Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

Made in Taiwan

User’s Guide

DATALOGGER 4 INPUT

THERMOMETER

HH1384

INSTRUCTION MANUAL

MAX MIN

ALA RM

-

INTV

m:s

d-h

FUL L

NO.

T 4

T 3

T 2T 1

Page 2

1. INTRODUCTION: FEATURES

This instrument is a digital 4 input thermometer and data logger

that works with any K, J, E, T, R, S, N, L, U, B and C-type

thermocouple temperature sensor.

Temperature indication follows the international temperature

scale of 1990 (ITS-90).

Read the following safety information carefully before

attempting to operate the meter.

Use the meter only as specified in this manual; otherwise, the

protection provided by the meter may be impaired.

Environment conditions

Altitude up to 2000 meters

Relatively humidity 80% max.

Operation Ambient 0~50°C(32°F ~122°F)

Features

Isolated Input Protection of 350Vp-p between any two inputs.

Highly accurate thermometer with thermocouple K, J, E, T, R,

S, N, L, U, B, C types.

4 input function T1/T2/T3/T4 temperature display.

Programmable Hi – Lo alarm for 4 inputs.

Display of MAX, MIN and MAX–MIN values of 4 inputs.

Independent Input Setup (type of thermocouple,

Hi – Lo alarm values).

Memory and Read function (99 sets)

512KB auto datalogging capacity.

USB interface.

