Page 1

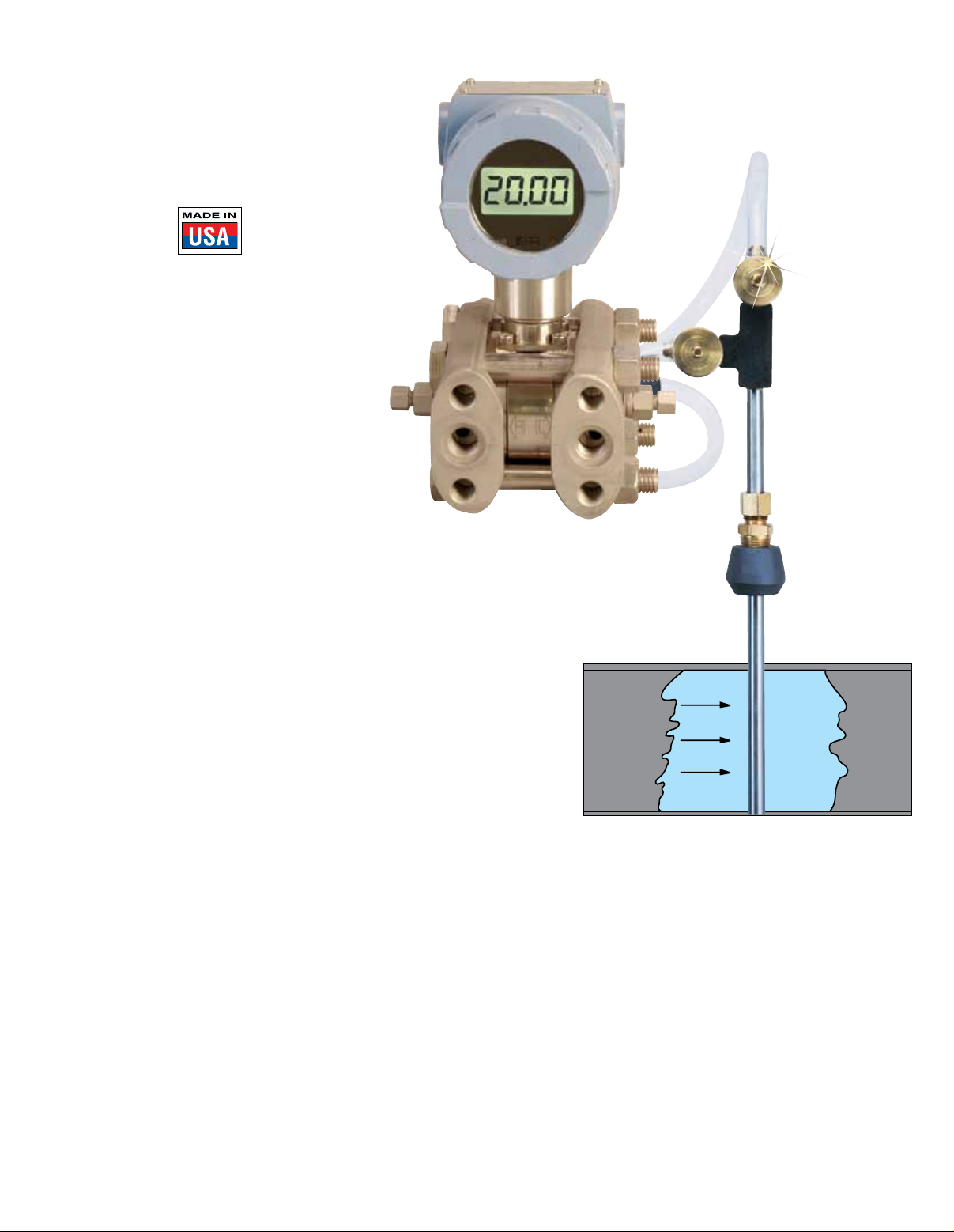

HIGH ACCURACY PITOT TUBES

FPT-6000.G-11.ill

FPT-6000 Series

U Up to ±1% of Rate Accuracy

U Easy Installation–Ideal

for Retrofits

U Very Low Pressure Drop

U Low Maintenance

U For Clean, Low Viscosity

Liquids, Gases, and Steam

U Valves Included as Standard

SAE flair brass

valves included

standard with

FPT-6110 Series

The FPT-6110 is a highly accurate

averaging pitot tube which generates

a pressure differential between its

upstream (stagnation) ports and its

downstream (static) ports that is

proportional to the flowrate squared

(Q2). The differential pressure can

then be measured by a differential

pressure transducer (visit

omega.com/pressure) to provide

a 4 to 20 mA output which is

proportional to the flowrate squared.

