Page 1

FPR 200

Flow Sensor

Flow Sensor with Stainless Steel Body

Flow Sensor with

Polypropylene Body

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

ISO 9001

CERTIFIED

CORPORATE QUALITY

STAMFORD, CT

ISO 9002

CERTIFIED

CORPORATE QUALITY

MANCHESTER, UK

Page 2

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Introduction

This manual is a service guide produced by the manufacturer. The

manual provides specific procedures and/or illustrations for installation, inspection, cleaning and filtration of all Omega FPR 200 flow

sensors. When properly followed, these procedures will keep your

flow sensor operating dependably for many years.

It is important for operators and maintenance personnel to be safety

conscience when operating or repairing equipment. Developing a thorough knowledge of the precautionary areas and following safe operating procedures, can prevent equipment damage and/or personal injury.

Before making any repair, read all of the repair procedures to learn

the correct method and all precautions.

General

Omega’s flow sensors integrate rugged tangential turbine technology

with a precision digital to analog conversion circuit hermetically

encapsulated within the body of the sensor. The flow sensor is ideal

for measuring flow rates in cooling circuits, HVAC systems and batching operations.

Additional features are:

simple in-the-field serviceability of its moving components

the integral 4-20mA circuit design eliminates the need for separate

signal conditioning modules

units come factory calibrated to your system requirements

the low impedance 4-20mA circuit can transmit a "clean" signal

over low-cost wire for several thousand feet without degradation

accurately measures flow in both directions.

(3)

Page 4

Installation - Mechanical

1. The flow sensor has NPT (National Pipe Thread) plumbing connections. It is recommended that a paste type pipe sealant be

used on these threads. [Teflon tape sealant can be used as long

as it is applied in such a way that it will not enter the flow stream.

Pieces of Teflon tape can wrap around the turbine and impede its

rotation.]

