Page 1

L-51

⻬ Easy Screwdriver

Service

⻬ Chemical Resistant

⻬ Flows to 230 U.S. GPM

or 94' TDH at 60 Hz

(725 LPM or 20 m at 50 Hz)

⻬ Constructed from

Glass-Reinforced

Polyester or Noryl

®

Thermoplastic

APPLICATIONS

For pumping, transferring, and

recirculating select wastes, acids,

plating solutions, chemicals, fume

scrubbers, and photographic

etchings and cleaning solutions.

WARNING

When pumping flammable or

combustible liquids, all containers

must be effectively bonded and

grounded to prevent sparks of

static electricity which could

cause an explosion.

mechanical seals can be made

metalless with EPDM and

siliconized graphite seal faces (add

suffix “-TPM” and add $638 to price).

If abrasives may be entrained in the

pumped liquid, order option “-SC”

for hard siliconized graphite-faced

shaft seal with EPDM and 316 SS

internals, and add $215 to price.

Note: In operation, mechanical

seals weep small quantities of the

pumped material through the seal

back onto the motor shaft adaptor.

All major pump parts in the

FPUC200 Series are precision

molded of tough, corrosion-resistant,

glass-reinforced polyester or Noryl

®

glass-reinforced thermoplastic.

These high-strength plastics provide

resistance to water and saltwater as

well as to many acids, bases, and

solvents. O-rings and seals are of

EPDM, Viton®, or Buna-N. The

pumps use 18-8 SS wetted internal

hardware. For extra corrosive

service, the motor shaft adaptor can

be made of titanium, the impeller

screw can be encapsulated in

polypropylene, and the mechanical

seals can be made metalless with

Viton®and siliconized graphite seal

faces (add suffix “-TPV” to the model

number and add $700 to price). The

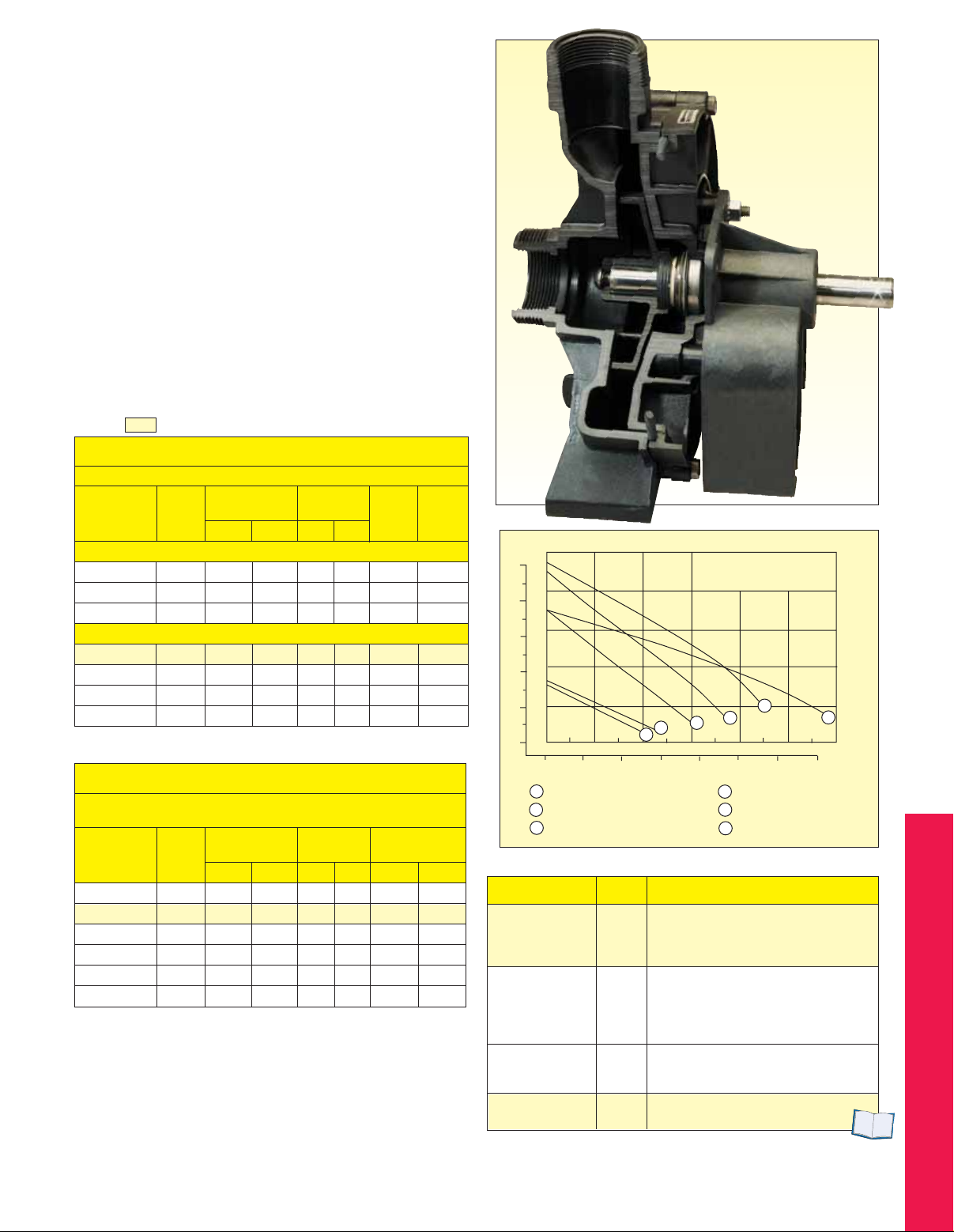

FPUC201 close coupled to

electric motor, $654, shown

smaller than actual size

FPUC201

$

654

END SUCTION CENTRIFUGAL PUMPS

Page 2

SPECIFICATIONS

Port Size: Combination of 11⁄2 female 2 male NPT (for all

except the FPUC213, which has 3 male NPT threaded

suction and discharge ports)

Wetted Parts: Glass-reinforced polyester body standard,

Noryl

®

optional; EPDM O-rings std, Viton®and Buna-N opt.;

18-8 SS internals and motor shaft with self-lubricating

carbon/ceramic mechanical seal with 316 SS case and

spring std; all non-metallic internals and siliconized graphite

mechanical seal (includes polypropylene-encapsulated

impeller screw and Halar

®

case, with titanium motor shaft

opt.). External hardware is 18-8 SS.

Max. Temperature/Pressure: Polyester body: up to

54°C (130°F) up to 41 psig; Noryl

®

body: up to 93°C (200°F)

up to 41 psig

Dimensions: Close coupled: 292 H x 349 L x 222 mm W

(11

1

⁄2 x 133⁄4 x 83⁄4"); L = 241 mm (9 1⁄2") max. for pedestal mount

Max. Weight: Close coupled: 21.8 kg (48 lb);

pedestal mount: 6.8 kg (15 lb)