This can then be read out as flowrate

by devices with square root extraction,

such as OMEGA’s DPF64-SQRT

meter or FC-20 mass flow computer.

The FPT-6000 can be used to

measure clean, low viscosity liquids,

gases and steam in a variety of

piping systems and pipe sizes

(to 72" and above on special order).

The FPT-6110 offers the following

advantages over orifice plates: easy,

low-cost installation (weld 1 small

coupling into place vs. 2 large

flanges); much lower permanent

pressure loss; low maintenance

(occasionally forcing gas through

the pressure ports clears the

sensing ports when dirt is a

problem); and good resistance to

wear. Bi-directional flow measurement

capability is standard. And, with

special double-mount construction,

the flow ranges listed can be

extended by to up to 4 times

(consult Flow Engineering

Department for details).

PX760 pressure transmitter,

sold separately. Visit omega.com/

pressure for more information.

SPECIFICATIONS

Accuracy: Up to 1% of rate (see

sizing). (Accuracy stated is for use in

schedule 40 pipe. If used in schedule

80 pipe, add 1% to accuracy or request

special construction)

Repeatability: ±0.1% of rate

Maximum Temperature: FPT-6100:

93°C (200°F); FPT-6200: 204°C (400°F)

“-SS” Models: 427ºC (800ºF)

Maximum Pressure:

FPT-6100: 150 psig;

FPT-6200: 1500 psig

Unrecoverable Pressure Drop

(inches H

DP = generated differential pressure

(inches H

CP = pressure loss coefficient

= 0.296 for

= 0.387 for

= 0.757 for

= 0.945 for 1"

D = inside pipe diameter (inches)

2

O): = DP x (CP/D) where:

2

O)

3

⁄8" diameter probe

1

⁄2"

3

⁄4"

FPT-6110, shown

smaller than

actual size.

Wetted Parts: FPT-6100: 316SS shaft,

brass packing and head, carbon steel

weld coupling,

FPT-6200: 316SS shaft, packing and

head, carbon steel weld coupling,

1

⁄2 FNPT Carbon Steel block valves

Dimensions

For Model FPT-6100: Add 4

line size to determine overall length

without valves. Add 7

determine clearance required to

install unit.

For Model FPT-6300: Add 8

size to determine overall length without

valves. Add 11

clearance required to install unit

1

⁄4" SAE flair brass valve;

7

⁄8" to

1

⁄2" to line size to

1

⁄4" to line

1

⁄2" to line size to determine

G-X

Page 2

HIGH ACCURACY PITOT TUBES

Sizing Equations

1. Any Liquid:

Q2(GPM) x S

DP (in. H2O) =

K2 x D 4 x 32.14

1

f

2. Steam or Any Gas (steam

requires min DP of 10" H2O):

Q2(lb/hr)

DP (in. H2O) =

K2 x D

1 4

x r x 128,900

3. Any Gas:

∆P (in. H2O) =

K2 x D

Q2 (scfm) x SS x (T + 460)

4

x P x 16,590

1

Where:

∆P = differential pressure

(in in H2O)

Q = flowrate

K = flow coefficient

(see “how to order”)

D1 = inside diameter of line size

(in inches for square and

rectangular ducts use):

________

4 x height x width

D1 =

π

P = static line pressure (psia)

T = temperature (in °F)

ρ = density of medium (in pounds

Sf = Sp. Gr. at flowing conditions

Ss = Sp. Gr. at 15°C (60°F)