Safety symbols

Comply with EMC

~ 1 ~

Page 3

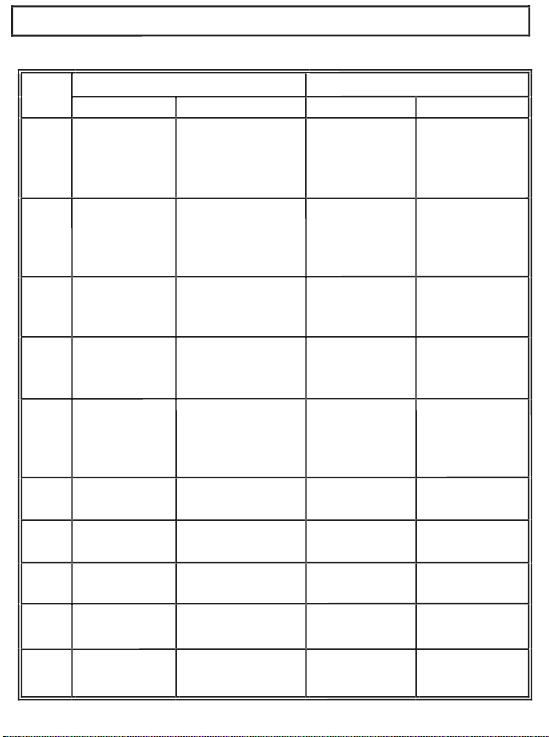

2. SPECIFICATIONS

2-1 Electronical Specifications

°C °F

Type

Range Accuracy Range Accuracy

K

-200 ~ -150

-150 ~ -100

-100 ~ 999.9

1000 ~ 1370

±3.0°C

±2.0°C

±0.05% ±1.0°C

±0.2% ±1.0°C

-328 ~ -238

-238 ~ -148

-148 ~ 999.9

1000 ~ 2498

±5.4°F

±3.6°F

±0.05% ±1.8°F

±0.2% ±1.8°F

J

-200 ~ -100

-100 ~ 100

100 ~ 999.9

±2.5°C

±1.5°C

±0.05% ±1.0°C

-328 ~ -148

-148 ~ 212

212 ~ 999.9

1000 ~ 1832

±4.5°F

±2.7°F

±0.05% ±1.8°F

±0.2% ±1°F

E

-150 ~ -100

-100 ~ 760

±3.0°C

±0.05% ±1.0°C

-238 ~ -148

-148 ~ 999.9

1000 ~ 1400

±5.4°F

±0.05% ±1.8°F

±0.2% ±1°F

T

-200 ~ -150

-150 ~ -100

-100 ~ 400

±3.0°C

±0.15% ±2.5°C

±0.1% ±1.0°C

-328 ~ -238

-238 ~ -148

-148 ~ 752

±5.4°F

±0.15% ±4.5°F

±0.1% ±1.8°F

R/S

0 ~ 100

100 ~ 300

300 ~ 999.9

1000 ~ 1600

±5.0°C

±3.0°C

±0.05% ±2.0°C

±0.25% ±2.0°C

32 ~ 212

212 ~ 572

572 ~ 999.9

1000 ~ 2912

±9.0°F

±5.4°F

±0.05% ±3.6°F

±0.25% ±3.6°F

N

0 ~ 999.9

1000 ~ 1300

±0.1% ±1.0°C

±0.2% ±1.0°C

32 ~ 999.9

1000 ~ 2372

±0.1% ±1.8°F

±0.2% ±1.8°F

L

-200 ~ 900 ±0.1% ±1.0°C

-328 ~ 999.9

1000 ~ 1652

±0.1 % ±1.8°F

±0.2% ±1°F

U

0 ~ 600 ±0.1% ±1.0°C

32 ~ 999.9

1000 ~ 1112

±0.1% ±1.8°F

±0.2% ±1°F

B

600 ~ 999.9

1000 ~ 1760

±0.05% ±2.0°C

±0.1% ±2.0°C

1112 ~ 1831

1832 ~ 3200

±0.05% ±3.6°F

±0.1% ±3.6°F

C

0 ~ 999.9

1000 ~ 1760

±0.1% ±1.5°C

±0.2% ±1.5°C

32 ~ 999.9

1000 ~ 3200

±0.1% ±2.7°F

±0.2% ±2.7°F

~ 2 ~

Page 4

This basic accuracy specification does not include the error of

the temperature probe. Please refer to the temperature probe

accuracy specification for additional details.

Temperature Coefficient:

0.01% of reading +0.1°C per °C (0.2°F per °F)

outside the specified +18°C to 28°C (+64°F to 82°F) range.

Isolated Input Protection between any Two Inputs : 350Vp-p

Manual Data Memory Capacity: 99 sets.

Continuity Data Logging Capacity: 36,000 sets.

NOTE

2-2 General Specifications

Power Supply: 6 pcs size AA battery or DC 9V AC adaptor.

Battery Life: approx. 55 hours (Alkaline battery)

Auto Power Off: 5, 15 or 30 minutes (If no key is pressed).

Low Battery Indicator: The (

battery voltage drops below the operating voltage.

Measurement Rate : One time per 2 seconds.

Weight : 405g / 14.3oz (batteries included)

Dimension : 18.7(L) × 7.3(W) × 5.3(T) cm

7.3”(L) × 2.9”(W) × 2.1”(T)

Operating Temperature: 0 to 50℃ (32 to 122℉)

and Humidity: Below 80% RH.

Storage Temperature: -10 to 60℃, 14 to 140℉

and Humidity: Below 70% RH.

Accessories: Instruction manual, alkaline batteries, USB cable,

software CD, carrying case and K-type

thermocouples (1 per channel).

) is displayed when the

~ 3 ~

Page 5

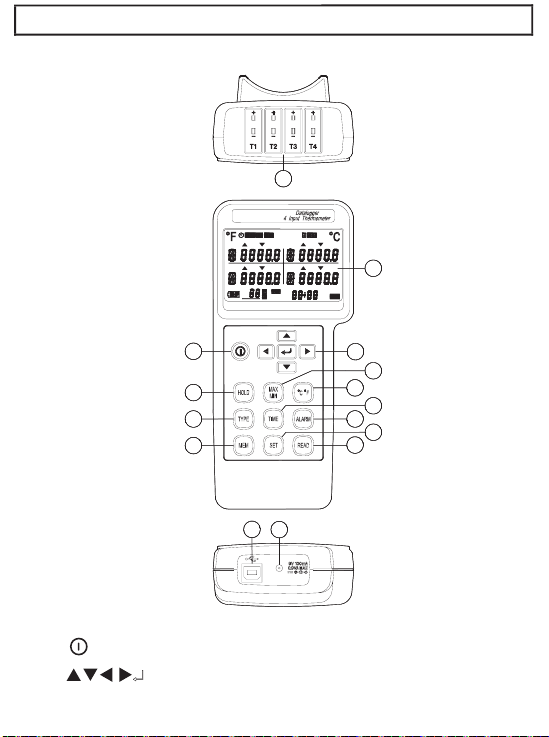

3. PARTS & CONTROLS

3-1 Description of Parts & Control keys

13

-

MAX MIN

T 2

ALARM

T 1

T 4

T 3

INTV

d-h

NO.

m:s

FULL

1

(1). LCD Display

(2).