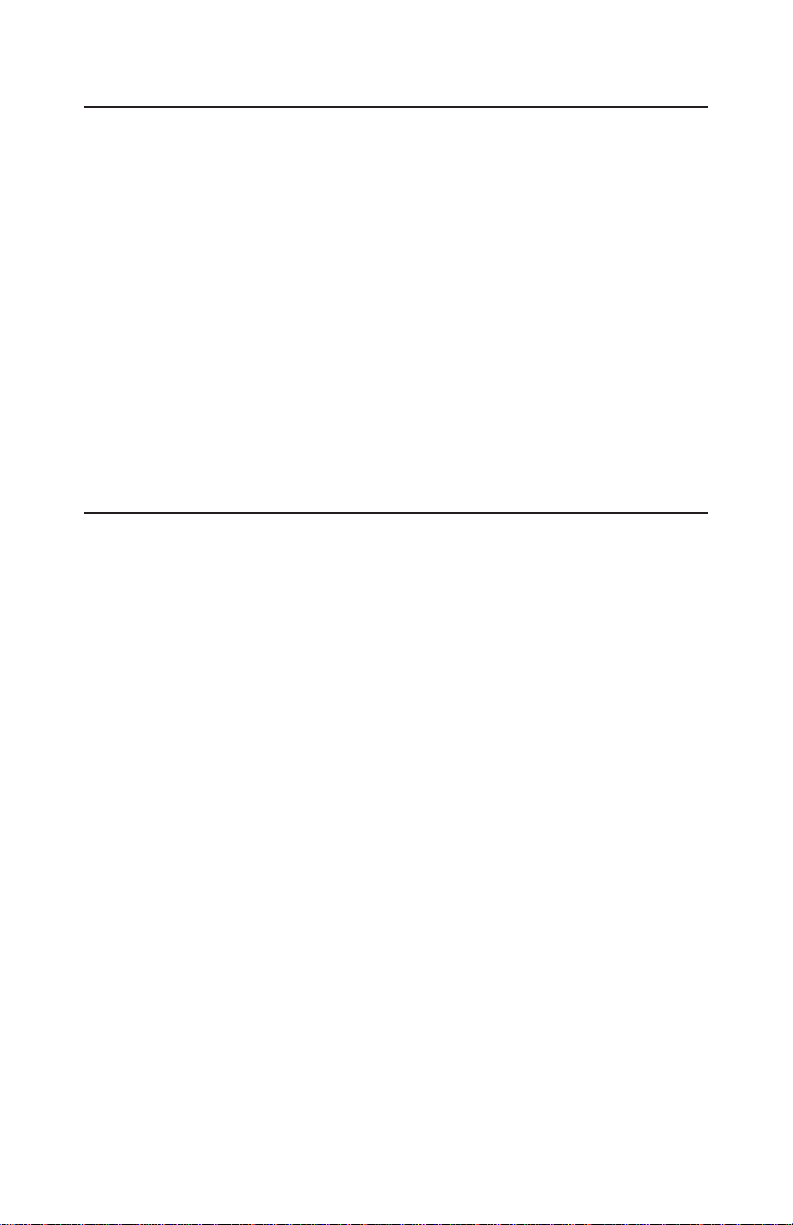

2. The recommended mounting orientation would be any plane that

will place the axis of the turbine horizontal with respect to the

ground. See Illustration 1. The unit will operate satisfactorily with

its axis at angles other than horizontal, but side loading of the

bearing surfaces will lead to premature wear of the rotating parts.

3. For the best flow measurement results, place the inlet (See Note 1)

of the flow sensor at least 10 straight pipe diameters downstream from any fitting, valve, elbow, reducer, etc. that causes

non-stable flow conditions. Ideally, 5 straight pipe diameters should

be placed at the outlet of the sensor. If the sensor must be placed

closer to a source of non-stable flow than these recommended distances, some instability of the output signal may result. The average signal will be accurate.

(4)

Illustration 1:

Mounting Instructions

Page 5

4. It is recommended that the sensor be placed in such a position

that the round access cover can be removed for cleaning and turbine servicing. It is also recommended that a union be placed

near the sensor to allow easy removal.

Note1: The flow sensor is a bi-directional measuring device.

References to “inlet” and “outlet” refer to uni-directional systems.

Installation - Electronic (4-20mA Only)

The flow sensor circuit is a two-wire loop-powered design that transmits

a 4-20mA signal that is proportional to flow rate. The noise-immune current transmission from the sensor can be routed with low cost two conductor twisted-pair cable. The circuit operates on 12-35 VDC and

requires a source capable of supplying at least 20mA of current. The

circuit has built in polarity protection and over-current limiting to protect

both the transmitter and what the transmitter is connected to.

1. Connect the red wire (pin 1 for units with the electronic disconnect

option) from the transmitter sensor to the positive 12-35 VDC

power supply output.

2. Connect the black wire (pin 2 for units with the electronic disconnect

option) from the transmitter to the positive side of the loop load

(resistor, chart recorder, data acquisition board, meter, etc.). This

connection may be labeled "4-20mA Input" or "4-20mA (+)" on

some devices.

3. If applicable, connect the negative side of the loop load to negative

side of the power supply.

4. Apply power to the system.

5. If everything is operating correctly, the green LED on the sensor

will dimly illuminate and 4mA will be flowing in the loop. If there is

fluid flowing through the sensor, the current will be higher than

4mA and the LED will be quite bright.

If the LED does not illuminate:

check wiring terminations for good connections

check wiring polarity

verify correct supply voltage

ensure that the load impedance is within allowable limits

(5)

Page 6

Apply the DC supply voltage directly across the sensor wires. If

the LED does illuminate, the load is either: too great of impedance or an open circuit. If the LED does not illuminate, the sensor's lead wires or circuit are defective.

6. The installation should be complete.

Installation - Electronic (0-5VDC Output Only)

1. Connect the red wire (pin 1 for units with the electronic disconnect

option) from the sensor to the positive terminal of the 12-35 VDC

power supply.

2. Connect the black wire from the transmitter (pin 2 for units with the

electronic disconnect option) to the negative terminal of the 12-35

VDC power supply.

3. Connect the green wire from the transmitter (pin 3 for units with

electronic disconnect) to the (+) 0-5 V

DC input of the data acquisi-

tion device. This connection may be labeled "Voltage Input" or

"Analog Input" on some devices.

4. If applicable, connect the negative side of the power supply to the

negative side of the pulse input.

5. Apply power to the system.

6. If everything is operating correctly, the green LED will illuminate

brightly and the data acquisition device should show an increase in

flow rate as fluid starts flowing through the sensor.

If data acquisition device does not show an increase in flow rate:

check wiring terminations for good connections

verify that the LED is illuminated

verify that the DC supply voltage is between 12 and 35 V

DC

(6)

Page 7

Installation - Electronic (Pulse Output Only)

The flow sensor pulse output circuit is a three-wire DC-powered design

that transmits a frequency proportional to flow rate. The circuit operates on

5-24 V

DC and will consume a maximum of 25 mA from the power supply.

