0.3° 0.3° 0.3° 0.3°

@ 50/60 Hz

Residual Noise 200 mA 200 mA 500 mA 500 mA 500 mA 500 mA 500 mA 500 mA

DC Offset 2 mV 5 mV 1 mV 2 mV 1 mV 2 mV 1 mV 2 mV

2 mV 1 mV 1 mV 1 mV

To Order

(Specify Model Number)

Model No. Price Current Range (A)

HHM801 $299 30

HHM802 299 200

HHM803 299 300

HHM804 299 300

HHM805 319 30/300

HHM806 299 500

HHM807 319 50/500

HHM808 299 1000

HHM809 319 100/1000

HHM810 319 3000

HHM811 339 300/3000

HHM812 469 6000

HHM813 469 600/6000

HHM814 519 10000

HHM815 489 1000/10000

HHM816 669 30000

HHM817 689 3000/30000

HHM70-CONN1 38 Accessory adaptor

Electrical Specifications

®

O

L

1

0

0

0

V

C

A

T

m

1

0

m

V

/

A

1

m

V

/

A

O

F

F

Standard length is 610 mm (24"). Please consult sales for

availability and pricing for 910, 1220, and 1520 mm (36, 48, and

60") models. Comes with 9 V battery and operator’s manual.

Ordering Example: HHM805, flexible current probe and

HHM70-CONN1, banana plug to BNC adaptor, $319 + 38 = $357.

MOST POPULAR MODELS HIGHLIGHTED!

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...