Page 1

GEARBOXES

WORM GEAR

SPEED REDUCERS

HDR Series

Starts at

$

116

l 8 Ratios Available from

5:1 to 60:1

l 7 Gear Box Sizes from

1.33 to 3.25"

l Universally Interchangeable

Design for OEM Replacement

l Double Bearings Used on Both

Shaft Ends

l Anti-Rust Primer Applied Inside

and Outside Gearbox

l Shaft Sleeve Protects All Shafts

l S45C Carbon Steel Shafts

HDRF133-20/1-R-56C right hand flange mount gearbox

with box size 133, mounts directly to 56C-frame

motors, $135, shown smaller than actual size.

Applications

l Food Processing

l Warehouse Material Handling

l Conveyors (Belt, Direct-Drive,

Inclined, etc.)

l Packaging Machinery (Shrink

Wrappers, Stretch Wrappers,

Case Sealers, etc.)

l Special Machinery

The HDR Series worm gear reducers are

used in low to moderate horsepower

applications to reduce speeds and increase

torque. Worm gear reducers are available in

direct or indirect drive, direct drive models

are 56C flange mount with either right, left

or dual output shafts or a hollow bore

output. The indirect drive models are shaft

input-shaft output boxes for use with

sprocket or pulley drive systems. They

provide an effective low cost solution to

speed reduction and increased torque, with

higher tolerances for shock loading than

helical gear reducers.

Flange input, shaft

output, left hand output.

Flange input, shaft

output, double end output.

Shaft input, shaft

output, right hand output.

D-1

Flange input, shaft

output, right hand output.

Flange input, hollow bore output.

Shaft input, shaft

output, left hand output.

