Page 1

FPU100 Series

FPU250 Series

FPU100 AND 250 SERIES

OMEGAFLEX®PERISTALTIC PUMPS

MADE IN

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

Shop online at

Page 2

1

INTRODUCTION

2

INTRODUCTION

General Description

The OMEGA®peristaltic pump is self-priming and can handle a wide

variety of viscosities (from air to heavy slurries) with positive

displacement.

The OMEGA

®

peristaltic pump can be used to pump fluids or gases

without contamination of the pump - the material contacts only the

tubing. The positive displacement feature makes this pump ideal for

metering applications. Each revolution of the roller assembly delivers a

precise amount of fluid.

The easy changeability of the OMEGA

®

peristaltic pump tubing makes

this the ideal pump for diverse quick change repetitive pumping jobs.

Flexible, reliable and cost efficient, the OMEGA

®

peristaltic pump can

fill most all of your fluid movement requirements.

Specifications

1. Priming Unit is self-priming and will hold vacuum when turned

off.

2. Operation: Pump can run dry without damage.

3. Weight: See model information chart.

4. Capacity: From 3mL/min to 987mL/min (see model information

chart).

5. Construction: High strength plastics and long-lasting alloy metals.

6. Maximum Head Pressure: 57 feet of water.

7. Maximum Suction Lift: 28 feet of water.

8. Maximum System Pressure: 20 psi continuous, 25 psi intermittent.

9. Certification: All motors are UL listed.

10. Rating: All gearmotors are rated for 100% continuous duty.

Page 3

2

OPERATIONAL INFORMATION

3

OPERATIONAL INFORMATION

Installation Instructions

Power Requirements: Voltage and frequency of power supply must be

the same as shown on unit.

Wiring Connections: All wiring and electrical connections must comply

with national electrical codes and local electrical codes.

Mounting:

a) Mount OEM model mounting bracket to any flat, rigid surface, using

four #10-32 screws.

b) Case enclosed model may be placed on any flat surface, assuring

space is provided at the back of the case for air circulation through

ventilation holes.

Mounting Location: Pump should be used in a dry location with an

adequate supply of cooling air. The ambient temperature should not

exceed 25°C.

This unit should not be used outdoors or in hazardous

locations.

Instructions for Optional Timer

1. Rotate the program disc in the direction of the arrows to align the

correct time of day with the time mark.

2. Set the desired switching program by pushing the switch actuators

toward the center of the time switch. Each actuator provides a 15

minute “ON” time. The now visible orange area(s) indicate the

switch “ON” period

WARNING

Page 4

3

FPU SERIES

ROLLER AND TUBING SELECTION

4

FPU SERIES

ROLLER & TUBING SELECTION

Use the following color coded rollers with the appropriate tubing ID:

Roller Color Tubing ID mL Per Revolution

Black

1

⁄4"3.5

Black

3

⁄16"2.1

Red

1

⁄8"0.84

Red

1

⁄6"0.21

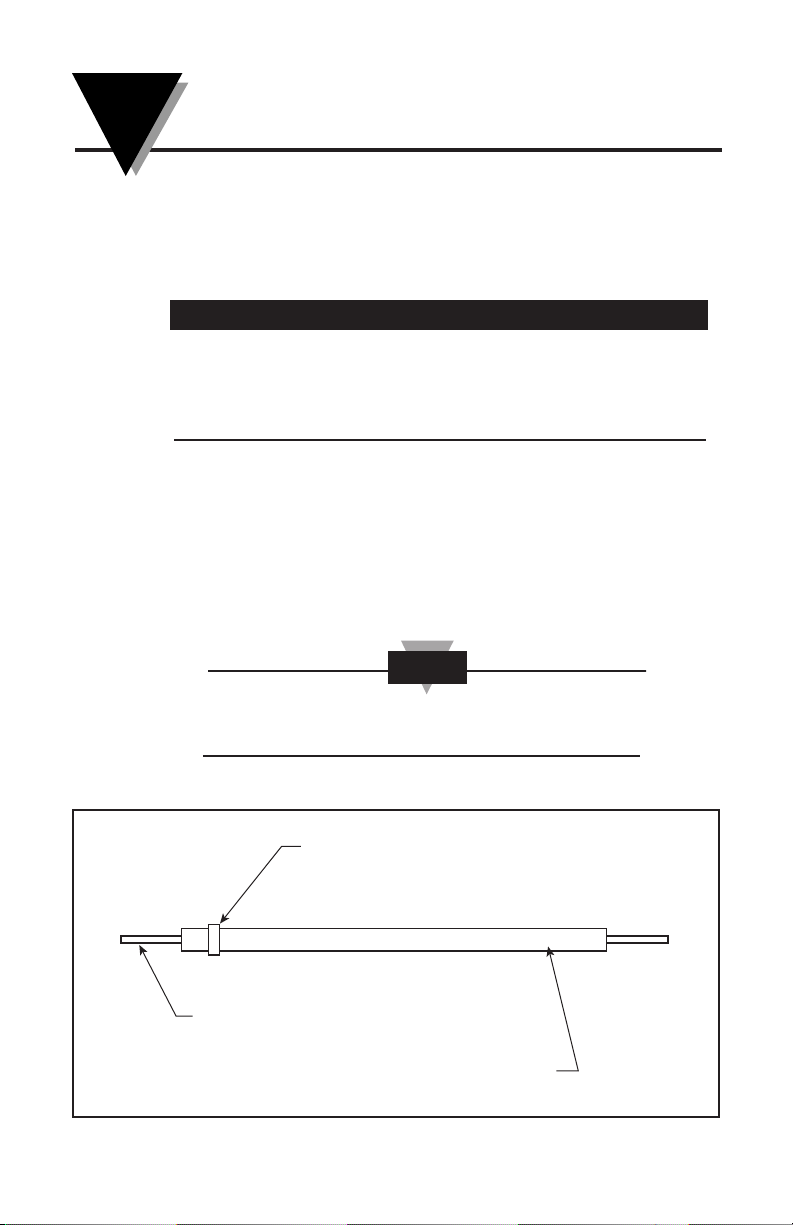

Instructions for 1/16" Tubing Assembly

Insert 1⁄16" tubing into the sleeve and pull out desired length of 1⁄16"

tubing. Secure

1

⁄16" tubing by placing the tie fastener approximately 1⁄4"

from one end of the sleeve and tighten fastener so that

1

⁄16" tubing is not

easily moved. Be careful not to collapse the inner tubing by overtightening the tie fastener. Install the tubing with the tie fastener on the

inlet side of the pump.

Make sure the tie fastener is on the outside of the pump

housing and is not interfering with the roller assembly.

NOTE

PLASTIC TIE FASTENER

1/16" I. D. TUBE

3/16" I. D. SLEEVE

Page 5

4

ASSEMBLY INSTRUCTIONS

5

ASSEMBLY INSTRUCTIONS

1. Assemble mounting plate (4) and pump housing (5) to gearmotor (3)

with with three #10-32 x 1

1

⁄4" long screws and one #8-32 x 7⁄8" long

screw (2).

2. Slide white plastic washer (8) onto motor shaft. Press roller bracket

assembly (9) onto the motor shaft with the four self-locking teeth

toward the gearmotor. (As shown in the view above.)

3. Insert tubing (6) into pump. housing (5) inlet and work tube into

roller race as you rotate the roller bracket assembly. See details on

page 5.

4. Assemble pump cover (10) to pump housing. (5) with four #8-32 x

5

⁄8"

long screws (11).

Page 6

5

TUBE INSPECTION AND REPLACEMENT

6

TUBE INSPECTION AND REPLACEMENT

Tubing Inspection:

Inspect all tubing regularly and replace it if deterioration occurs. Use

the following instructions to replace pump tubing.

Tubing Replacement

1. Disconnect the power to the pump.

2. Disconnect the suction and discharge tubing from the tubing.

3. Remove four screws and pump cover.

4. Remove old pump tubing and discard.

5. Clean roller race, removing any particles that could damage tubing.

6. Position the roller bracket assembly as shown in Fig. 1.

7. Push the new tubing into the inlet port anchoring the tubing in

grippers (see Fig. 2) while rotating the roller bracket assembly.

8. Continue to rotate the roller bracket assembly, pushing the tubing

into the roller race.

9. Finally, insert the tubing into the outer port (Fig. 4), and replace the

cover and screws.

Page 7

6

OMEGA®VARIABLE SPEED DRIVES

FPU250 SERIES

7

OMEGA®VARIABLE SPEED DRIVES

SERIES FPU 250

OMEGA®variable speed drives are powered by a DC gearmotor. A

specially designed electronic speed control system provides smooth

acceleration control over the entire flow range. The three position

on/off switch allows the user to maintain speed setting when unit is

turned off or reversed. This unit is designed for continuous operation at

any speed. All variable speed drives are rated for continuous duty at

25°C ambient.

Fuse: Replace with type AGC-1/2 Amp. Use AGC-1 Amp for dual head

pump.

Alternate Tubing Replacement Method for Medium and High

Variable Speed Units

With unit running at high RPM, pull old tubing out from outlet port of

pump. Install new tube by inserting into inlet port; continue feeding

tube

1

⁄4" in at a time, allowing the roller assembly to push tubing until

tube extends out from outlet port. Pull tubing from outlet port until

desired tubing extension is obtained. Run unit for about one minute to

allow tube to seat properly.

Depending on pump model, tubing in use and fluid being

pumped, roller assembly may stop rotating when

speed/flow control is set at the low end range. Avoid

prolonged operation in the stalled position for longer motor

life.