(3).

Key : Power on – off control key.

Keys

(4). HOLD Key:

2

4

7

10

14

15

: Setting keys.

~ 4 ~

3

5

6

8

9

11

12

Page 6

Data hold function key, press “HOLD” key to hold data, the

“ H ” symbol is displayed, press this key again to exit this

function.

Press and hold down “HOLD” key then press " " key to

turn on the meter, the “

” symbol disappear, exit auto

power off function.

(5). MAX MIN Key: Press “MAX MIN” key to circulate the

reading of Maximum, Minimum, Maximum minus

Minimum, and Current. Press this key for 2 seconds to

exit this mode.

(6). °C / °F Key: Press “°C / °F” key to switch the units

between Celsius (°C) and Fahrenheit (°F).

(7). TYPE Key: Press "TYPE" key to enter the thermocouple

type select mode, press this key again to exit this mode.

(8). TIME Key: Press “TIME” key to circulate display data and

time.

(9). ALARM Key: Press “ALARM” key to enable or disable

Alarm function.

(10). MEM Key: Manual data memory control key.

(11). SET Key: Press “SET” key to

start or exit setup.

(12). READ Key: Manual memory data reading control key.

(13). T1, T2, T3, T4 : Thermocouple T1, T2, T3 and T4 inputs.

(14). USB Interface Jack.

(15). AC Adaptor Input Jack.

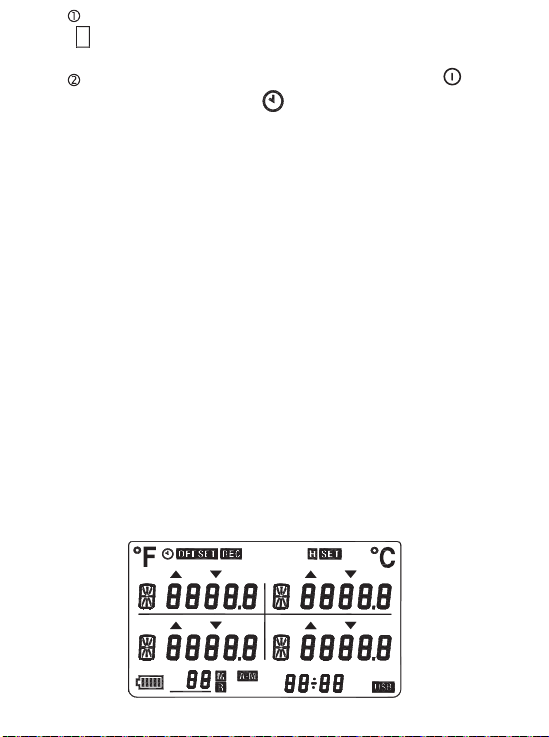

3-2 Description of Display

-

MAX MIN

ALAR M

T 2T 1

T 3

NO.

FULL

T 4

d-h

m:s

INTV

~ 5 ~

Page 7

°F, °C : Temperature units.

: Auto power off indication.

OFFSET : The thermocouple measurement includes an offset

indication.

REC : MAX MIN Recording mode and current reading indication.

REC MAX : Maximum reading indication.

REC MIN : Minimum reading indication.

REC MAX-MIN : Maximum minus Minimum value indication.

H : Data hold function indication.

SET : Setting mode indication.

: Thermocouple type indication.

ALARM : Alarm mode indication.

ALARM

: Input temperature exceeds the high limit value

indication.

ALARM : Input temperature is below the low limit value

indication.

T1, T2, T3, T4 : Thermocouple T1, T2, T3, T4 input temperature

measurement display.

: Battery capacity indication.

: Replace batteries indication.

NO.

: Last manual data memory address number indication (01–99).