Page 2

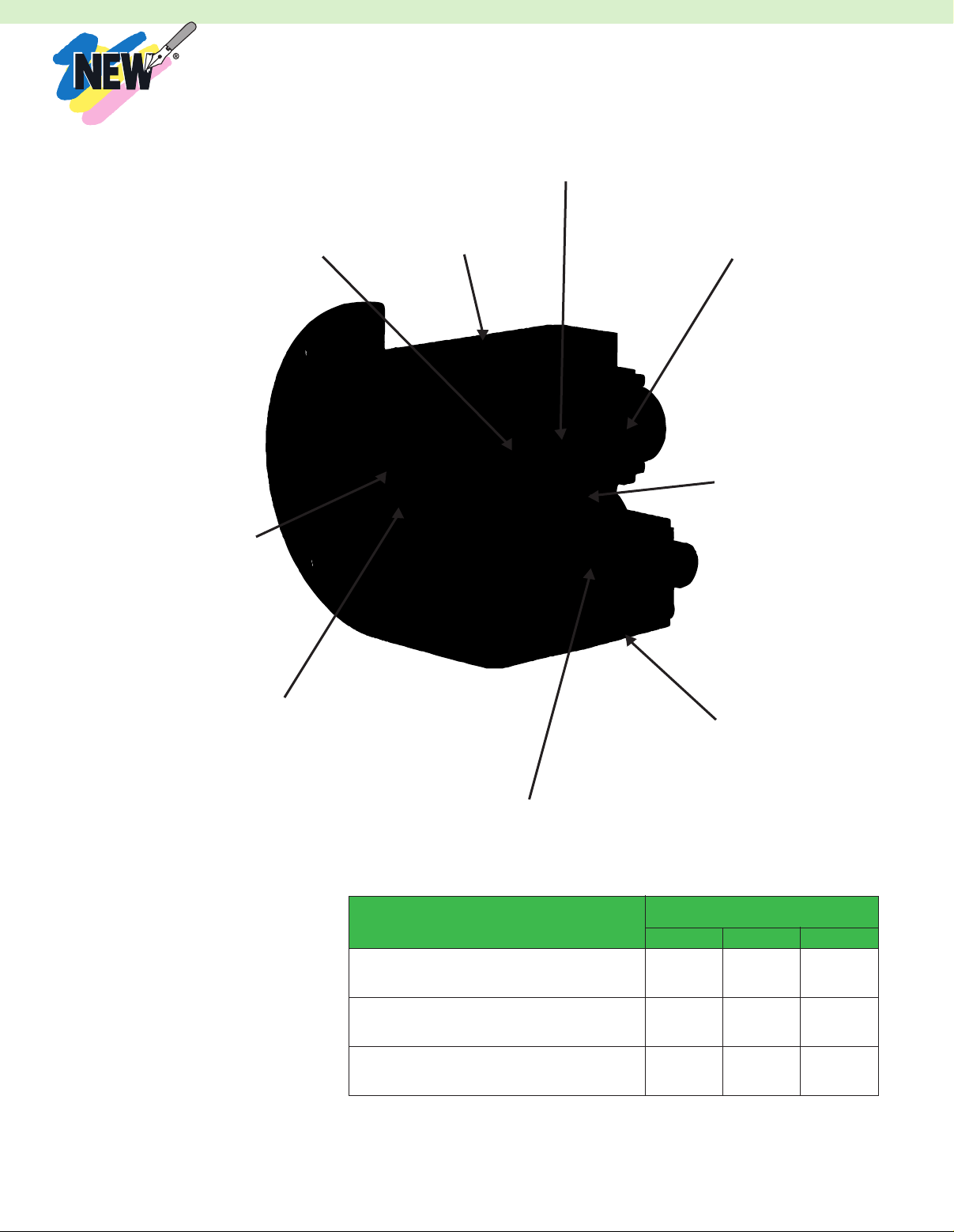

All units filled with

mobile # SHC634

synthetic oil.

Main gear is Albc3 which is

aluminum–bronze and much

harder than the normally

used phosphor–bronze.

Interior channel guides

oil to directly and

constantly lube bearings.

One piece # Fc20 all

cast iron housing.

Embedded oil seals

(double lip) prevent

leakage on both ends.

Two tapered

roller bearings

on both shaft ends.

Universally interchangeable

compact design assures you

better OEM replacement

(more compatibility).

In order to select a gearbox speed reducer,

you will need to determine the required

torque and service factor for the application.

The table to the right will assist in

determining the service factor. For service

factors above 1.0, multiply the required

torque by the service factor.

Example: Review the mechanical ratings

table (next page): A torque requirement of

675 in. lbs. and a ratio of 20:1 (88 RPM),

you would choose a box size 175 and it

would require a 1.26 input HP, or a 1.5 HP

Special black

paint (natural dry).

Shaft sleeves

protect all shafts.

RECOMMENDED SERVICE FACTOR (S.F.)

AVERAGE OPERATING

HOURS PER DAY

LOAD CHARACTERISTICS Up to 8 8 to 16 16 to 24

- Uniform load and continuous operation

- No reversal

- Light Inertia load

- Medium shock, intermittent operation

- Frequent start and frequent reversal

- Medium inertia load

- Heavy shock, intermittent operation

- Frequent start and frequent reversal

- Heavy inertia load

motor. However, if the service factor is

determined to be 1.4, then your required

torque would be 1.4 x 675, or 945 lbs in. In

D-2

this case you would select a box size

237 rated at 1195 in. lbs and require an

input HP of 2.06, or a 2 HP motor.

1.0 1.1 1.2

1.3 1.4 1.5

1.7 1.9 2.0

Page 3

Input Speed 1750 RPM

Box

*

Size Ratio

1.0 Service Factor 1.2 Service Factor

(%)

Over

Hung

Load

(lbs.)

Output

Shaft

Thrust

Load

(lbs.)

Backlash

(Angular

Minutes)

(ft.)

Input

HP

Output

To

rque

(lbs. in.)

OutputHPInput

HP

Output

Torque

(lbs. in.)

