Page 1

www.omega.com

e-mail:

FPR1500

info@omega.

SERIES

corn

Page 2

OMEGAnet@

www.omega.com

On-Line Service

Internet e-mail

info@omega.com

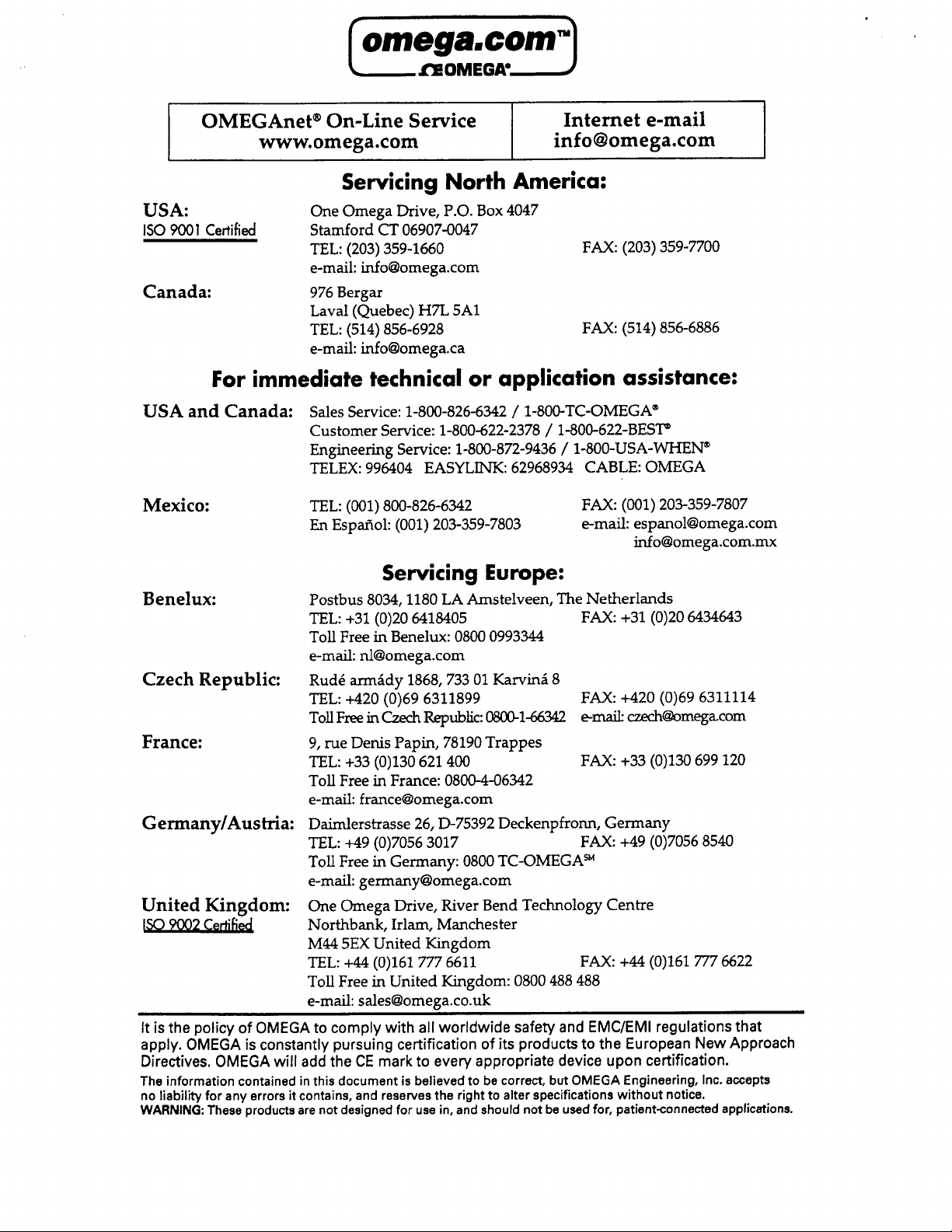

Servicing North America:

USA:

IS0

9001 Certified

Canada:

For immediate technical or application assistance:

USA and Canada:

Mexico:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

One

Omega Drive, P.O. Box 4047

Stamford CT 06907-0047

TEL: (203) 359-1660

e-mail:

976 Bergar

Lava1 (Quebec)

TEL: (514) 856-6928

e-mail:

Sales Service: l-800-826-6342

Customer Service: l-800-622-2378

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

TEL: (001) 800-826-6342

En

info@omega.com

infoQomega.ca

Espai=iol:

(001) 203-359-7803

H7L

5Al

/

l-800-TC-OMEGA”

FAX: (203) 359-7700

FAX: (514) 856-6886

l-800-622-BESTm

/

l-800-USA-WHENQ

/

FAX:

e-mail: espanol@omega.com

203-359-7807

(001)

info@omega.com.mx

Servicing Europe:

Postbus

TEL:

Toll Free in Benelux: 0800 0993344

e-mail:

Rude

TEL:

Toll Free in Czech Republic:

9, rue

TEL:

Toll Free in France:

e-mail: france@omega.com

DaimIerstrasse 26, D-75392 Deckenpfronn, Germany

TEL:

