Page 1

Model HHG-23

GAUSS / TESLA METER

Instruction Manual

Manual M3685 (UN-01-246)

June 1998

Rev. - 06/98

Omega

All rights reserved.

Page 2

This symbol appears on the instrument and probe. It

refers the operator to additional information

contained in this instruction manual, also identified

by the same symbol.

NOTICE:

See Pages 3-1 and 3-2

for SAFETY

instructions prior to first use!

Page 3

Table of Contents

SECTION-1 INTRODUCTION

Understanding Flux Density.............................................. 1-1

Measurement of Flux Density............................................

Product Description........................................................... 1-5

Applications.......................................................................

SECTION-2 SPECIFICATIONS

Instrument......................................................................... 2-1

Standard Transverse Probe.............................................. 2-5

Standard Axial Probe........................................................ 2-6

Optional Probe Extension Cable....................................... 2-7

Zero Flux Chamber............................................................ 2-8

SECTION-3 OPERATING INSTRUCTIONS

Operator Safety.................................................................

Operating Features........................................................... 3-3

Instrument Preparation......................................................

Power-Up.......................................................................... 3-8

Power-Up Settings............................................................ 3-9

Low Battery Condition....................................................... 3-10

Overrange Condition......................................................... 3-11

AC or DC Measurement Selection..................................... 3-12

UNITS of Measurement Selection..................................... 3-13

RANGE Selection.............................................................. 3-14

HOLD Mode Selection....................................................... 3-16

MIN / MAX Hold Usage...................................................... 3-17

Peak Hold Usage.............................................................. 3-18

ZERO Function.................................................................. 3-20

Automatic ZERO Function................................................. 3-21

Manual ZERO Function..................................................... 3-23

RELATIVE Mode............................................................... 3-25

Automatic RELATIVE Mode.............................................. 3-28

1-2

1-6

3-1

3-6

i

Page 4

Manual RELATIVE Mode................................................... 3-30

ANALOG OUTPUT Function............................................. 3-31

Analog Output Usage........................................................ 3-33

Sources of Measurement Errors........................................ 3-35

More details on AC Mode Operation................................. 3-38

More details on DC Mode Operation................................. 3-40

SECTION-4 REMOTE OPERATION

RS-232 Interface Parameters............................................

RS-232 Interface Connection............................................ 4-1

Remote Command Standards........................................... 4-3

Command Format.............................................................. 4-4

Message Terminators........................................................

Error Buffer........................................................................

Status Registers................................................................ 4-5

Status Byte and Request For Service (RQS).................... 4-6

Standard Event Register................................................... 4-9

Measurement Event Register............................................ 4-10

Operation Event Register.................................................. 4-10

Questionable Event Register............................................. 4-11

“Common” Command Syntax............................................ 4-11

“Common” Commands………........................................... 4-13

SCPI Command Syntax..................................................... 4-16

SCPI Commands............................................................... 4-18

Error Messages and Commands....................................... 4-21

Status Commands............................................................. 4-23

MODE Commands............................................................ 4-25

RANGE Commands.......................................................... 4-26

HOLD Commands............................................................. 4-27

ZERO Command............................................................... 4-28

RELATIVE Commands...................................................... 4-28

MEASUREMENT Command............................................. 4-29

ANALOG OUTPUT Command.......................................... 4-30

Intermixing Common and SCPI commands....................... 4-31

Using Query Commands................................................... 4-31

4-1

4-4

4-5

ii

Page 5

Using the Operation Complete Status............................... 4-32

Example Program.............................................................. 4-33

WARRANTY....................................................................

5-1

List of Tables

Table 4-1 Common Command Summary.................. 4-13

Table 4-2 SCPI Command Summary........................ 4-18

List of Illustrations

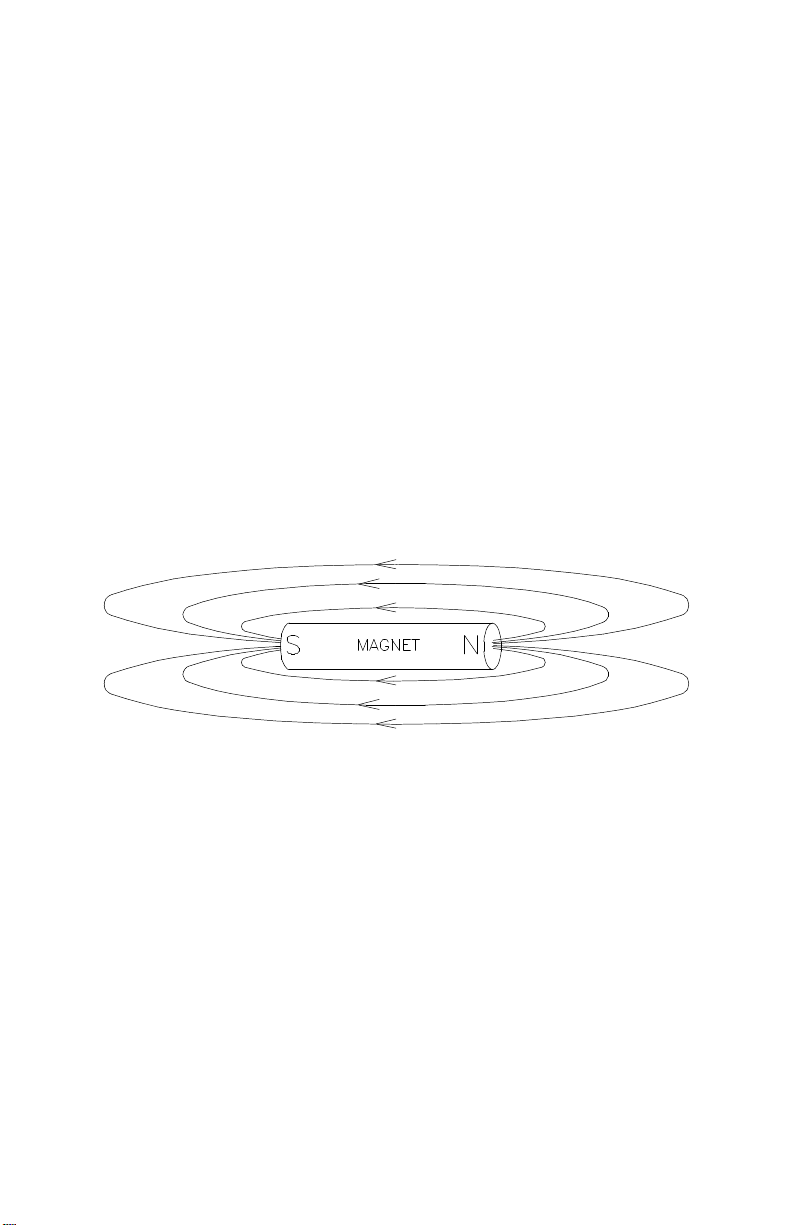

Figure 1-1 Flux Lines of a Permanent Magnet............ 1-1

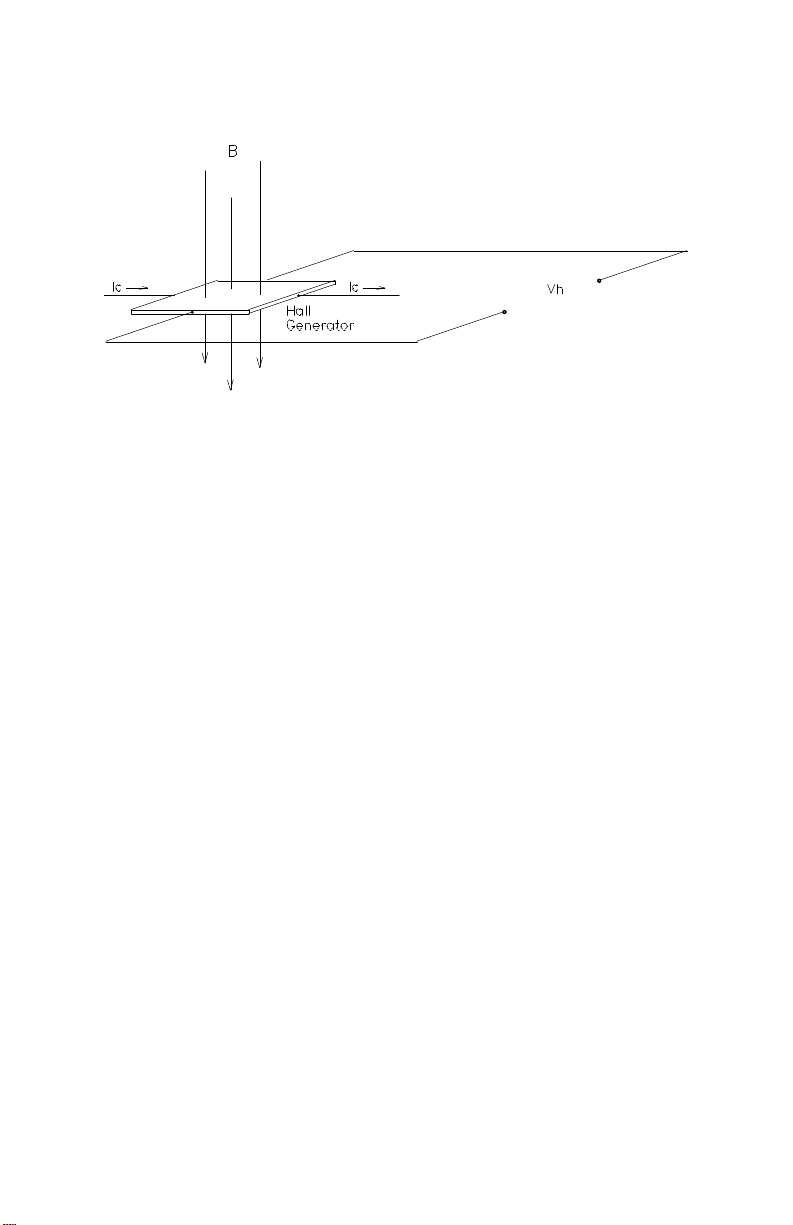

Figure 1-2 Hall Generator............................................