M : Manual data memory indication, M displays one time store one

sets data into the memory.

NO.

R : Manual data memory read address number indication,

the memory data displayed for read.

A-M : Auto data logging indication, A-M will disappear after storing

the data.

INTV : Auto data log interval time setting indication.

~ 6 ~

Page 8

Full : Auto data logged memory full indication, if exceeds 255

memory blocks, total maximum record capacity size is

36,000 sets of data for 4 input thermocouple temperature

measurement (100,000 sets data for 1 input record).

m:s

: Time display indication.

4. OPERATION INSTRUCTION

WARNING

Before using the meter inspect the case. Do not use the

meter if it appears damaged. Look for cracks or missing

plastic. Pay particular attention to the insulation around the

connectors.

Disconnect thermocouples from the meter before opening the

case.

Replace the batteries as soon as the battery indicator “

appears. The possibility of false reading can lead to personal

injury.

Do not use the meter if it operates abnormally. Protection

may be impaired.

Do not operate the meter around explosive gas, vapor or dust.

Do not use the meter with any part of the case or cover

removed.

4-1 Setting the meter

1. Real – Time setting:

(a). Press "

(b). Press “SET” key to enter the setting mode, the “Set clock”

and “ SET ” symbols are displayed.

(c). Press "

flicking numbers of year.

(d). Press

" key to turn on the meter.

" key to enter real time setting mode and the two

key to set the year (real time).

or

~ 7 ~

”

Page 9

(e). Press "

(f). Press

(g). Press "

(h). Press

(i). Press "

(j). Press

(k). Press "

(l). Press

(m). Press "

(n). Press

(o). Press "

(r). Press “SET” key to exit this mode.

minutes.

" key and move to the two flicking digits of month.

or

key to set month (real time).

" key and move to the two flicking digits of day.

or

key to set day (real time).

" key and move to the two flicking digits of hour.

or

key to set hour (real time).

" key and move to the two flicking digits of

or

key to set minutes (real time).

" key and move to the two flicking digits of second.

or

key to set seconds (real time).

" key to store real time values.

2. Interval – Time setting :

The logging interval time determines how often the meter stores

logged readings in memory.

(a). Press "

(b). Press “SET” key to enter the setting mode, then press

(c). Press "

three flicking numbers of second.

(d). Press

(1 to 255 seconds).

(e). Press "

(f). Press “SET” key to exit this mode.

" key to turn on the meter.

key until the display shows “Set Intr”.

" key to enter the interval time setting mode and the

or

key to set the desired second of interval time

" key to store the auto datalogging interval time.

3. Offset setting :

You can adjust the meter readings to compensate for the errors

of a specific thermocouple. The allowable adjustment range is

from +12.7 to -12.8 degree, regardless of the temperature units.

You can store individual offsets for T1, T2, T3 and T4.

(a). Press "

(b). Press “SET” key to enter the setting mode, then press

" key to turn on the meter.

key until the display shows “SEt OFSEt”.

or

or

~ 8 ~

Page 10

(c). Press "

(d). Press

(e). Press

(f).. Press "

(g). Press “SET” key to exit this mode.

The temperature measurement plus the offset appears in the

display. Remember to set the offset to 0.0 when it is no longer

needed. The “ OFFSET ” symbol will disappear when the offset

values all are 0.0.

" key to enter the offset setting mode, the

“ OFFSET ” symbol is displayed.

or

key to select the desired T1, T2, T3 or T4.

or

key to set the desired offset values.

" key to store the offset value.

4. Auto Power Off Time setting :

(a). Press "

(b). Press “SET” key to enter the setting mode, then press

(c). Press "

the “SLEEP” symbol is displayed.

(d). Press

time. The choices are: 5, 15 and 30 minutes.

(e). Press "

(f). Press “SET” key to exit this mode.

" key to turn on the meter.

key until the display shows “SEt SLEEP”.

" key to enter the auto power off time setting mode,

or

key to choose the desired auto power off

" key to store the choice.

5. Alarm High / Low Limit setting :

(a). Press "

(b). Press “SET” key to enter the setting mode, then press

(c). Press "

setting mode, the “ ALARM ” symbol is displayed.

(d). Press

(e). Press "

symbol is displayed.