L

L-52

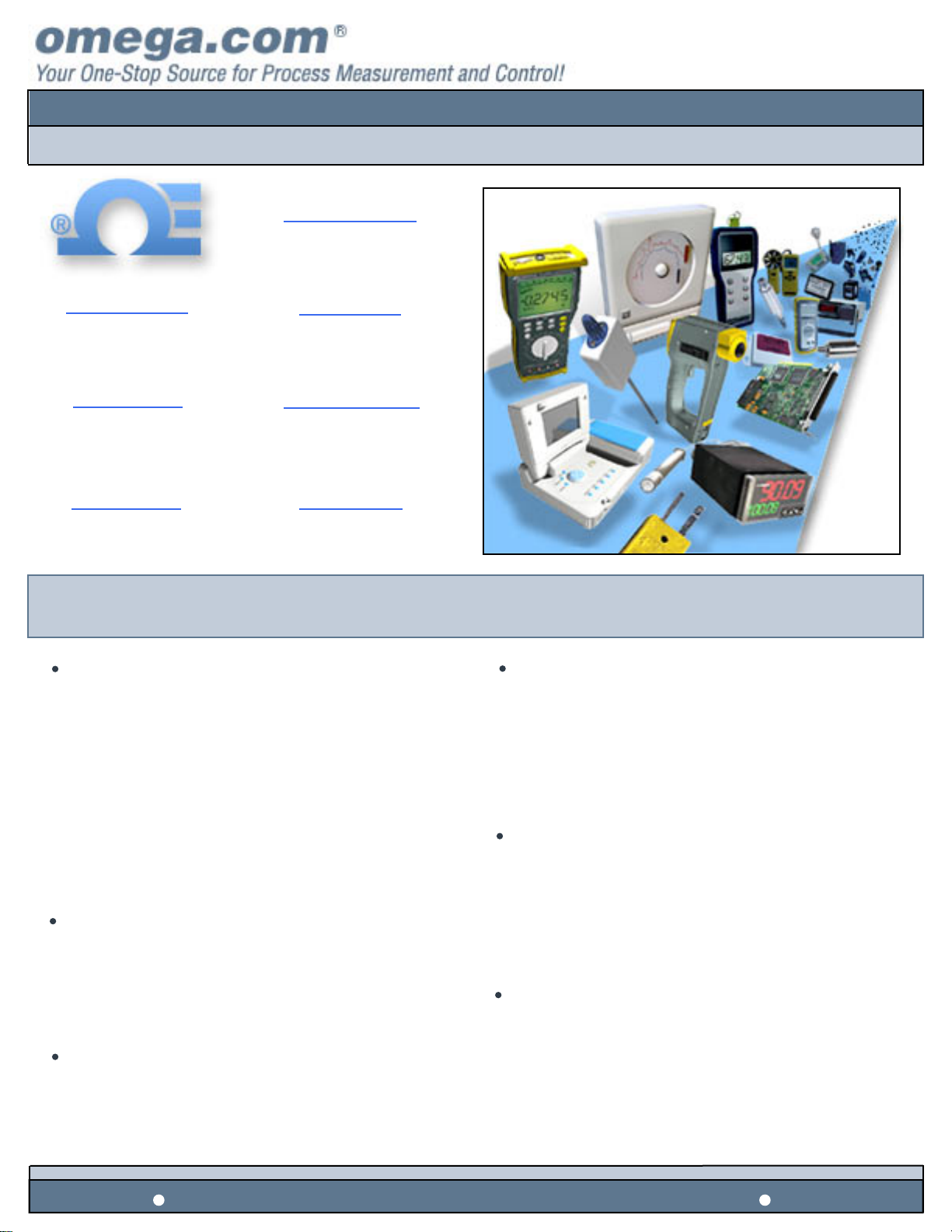

70 and 90 GPM units are 1750 RPM motors; all others are 3450 RPM.

Accessories for Pedestal-Mount Pumps

Ordering Example: FPUC208, epoxy-coated cast iron pedestal

mount, and FPUCS100-BP, baseplate kit, $379 + 155 = $534.

FPUC200 Series

cutaway view.

Comes with complete operator’s manual.

* GPM @ 1725 and 3450 RPM, 60 cycle motors: LPM @ 1450 and

2850 RPM, 50 cycle motors. For Noryl®body instead of polyester,

add suffix “-NL” to model number and add $45 to price. For optional

Buna-N or Viton®elastomers, add suffix “-B” or “-V” to model number

and add $138 for Viton®, no charge for Buna-N. For 50 Hz motor,

please specify ”-Voltage/Phase/50 Hz”(consult OMEGA’s Flow

Engineering department). To order an EDPM fitted hard-siliconized,

graphite-faced shaft seal for abrasive applications, add suffix

“-SC” to model number and add $215 to price.

To Order

(Specify Model Number)

With Single Phase, 115/230 Vac, TEFC Motor

Max Max Motor Max

Flow Rate* TDH

HP Spec.

Model No. Price GPM LPM Ft. M 60 Hz Grav.

With Single-Phase, 115/230 VAC, TEFC Motor

FPUC201 $654 70 220 30 6.5 0.75 1.8

FPUC202 784 90 285 32 7 1.5 1.6

FPUC203 798 120 380 70 15 2.0 1.1

With 3-Phase, 230/460 Vac, TEFC Motor

FPUC204 614 70 220 30 6.5 0.75 1.8

FPUC205 664 90 285 32 7 1.5 1.6

FPUC206 723 120 380 70 15 2.0 1.6