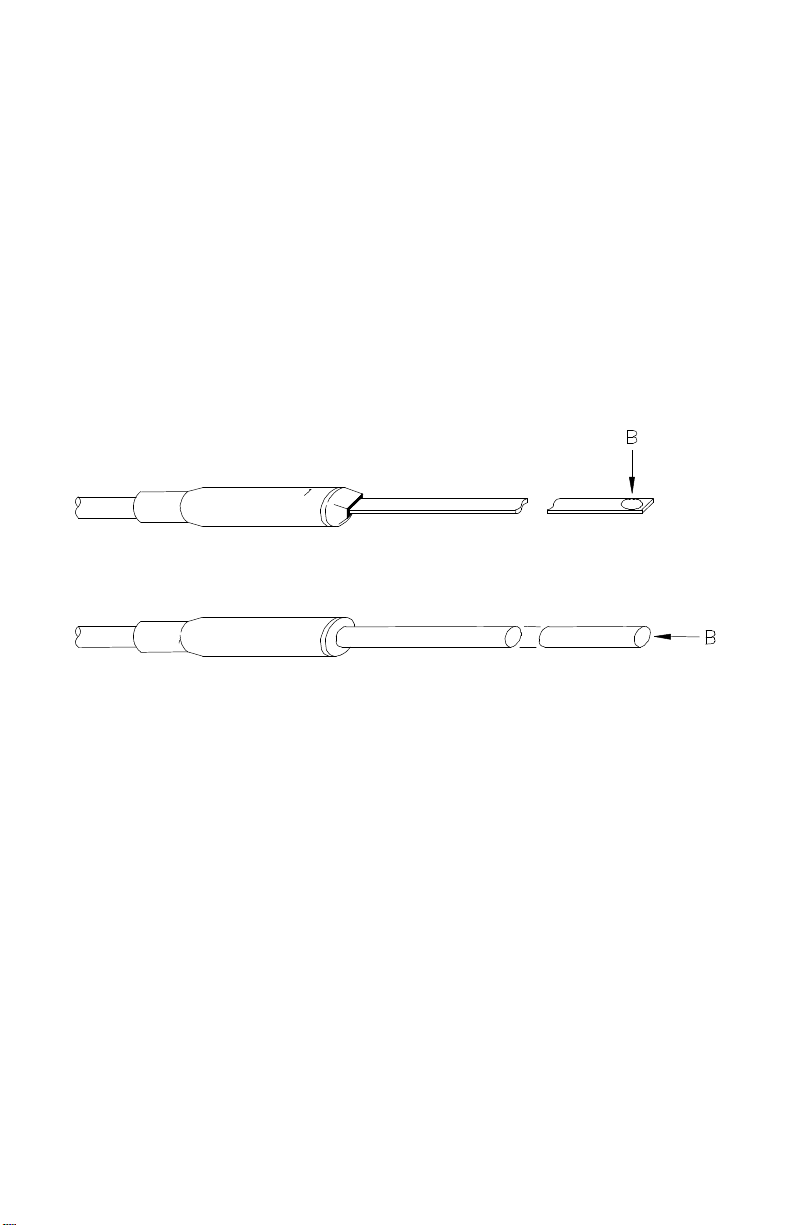

Figure 1-3 Hall Probe Configurations.......................... 1-4

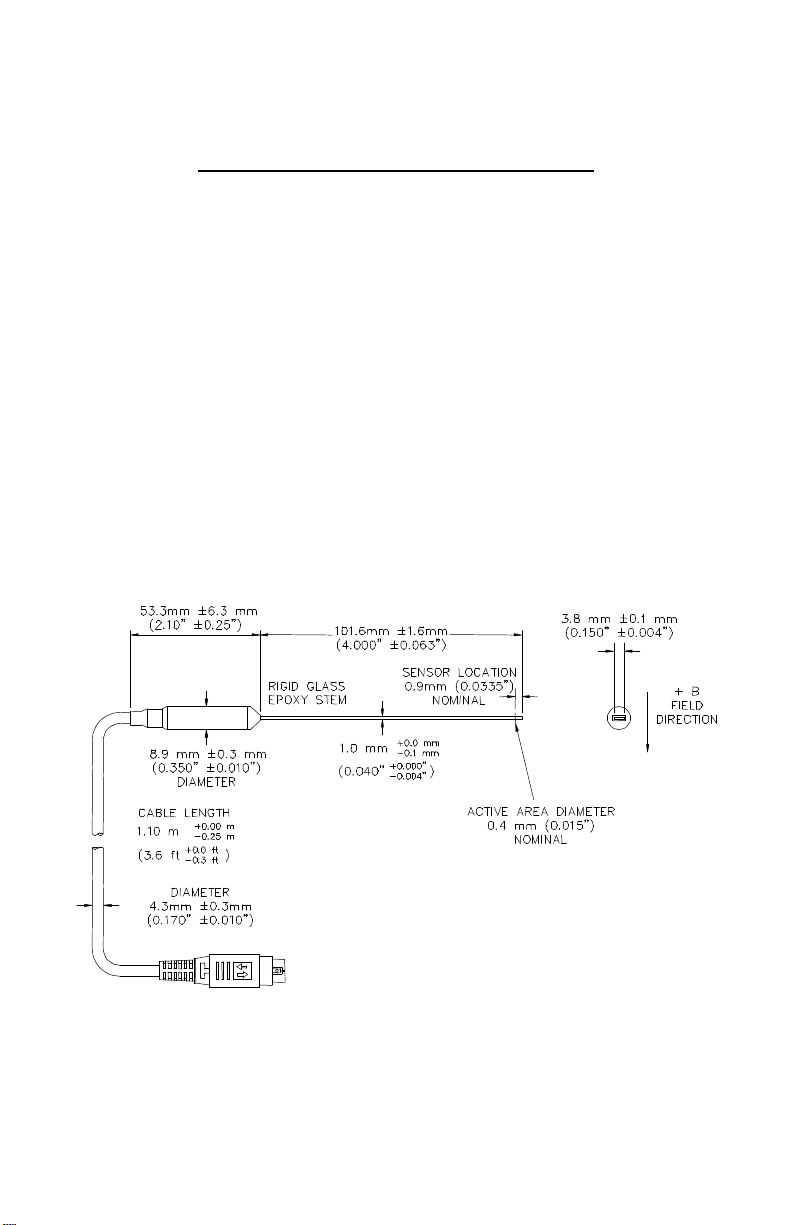

Figure 2-1 Standard Transverse Probe.......................

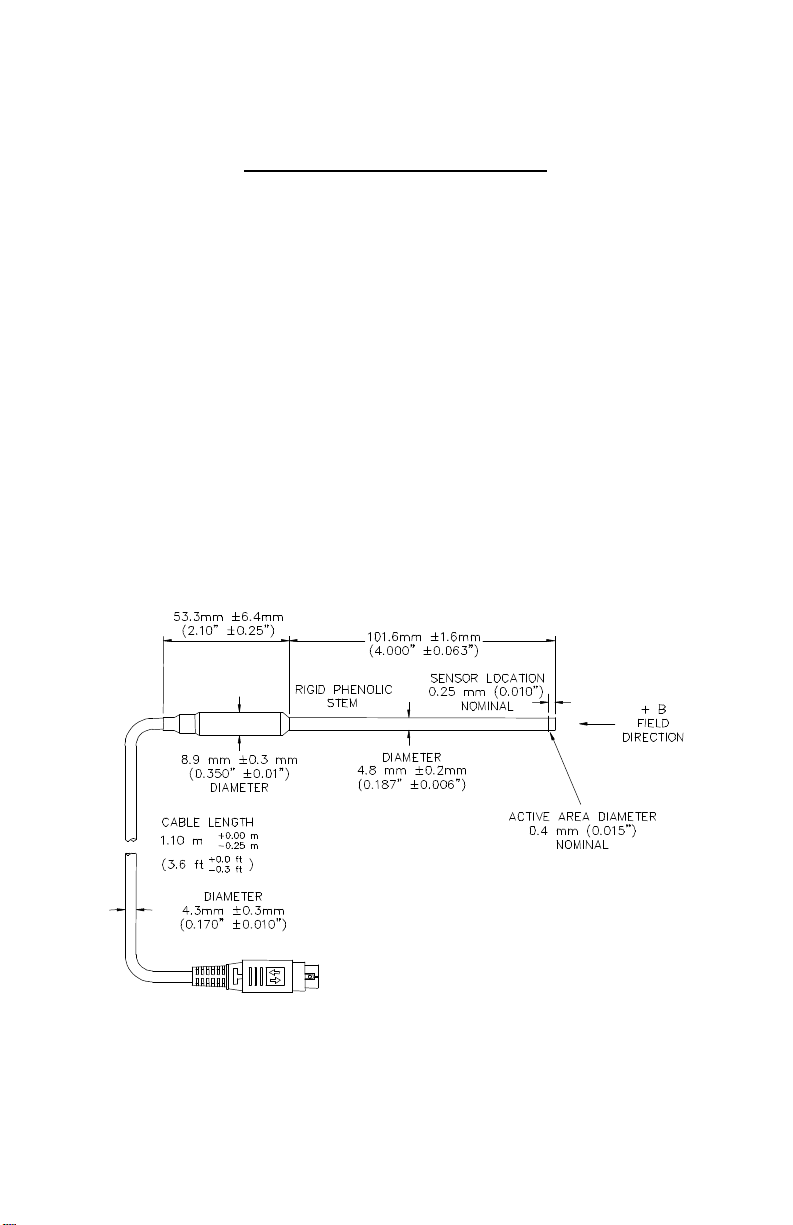

Figure 2-2 Standard Axial Probe................................. 2-6

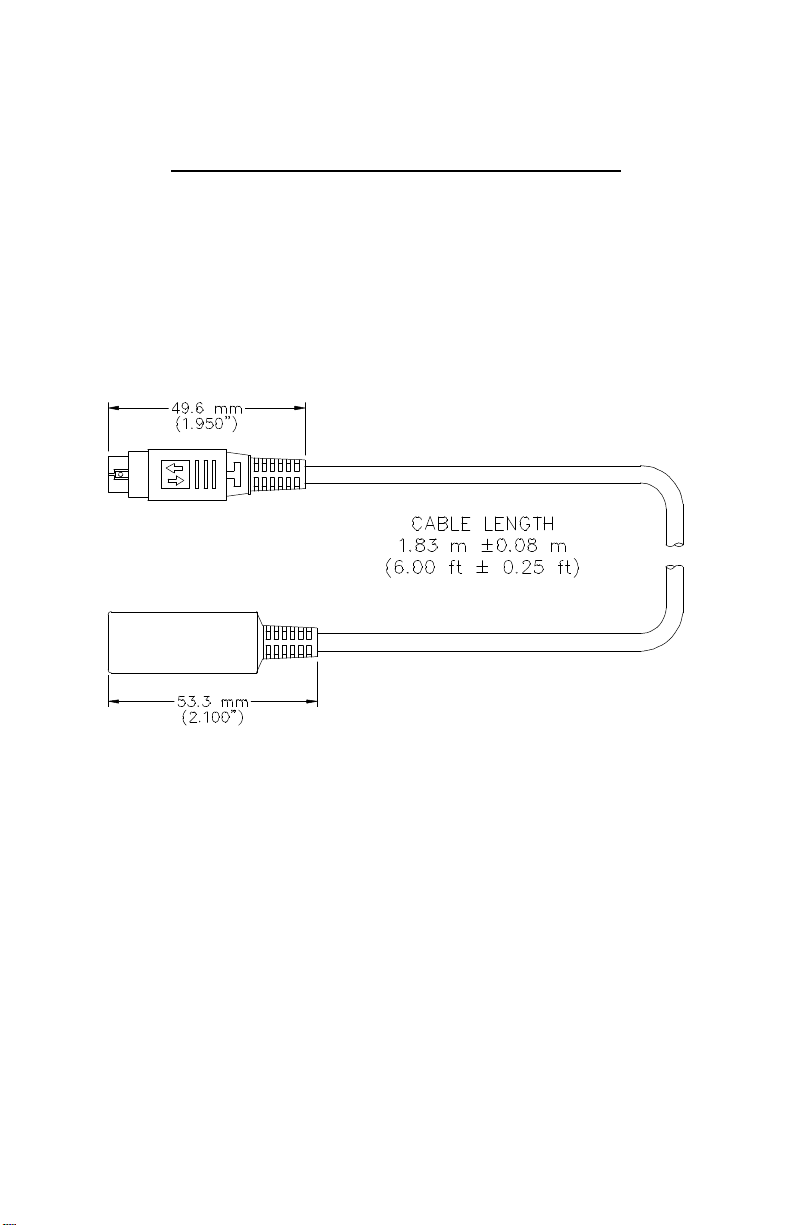

Figure 2-3 Optional Probe Extension Cable................