CAUTION

Omega Water Tube Case Amps

Model Range (inner dia.) Dimensions @ Weight

No. (ml/min) mm (in.) cm (in.) RPM 60Hz kgs. (lbs)

FPU251 0.36-5.5 1.59 (1⁄16) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 1.5 to 26 0.5 3.63 (8)

FPU252 3.0-50 4.76 (3⁄16) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 1.5 to 26 0.5 3.63 (8)

FPU253 6.0-90 6.35 (1⁄4) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 1.5 to 26 0.5 3.63 (8)

FPU254 0.9-24 1.59 (1⁄16) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 4 to 114 0.5 3.63 (8)

FPU255 8.0-220 4.76 (3⁄16) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 4 to 114 0.5 3.63 (8)

FPU256 14-400 6.35 (1⁄4) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 4 to 114 0.5 3.63 (8)

FPU257 1.7-49 1.59 (1⁄16) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 8 to 228 1 3.63 (8)

FPU258 15-440 4.76 (3⁄16) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 8 to 228 1 3.63 (8)

FPU259 28-800 6.35 (1⁄4) 22.5 x 14.2 x 19.1 (8.85 x 5.6 x 7.5) 8 to 228 1 3.63 (8)

Page 8

7

REPLACEMENT PARTS

8

MODEL NO. DESCRIPTION (ID X OD)

FPU16-N 1/16" X 1/8" Norprene

®

Tubing

FPU16-S 1/16" X 1/8" Silicone Tubing

FPU18-N 1/8" X 3/8" Norprene

®

Tubing

FPU18-S 1/8" X 3/8" Silicone Tubing

FPU316-H 3/16" X 3/8" Norprene® Tubing

FPU316-S 3/16" X 3/8" Silicone Tubing

FPU14-N 1/4" X 7/16" Norprene® Tubing

FPU15-S 1/4" X 7/16" Silicone Tubing

TUBING REPLACEMENT CHART

REPLACEMENT PARTS

ITEM NUMBER PART

NUMBER REQUIRED DESCRIPTION

1 1 Fan

2 1 Screw, Gearmotor

3 1 Gearmotor

4 1 Mounting Plate or Case (Enclosure)

5 1 Pump Housing

6 1 Tubing (See Tubing Replacement Chart)

7 3 Screws, Pump Housing

8 1 Washer

9 1 Roller Bracket Assembly

10 1 Pump Housing Cover

11 4 Screws, Pump Housing Cover

12 1 Motor Starter (Not all models)

Page 9

8

FPU SERIES

AC AND DC MODELS

9

FPU SERIES - AC MODELS, OEM Style, Fixed Speed

FPU SERIES - DC MODELS, OEM Style, Fixed Speed

130.0 (5.12) A

110.2 (4.34)

77.7

(3.06)

5.59 DIA. (0.22) - (4) PLCS.

9.9 (0.39)

9.4 (0.37)

76.2

(3.74)

(3.00)

26.2

(1.03)

95.0

DIMENSIONS mm (in.)

The following models require a

motor starter as shown in the

drawing at right.

FPU-123 Single Head

*

FPU-124 Single Head

*

FPU-125 Single Head

*

FPU-122 DUAL Dual Head

*

FPU-123 DUAL Dual Head

*

FPU-124 DUAL Dual Head

*

*These models are not UL listed.

33.3

(1.31)

33.3

(1.31)

24.4

(0.96)

1.3

(0.5)

24.4

(0.96)

1.3 THK.

(0.5)

B

(3.65)

92.7

38.1

(1.5)

66.6

(2.62)

11.9

(0.47)

6.4 (0.25) O. C.

TERMINALS

66.6

(2.62)

11.9

(0.47)

MOTOR

STARTER

98.3

(3.87)

1.27

(0.05)

30.0

(1.18)

90.2

(3.55)

5.59 DIA. (0.22), 4 HOLES

77.7

(3.06)

110.2

(4.34)

130.0

(5.12)

(1.50)

62.5

(2.46)

76.2

(3.00)

DIMENSIONS mm (in.)

38.1

76.2

(3.00)

9.9

(0.39)

9.4

(0.37)

95.0

(3.74)

Page 10

9

MODEL INFORMATION CHART

10

Page 11

1

FPU100 AND FPU250 SERIES

OMEGAFLEX

®

PERISTALTIC PUMPS

11

NOTES:

Page 12

M1116-0404

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing

certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the

right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from

date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product

warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each

product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an

Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be

defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the

purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of

having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted,

include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility

for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION

OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this

order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential,

incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR

21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s)

be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes

no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY

PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY

RETURNS, please have the following informa-

tion available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was

PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the

product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to

the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in

technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2008 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Canada: Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail:espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing Europe:

Czech Frystatska 184, 733 01 Karviná, Czech Republic

Republic: TEL: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Tol Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/ Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Austria: Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United One Omega Drive, River Bend Technology Centre

Kingdom: Northbank, Irlam, Manchester

ISO 9001 Certified

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Loading...

Loading...