1. Connect the red wire (pin 1 for units with the electronic disconnect

option) from the sensor to the positive terminal of the 5-24VDC

power supply.

2. Connect the black wire from the transmitter (pin 2 for units with the

electronic disconnect option) to the negative terminal of the 5-24

V

DC power supply.

3. Connect the green wire from the transmitter (pin 3 for units with

electronic disconnect) to the (+) pulse input of the data acquisition

device. This connection may be labeled "Pulse In" or "DC Input"

on some devices.

4. If applicable, connect the negative side of the power supply to the

negative side of the pulse input.

5. Apply power to the system.

6. If everything is operating correctly, the data acquisition device should

begin "counting" pulses when fluid starts flowing through the sensor.

If the data acquisition device is not “counting”:

check wiring terminations for good connections

verify correct supply voltage and current

7. The installation should be complete. The relationship between the

frequency output and flow rate is shown in the graphs above.

(7)

Flow Rate vs. Frequency Output

60

50

40

30

20

Frequency (Hz)

10

0

Standard 1/2" NPTF Units

0246810121416

Flow Rate (GPM)

Flow Rate vs. Frequency Output

Standard 3/4" & 1" NPTF Units

60

50

40

30

20

Frequency (Hz)

10

0

0 102030405060

Flow Rate (GPM)

Page 8

Installation - Electronic (Relay Output Only)

1. Connect the red wire from the sensor to the positive terminal of the

12-35 V

DC power supply.

2. Connect the black wire from the transmitter to the negative terminal

of the 12-35 V

DC power supply.