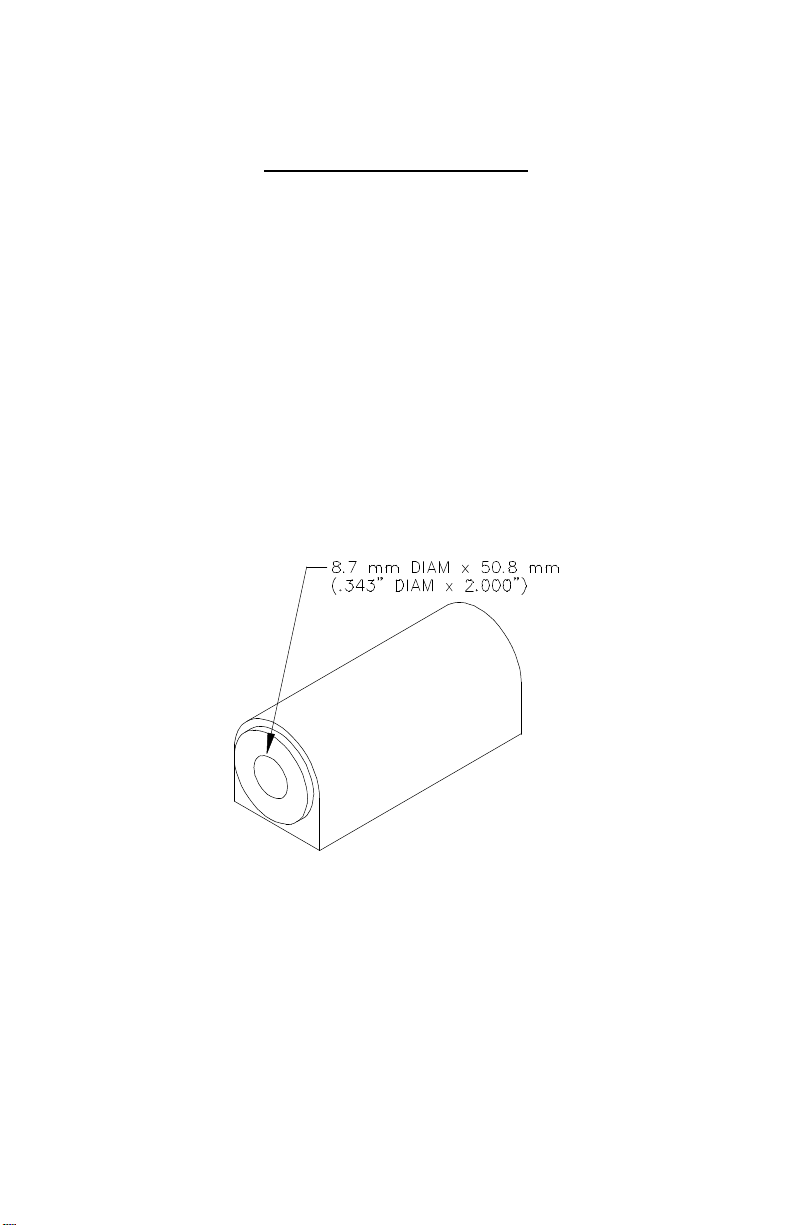

Figure 2-4 Zero Flux Chamber.................................... 2-8

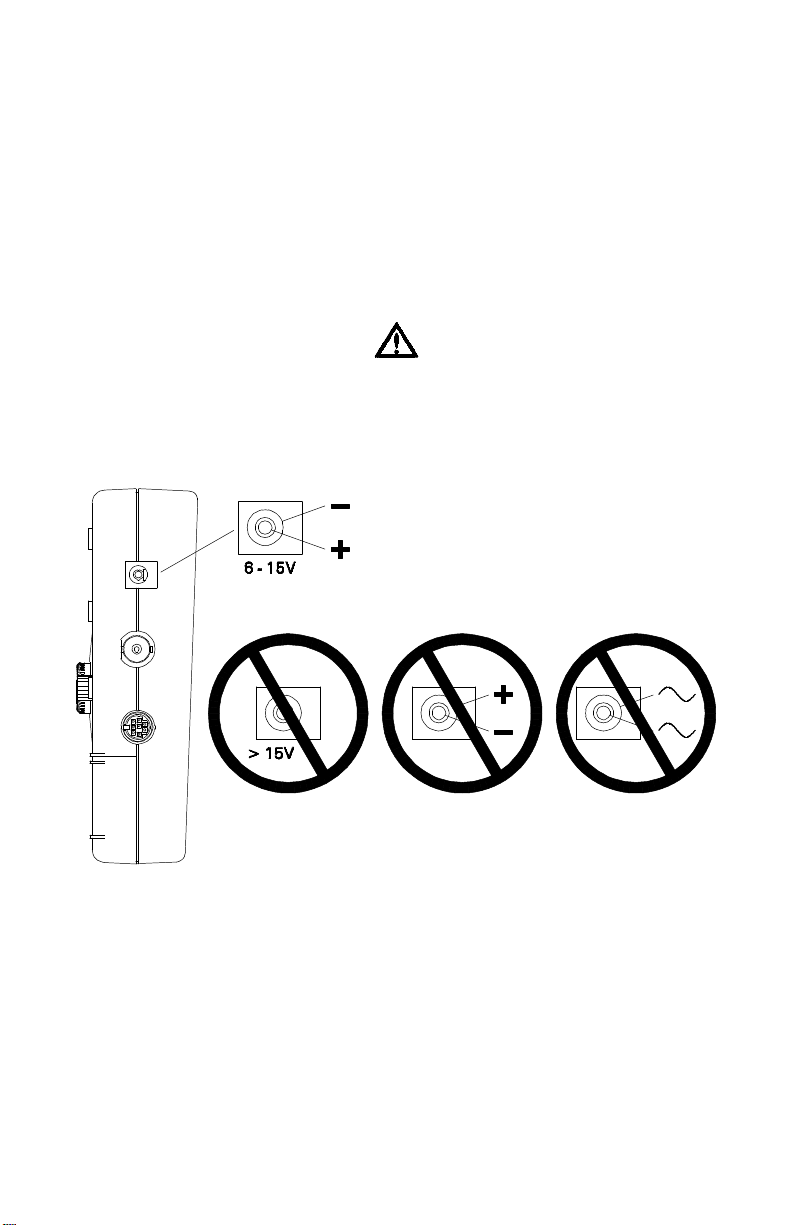

Figure 3-1 Auxiliary Power Connector Warnings.........