Toll Free in Germany: 0800

e-mail:

One Omega Drive, River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5EX United Kingdom

TEL:

Toll Free in United Kingdom: 0800 488 488

e-mail:

8034,118O

+31(0)20 6418405

nl@omega.com

armady 1868,733 01

+420

(0)69 6311899

Denis

(0)130

+33

(0)7056

+49

germany@omega.com

+44

(0)161777 6611

sales@omega.co.uk

LA Amstelveen, The Netherlands

Karvina 8

080&l&6342

Papin, 78190 Trappes

621400

0800-4-06342

3017

TC-OMEGA%

FAX:

e-mail:

FAX:

FAX:

FAX:

(0)20

+31

(0)69

+420 FAX:

czech@omegacom

(0)130

+33

(0)7056

+49

(0)161777 6622

+44

6434643

6311114

699 120

8540

It is the policy of OMEGA to comply with all worldwide safety and

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and

WARNING: These products are not designed for use in, and should not be used for, patientconnected applications.

resmms the right to alter specifications without notice.

EMUEMI regulations that

Page 3

Installation and Operating Instructions

Caution: It is recommended that this publication be read in its entirety

before performing any operation. Failure to understand and follow

these instructions could result in serious personal injury and/or

damage to the equipment.

General Description

The FPR-I 500 Series liquid service flow sensors are capable of

measuring low flow rates (Model FPR- 150 1) up to medium and

higher flow rates (Model FPR-1506). These sensors are suitable for a

wide variety of industrial, commercial, and laboratory flow

measurement applications.

Flow rate is unidirectional, and proper direction is indicated on the

serial number nameplate.

The FPR

I500 Series is similar to the

FPRl 000 Series but has

additional flexibility to handle low viscosity corrosive fluids

compatible with the

and

Kalrez@

(gasket).

FPRl500

wetted materials: Teflon@, sapphire,

The FPR1500 Series use a Pelton-type turbine wheel to determine

flow rate of the liquid. Rotation of the wheel is linear over a wide

range of flow. Electra-optical signals proportional to the turbine

wheel speed are converted to O-5 VDC analog signal and also to a

buffered square wave pulse output.

Installation Details

All units are calibrated with water. Do not exceed the flow rate

specified for long periods of time and DO NOT USE GASES for

flushing out sensor. Bearing life may be shortened by such abuse.

The flow must be in the direction indicated on the serial number

nameplate. Preferred mounting orientation is with the serial number

nameplate facing upward.

PFA Teflon@ fittings are provided. Be

careful to install tubing to these carefully to avoid damage or leaking.

Hand tighten! DO NOT overtighten fittings. See Figure

1.

I’Acili

2

Page 4

;

N u t

7

T ub i ng

)-- _

G aske t

Figure

I

Electrical Connection Details

-

C au ti on : DO NO T LET W I RE S t ouch each o t he r

t ape a ll

connec ti on s !

(+12

VDC)

Out

0 - S VDC

BRO W N

OU T i s fr o m ORANG E ( + ) t o

(-).

RED

BLACK

GREEN

YELLOW

ORANGE

BROWN

(-).

Standard

N o t es :

Power

Power Ground

Pulse Output

Filtered 0-SVDC Out

0-SVDC

Signal Ground

Po w e r i s fr o m R E D ( + ) t o BL ACK

S t anda r d

T he

+12

VDC Po w e r Supp l y s hou l d be r egu l a t ed . T he

FP R l 500 - P W

po w e r s upp l y i s r eco mm ended f o r u se .

Installation Details

T w o 4 - 40 t h r eaded ho l es a r e p r ov i ded on t he l o w e r s i de o f t he

FP R I

500 Se ri es f o r m oun ti ng (s ee F i gu r e 2 ).

T he r e a r e app r ox i m a t e l y 2 . 13 i nches be t w een m oun ti ng ho l e cen t e rs .

C o m p r ess i on f o r ces M U ST BE M A I N T A I N E D be t w een m oun ti ng

b r acke t s , o r l eakage m ay occu r.

Page 5

Flow

Ranges

Figure 2.

Mounting Holes

4-40 x 0.37

Inches Deep

Model Number

FPRISOI

FPR1502

FPRl503

FPR 1504

FPR1505

FPR1506 500-5000 ml/minute

Flow ranges specified for an equivalent flow of water at

Flow Range

15-

100 ml/minute

25-200 ml/minute

50-500 ml/minute

60-

1000 ml/minute

100-2000 ml/minute

Max AP

10-15

8-10

8-10

5-7

7

10

23OC.

Maximum differential pressure (AP) occurs at maximum rated flow

using water at 23°C. At 50% of rated flow AP is 0.25 times above

value, and at 20 % o f rated flo w AP is 0.04 times value.

More

Installntion Details

Be sure fluid lines are clean before connection the flow sensor. A 7

micron filter placed BEFORE the flow sensor is recommended for

protection.

Do not exceed the maximum rated pressure of the unit (see

-

specifications). Do not disassemble the flow sensor

damage and

improper operation may occur. Avoid dropping the flow sensor to

insure longest life of sapphire bearings. Entrapped air (or other

gases) in the liquid lines will cause measurement errors. Be sure all

gas is purged from the measurement lines.