(f). Press

the resolution of setting value is 0.1 degree, regardless of

the temperature units.

" key to turn on the meter.

key until the display shows “SEt ALArn”.

" key to enter the alarm high limit and low limit

or

key to select the desired T1, T2, T3 or T4.

" key to enter the high limit value setting, the “

or

key to set the desired alarm high limit value,

-9-

or

or

”

Page 11

(g). Press "

(h). Press

(i). Press "

(j). Press “SET” key to exit this mode.

(k). Press “ALARM” key to enter the alarm function, the

(l). Press “ALARM” key again to exit the alarm function.

the alarm low limit value setting, the symbol “

resolution of setting value is 0.1 degree, regardless of the

temperature units.

individual alarm High / Low limit values for T1, T2, T3 and T4,

by repeating (c) to (i) procedure.

“ALARM” symbol is displayed. When the measured

temperature value exceeds the setting High temperature

value (the “

setting Low temperature value (the “

display.) the beep will sound one time per 4 seconds.

" key to store the alarm high limit value and to enter

” is displayed.

or

key to set the desired alarm low limit value, the

" key to store alarm low limit value. You can store

” symbol will flicker the display) or below the

” symbol will flicking

4-2 Setting the Thermocouple Type

1. Press "

2. Press “TYPE” key to enter the thermocouple type choices.

The currently selected thermocouple type blinks.

3. Press

4. Press

appears on the display.

5. Press "

store individual thermocouple types for T1, T2, T3 and T4, by

repeated (3) to (5) procedure.

6. Press “TYPE” key again to exit this choices.

" key to turn on the meter.

or

key to select the desired T1, T2, T3 or T4.

or

key until the thermocouple type you want

" key to store the thermocouple type. You can

4-3 Temperature Measurement

1. Press "

2. Plug the thermocouple (s) into the thermocouple input. If no

thermocouple is plugged into the selected input or the

thermocouple is "open", the display will show "- - -".

" key to turn on the thermometer.

~ 10 ~

Page 12

3. Press "°C / °F" key to desired temperature scale.

4. Perform measurements by contacting the object being

measured with the probe sensor.

5. Read the temperature on the display. The display shows

“OL” (overload) or “Un” (under ranges) when the

temperature being measured is outside the meter valid

range.

4-4 Maximum (MAX), Minimum (MIN) Recording

Measurement

1. Press “MAX MIN” key to enter the recording mode, the “ REC ”

symbol is displayed.

2. Press “MAX MIN” key to circulate the display of the maximum

(REC MAX), minimum (REC MIN), maximum minus minimum

(REC MAX-MIN) and current REC) reading.

3. Press “HOLD” key to paused recording, the “H” symbol is

displayed, press “HOLD” key again will resume recording.

4. Press “MAX MIN” key for 2 seconds to exit this mode.

4-5 Manual Data Memory and Read Function Operation

1. Clear the manual memorized data

(a). Press "

(b). Press and hold down “MEM” key, then press "

turn on the meter, the “CLr YES no M” symbol is displayed.

(c). Press or

flicking.

(d). Press "

(e). Press "

2. Store manual data to memory

(a). Pressing “MEM” key one time will store one set of

measured data to memory. The “M” symbol will disappear

and the stored memory address will displayed.

(b). Maximum store memory capacity size is 99 sets.

" key to turn off the meter.

" key again to

key to select “YES” symbol is displayed

" key to clear the manual memorized data.

" key again to exit this mode.

~ 11 ~

Page 13

3. Read the manual store data

(a). Press “READ” key to enter the read mode, the “R” symbol

is displayed.

(b). Press

memories data address will be displayed.

(c). Press “READ” key again to exit this mode.

or

key to read the memories data, the

4-6 Auto Datalogging Function Operation

1. Clear the Auto datalogged data :

Before entering into the clear memory data mode, users must

down load the previous memory data to PC.

(a). Press "

(b). Press and hold down “

to turn on the meter, the “

displayed.

(c). Press "

mode, the “CLr YES no AM” symbol is displayed.

(d). Press

flickering

(e). Press "

this mode.

" key to turn off the meter.