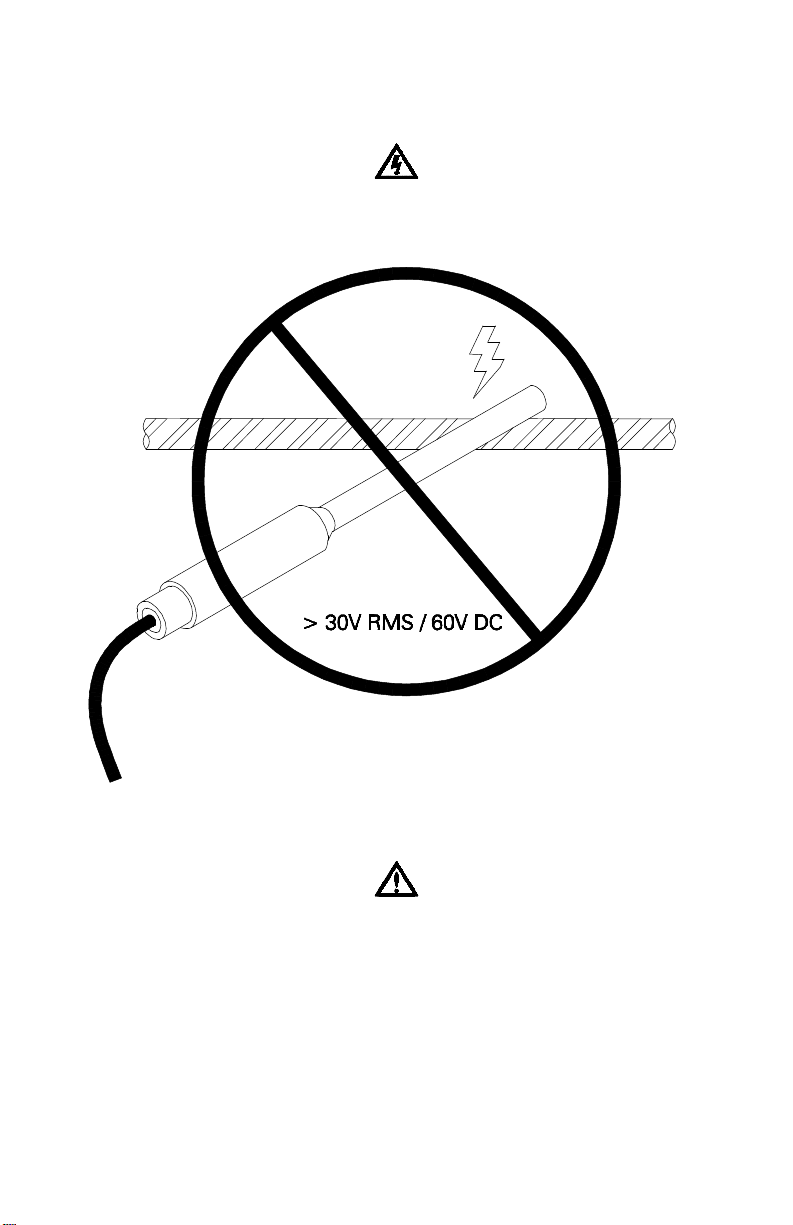

Figure 3-2 Probe Electrical Warning........................... 3-2

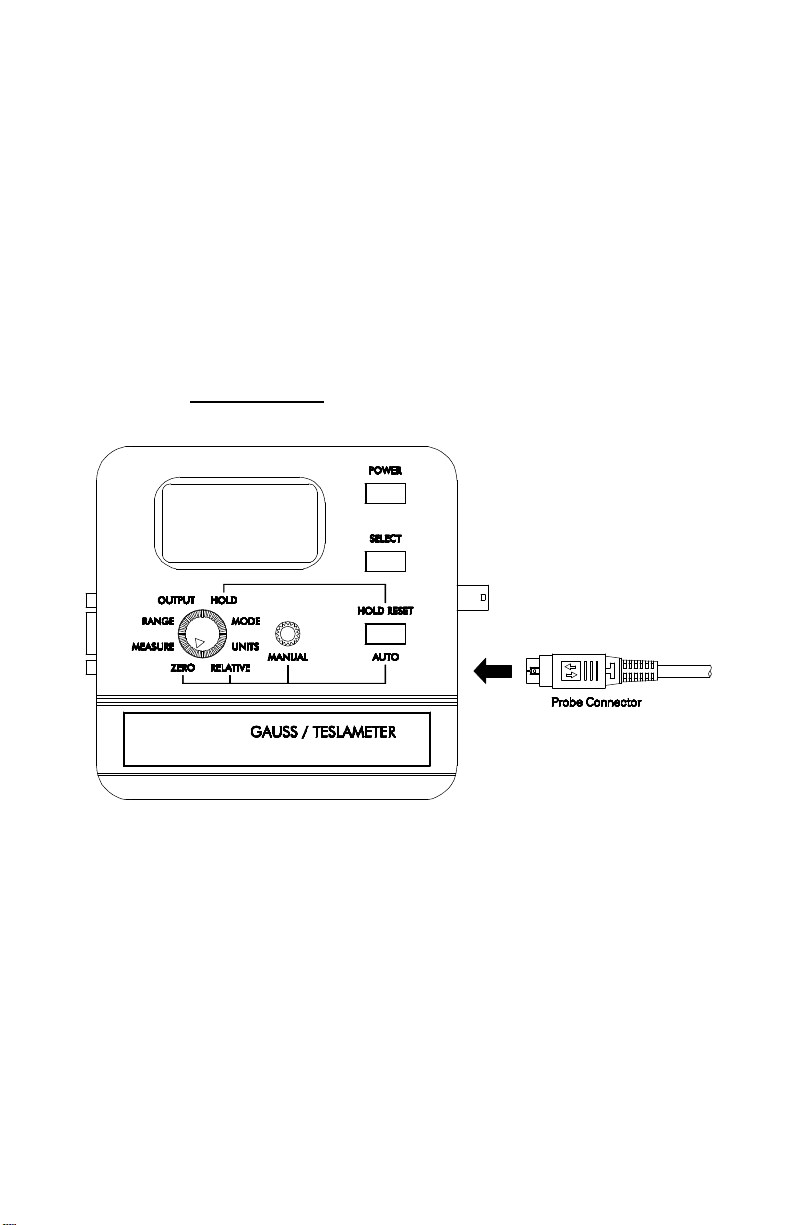

Figure 3-3 Operating Features.................................... 3-3

Figure 3-4 Battery Installation..................................... 3-6

Figure 3-5 Probe Connection...................................... 3-7

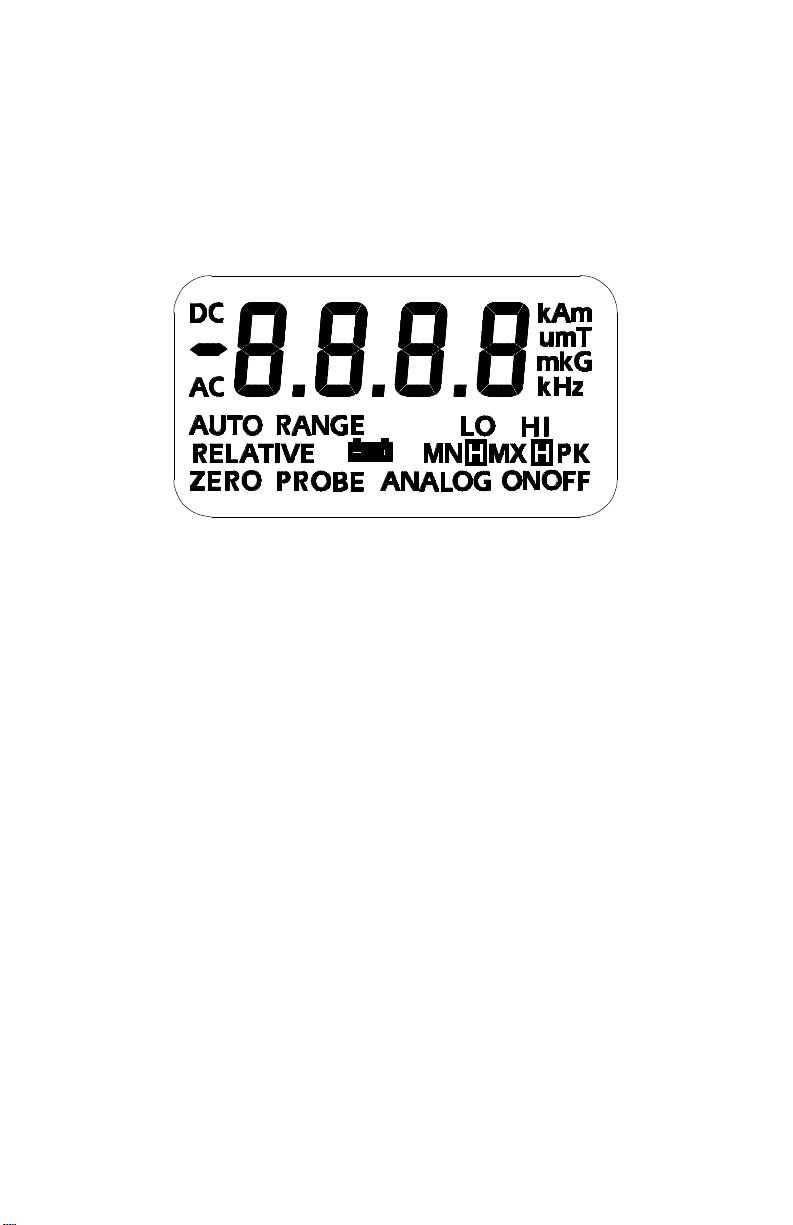

Figure 3-6 Power-Up Display...................................... 3-8

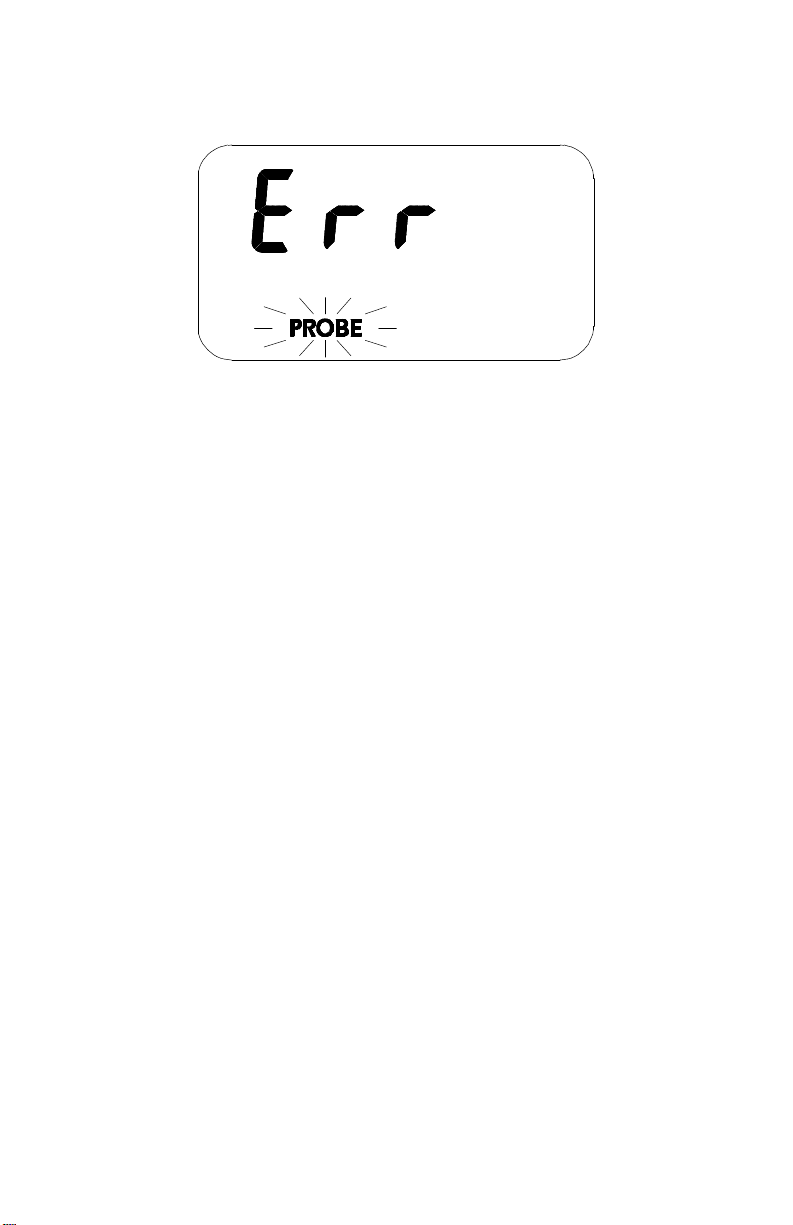

Figure 3-7 Missing Probe Indication............................ 3-9

Figure 3-8 Low Battery Indication................................ 3-11

Figure 3-9 Overrange Indication ................................ 3-11

Figure 3-10 MODE (AC-DC) Function........................... 3-12

Figure 3-11 UNITS Function.......................................... 3-13

Figure 3-12 RANGE Function....................................... 3-15

1-3

2-5

2-7

3-1

iii

Page 6

Figure 3-13 HOLD Function.......................................... 3-17

Figure 3-14 Automatic ZERO Function......................... 3-22

Figure 3-15 Manual ZERO Function.............................. 3-24

Figure 3-16 RELATIVE Function................................... 3-28

Figure 3-17 Automatic RELATIVE Function................ 3-29

Figure 3-18 Manual RELATIVE Function...................... 3-31

Figure 3-19 OUTPUT Function...................................... 3-32

Figure 3-20 LO and HI Analog Output Displays............ 3-34

Figure 3-21 Adjusting the DC Offset of the Analog

Output........................................................

3-35

Figure 3-22 Probe Output versus Flux Angle................ 3-36

Figure 3-23 Probe Output versus Distance................... 3-37

Figure 3-24 Flux Density Variations in a Magnet........... 3-37

Figure 3-25 Low AC Signal Indication........................... 3-39

Figure 4-1 9-Pin Interface Connector.......................... 4-2

Figure 4-2 Serial Port Connection Schemes............... 4-3

Figure 4-3 Condition, Event and Enable registers.......

Figure 4-4 Status Byte and Enable registers...............

4-6

4-7

Figure 4-5 Standard Event register............................. 4-9

Figure 4-6 Measurement Event register...................... 4-10

Figure 4-7 Operation Event register............................ 4-10

Figure 4-8 Questionable Event register....................... 4-11

iv

Page 7

Section 1

Introduction

UNDERSTANDING FLUX DENSITY

Magnetic fields surrounding permanent magnets or electrical

conductors can be visualized as a collection of magnetic flux

lines; lines of force existing in the material that is being subjected

to a magnetizing influence. Unlike light, which travels away from

its source indefinitely, magnetic flux lines must eventually return

to the source. Thus all magnetic sources are said to have two

poles. Flux lines are said to emanate from the “north” pole and

return to the “south” pole, as depicted in Figure 1-1.

Figure 1-1

Flux Lines of a Permanent Magnet

One line of flux in the CGS measurement system is called a

maxwell (Mx), but the weber (Wb), which is 108 lines, is more

commonly used.

Flux density, also called magnetic induction, is the number of flux

lines passing through a given area. It is commonly assigned the

symbol “B” in scientific documents. In the CGS system a gauss

(G) is one line of flux passing through a 1 cm2 area. The more

1-1

Page 8

INTRODUCTION

commonly used term is the tesla (T), which is 10,000 lines per

cm2 . Thus

1 tesla = 10,000 gauss

1 gauss = 0.0001 tesla

Magnetic field strength is a measure of force produced by an

electric current or a permanent magnet. It is the ability to induce

a magnetic field “B”. It is commonly assigned the symbol “H” in

scientific documents. The unit of “H” in the CGS system is an

oersted (Oe), but the ampere/meter (A/m) is more commonly

used. The relationship is

1 oersted = 79.6 ampere/meter

1 ampere/meter = 0.01256 oersted

It is important to know that magnetic field strength and magnetic

flux density are not the same. The only time the two are

considered equal is in free space (air). Only in free space is the

following relationship true:

1 G = 1 Oe = 0.0001 T = 79.6 A/m

MEASUREMENT OF FLUX DENSITY

A device commonly used to measure flux density is the Hall

generator. A Hall generator is a thin slice of a semiconductor

material to which four leads are attached at the midpoint of each

edge, as shown in Figure 1-2.

1-2

Page 9

INTRODUCTION

Figure 1-2

Hall Generator

A constant current (Ic) is forced through the material. In a zero

magnetic field there is no voltage difference between the other

two edges. When flux lines pass through the material the path of

the current bends closer to one edge, creating a voltage

difference known as the Hall voltage (Vh). In an ideal Hall

generator there is a linear relationship between the number of

flux lines passing through the material (flux density) and the Hall

voltage.

The Hall voltage is also a function of the direction in which the

flux lines pass through the material, producing a positive voltage

in one direction and a negative voltage in the other. If the same

number of flux lines pass through the material in either direction,

the net result is zero volts. This sensitivity to flux direction makes

it possible to measure both static (dc) and alternating (ac)

magnetic fields.

The Hall voltage is also a function of the angle at which the flux

lines pass through the material. The greatest Hall voltage occurs

when the flux lines pass perpendicularly through the material.

Otherwise the output is related to the cosine of the difference

between 90° and the actual angle.

1-3

Page 10

INTRODUCTION

The sensitive area of the Hall generator is generally defined as

the largest circular area within the actual slice of the material.

This active area can range in size from 0.2 mm (0.008”) to 19

mm (0.75”) in diameter. Often the Hall generator assembly is too

fragile to use by itself so it is often mounted in a protective tube

and terminated with a flexible cable and a connector. This

assembly, known as a Hall probe, is generally provided in two

configurations:

TRANSVERSE PROBE

AXIAL PROBE

Figure 1-3

Hall Probe Configurations

In “transverse” probes the Hall generator is mounted in a thin, flat

stem whereas in “axial” probes the Hall generator is mounted in a

cylindrical stem. The axis of sensitivity is the primary difference,

as shown by “B” in Figure 1-3. Generally transverse probes are

used to make measurements between two magnetic poles such

as those in audio speakers, electric motors and imaging

machines. Axial probes are often used to measure the magnetic

field along the axis of a coil, solenoid or traveling wave tube.

Either probe can be used where there are few physical space

limitations, such as in geomagnetic or electromagnetic

interference surveys.

1-4

Page 11

INTRODUCTION

Handle the Hall probe with care. Do not bend the stem or

apply pressure to the probe tip as damage may result. Use

the protective cover when the probe is not in use.

PRODUCT DESCRIPTION

The MODEL HHG-23 GAUSS / TESLAMETER is a portable

instrument that utilizes a Hall probe to measure magnetic flux

density in terms of gauss, tesla or ampere/meter. The

measurement range is from 0.01 mT (0.1 G or 0.01 kA/m) to

2.999T (29.99 kG or 2387 kA/m). The instrument is capable of

measuring static (dc) magnetic fields and alternating (ac) fields.

The MODEL HHG-23 consists of a palm-sized meter and various

detachable Hall probes. The meter operates on standard 9 volt

alkaline batteries or can be operated with an external ac-to-dc

power supply. A retractable bail allows the meter to stand upright

on a flat surface. A notch in the bail allows the meter to be wall

mounted when bench space is at a premium. The large display is

visible at considerable distances. The instrument is easily

configured using a single rotary selector and two pushbuttons.

Three measurement ranges can be selected or the meter can

automatically select the best range based on the present flux

density being measured. A “zero” function allows the user to

remove undesirable readings from nearby magnetic fields

(including earth’s) or false readings caused by initial electrical

offsets in the probe and meter. Included is a “zero flux chamber”

which allows the probe to be shielded from external magnetic

fields during this operation. Another feature called “relative

mode” allows large flux readings to be suppressed so that small

variations within the larger field can be observed directly. Both

the “zero” and “relative” adjustments can be made manually or

automatically.

1-5

Page 12

INTRODUCTION

Other features include three “hold” modes, allowing either the

arithmetic maximum, minimum or true peak values to be held

indefinitely until reset by the user. An analog signal is available

from a standard BNC connector that is representative of the

magnetic flux density signal and is calibrated to ± 3 volts full scale

in dc mode or 3 Vrms in ac mode. This output can be connected

to a voltmeter, oscilloscope, recorder or external analog-to-digital

converter.

The meter can be fully configured and flux density readings

acquired from a remote computer or PLC using the RS-232

communications port. This is a standard 9-pin “D” connector

commonly used in personal computers. The commands follow

widely accepted protocols established by the IEEE-488.2 and

SCPI-1991 standards.

The meter, probes and accessories are protected when not in

use by a sturdy carrying case.

APPLICATIONS

• Sorting or performing incoming inspection on permanent

magnets, particularly multi-pole magnets.

• Testing audio speaker magnet assemblies, electric motor

armatures and stators, transformer lamination stacks,

cut toroidal cores, coils and solenoids.

• Determining the location of stray fields around medical

diagnostic equipment.

• Determining sources of electromagnetic interference.

• Locating flaws in welded joints.

• Inspection of ferrous materials.

• 3-dimensional field mapping.

• Inspection of magnetic recording heads.

1-6

Page 13

Section 2

Specifications

INSTRUMENT

RANGE RESOLUTION

gauss tesla A/m gauss tesla A/m

300 G

3 kG 300 mT 238 kA/m

30 kG

ACCURACY (reading on display and from RS-232 port,

including probe)

dc mode: ± 1 % of reading, ± 3 counts

ac mode:

20 - 10,000 Hz: ± 2.5 % of reading, ± 5 counts

10,000 - 20,000 Hz: ± 5 % of reading, ± 5 counts

ACCURACY (analog output, including probe)

dc mode: ± 1 % of reading, ± 5 mV.

ac mode, low range:

20 - 2000 Hz: ± 3 % of reading, ± 5 mV

10,000 Hz: - 3 dB

ac mode, mid and high range:

20 - 4000 Hz: ± 3 % of reading, ± 5 mV

15,000 Hz: - 3 dB

WARMUP TIME TO RATED

ACCURACY: 15 minutes

30 mT

3 T 2388 kA/m

23 kA/m

0.1 G

1 G

10 G

0.01 mT 0.01 kA/m

0.1 mT

1 mT

0.1 kA/m

1 kA/m

2-1

Page 14

SPECIFICATIONS

MIN / MAX HOLD ACQUISITION TIME:

dc mode: 180 ms typical

ac mode: 300 ms typical

PEAK HOLD ACQUISITION TIME:

dc mode: 1 ms typical

ac mode: 1 ms typical

ANALOG OUTPUT SCALING:

dc mode: ± 3 Vdc

ac mode: 3 Vrms

ANALOG OUTPUT NOISE: 4 mV rms typical

ANALOG OUTPUT LOAD: 10 kΩ min, 100 pF max.

ACCURACY CHANGE WITH

TEMPERATURE

(not including probe): ± 0.02 % / ºC typical

BATTERY TYPE: 9 Vdc alkaline (NEDA 1640A)

BATTERY LIFE: 8 hours typical (two batteries,

analog output and RS-232 port

not used)

AUXILIARY POWER: 6 to 12 Vdc, 300 mA minimum.

AUXILIARY POWER CONNECTOR: Standard 2.5 mm I.D. / 5.5 mm

O.D. connector. Center post is

positive (+) polarity.

ANALOG OUTPUT CONNECTOR: BNC

OPERATING TEMPERATURE: 0 to +50ºC (+32 to +122ºF)

2-2

Page 15

SPECIFICATIONS

STORAGE TEMPERATURE: -25 to +70ºC (-13 to +158ºF)

METER DIMENSIONS:

Length: 13.2 cm (5.2 in)

Width: 13.5 cm (5.3 in)

Height: 3.8 cm (1.5 in)

WEIGHT:

Meter w/batteries: 400 g (14 oz.)

Shipping: 1.59 kg (3 lb., 8 oz.)

REGULATORY INFORMATION:

Compliance was demonstrated to the following specifications as

listed in the official Journal of the European Communities:

EN 50082-1:1992 Generic Immunity

IEC 801-2:1991 Electrostatic Discharge

Second Edition Immunity

IEC 1000-4-2:1995

ENV 50140:1993 Radiated Electromagnetic

IEC 1000-4-3:1995 Field Immunity

EN 50081-1:1992 Generic Emissions

EN 55011:1991 Radiated and Conducted

Emissions

2-3

Page 16

SPECIFICATIONS

COMMUNICATIONS PORT:

Format: RS-232C

Lines supported: Transmit, receive, common.