Output

HP

133

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

1.15

0.77

0.63

0.5

0.47

0.38

0.29

0.23

209

247

283

276

336

356

312

219

1.05

0.66

0.5

0.39

0.31

0.25

0.17

0.12

1.21

0.75

0.53

0.48

0.31

0.30

0.26

0.22

221

240

238

266

221

282

282

213

1.11

0.64

0.42

0.38

0.20

0.19

0.16

0.12

91

86

80

78

66

65

59

53

300 300 27

154

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

2.04

1.03

0.78

0.65

0.48

0.4

0.34

0.29

341

327

363

384

388

397

407

373

1.88

0.9

0.67

0.53

0.36

0.27

0.22

0.17

2.06

1.29

1.11

0.86

0.62

0.51

0.47

0.39

345

411

518

509

504

503

565

502

1.90

1.13

0.95

0.70

0.46

0.35

0.31

0.23

92

88

86

81

74

68

66

59

450 400 23

175

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

2.83

1.57

1.24

1.26

0.89

0.79

0.5

0.38

499

515

554

737

666

714

538

433

2.62

1.38

1.06

1.04

0.61

0.49

0.3

0.2

2.28

1.36

1.13

0.98

0.54

0.45

0.41

0.35

402

445

506

572

405

404

446

404

2.11

1.19

0.96

0.81

0.37

0.28

0.25

0.19

93

88

85

83

69

62

59

52

650 550 20

206

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

3.62

2.77

2.09

1.57

1.65

1.09

0.74

0.6

925

935

1002

914

1310

112 0

830

750

3.33

2.5

1.78

1.29

1.21

0.77

0.46

0.35

2.57

2.10

1.40

1.17

0.76

0.71

0.54

0.48

657

708

673

681

606

726

606

606

2.36

1.89

1.20

0.96

0.56

0.50

0.33

0.28

92

90

85

82

73

71

62

58

700 750 17

237

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

4.32

3.47

2.64

2.06

1.82

1.45

1.32

0.86

766

115 8

1249

119 5

1507

1483

1527

114 9

4.02

3.09

2.22

1.69

1.39

1.02

0.84

0.53

3.56

2.24

1.55

1.36

1.02

0.83

0.67

0.63

630

746

732

791

847

845

779

844

3.31

1.99

1.30

1.12

0.78

0.58

0.43

0.39

93

89

84

82

76

71

64

61

900 900 17

262

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

5.24

4.17

3.22

2.67

2.22

1.85

1.37

1.16

924

1445

1577

1563

1827

1919

1658

1670

4.86

3.74

2.81

2.21

1.68

1.32

0.92

0.77

4.32

3.06

2.47

1.84

1.30

1.11

0.95

0.94

761

1061

1212

1078

1072

1153

1152

1346

4.00

2.75

2.16

1.53

0.99

0.80

0.64

0.62

93

90

87

83

76

72

67

66

1000 1000 17

325

5:1

10:1

15:1

20:1

30:1

40:1

50:1

60:1

9.72

7.19

5.45

4.74

3.66

3.35

2.49

2.03

1724

2419

2611

2875

3045

3692

3413

3127

9.06

6.46

4.65

4.07

2.8

2.55

1.88

1.44

6.93

4.63

3.19

3.31

2.00

1.96

1.92

1.61

1228

1558

1527

2011

1661

2156

2637

2476

6.46

4.16

2.72

2.85

1.53

1.49

1.46

1.14

93

90

85

86

77

76

76

71

1200 1200 15

Need assistance with your selection? Call 1-888-55-OMEGA.

MECHANICAL RATING AND SPECIFICATIONS

Note: Maximum input speed is 2000 RPM.

Box size is distance between center line of input and outputs shafts.

*

D-3

Page 4

A

d (4)

t

BC E

d1 (4)

D

F

HDRBASE133, $20, shown

smaller than actual size.