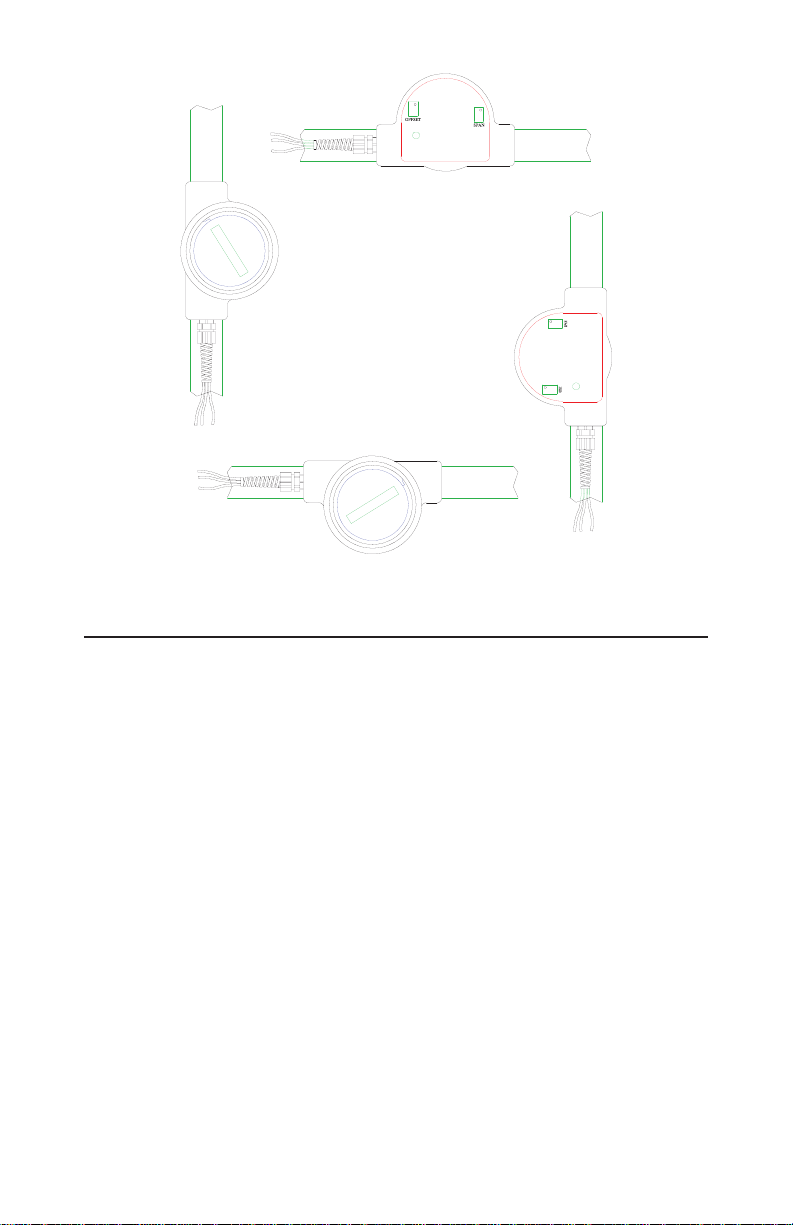

3. (Versions with stainless steel sensor body only) Be sure to properly

ground the flow sensor by using the ground screw shown

in Illustration 2 to

connect the sensor body

Earth ground. This step

may be unnecessary if

the piping system that the

flow sensor is plumbed

into is already connected

to Earth ground.

4. Wire the appropriate relay contacts to the load that is to be

switched per Table 1 below.

5. If the unit is operating correctly, the green power indication LED

and the red relay status LED should illuminate after the DC supply

voltage is turned on. As fluid flow is increased above the factoryadjusted set point, the red relay status LED should turn off.

If the LEDs do not illuminate when power is applied:

check wiring terminations for good connections

verify that the DC supply voltage is between 12 and 35 V

DC

Table 1.: Wiring Connections

(8)

Wire Color Connection

Red +12-35 VDC

Black DC Ground

Green Relay Common

White Relay Normally Closed Contact

Brown Relay Normally Open Contact

Illustration 2

GROUND SCREW

Page 9

Set Point Adjustment (Relay Output Only)

1) Adjust the flow rate through the line in which the flow sensor is

installed to the rate that corresponds to the desired relay trip point.

2) If the red LED on the back side of the sensor is not illuminated, use a

small flat bladed screwdriver to slowly turn the adjustment screw on the

set point potentiometer counter-clockwise until the red LED illuminates.

3) If the red LED is already illuminated, turn the adjustment screw on

the potentiometer clockwise until red LED turns off. Next, slowly

rotate the adjustment screw counter-clockwise until the red LED

illuminates.

4) Once the set point has been adjusted, the relay will operate as

shown in the Truth Table illustrated in Table 2 below.

Table 2.: Truth Table - Relay Operation

Ser vice and Maintenance

The sensor is designed to provide years of low maintenance service

in industrial environments. As with all mechanical rotating devices, the

bearing surfaces will wear with use. The life of the parts will depend

on factors such as cleanliness of the fluid, media, mounting orientation, temperature, fluid velocity and frequency of operation. The flow

sensor was designed with simple field-replacement of the rotating

parts in mind. To inspect or replace the rotating components:

(9)

Condition

Relay NC

Contact

Relay NO

Contact

Red LED Green LED

Flow rate<

set point

Open Closed Illuminated Illuminated

Flow rate >

set point

Closed Open

Not

Illuminated

Illuminated

Loss of power

to sensor

Open Closed

Not

Illuminated

Not

Illuminated

Page 10

1. Relieve pressure in the piping system.

2. Remove the retainer ring that secures the turbine access cover.

3. Remove the access cover with a pliers, taking care not to damage

the o-ring seal.

4. Pull out the turbine assembly and the shaft.

5. Inspect the shaft for things that may have wrapped around it.

6. Inspect the turbine bearing surface for wear and elongation.

Replace as necessary.

7. Clean any rust off of the magnets that may have accumulated.

8. Reassemble the unit by placing the turbine into the body cavity

with the two magnet pockets facing inward. Place the shaft into the

turbine hole and guide it into the retaining hole in the body cavity.

Lubricate the o-ring seal with some glycerin or other lubricant and

press it into the pocket of the body. Replace the retaining ring

securely before applying pressure to the system.

Circuit recalibration (4-20mA version):

1. Place a milliamp meter into the current loop.

2. Turn off the flow going though the sensor. Adjust the OFFSET

control for a reading of 4mA on the milliamp meter.

3. Adjust the flow rate though the meter to full flow rate. Adjust the

SPAN control for a reading of 20mA on the milliamp meter. The

two controls are not interactive, so further adjustment should not

be necessary.

Circuit recalibration (0-5V

DC version):

1. Place a voltmeter across the black & green wires of the sensor pigtail.

2. Turn off the flow going though the sensor. Verify a reading of less

than 50 mV

DC on the voltmeter.