Connector type: 9-pin “D” female

Cable length: 3 m (9.8 ft.) maximum

Receive input resistance: 3 kΩ minimum

Receive voltage limit: ± 30 V maximum

Transmit output voltage: ± 5 V min, ± 8 V typical

Baud rate: 2400

Stop bits: 1

Character length: 8

Parity: None

Standards supported: IEEE-1987.2, SCPI-1991

EMC APPLICATION NOTE

Use only high quality, double shielded cables for RS-232

connection. Keep the length of the cables less than

3 meters (9.8 ft.). Long cables (>3m) with insufficient EMI

shielding can cause excessive emissions or may be

susceptible to external interference.

2-4

Page 17

SPECIFICATIONS

STANDARD TRANSVERSE PROBE

MODEL NUMBER: STD58-0404

FLUX DENSITY RANGE: 0 to ± 3 T (0 to ± 30 kG)

FREQUENCY BANDWIDTH: 0 - 20 kHz

OFFSET CHANGE WITH

TEMPERATURE: ± 30 µT (300 mG) / ºC typical

ACCURACY CHANGE WITH

TEMPERATURE: - 0.05% / ºC typical

OPERATING TEMPERATURE RANGE: 0 to +75 ºC (+32 to +167ºF)

STORAGE TEMPERATURE RANGE: -25 to +75 ºC (-13 to +167ºF)

Figure 2-1

Standard Transverse Probe

2-5

Page 18

SPECIFICATIONS

STANDARD AXIAL PROBE

MODEL NUMBER: SAD58-1904

FLUX DENSITY RANGE: 0 to ± 3 T (0 to ± 30 kG)

FREQUENCY BANDWIDTH: 0 - 20 kHz

OFFSET CHANGE WITH

TEMPERATURE: ± 30 µT (300 mG) / ºC typical

ACCURACY CHANGE WITH

TEMPERATURE: - 0.05% / ºC typical

OPERATING TEMPERATURE RANGE: 0 to +75 ºC (+32 to +167ºF)

STORAGE TEMPERATURE RANGE: -25 to +75 ºC (-13 to +167ºF)

2-6

Figure 2-2

Standard Axial Probe

Page 19

SPECIFICATIONS

OPTIONAL PROBE EXTENSION CABLE

MODEL NUMBER: X5000-0006

OPERATING TEMPERATURE RANGE: 0 to +75 ºC (+32 to +167ºF)

STORAGE TEMPERATURE RANGE: -25 to +75 ºC (-13 to +167ºF)

Figure 2-3

Optional Probe Extension Cable

2-7

Page 20

SPECIFICATIONS

ZERO FLUX CHAMBER

MODEL NUMBER: YA-111

CAVITY DIMENSIONS:

Length: 50.8 mm (2”)

Diameter: 8.7 mm (0.343”)

ATTENUATION: 80 dB to 30 mT (300 G)

PURPOSE: To shield the probe from

external magnetic fields during

the ZERO or RELATIVE

operations.

2-8

Figure 2-4

Zero Flux Chamber

Page 21

Section 3

Operating Instructions

OPERATOR SAFETY

Do not connect the auxiliary power connector to an ac power

source. Do not exceed 15 Vdc. Do not reverse polarity. Use

only an ac-to-dc power supply certified for country of use.

Figure 3-1

Auxiliary Power Connector Warnings

3-1

Page 22

OPERATING INSTRUCTIONS

Do not allow the probe to come in contact with any voltage

source greater than 30 Vrms or 60 Vdc.

Figure 3-2

Probe Electrical Warning

This instrument may contain ferrous components which will

exhibit attraction to a magnetic field. Care should be utilized

when operating the instrument near large magnetic fields, as

pull-in may occur. Extension cables are available to increase

the probe cable length, so that the instrument can remain in a

safe position with respect to the field being measured with

the probe.

3-2

Page 23

OPERATING INSTRUCTIONS

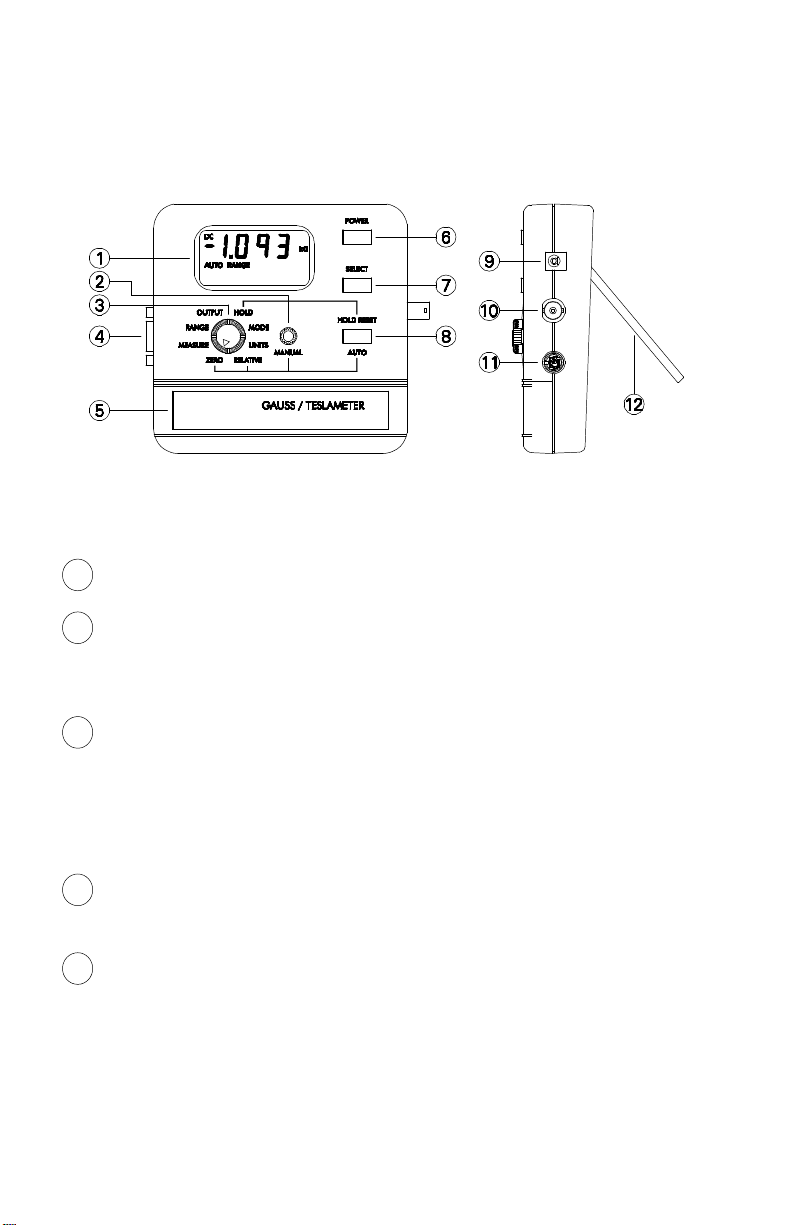

OPERATING FEATURES

Figure 3-3

Operating Features

1 Display. Liquid crystal display (LCD).

2 Manual ZERO / RELATIVE Control. In the ZERO and

RELATIVE modes of operation the user can manually

adjust the zero or relative point using this control.

3 Function Selector. This control allows the operator to

change the meter’s range, units of measure, ac or dc

measurement, hold modes and operation of the analog

output. It also engages the ZERO, RELATIVE and

MEASURE modes of operation.

4 RS-232 Port. Shielded 9-pin “D” connector supporting

RS-232-C serial communications.

5 Battery Compartment Cover. This cover slides open to

allow one or two 9 volt batteries to be installed.

3-3

Page 24

OPERATING INSTRUCTIONS

6 Power Switch. Push-on / push-off type switch to apply

power to the meter.

7 SELECT Switch. Momentary pushbutton used in

conjunction with the Function Selector 3 to configure

the meter’s range, units of measure, ac or dc

measurement, hold modes and operation of the analog

output.

8 AUTO/HOLD RESET Switch. Momentary pushbutton

used to reset the held reading when one of the HOLD

modes is being used, or to start an automatic ZERO or

RELATIVE operation when in the ZERO or RELATIVE

modes.

9 Auxiliary Power Connector. This is an industry standard

2.5 mm I.D. / 5.5 mm O.D. dc power connector. The

meter will accept a dc voltage in the range of 6 - 15 Vdc at

300 mA minimum current. The center pin is positive (+).

The internal batteries are disconnected when using this

connector.

Do not connect the auxiliary power connector to an ac power

source. Do not exceed 15 Vdc. Do not reverse polarity. Use

only an ac-to-dc power supply certified for country of use.

3-4

Page 25

OPERATING INSTRUCTIONS

10 Analog Output Connector. A voltage signal

representative of the magnetic flux density being

measured is available at this BNC connector. Calibration

is set to ± 3.0 V full scale dc or 3.0 Vrms ac, depending

upon the mode of operation . Minimum load is 10 kΩ.

The analog output will be active when the ANALOG

ON/OFF function has been turned ON using the Function

Selector 3 .

11 Probe Connector. The Hall probe or probe extension

cable plugs into this connector and locks in place. To

disconnect, pull on the body of the plug, not the cable !

12 Meter Stand. Retractable stand that allows the meter to

stand upright when placed on a flat surface. A notch in

the stand allows the meter to be mounted to a vertical

surface.

3-5

Page 26

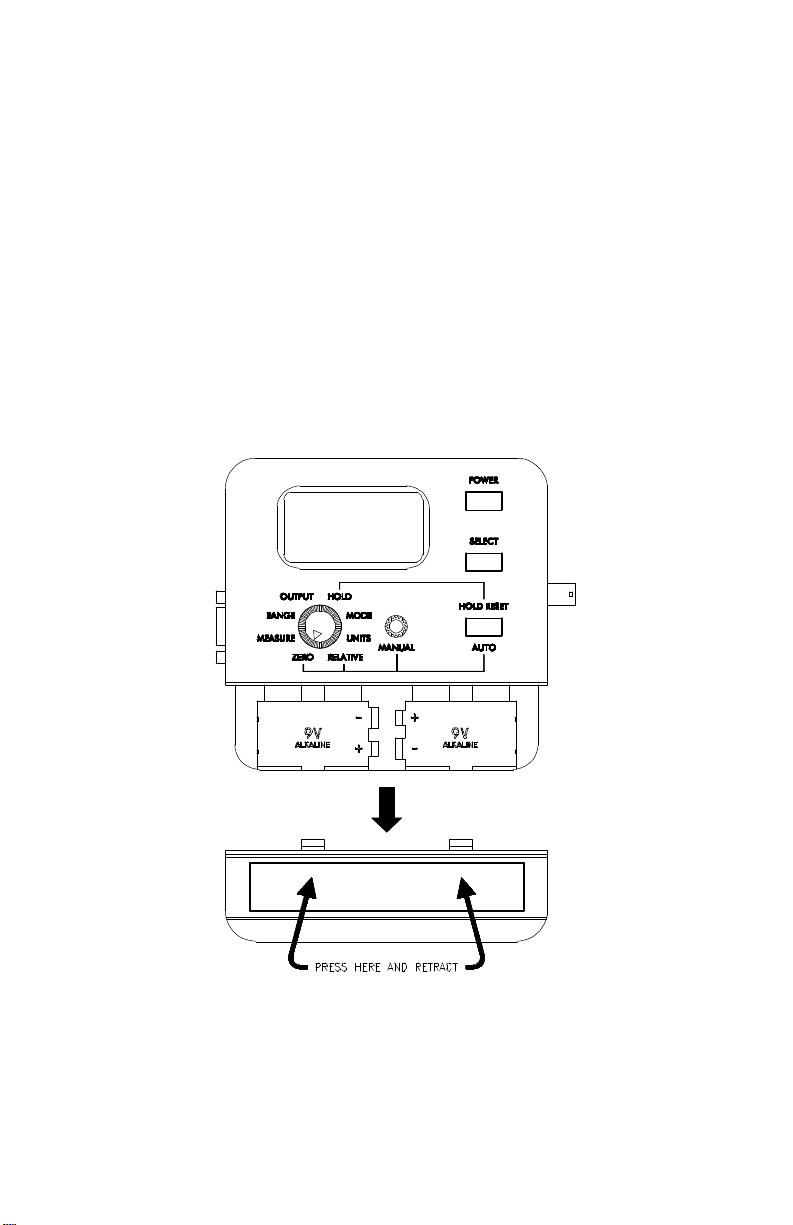

OPERATING INSTRUCTIONS

INSTRUMENT PREPARATION

1) With the power switch turned off (POWER pushbutton in the

full up position) apply pressure to the battery compartment cover

at the two points shown in Figure 3-4. Slide the cover open and

remove.

2) Install one or two 9 volt alkaline batteries (two batteries will

provide longer operating life). The battery compartment is

designed so that the battery polarity cannot be reversed.

Reinstall the battery compartment cover.

3-6

Figure 3-4

Battery Installation

Page 27

OPERATING INSTRUCTIONS

3) If using an ac-to-dc power supply review Figure 3-1 for safety

notes and the SPECIFICATIONS section for voltage and current

ratings. When using a power supply the batteries are

automatically disconnected.

4) Install the probe or probe extension cable by matching the key

way in the connector to that in the mating socket in the meter.

The connector will lock in place. To disconnect, pull on the body

of the plug, not the cable!

Figure 3-5

Probe Connection

3-7

Page 28

OPERATING INSTRUCTIONS

POWER-UP

Depress the POWER switch. There will be a momentary audible

beep and all display segments will appear on the display.