PA(ili

4

Page 6

Specifications

Output signals:

a. O-5 VDC (orange is regular response,

yellow

filtered O-5 VDC for less noise). Load resistance

is

should be

-

b. Pulse

square wave pulses typically

Green wire to ground

FPRI501: 230 Hz

FPR1503: 325 Hz

FPR1505:

Power required: 12.5

Pressure rating: 60

Dimensions:

2.16”~2.32”~1.87”,

Electrical cable:

VDC

psig maximum operation

6-wire flexible color coded

stripped wire ends

Fittings:

PFA Teflon@ included. All

Temperature rating: 0-50°C

Temperature sensitivity:

Accuracy/Linearity:

Repeatability: +/-0.2%

+I-

.O%

+I-3

Full scale (from 20% to 100% of rated flow)

2.5K

ohms or higher.

-

typical pulses as follows:

FPR1502: 250 Hz

FPR1504: 370 Hz

375 Hz

+/-

2 volts regulated, at less than

FPR1506: 500 Hz

not including fittings

-

approx. 30” long,

l/4”

OD connections except for:

(l/8”

0.2%

OD), FPR1506 FPRl501

per

“C

(3/8”

Full scale

7.5

VDC peak

OD)

15

mA

3

Wetted materials:

Teflon@’ Sapphire, and

Applicable liquids:

Any low viscosity liquid compatible with wetted

Kalrez@

materials

Maintenance

Do not open or tamper with flow sensor. Evidence of tampering may

void warranty.

If problems arise with operation of the Flo-Sensor the

complete unit should be returned to the factory for servicing.

Options

Regulated 12 VDC Power Supply

‘a’l’cllon

and

FPRI

FPRl500-230PW

lialrcz

arc rcgistcrcd

SVAC

for 230VAC operation

ol’l!.l.

DuPont

m&marks

operation500-PW for 11

&

dc

CoNemourr

I’AGli 5

Page 7

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants

period of 13

grace

ensures that

months

period to the normal

from date of purchase.

one (1) year product warranty

OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA ’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA ’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and

OMEGA is

pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects.

REPRESENTATlONS

OF ANY KIND WHATSOEVER,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based.

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall

Component” under 10

CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

this unit to be free of defects in materials and workmanship

OMEGA’s

WARRANTY

adds an additional one (1) month

to cover handling and shipping time. This

triacs.

OMEGA MAKES NO OTHER WARRANTIES OR

EKPRESS

OR

IMPUED,

EKCEPT

THAT OF

In no event shall OMEGA be liable

it be used: (1) as a

way, OMEGA assumes no responsibility

for a

TITLE,

for

“Basic

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA ’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR

WARRANTY

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s

our customers the latest

OMEGA is a registered trademark of OMEGA ENGINEERING,

cb

Copyright 1999 OMEGA ENGINEERING,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

policy is to make running changes, not model changes, whenever an improvement is possible. This affords

RETURNS, please have the

in technology and engineering.

INC.

All rights reserved. This document may not be copied, photocopied,

NON-WARRANTY

FOR

REPAIRS, consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

INC.

Page 8

I

I

Find Everything Where Do

Need for

Process Measurement and Control?

OMEGA ...Of Course!

TEMPERATURE

&

&

@’

Thermocouple, RTD

0 Wire: Thermocouple, RTD

0 Calibrators

0 Recorders, Controllers

0 Infrared Pyrometers

&

Ice Point References

Thermistor Probes, Connectors, Panels

&

&

Thermistor

Process Monitors

Assemblies

PRESSURE, STRAIN

&

0

Transducers

0

0

0

Cells

Load

Displacement Transducers

Instrumentation

Strain Gages

&

Pressure Gages

&

Accessories

AND FORCE

FLOW/LEVEL

FIow

Computers

&

0

Rotameters, Gas Mass Flowmeters

0 Air Velocity Indicators

Turbine/PaddlewheeI

0

0

Totalizers

&

Batch Controllers

Systems

pH/CONDUCTIVITY

&

pH Electrodes, Testers

0

0 Ben&top/Laboratory Meters

0

Controllers, Calibrators, Simulators

&

Conductivity Equipment

pH

0

Industrial

Accessories

&

Pumps

DATA ACQUISITION

&

0

Data Acquisition

0 Communications-Based Acquisition Systems

0

Plug-in Cards for Apple, IBM

0

Datalogging

0 Recorders, Printers

Systems

Engineering Software

&

Compatibles

&

Plotters

HEATERS

0

Heating Cable

&

0

Cartridge

0

Immersion

0

Flexible Heaters

0

Laboratory Heaters

Strip Heaters

&

Band Heaters

ENVIRONMENTAL

MON ITORING AND CONTROL

&

Metering

Refractometers

Pumps

Air,

Industrial Water

pH,

Conductivity & Dissolved Oxygen Instruments

Control Instrumentation

&

Tubing

&

Water Monitors

Soil

&

Wastewater Treatment

M3415/0899

Loading...

Loading...