MEM

” key, then press "

CLr YES no M

" key to enter the clear auto datalogged data

or

key to select “YES” symbol is displayed

" key to clear the auto datalogged data and exit

" key again

” symbol is

2. Store Auto datalogging data to memory :

(a). Press “MEM” key for 3 seconds to start auto datalogging,

the “A-M” symbol is displayed, the “A-M” symbol

according to the interval time will disappear after storing

one set of data into the memory.

(b). Press “MEM” key for 3 seconds to stop data record, the

current block number will be displayed for one second.

Press “MEM” key for 3 seconds will resume data record,

but maximum is divided to 255 memory blocks. Total

maximum record capacity size is 36,000 sets data for 4

-12-

Page 14

(b). input thermocouple temperature measurement (100,000

sets data for 1 input record).

(c). When maximum block or maximum capacity is full, the

“FULL” symbol will be displayed, the data record is auto

stopped.

3. Download data to PC :

Please refer to the software manual (CD-ROM) to download

the data.

4-7 Disable Auto Power off Function

The meter will automatically enter sleep mode approx. 5, 15 or

30 minutes decided by user setting to save power

consumption.

1. Disable auto power off procedure :

(a). Press "

(b). Press and hold down "HOLD" key then press "

turn on the meter, the auto power off function will be

disabled, and the auto power off symbol “

disappear.

2. Auto power off mode is enabled each time you turn on the

meter and is automatically disabled bt the follow modes :

(a). MAX MIN record mode.

(b). Auto datalogging function is active.

(c). PC linked.

" key to turn off the meter.

" key to

” will

5. MAINTENANCE

5-1 General Maintenance

1. Clean the meter and accessories with a damp cloth and a mild

soap. Do not use abrasives, solvent or alcohol.

~ 13 ~

Page 15

5-2 Battery Replacement :

To AVOID electrical shock, remove any inputs before

replacing the batteries.

1. When operating the meter on batteries, periodically check the

battery symbol to determine the remaining battery capacity.

The number of black segments decreases as the batteries are

used up. When the “

correct measurement is no longer possible. Replace the

batteries with a fresh set.

2. Take care not to reverse the (+) and (-) polarity when inserting

the batteries. Always replace all six batteries together. Do

not mix old and new batteries or batteries of different type.

Remove the batteries from the meter, if the meter is not to be

used for a month or longer.

WARNING

” symbol display starts to flash,

6. USB INTERFACE, SOFTWARE INSTALLATION AND

OPERATION

For the detailed instruction, please refer to the content of

attached CD-ROM, which has the complete instruction of

software operation and relevant information.

Protocol : are enclosed within the content of CD-ROM,

※ All rights reserved.

※ Do not reproduce without authorization.

please open the CD-ROM for details.

Page 16

Servicing North America:

U.S.A.:

Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada:

976 Bergar

Laval (Quebec), Canada H7L 5A1

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada:

Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico:

En Español: 001 (203) 359-7803 FAX: (001) 203-359-7807

info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux:

Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omega.nl

Czech Republic:

Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France:

Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria:

Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0 800 6397678 TEL: +49 (0) 7059 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom:

OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD England

Toll-Free: 0800-488-488 TEL: +44 (0)161 777-6611

FAX: +44 (0)161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the pol icy of OMEGA Enginee ring, Inc. to comply with all worldwide safety and EMC/EMI

regulations t hat apply. OMEGA is constantly pursuing certification of its products to the Eur opean New

Approach Dire ctives. OMEGA will a dd the CE mark to ev ery appropriate devi ce upon certificatio n.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not des igned for use in, and should not be used for, human applications.

Page 17

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds

an additional one (1) month grace period to the normal one (1) year product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use

of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by the company will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence , indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1)

as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or

activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or

with any nuclear

installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from

any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN A N

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of theproduct, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2009 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, o r reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 18

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

SM

TEMPERATURE

Thermocouple, RTD & Thermistor Pro bes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Therm istor

Calibrators & Ice Point Referen ces

Recorders, Controllers & Pro cess Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simul ators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Softwa re

Communications-Based Acquisitio n Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotte rs

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentat ion

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Inst ruments

M4945/0810

Loading...

Loading...