Figure 3-6

Power-Up Display

The instrument will conduct a self test before measurements

begin. If a problem is detected the phrase “Err” will appear on the

display followed by a 3-digit code. The circuitry that failed will be

retested and the error code will appear after each failure. This

process will continue indefinitely or until the circuitry passes the

test. A condition in which a circuit fails and then passes should

not be ignored because it indicates an intermittent problem that

should be corrected.

If the self test is successful the meter will perform a self

calibration. During this phase the meter will display the software

revision number, such as “r 1.0”. Calibration will halt if there is no

Hall probe connected. Until the probe is connected the phrase

“Err” will appear accompanied by a flashing “PROBE” annunciator

as shown in Figure 3-7.

3-8

Page 29

OPERATING INSTRUCTIONS

Figure 3-7

Missing Probe Indication

After power-up the position of the FUNCTION selector switch will

determine what happens next. For instance if the selector is in

the RANGE position the meter will wait for the user to change the

present range. If in the MEASURE position flux density

measurements will begin.

Allow adequate time for the meter and probe to reach a stable

temperature. See the SPECIFICATIONS section for specific

information.

POWER-UP SETTINGS

The meter permanently saves certain aspects of the instrument’s

setup and restores them the next time the meter is turned on.

The conditions that are saved are:

RANGE setting (including AUTO range)

MODE (ac or dc)

UNITS of measure (gauss, tesla or ampere/meter)

HOLD mode (min, max or peak)

3-9

Page 30

OPERATING INSTRUCTIONS

Other aspects are not saved and default to these conditions:

RELATIVE mode (turned OFF)

RELATIVE value (set to 0)

ZERO mode (inactive)

OUTPUT function (turned OFF and output set to 0 Vdc)

NOTE: The present setup of the instrument is saved only when

the FUNCTION selector is returned to the MEASURE position.

For example assume the meter is in the MEASURE mode on the

30 mT range. The FUNCTION selector is now turned to the

RANGE position and the 300 mT range is selected. The meter is

turned off and on again. The meter will be restored to the 30 mT

range because the FUNCTION selector was never returned to the

MEASURE mode prior to turning it off.

LOW BATTERY CONDITION

The meter is designed to use one or two standard 9V alkaline

batteries (two batteries will provide longer operating life). When

the battery voltage becomes too low the battery symbol on the

display will flash, as shown in Figure 3-8. Replace the batteries

or use an external ac-to-dc power supply.

Instrument specifications are not guaranteed when a low

battery condition exists !

3-10

Page 31

OPERATING INSTRUCTIONS

Figure 3-8

Low Battery Indication

OVERRANGE CONDITION

If the magnitude of the magnetic flux density exceeds the limit of

the selected range the meter will display a flashing value of

“2999” (gauss or tesla mode) or “2387” (ampere/meter mode).

The next highest range should be selected. If already on the

highest range then the flux density is too great to be measured

with this instrument.

Figure 3-9

Overrange Indication

3-11

Page 32

OPERATING INSTRUCTIONS

AC OR DC MEASUREMENT SELECTION

The meter is capable of measuring either static (dc) or alternating

(ac) magnetic fields. To choose the desired mode rotate the

function selector to the MODE setting, then press the SELECT

pushbutton to select AC or DC on the display.

The dc and ac modes is discussed in more detail later in this

section.

This setting is saved and will be restored the next time the meter

is turned on.

3-12

Figure 3-10

MODE (AC-DC) Function

Page 33

OPERATING INSTRUCTIONS

UNITS OF MEASUREMENT SELECTION

The meter is capable of providing flux density measurements in

terms of gauss (G), tesla (T) or ampere/meter (A/m). To choose

the desired units, rotate the function selector to the UNITS

position. Press the SELECT pushbutton to select G, T or A/m on

the display.

This setting is saved and will be restored the next time the meter

is turned on.

Figure 3-11

UNITS Function

3-13

Page 34

OPERATING INSTRUCTIONS

RANGE SELECTION

The meter is capable of providing flux density measurements on

one of three fixed ranges, or it can be programmed to

automatically select the best range for the present flux density.

The available ranges are listed in the SPECIFICATIONS section

of this manual. The ranges advance in decade steps. The

lowest range offers the best resolution while the highest range

allows higher flux levels to be measured.

In the AUTO range mode the range is advanced if the reading

reaches the full scale of the present range. This is 2999 if in the

gauss or tesla mode (such as 299.9 G or 299.9 mT), or 2387 if in

the ampere/meter mode (such as 23.87 kA/m). The range is

lowered if the present reading falls below 10% of full scale for the

present range. The speed at which the readings are updated

decreases slightly when AUTO ranging is used.

NOTE: The AUTO range selection will be canceled if the

RELATIVE mode is turned on.

To choose the desired range rotate the function selector to the

RANGE position. The “RANGE” legend will flash. Press the

SELECT pushbutton to select the desired range or AUTO

RANGE on the display.

This setting is saved and will be restored the next time the meter

is turned on.

3-14

Page 35

OPERATING INSTRUCTIONS

Figure 3-12

RANGE Function

3-15

Page 36

OPERATING INSTRUCTIONS

HOLD MODE SELECTION

In some applications it may be desirable to hold a reading that is

either greater than or less than all previous readings, or which

has the greatest peak value whether positive or negative.

The MAX HOLD function holds the reading that is arithmetically

greater than all previous readings. For instance a reading of

+125.0 is greater than +99.0 or -150.0.

The MIN HOLD function holds the reading that is arithmetically

less than all previous readings. For instance a reading of -125.0

is less than -99.0 or +150.0.

The PEAK HOLD function captures and holds the peak value of

the flux density waveform within the response time capabilities of

the meter. See the SPECIFICATIONS section of this manual for

more information. The peak can be either positive or negative,

whichever has the greatest magnitude. For instance a peak

value of -100.0 is greater than a peak value of +90.0.

To choose the desired hold mode rotate the function selector to

the HOLD position. Press the SELECT pushbutton to select the

desired mode on the display. MAX HOLD is indicated by “MX”.

MIN HOLD is indicated by “MN”. PEAK HOLD is indicated by

“PK”. The “OFF” legend will appear when all HOLD modes are

turned off.

This setting is saved and will be restored the next time the meter

is turned on.

3-16

Page 37

OPERATING INSTRUCTIONS

Figure 3-13

HOLD Function

MIN / MAX HOLD USAGE

See the SPECIFICATIONS section for response time information.

The MAX HOLD function holds the reading that is arithmetically

greater than all previous readings. The MIN HOLD function holds

the reading that is arithmetically less than all previous readings.

These modes are useful in determining the maximum or minimum

value of magnetic events that occur over a period of time.

The MIN or MAX HOLD operation begins when the function

selector is returned to the MEASURE position. If the reading

exceeds the range limit the meter will hold a flashing value of

3-17

Page 38

OPERATING INSTRUCTIONS

“2999” (gauss or tesla mode), “2387” (ampere/meter mode) or

the maximum value allowed in the RELATIVE mode.

The held value can be reset by pressing the HOLD RESET

pushbutton. The next value displayed after a reset will be the

present value of flux density. For instance if the held reading is

200.0 G and the present flux density is -100.0 G, the meter will

display -100.0 G after the reset.

If the analog output is being used the output signal will continue

to represent the real time flux density as seen by the probe. It is

not affected by the HOLD function.

PEAK HOLD USAGE

See the SPECIFICATIONS section for acquisition time.

In the PEAK HOLD mode the input signal is sampled many times

each second. Each sample is compared to all previous samples

and that which has the greatest amplitude (regardless of polarity)

is held on the display. This mode can be used to capture the

peak value of a fast, one-time magnetic event such as a

magnetizing pulse.

The PEAK HOLD operation begins when the function selector is

returned to the MEASURE position. If the reading exceeds the

range limit the meter will hold a flashing value of “2999” (gauss or

tesla mode), “2387” (ampere/meter mode) or the maximum value

allowed in the RELATIVE mode. The held value can be reset by

pressing the HOLD RESET pushbutton.

These are the differences between the PEAK HOLD mode and

the MIN / MAX HOLD modes:

3-18

Page 39

OPERATING INSTRUCTIONS

- The PEAK HOLD mode considers only the magnitude of

the reading and not the polarity.

- The response time of the PEAK HOLD mode is much

faster but final accuracy is less.

If the analog output is being used the output signal will continue

to represent the real time flux density as seen by the probe. It is

not affected by the HOLD function.

3-19

Page 40

OPERATING INSTRUCTIONS

ZERO FUNCTION

“Zeroing” the probe and meter is one of the most important steps

to obtaining accurate dc flux density measurements. The ideal

Hall generator produces zero output in the absence of a magnetic

field, but actual devices are subject to variations in materials,

construction and temperature. Therefore most Hall generators

produce some output even in a zero field. This will be interpreted

by the meter as a flux density signal.

Also, the circuits within the meter can produce a signal even

when there is no signal present at the input. This will be

interpreted as a flux density signal. Lastly magnetic sources

close to the actual field being measured, such as those from

electric motors, permanent magnets and the earth (roughly 0.5

gauss or 50 µT), can induce errors in the final reading.

It is vital to remove these sources of error prior to making actual

measurements. The process of “zeroing” removes all of these

errors in one operation. The meter cancels the combined dc

error signal by introducing another signal of equal magnitude with

opposite polarity. After zeroing the only dc signal that remains is

that produced by the probe when exposed to magnetic flux.

NOTE: Zeroing the meter and probe affects only the static (dc)

component of the flux density signal.

NOTE: The process of zeroing also affects the analog signal.

There may be situations when the user prefers to shield the

probe from all external magnetic fields prior to zeroing. Provided

with the meter is a ZERO FLUX CHAMBER which is capable of

shielding against fields as high as 30 mT (300 G or 23.88 kA/m).

The probe is simply inserted into the chamber before the zeroing

process begins.

3-20

Page 41

OPERATING INSTRUCTIONS

Handle the Hall probe with care. Do not bend the stem or

apply pressure to the probe tip as damage may result.

In other situations the user may want the probe to be exposed to

a specific magnetic field during the zeroing process so that all

future readings do not include that reading (such as the earth’s

field). This is possible with the following restrictions:

1) The external field must not exceed 30 mT (300 G or

23.88 kA/m).

2) The field must be stable during the zeroing process. It should

not contain alternating (ac) components.

AUTOMATIC ZERO FUNCTION

The meter provides two methods to zero the probe. The first is

completely automatic. Prepare the probe for zeroing, then rotate

the function selector to the ZERO position. The “ZERO” legend

will flash and actual dc flux density readings will appear on the

display. The meter will select the lowest range regardless of

which range was in use prior to using the ZERO function. Recall

that the maximum flux density level that can be zeroed is 30 mT

(300 G or 23.88 kA/m). If the existing field is too large consider

using the RELATIVE mode (discussed later in this section). The

meter will switch over to the dc mode of operation during zeroing.

Recall that the zeroing operation affects dc errors only. If you

wish to suppress an ac field consider using the RELATIVE mode.

3-21

Page 42

OPERATING INSTRUCTIONS

Figure 3-14

Automatic ZERO Function

Press the AUTO pushbutton and the process will begin. The

“AUTO” legend will also flash. Once automatic zeroing begins it

must be allowed to complete. During this time all controls are

disabled except for the POWER switch. The process normally

takes from 5 to 15 seconds.

The meter selects the lowest range and adjusts the nulling signal

until the net result reaches zero. If the existing field is too large

or unstable the meter will sound a double beep and the phrase

“OVER” will appear momentarily on the display. At this point the

automatic process is terminated and the flashing “AUTO” legend

will disappear. The “ZERO” legend will continue to flash to

remind the user that the ZERO mode is still active.

3-22

Page 43

OPERATING INSTRUCTIONS

If the nulling process is successful, the next highest range is

selected. No further electronic adjustments are made, but at this

stage a reading is acquired which will be mathematically

subtracted from all future readings on this range. This process is

then repeated for the highest range. When finished, the meter

will sound an audible beep and the flashing “AUTO” legend will

disappear. The “ZERO” legend will continue to flash to remind

the user that the ZERO mode is still active. At this point the

automatic process can be repeated or a manual adjustment can

be performed (see “Manual Zeroing”).

The final zero values will remain in effect until the meter and

probe are zeroed again, if the probe is disconnected or if the

meter is turned off and back on again.

NOTE: Zeroing the probe cancels the RELATIVE mode if it was

turned on.

MANUAL ZERO FUNCTION

The second zeroing method is a manual adjustment. This

feature also allows the user to set the “zero” point to something

other than zero, if desired. Position the probe for zeroing, then

rotate the function selector to the ZERO position. The “ZERO”

legend will flash and actual dc flux density readings will appear

on the display. The meter will select the lowest range regardless

of which range was in use prior to selecting the ZERO function.

Recall that the maximum flux density level that can be zeroed is

30 mT (300 G or 23.88 kA/m). If the existing field is too large,

consider using the RELATIVE mode (discussed later in this

section). The meter will switch over to the dc mode of operation

during zeroing. Recall that the zeroing operation affects dc errors

only. If you wish to suppress an ac field consider using the

RELATIVE mode.

3-23

Page 44

OPERATING INSTRUCTIONS

Figure 3-15

Manual ZERO Function

By turning the MANUAL control in either direction the reading will

be altered. Turning the control clockwise adds to the reading,

turning it counterclockwise subtracts from the reading. Turning it

slowly results in a fine adjustment, turning it quickly results in a

coarse adjustment.