3. Adjust the flow rate though the meter to full-scale flow rate. Adjust

the SPAN control for a reading of 20mA on the milliamp meter.

The two controls are not interactive, so further adjustment should

not be necessary.

(10)

Page 11

Mechanical Specifications

FLOW SENSOR WITH STAINLESS STEEL BODY

Maximum pressure: 200 PSI clear cover, 500 PSI SS cover

Maximum temperature: 225ºF

Measuring range*

1/2" NPT Ported: 0.5 - 15 GPM

3/4" & 1" NPT Ported: 1.5 - 50 GPM

Wetted materials: 316SS, acetal copolymer, Buna, PEEK

and polycarbonate

Non-wetted materials: Epoxy, Lexan®and PVC

FLOW SENSOR WITH POLYPROPYLENE BODY

Maximum pressure: 150 PSI

Maximum temperature: 150ºF

Measuring range*

1/2" NPT Ported:: 0.5 - 15 GPM

Wetted materials: 316SS, acetal copolymer, Buna, PEEK,

polycarbonate and polypropylene

Non-wetted materials: Epoxy, Lexan®and PVC

*Important: Chose a maximum flow rate. For 1/2": 5 - 15 maximum GPM.

For 3/4" and 1": 15 - 50 maximum GPM. Minimum flow rate will

be 10% of maximum flow rate. Example: If your maximum flow

rate is 8 GPM, the minimum flow rate would be .8 (8 x .1 = .8).

Thus, the correct flow range would be .8 - 8.0 GPM.

Electronic Specifications

ALL VERSIONS WITH 4-20 MA CIRCUIT

Power requirements: 12-35V

DC, 20mA

Load driving capacity: Max. Load (Ω) = 50(Power Supply Voltage - 12)

Trans. Distance: limited only by wire resistance & supply voltage

LED: provides power indication

Flow rate accuracy: ±2% of full scale

Repeatability: ±0.5% of scale

Resolution: infinite

Response time: 2 seconds to 90%

Over-current protection: self limiting at 30mA

Fail safe indication: 4 mA

(11)

Page 12

ALL VERSIONS WITH 0-5 VDC CIRCUIT

Power requirements: 12-35VDC, 20 mA

Maximum Current: 30 mA DC

Max. Trans. Distance: <200 feet recommended

Min. Load Resistance: 1000 Ω

Flow rate accuracy: 2% of full scale

Repeatability: 0.5% of scale

Resolution: infinite

Response time: 2 seconds to 90%

ALL VERSIONS WITH PULSE OUTPUT CIRCUIT

Power requirements: 5-24VDC, 20 mA

Maximum Current: 25 mA DC

Max. Trans. Distance: <200 feet recommended

Flow rate accuracy: 2% of full scale

Linearity: 0.5% of scale

Resolution: Infinite

Response time: < 100 mS

ALL VERSIONS WITH RELAY OUTPUT CIRCUIT

Power Requirements 12-35 VDC

Max. Trans. Distance < 200 feet recommended

Switch Contact Form C, 5A max @120 or 240 VAC

Hysteresis 5% of reading max.

(12)

Page 13

Dimension Drawings

1

Dimension with optional clear cover installed

2

Polypropylene version only

DIM 1/2" NPTF Ports 3/4" & 1" NPTF Ports

A 1.94" (49 mm) 3.06" (78 mm)

B 1.13" (29 mm) 1.33" (34 mm)

C 2.00" (51 mm) 2.46" (62 mm)

D 2.45" (62 mm) 2.78" (71 mm)

D

1

2.60" (66 mm) 2.88" (73 mm)

E 3.70" (94 mm) 5.25" (133 mm)

F 2.63" (67 mm) 3.80" (97 mm)

F

2

3.38" (86 mm) n/a

(13)

Page 14

NOTES:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

(14)

Page 15

WARRANTY/ DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds an

additional one (1) month grace period to the normal one (1) year product warranty to cover

handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper interfacing,

operation outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of

OMEGA’s control. Components in which wear is not warranted, include but are not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability

for any damages that result from the use of its products in accordance with information

provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by the company will be as specified and free of defects. OMEGA MAKES

NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this

order, whether based on contract, warranty, negligence, indemnification, strict liability or

otherwise, shall not exceed the purchase price of the component upon which liability is

based. In no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;

or (2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 16

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M-2582/0905

Loading...

Loading...