Mounting Base

MOUNTING BASES

To Order (Specify Model Number)

MODEL NO. PRICE BOX SIZE

HDRBASE133 $20 133

HDRBASE154 23 154

HDRBASE175 27 175

HDRBASE206 30 206

HDRBASE237 37 237

HDRBASE262 45 262

HDRBASE325 50 325

Mounting base comes complete with bolts.

RATIO 5:1 10:1 15:1 20:1 30:1 40:1 50:1 60:1

RPM @ 1750

INPUT SPEED

RATIO CODE 5/1 10/1 15/1 20/1 30/1 40/1 50/1 60/1

350 175 120 88 58 44 35 29

Dimensions: mm (in)

BOX

SIZE ABCD E Ftdd1

133 82.5 (3.25) 51 (2) 84 (3.31) 111 (4.38) 106 (4.19) 137 (5.38) 0.53

154 106 (4.19) 70 (2.75) 109 (4.31) 133 (5.25) 138 (5.44) 164 (6.44) 0.59

175 106 (4.19) 70 (2.75) 114 (4.5) 146 (5.75) 145 (5.69) 178 (7) 0.69

206 127 (5) 73 (2.88) 119 (4.69) 162 (6.38) 151 (5.94) 192 (7.55) 0.72

237 127 (5) 73 (2.88) 124 (4.88) 179 (7.06) 158 (6.22) 216 (8.5) 0.75

262 162 (6.38) 86 (3.38) 133 (5.25) 203 (8) 169 (6.66) 245 (9.63) 0.75

325 190 (7.5) 102 (4) 156 (6.13) 241 (9.5) 195 (7.66) 284 (11.19) 0.88

D-4

11

11

13

15

15

17

17

3

⁄

32

⁄

32

⁄

32

⁄

32

⁄

32

⁄

32

⁄

32

⁄

8

3

⁄

8

3

⁄

8

7

⁄

16

7

⁄

16

7

⁄

16

1

⁄

2

Page 5

Gearboxes come in fixed ratio units that provide the user with

speed reduction along with a mechanical advantage to increase

torque. A 1 HP motor at 1750 RPM provides 35 in. lbs. of torque.

Adding a 10:1 ratio gearbox will reduce the speed

to 175 RPM and increase the torque to 350 in. lbs. and the

resulting HP will remain close to 1 HP with little loss efficiency.

WORM GEAR REDUCERS FOR 56C FRAME MOTORS

OUTPUT RPM OUTPUT

INPUT ( RATIO) TORQUE

BOX

SIZE

at 1800 RPM (lbs. in.)

OUTPUT INPUT

HP HP

175 (10:1) 445 1.19 1.36 HDRF175-10/1-R-56C 1.5 OMT1.5-18-56C OMAT1.5-18-56C

120 (15:1) 506 0.96 1.13 HDRF175-15/1-R-56C 1.5 OMT1.5-18-56C OMAT1.5-18-56C

175

(1.75")

88 (20:1) 572 0.81 0.98 HDRF175-20/1-R-56C 1 OMT1-18-56C OMAT1-18-56C

44 (40:1) 404 0.28 0.45 HDRF175-40/1-R-56C

35 (50:1) 446 0.25 0.41 HDRF175-50/1-R-56C

29 (60:1) 404 0.19 0.35 HDRF175-60/1-R-56C

206

(2.06")

44 (40:1) 726 0.5 0.71 HDRF206-40/1-R-56C

35 (50:1) 606 0.33 0.54 HDRF206-50/1-R-56C

29 (60:1) 606 0.28 0.48 HDRF206-60/1-R-56C

44 (40:1) 845 0.58 0.83 HDRF237-40/1-R-56C 1 OMT1-18-56C OMAT1-18-56C

237

(2.37")

35 (50:1) 779 0.43 0.67 HDRF237-50/1-R-56C

29 (60:1) 844 0.39 0.63 HDRF237-60/1-R-56C

262

(2.62")

44 (40:1) 1153 0.8 1.11 HDRF262-40/1-R-56C 1.5 OMT1.5-18-56C OMAT1.5-18-56C

35 ( 50:1) 1152 0.64 0.95 HDRF262-50/1-R-56C 1 OMT1-18-56C OMAT1-18-56C

29 (60:1) 1346 0.62 0.94 HDRF262-60/1-R-56C 1 OMT1-18-56C OMAT1-18-56C

Note: Box size is distance between center line of input shaft and center line of output shaft.