NOTE: Making a manual ZERO adjustment not only affects the

lowest range but also the higher ranges, though to a lesser

extent. For example, assume an automatic ZERO has already

been performed, after which all three ranges should read zero.

Now a manual adjustment is made that causes the reading on

the lowest range to be non-zero. The reading on the other

ranges may also be non-zero depending upon the magnitude of

the change. The adjustment has 10 times less effect on the

middle range and 100 times less effect on the highest range.

3-24

Page 45

OPERATING INSTRUCTIONS

NOTE: Zeroing the probe cancels the RELATIVE mode if it was

turned on.

RELATIVE MODE

The RELATIVE mode allows a specific flux density value to be

subtracted from all future readings. Thus all future readings will

be “relative” to that value. For instance if the relative value is

+100.0 gauss, and the present flux density is +112.0 gauss, the

actual displayed value will be +12.0 gauss. If the flux density

drops to +77.0 gauss, the actual displayed value will be -23.0.

Thus the RELATIVE mode allows for the direct readout of

variations around a given field, whether static (dc) or alternating

(ac).

There are two ways to generate a relative value. In the automatic

mode the meter uses the present flux density reading from the

probe as the relative value. In the manual mode, the user can

specify a value using the MANUAL control. Each mode will be

discussed in more detail.

There are three restrictions when using the RELATIVE mode:

1) The RELATIVE mode can only be used on a fixed range. If the

AUTO range feature is in use and then the RELATIVE mode is

turned on the AUTO range feature is canceled. Conversely, if the

RELATIVE mode is turned on and then the AUTO range feature

is turned on, the RELATIVE mode is canceled.

2) If the RELATIVE mode has been turned ON and the probe is

zeroed via the ZERO function, the RELATIVE mode is canceled.

3) The point at which the meter declares an OVERRANGE

condition changes when using the RELATIVE mode. Normally

3-25

Page 46

OPERATING INSTRUCTIONS

an overrange occurs when the reading reaches the full scale limit

of ± 2999 in the gauss or tesla mode (such as ± 299.9 G, ± 29.99

mT, etc.) or ± 2387 if in the ampere/meter mode (such as 23.87

kA/m). At that point the digits will remain at “2999” or “2387” and

will flash to indicate an overrange condition (see Figure 3.9).

In the RELATIVE mode this limit can be exceeded by about 35%

to a maximum value of ± 4095 as seen by the probe.

To clarify this, suppose the meter is set to the 300 mT range and

the probe is in a +350.0 mT field. Under normal conditions this

would have resulted in an overrange condition (a flashing reading

of +299.9 mT). Now the RELATIVE mode is turned on with an

initial relative value of 0. In this mode the meter is able to

measure flux density up to ± 409.5 mT. A non-flashing reading of

+350.0 mT will now appear on the display.

Now the probe is inserted into the zero flux chamber and a

relative value is set to +200.0 mT. The probe is now inserted

back into the original +350.0 mT field. The displayed value will

now be +150.0 mT (+350.0 - 200.0 = +150.0). The field then

increases to +420.0 mT. This is an overrange condition because

the limit of 409.5 mT (as seen by the probe) has been exceeded.

A flashing reading of +209.5 will appear on the display to indicate

an overrange condition (+409.5 - 200.0 = +209.5).

There may be situations when the user may prefer to shield the

probe from all external magnetic fields prior to performing a

RELATIVE operation. Provided with the meter is a ZERO FLUX

CHAMBER which is capable of shielding against fields as high as

30 mT (300 G or 23.88 kA/m). The probe is simply inserted into

the chamber before the RELATIVE operation begins.

3-26

Page 47

OPERATING INSTRUCTIONS

Handle the Hall probe with care. Do not bend the stem or

apply pressure to the probe tip as damage may result.

To activate or deactivate the RELATIVE mode rotate the function

selector to the RELATIVE position. The RELATIVE legend will

flash and actual flux density readings will appear on the display.

Press the SELECT pushbutton to turn the mode ON or OFF.

Then set the relative point using either the automatic or manual

mode.

NOTE: The RELATIVE mode is canceled if the probe and meter

are zeroed, if the probe is disconnected, if the meter’s range is

changed or if the meter is turned off and back on again.

NOTE: If the analog output is being used the output signal will

continue to represent the flux density as seen by the probe. It is

not affected by the RELATIVE operation.

3-27

Page 48

OPERATING INSTRUCTIONS

Figure 3-16

RELATIVE Function

AUTOMATIC RELATIVE MODE

In the automatic mode, the present flux density as seen by the

probe is used as the relative value. Prepare the probe and

select an appropriate range and mode (ac or dc) as needed

(AUTO range is deactivated when RELATIVE mode is used).

3-28

Page 49

OPERATING INSTRUCTIONS

Figure 3-17

Automatic RELATIVE Function

Press the AUTO pushbutton. The “AUTO” legend will flash for a

moment and a reading will be acquired. This now becomes the

new relative value. The meter will sound a single beep and the

“AUTO” legend will disappear. The reading should now be zero.

From this point the relative value will be subtracted from all future

readings. The “RELATIVE” legend will continue to flash to

remind the user that the RELATIVE mode is still active. At this

point, the automatic process can be repeated, or a manual

adjustment can be made (see “Manual Relative Mode”). When

returning to the MEASURE mode, the “RELATIVE” legend will

remain on to remind the user that the displayed value is a relative

value, not an absolute value.

3-29

Page 50

OPERATING INSTRUCTIONS

MANUAL RELATIVE MODE

The second method by which to set a relative value is a manual

adjustment. In some cases the user will wish to set an absolute

relative value. To do this, insert the probe in the ZERO FLUX

CHAMBER provided with the meter.

Handle the Hall probe with care. Do not bend the stem or

apply pressure to the probe tip as damage may result.

At this point the “RELATIVE” legend will be flashing and actual

flux density readings will be displayed. By turning the MANUAL

control in either direction the reading will be altered. Turning the

control clockwise adds to the reading, turning it counterclockwise

subtracts from the reading. Turning it slowly results in a fine

adjustment. Turning it quickly results in a coarse adjustment.

Once the desired relative value has been reached, the probe can

be removed from the ZERO FLUX CHAMBER and measurements can begin. The final relative value will be subtracted from

all future readings.

In other cases, the probe may be positioned in a stable dc or ac

magnetic field that does not exceed the present range limit (see

the prior discussion on overrange conditions in the RELATIVE

mode). In most cases the reading will be adjusted to zero so that

the value of the reference is subtracted from all future readings.

3-30

Page 51

OPERATING INSTRUCTIONS

Figure 3-18

Manual RELATIVE Function

ANALOG OUTPUT FUNCTION

The meter is capable of providing an analog voltage signal

proportional to the present flux density level. Calibration is set to

± 3.0 V full scale dc or 3.0 Vrms ac, depending upon the mode of

operation. This signal, available at the BNC connector, can be

connected to a voltmeter, oscilloscope, recorder or external

analog-to-digital converter.

Power consumption increases when using the analog output. For

this reason the analog output is set to zero volts upon power-up

and the analog function is turned OFF. To activate or deactivate

the output, rotate the function selector to the OUTPUT position,

then press the SELECT pushbutton to select the desired setting.

3-31

Page 52

OPERATING INSTRUCTIONS

There are two modes of operation that affect the upper frequency

limit of the output signal (see Figure 3-19). The LO setting has

an upper frequency limit of 1 kHz. When returning to the

MEASURE mode the user will be provided with both an analog

output signal and flux density readings on the display. The use

of the LO mode will reduce the rate at which the display is

updated with new readings.

The HI setting has an upper frequency limit of 20 kHz. When

returning to the MEASURE mode the user will be provided only

with an analog output signal. In this mode the only legends that

will appear will be “ANALOG ON” and “HI” (see Figure 3-20).

Figure 3-19

OUTPUT Function

3-32

Page 53

OPERATING INSTRUCTIONS

ANALOG OUTPUT USAGE

See the SPECIFICATIONS section for frequency range and

accuracy of the analog output.

The analog output signal is calibrated to ± 3 Vdc or 3 Vrms,

depending upon the selected mode. For instance on the 30 mT

range a reading of -12.3 mT relates to a output voltage of -1.23

Vdc whereas on the 3 T range a reading of -1.23 T produces the

same output. The analog output can reach a maximum output of

about ± 4.25 Vdc in order to accommodate the peak value of a

3 Vrms ac signal. This means that the analog output can be

used to measure flux density levels that exceed the normal range

of the displayed readings. For instance a level of 36.5 mT on the

30 mT range would normally result in a flashing “29.99” mT

overrange condition, but the output will still be +3.65 Vdc.

There are two modes of operation that affect the upper frequency

limit of the output signal. The LO setting provides the user with

flux density readings on the display or from the communications

port as well as an analog output signal from the output connector.

The use of the LO mode will reduce the rate at which the display

is updated with new readings. The LO setting is usable at

frequencies from 0 - 1 kHz.

In the HI setting the display is disabled, showing only the

“ANALOG ON” and “HI” legends (see Figure 3-20). Only an

analog output signal is available in this mode but the accuracy of

this signal is much better at higher frequencies.

3-33

Page 54

OPERATING INSTRUCTIONS

Figure 3-20

LO and HI Analog Output Displays

When using the AUTO range and the analog output features

together the following situation can occur. Suppose the present

range is 3 kG and the present reading is +2.8 kG. The analog

output will be +2.8 Vdc. The signal then increases to +3.2 kG,

which would force an automatic change to the 30 kG range

setting. The analog output will now be +0.32 Vdc because of the

range change. This can lead to problems if the analog signal is

being used to make decisions because there is no indication that

a range change has occurred. In these situations it is best to

select a fixed range that covers the expected flux density span.

The analog output will be set to 0 Vdc whenever the FUNCTION

selector is turned to the RANGE, HOLD, MODE, UNITS or

OUTPUT position.

The analog output signal contains both the dc and ac

components of the flux density signal. This means that it will also

contain any initial dc offsets in the probe and the meter’s circuitry.

These offsets can be removed by the ZERO function.

The ZERO function can also be used to introduce a dc offset if

desired. This is useful when observing ac waveforms in which

one portion of the waveform is being clipped because it exceeds

the ± 4.25 Vdc limit of the meter. Using the ZERO function the

3-34

Page 55

OPERATING INSTRUCTIONS

center of the waveform can be moved to reduce or eliminate the

clipping, as depicted in the next figure.

Figure 3-21

Adjusting the DC Offset of the Analog Output

SOURCES OF MEASUREMENT ERRORS

When making flux density measurements there are several

conditions that can introduce errors:

1) Operating the meter while the LOW BATTERY symbol

appears.

Instrument specifications are not guaranteed when a low

battery condition exists !

2) Failure to zero the error signals from the meter, probe and

nearby sources of magnetic interference.

3-35

Page 56

OPERATING INSTRUCTIONS

3) Subjecting the probe to physical abuse.

Handle the Hall probe with care. Do not bend the stem or

apply pressure to the probe tip as damage may result. Use

the protective cover when the probe is not in use.

4) One of the most common sources of error is the angular

position of the probe with respect to the field being measured.

As mentioned in Section-1, a Hall generator is not only sensitive

to the number of flux lines passing through it but also the angle at

which they pass through it. The Hall generator produces the

greatest signal when the flux lines are perpendicular to the

sensor as shown in Figure 3-22.

Figure 3-22

Probe Output versus Flux Angle

The probe is calibrated and specified with flux lines passing

perpendicularly through the Hall generator.

5) As shown in Figure 3-23 the greater the distance between the

magnetic source and the Hall probe the fewer flux lines will pass

through the probe, causing the probe’s output to decrease.

3-36

Page 57

OPERATING INSTRUCTIONS

Figure 3-23

Probe Output versus Distance

6) Flux density can vary considerably across the pole face of a

permanent magnet. This can be caused by internal physical

flaws such as hairline cracks or bubbles, or an inconsistent mix of

materials. Generally the sensitive area of a Hall generator is

much smaller than the surface area of the magnet, so the flux

density variations are very apparent. Figure 3-24 illustrates this

situation.

Figure 3-24

Flux Density Variations in a Magnet

3-37

Page 58

OPERATING INSTRUCTIONS

7) Using more than one extension cable can result in

measurement errors. In some cases the meter may report an

error. Total cable length between the meter and the probe

connector should not exceed 2.1 m (7 ft).

The use of more than one extension cable can result in

measurement errors and increase susceptibility to radio

frequency interference (RFI).

8) The accuracies of the meter and probe are effected by

temperature variations. Refer to the SPECIFICATIONS section

for specific information.

MORE DETAILS ON AC MODE OPERATION

It is possible for the flux density signal to contain both a dc

component and an ac component. In the ac mode the value

displayed is the true rms value of the waveform with its dc

component removed. However if the dc component is too high it

may force the peak value of the waveform to exceed the

electrical limits of the meter, causing the waveform to clip and

introducing errors in the final reading. This can also lead to an

overrange condition on the display and can lead to erratic

behavior if the AUTO range feature is being used. The presence

of a clipped ac signal can be verified by observing the analog

output signal.

The accuracy of the true rms reading applies to reading values

greater than 3.3% of full scale range. For example this would be

1mT on the 300 mT range. When the reading falls below 3.3% of

full scale the “AC” legend on the display will flash, as shown in

Figure 3-25. This is intended to remind the user that the reading

3-38

Page 59

OPERATING INSTRUCTIONS

may not be accurate. Select a lower range if possible to regain

accuracy.