NOTE: Use of these equations for

liquids yields an accuracy of ±2%

of rate. When used for steam,

accuracy is ±10% of rate (when

steam tables are used). Gas

equation yields ±2% of rate

accuracy from 21 to 204°C (70 to

400°F) and 0 to 150 psig (when gas

is not near its critical point). A ±1%

of rate accuracy requires the use

of more precise equations which

account for shift in K with change

in flowrate, gas compressibility,

etc. Request a precision flow

calibration sheet and please

supply the following data: name

of fluid, specific gravity, pressure,

temperature, inside pipe diameter,

viscosity, steam quality, degrees

superheat, and ratio of specific

heat at constant pressure to that at

constant volume (for gas velocities

approaching 500 fps).

per cubic foot)

To Order

Visit omega.com/fpt6100_6200 for Pricing and Details

Model No. Nominal Differential

(Low Line Probe Pressure

Pressure) Size Dia. (inches H

FPT-6110 1"

FPT-6112 11⁄4"

FPT-6115 1

FPT-6120 2"

FPT-6125 21⁄2"

FPT-6130 3"

FPT-6135 31⁄2"

FPT-6140 4"

FPT-6160 6"

FPT-6180 8"

FPT-6181 10"

FPT-6182 12"

(High Pressure)

†

FPT-6220 2"

FPT-6225 21⁄2"

FPT-6230 3"

FPT-6235 31⁄2"

FPT-6240 4"

FPT-6260 6"

FPT-6280 8"

FPT-6281 10"

FPT-6282 12" 1" 140 6565 0.677 3.0 (6.65)

FPT-6283 14" 1" 117 7325 0.665 3.1 (6.78)

FPT-6284 16" 1" 90 8285 0.691 3.2 (6.98)

FPT-6285 18" 1" 72 9683 0.678 3.3 (7.19)

FPT-6286 20" 1" 59 11000 0.705 3.4 (7.40)

FPT-6287 24" 1" 41 13900 0.708 3.5 (7.81)

FPT-6288 36" 1" 18 21400 0.664 4.1 (9.08)

Options

Add Suffix Additional Price Description

-SS For

For

For

For 1" probe dia. and up

Comes complete with operator’s manual.

Max differential pressure shown is for up to 150°C (300°F). Above 150°C (300°F),

*

reduce value by 4% per 56°C (100°F).

† Please complete and send in questionnaire with your order, from omega.com/flowq.

For units with stainless steel construction add “-SS” to part number and adjust price based on

options available at omega.com/fpt6100_6200.

Ordering Examples: FPT-6220, high pressure model pitot tube.

FPT-6160-SS, low pressure, 3⁄8" diameter pitot tube with 316SS.

G-X

Carbon steel

block valves

included

Maximum

3

⁄8" 1200 115 0.517 0.31 (0.68)

3

1

⁄2"

3

⁄8" probe diameter

1

⁄2" probe diameter

3

⁄4" probe diameter

⁄8" 833 179 0.583 0.31 (0.69)

3

⁄8" 668 220 0.580 0.31 (0.69)

3

⁄8" 459 315 0.638 0.31 (0.70)

3

⁄8" 338 410 0.617 0.31 (0.71)

3

⁄8" 237 552 0.665 0.32 (0.72)

3

⁄8" 186 657 0.661 0.32 (0.72)

3

⁄8" 150 756 0.672 0.33 (0.73)

3

⁄8" 72 1230 0.706 0.35 (0.77)

3

⁄4" 164 3109 0.686 0.74 (1.64)

3

⁄4" 107 4006 0.676 0.80 (1.76)

3

⁄4" 77 4830 0.683 0.85 (1.88)

1

⁄2" 1064 479 0.557 1.0 (2.30)

1

⁄2" 713 609 0.598 1.1 (2.32)

1

⁄2" 510 809 0.645 1.1 (2.34)

1

⁄2" 400 963 0.630 1.1 (2.36)

1

⁄2" 328 1119 0.656 1.1 (2.37)

1

⁄2" 163 1845 0.662 1.1 (2.45)

1

⁄2" 100 2428 0.673 1.1 (2.52)

1

⁄2" 66 3139 0.682 1.2 (2.59)

316SS construction includes head,

probe, block valves and threadolet

FPT-6220,

shown smaller

than actual size.

Carbon steel

weld coupling

included

Max GPM Weight

2

O)* (Liquids) K Kg (lb)

G

Loading...

Loading...