MODEL NO.

GEAR REDUCER H.P. SINGLE PHASE 3-PHASE

AC MOTORS

1

OMT12-18-56C OMAT12-18-56C

⁄

2

1

OMT12-18-56C OMAT12-18-56C

⁄

2

1

OMT12-18-56C OMAT12-18-56C

⁄

2

3

OMT34-18-56C OMAT34-18-56C

⁄

4

3

OMT34-18-56C OMAT34-18-56C

⁄

4

1

OMT12-18-56C OMAT12-18-56C

⁄

2

3

OMT34-18-56C OMAT34-18-56C

⁄

4

3

OMT34-18-56C OMAT34-18-56C

⁄

4

To Order (Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

MODEL NO. PRICE DESCRIPTION

GEARBOX MODELS WITH FLANGE INPUT —SHAFT OUTPUT

HDRF133-*-**-56C $135 Gear speed reducer with box size 1.33" for 56C frame motor

HDRF154-*-**-56C 148 Gear speed reducer with box size 1.54" for 56C frame motor

HDRF175-*-**-56C 163 Gear speed reducer with box size 1.75" for 56C frame motor

HDRF206-*-**-56C 207 Gear speed reducer with box size 2.06" for 56C frame motor

HDRF237-*-**-56C 249 Gear speed reducer with box size 2.37" for 56C frame motor

HDRF262-*-**-56C 268 Gear speed reducer with box size 2.62" for 56C frame motor

HDRF325-*-**-56C 379 Gear speed reducer with box size 3.25" for 56C frame motor

GEARBOX MODELS WITH FLANGE INPUT—HOLLOW BORE OUTPUT

HDRF133-*-H-56C $182 Hollow bore gearbox with 1.33" box size

HDRF175-*-H-56C 215 Hollow bore gearbox with 1.75" box size

HDRF206-*-H-56C 258 Hollow bore gearbox with 2.06" box size

HDRF237-*-H-56C 295 Hollow bore gearbox with 2.37" box size

HDRF262-*-H-56C 363 Hollow bore gearbox with 2.62" box size

HDRF325-*-H-56C 504 Hollow bore gearbox with 3.25" box size

GEARBOX MODELS WITH SHAFT INPUT—SHAFT OUTPUT

HDRS133-*-** $116 Shaft-to-shaft indirect drive gearbox with 1.33" box size

HDRS175-*-** 140 Shaft-to-shaft indirect drive gearbox with 1.75" box size

HDRS206-*-** 168 Shaft-to-shaft indirect drive gearbox with 2.06" box size

HDRS237-*-** 193 Shaft-to-shaft indirect drive gearbox with 2.37" box size

HDRS262-*-** 237 Shaft-to-shaft indirect drive gearbox with 2.62" box size

HDRS325-*-** 333 Shaft-to-shaft indirect drive gearbox with 3.25" box size

Insert ratio code into model number, see chart on previous page for ratio codes; “5/1”, “10/1”, “15/1”, “20/1”, “30/1”, “40/1”, “50/1”, “60/1”.

*

For right hand shaft insert “R”, for left hand shaft “L”, or for double end shaft “DE” (dual shaft not available on shaft-to-shaft models).

**

Order Examples: HDRF154-15/1-R-56C, for 15:1 ratio right hand flange mount gearbox, with a 1.54" box size, $148.

HDRS133-5/1-R, 5:1 ratio, 350 RPM shaft input-shaft output gearbox with 1.33" box size, $116.

D-5

Page 6

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...