FPUC207 740 150 475 90 19 3.0 1.0

To Order

(Specify Model Number)

Epoxy-Coated Cast Iron Pedestal Mount, No Motor or

Baseplate [6.8 kg (15 lb) Ship Wt.]

Max Max Required

Flow Rate* TDH HP

Model No. Price GPM LPM Ft. M 60 Hz 50 Hz

FPUC208 $379 70 220 30 6.5 0.4 0.31

FPUC209 379 90 285 32 7 0.9 0.5

FPUC210 379 120 380 70 15 1.8 1.0

FPUC211 379 150 475 90 19 3.0 1.7

FPUC212 379 180 570 94 20 4.8 2.8

FPUC213 459 230 725 70 15 4.9 2.8

Model No. Price Description

FPUCS100-BP $155 Baseplate kit for FPUC208

through FPUC211. Includes

coupling guard, shims, screws,

nut, washers and steel base plate.

FPUCS201-BP 255 Baseplate kit for FPUCS212 and

FPUC213. Includes coupling

guard, shims, screws, nut,

washers and epoxy-painted

steel base plate.

FPUCS100-SC 35 Coupling from 1.9 cm (3⁄4") pump

shaft to 1.6 cm (5⁄8") NEMA 56

face motor shaft

CM-4391 99 Reference Book: Centrifugal

Pump Design

MOST POPULAR MODELS HIGHLIGHTED!

TDH

100

20

80

16

60

12

40

8

20

4

M

FT

60

Hz

Hz

50

100

A

: FPUC201, 209, 28

B

: FPUC202, 205, 209

C

: FPUC203, 206, 210

40

200

80

B

A

120

300

A & B: 1750 RPM@60Hz

C, D, E & F: 3450 RPM@60Hz

C

400

1450 RPM@50Hz

2850 RPM@50Hz

E

D

160

600

500

D

: FPUC207, 211

E

: FPUC212

F

: FPUC213

200

700

F

240

LPM

GPM

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...