Figure 3-25

Low AC Signal Indication

An ac reading, being a true rms value, has no polarity. However

when using the RELATIVE function in the ac mode readings can

be negative. A negative ac reading means that the present

reading is less than the RELATIVE value. An unsigned value

means the present reading is greater than or equal to the

RELATIVE value. For example if the original RELATIVE value

was 100 mT and the present field is 80 mT the result will be

-20 mT.

When using the MIN HOLD function without the RELATIVE

function turned on the minimum reading will be 0.0. With the

RELATIVE function turned on the minimum reading can reach the

negative full scale limit of the meter.

3-39

Page 60

OPERATING INSTRUCTIONS

MORE DETAILS ON DC MODE OPERATION

It is possible for the flux density signal to contain both a dc

component and an ac component. In the dc mode this can lead

to instable readings. If the peak value of the ac component

reaches the electrical limits of the meter, even though the

average dc level is within the limits, an overrange condition may

appear on the display. This situation can also lead to erratic

behavior if the AUTO range feature is being used.

The presence of an ac signal can be verified by observing the

analog output signal or by using the ac mode to determine the

magnitude of the ac component.

3-40

Page 61

Section 4

Remote Operation

RS-232 INTERFACE PARAMETERS

Prior to using the RS-232 serial port several parameters such as

baud rate and character length must be set on the computer or

PLC to match that of the meter. The meter’s parameters cannot

be changed. These are:

BAUD RATE: 2400

CHARACTER LENGTH: 8

PARITY: NONE

STOP BITS: 1

RS-232 INTERFACE CONNECTION

EMC APPLICATION NOTE:

Use only high quality, double shielded cables for RS-232

connection. Keep the length of the cables less than 3 meters.

Long cables (>3m) with insufficient EMI shielding can cause

excessive emissions or may be susceptible to external

interference.

The interface connector is a standard 9-pin “D” type connector

commonly used on personal computers. Five signals are

supported as shown in Figure 4-1. One of these is the common

(ground) connection. Pins-1,4,6 and 9 are not connected.

4-1

Page 62

REMOTE OPERATION

Figure 4-1

9-Pin Interface Connector

Data is transmitted to the meter on the receive (RX) line. Data is

transmitted from the meter on the transmit (TX) line. This is

known as a “full duplex” link.

In some RS-232 applications two lines called Clear-To-Send

(CTS) and Request-To-Send (RTS) are used to control the flow

of data between devices. This is often referred to as “hardware

handshaking”. However, although these signals are connected

electrically within the meter, the signals are not presently used.

The user’s computer or PLC should be configured to ignore

hardware handshaking lines.

In most cases a straight-through cable can be used between the

meter and a personal computer. In other words Pin-1 on the

meter would attach to Pin-1 on the computer, Pin-2 to Pin-2, etc.

Figure 4-2 depicts two possible connection schemes.

4-2

Page 63

REMOTE OPERATION

Figure 4-2

Serial Port Connection Schemes

Generally most communications problems are caused by

incorrect wiring or failure to match the characteristics (baud rate,

parity, etc.). Consult the documentation for the computer or PLC

to determine the signal assignments for its communication

connector. Again, the hardware handshake lines RTS and CTS

are not supported and should be ignored.

REMOTE COMMAND STANDARDS

Prior to 1987 most instruments that featured RS-232 communi-

cations interfaces had their own unique commands for

exchanging information. Eventually some manufacturers began

offering models that recognized other manufacturer’s commands

so that customers could easily switch over without making

extensive changes to their programs.

The IEEE-488-1987.2 standard (also called “IEEE-488.2”) was

one step toward creating a universal way to communicate with

any instrument, regardless of the manufacturer or the type of

instrument used. This was later enhanced by the SCPI-1991

4-3

Page 64

REMOTE OPERATION

standard (Software Commands for Programmable Instruments),

which defined specific commands and responses that covered a

broad range of applications. Though these standards were

targeted for use with the IEEE-488 instrumentation bus they are

commonly used with serial (RS-232) interfaces as well.

The Model HHG-23 supports many of the IEEE-488-1987.2

“common” commands as well as a subset of the SCPI-1991

commands.

COMMAND FORMAT

All commands consist of ASCII character strings. Some

commands contain numeric parameters that are used to set or

reset individual bits within binary registers. For instance a value

of 45 decimal is the same as binary 101101, thus setting bits 5, 3,

2 and 0 in the register and resetting all others. Sending the value

“00101101” would be interpreted as the number 101,101.

NOTE: No more than 500 characters can be sent in one

command string.

MESSAGE TERMINATORS

When transmitting a string to the instrument the message must

be “terminated” properly to notify the instrument that the message

is complete. This is done by appending an ASCII line feed (LF)

character as the final character in the string, which is a 0A hex or

00001010 binary. Note that 0A hex is equivalent to 10 decimal,

but sending the two ASCII characters “10” will not work. It must

be the single byte representation of the LF control character.

The meter will always send the LF character every time it

transmits a message to the host system.

4-4

Page 65

REMOTE OPERATION

ERROR BUFFER

Errors are generated by a variety of sources, such as hardware

errors or errors in the command syntax. If an error occurs a

message is stored in an ERROR BUFFER. The message can be

retrieved by a specific command discussed later in this section.

STATUS REGISTERS

There are four register sets that indicate the status of the

instrument, such as errors or the present state of the meter.

These are 8-bit registers, but in many cases not all of the bits are

used. The four register sets are called

MEASUREMENT EVENT

OPERATION EVENT

STANDARD EVENT

QUESTIONABLE EVENT

There is also an 8-bit register that provides a 1-bit summary for

each of the four register sets. This is called the STATUS BYTE.

Each register set consists of three individual registers, as

depicted in Figure 4-3.

1) The CONDITION register is a real time, read-only register that

is constantly updated to reflect current operating conditions.

2) The EVENT register is fed by the CONDITION register, but

operates as a latch. Whenever any bit in the CONDITION

register goes to “1”, a corresponding “1” is latched into the

EVENT register and remains that way until cleared by a specific

command.

4-5

Page 66

REMOTE OPERATION

3) The ENABLE register is a mask register that is used to

generate the single status bit for the STATUS BYTE. Setting any

bit in the ENABLE register to “1” will allow a corresponding “1” in

the EVENT register to set the summary bit in the STATUS BYTE.

Figure 4-3

Condition, Event and Enable registers

STATUS BYTE AND REQUEST FOR SERVICE (RQS)

A bit in the STATUS BYTE called RQS (request for service) sets

whenever an event occurs that requires the attention of the

computer. The RQS bit can set if any of the summary bits from

the MEASUREMENT EVENT, OPERATION EVENT, STANDARD

EVENT or QUESTIONABLE EVENT registers are set, or if an

error message exists. The STATUS ENABLE register is a mask

register that is used to allow any of these conditions to set the

RQS bit. Setting any bit in the STATUS ENABLE register to “1”

will allow a corresponding “1” in the STATUS BYTE register to set

the RQS bit. These registers are depicted in Figure 4-4.

4-6

Page 67

Status Byte and Enable registers

OSB -

Operation

Summary Bit:

ESB -

Event

Summary Bit:

QSB -

Questionable

REMOTE OPERATION

Figure 4-4

If any of the bits in the OPERATION

EVENT register set, and their respective

enable bits are set, the Operation

Summary Bit (OSB) will set.

If any of the bits in the STANDARD

EVENT register set, and their respective

enable bits are set, the Event Summary

Bit (ESB) will set.

If any of the bits in the QUESTIONABLE

EVENT register set, and their respective

4-7

Page 68

REMOTE OPERATION

Summary Bit: enable bits are set, the Questionable

Summary Bit (QSB) will set.

MSB -

Measurement

Summary Bit:

If any of the bits in the MEASUREMENT

EVENT register set, and their respective

enable bits are set, the Measurement

Summary Bit (MSB) will set.

EAV -

Error Available:

This bit sets any time there is an error

message available in the error buffer.

RSQ -

Request For

Service:

If any of the other bits in the STATUS

BYTE are set, and their respective

enable bits are set in the STATUS

ENABLE register, the Request For

Service (RQS) will set.

4-8

Page 69

REMOTE OPERATION

STANDARD EVENT REGISTER

If any of these bits set, and their respective enable bits are set,

the Event Summary Bit (ESB) will set in the STATUS BYTE.

Figure 4-5

Standard Event register

PON -

Power On:

Indicates that the meter was turned off

and on since the last communication.

CME -

Command Error:

Indicates that there was a syntax or

spelling error in the command, or the

command received is not supported.

EXE -

Execution Error:

Indicates that the meter detected an

error while attempting to execute a

command.

DDE -

Device Dependent

Error:

Indicates that the meter did not operate

properly due to some internal error.

OPC -

Operation Complete:

Indicates that all requested operations

have been completed.

4-9

Page 70

REMOTE OPERATION

MEASUREMENT EVENT REGISTER

If any of these bits set, and their respective enable bits are set,

the Measurement Summary Bit (MSB) will set in the STATUS

BYTE.

Figure 4-6

Measurement Event register

ROF -

Reading Overflow:

Indicates that the present reading

exceeds the present measurement

range.

RAV -

Reading Available:

Indicates a reading was acquired and

processed.

OPERATION EVENT REGISTER

If any of these bits set, and their respective enable bits are set,

the Operation Summary Bit (OSB) will set in the STATUS BYTE.

MEAS -

Measure mode:

4-10

Figure 4-7

Operation Event register

Indicates the meter is in the process of

acquiring and processing a reading.

Page 71

REMOTE OPERATION

QUESTIONABLE EVENT REGISTER

If any of these bits set, and their respective enable bits are set,

the Questionable Summary Bit (QSB) will set in the STATUS

BYTE.

Figure 4-8

Questionable Event register

CAL -

Calibration summary:

Indicates that an invalid calibration

constant was detected during power up

or when the probe was installed. The

instrument will instead use a default

parameter. This bit will clear once the

meter and probe have been successfully

calibrated.

NOTE: Meter specifications are not

guaranteed when the CAL bit is set!

“COMMON” COMMAND SYNTAX

The “common” commands are recognized and acted upon in a

similar manner by all instruments that follow the IEEE-488.2

standard, whether a DVM, scope, frequency meter, gaussmeter,

etc. These are the syntax rules:

1) A common command always begins with an asterisk character

(*) followed by a three or four character acronym and possibly

one other parameter. For instance the command to clear the

event registers is *CLS.

4-11

Page 72

REMOTE OPERATION

2) The commands are not case sensitive. For instance the *CLS,

*cls and *cLS commands are identical.

3) If there is a fourth character in the acronym it will always be a

question mark (?) and indicates that information is being

requested from the instrument. For instance a command to read

the model number and manufacturer of the instrument is *IDN?

4) If a parameter follows a command it must be separated from

the acronym by one space. The parameter is the ASCII

representation of an integer. For instance if the parameter to be

sent is binary 1100, the actual parameter sent would be the two

ASCII characters 12, since binary 1100 = decimal 12. If you were

to send the four ASCII characters 1100 it would be interpreted as

decimal 1100 (eleven hundred).

5) A number returned from the instrument is an ASCII

representation of a number. For instance if the instrument

returns the ASCII string 345 the number is decimal 345 (three

hundred forty five), which translates to 159 hex.

6) Multiple commands can be sent in one string. The commands

must be separated by semicolons (;). For instance, *CLS;*IDN?

first clears the event registers and then requests model and

manufacturer information. If more than one of the commands in

the string requests information from the instrument, the

instrument’s response will also have semicolons separating the

responses, such as 345;0;10.

4-12

Page 73

REMOTE OPERATION

“COMMON” COMMANDS

ACRONYM NAME BRIEF DESCRIPTION

*CLS Clear status Clear all event registers

and error buffer.

*ESE <NRf> Program event

enable

Program standard event

enable register.

*ESE? Event enable query Read standard event

enable register.

*ESR? Event status query Read standard event

register and clear it.

*IDN? Identification query Return manufacturer,

model number, software

version number.

*OPC Set operation

complete

Set the Operation

Complete bit in the

standard event register

after all commands have

been executed.

*OPC? Operation complete

query

Returns an ASCII “1” after

all commands have been

executed.

*OPT? Option identification

query

*SRE <NRf> Program Status

enable

Returns information about

the attached Hall probe.

Program STATUS enable

register.

*SRE? Status enable query Read STATUS enable

register.

*STB? Status byte query Read status byte register.

Table 4-1

Common command summary

4-13

Page 74

REMOTE OPERATION

*CLS -

CLEAR STATUS

*ESE <NRf> PROGRAM

STANDARD EVENT

ENABLE

REGISTER

*ESE? STANDARD EVENT

ENABLE

REGISTER QUERY

*ESR? STANDARD EVENT

REGISTER QUERY

*IDN? IDENTIFICATION

QUERY

*OPC - SET

OPERATION

COMPLETE

Clears the MEASUREMENT EVENT,

OPERATION EVENT, STANDARD

EVENT and QUESTIONABLE EVENT

registers, but not their enable registers. It

also clears the error buffer.

A set bit in the STANDARD EVENT

ENABLE register allows its corresponding

event to set the ESB (event summary bit)

in the STATUS BYTE register. <NRf> is

an ASCII string representing an integer

mask. For instance a value of 45 decimal

is the same as binary 00101101, thus

setting bits 5, 3, 2 and 0 in the enable

register.

Returns the contents of the STANDARD

EVENT ENABLE register.

Returns the contents of the STANDARD

EVENT register.

NOTE: The STANDARD EVENT register

is cleared after an *ESR? command.

Returns the following string: Omega,

MODEL HHG-23,Rx.x. The Rx.x string is

the firmware revision level, where x.x is a

decimal number, such as 1.1.