Page 1

= Caution, refer to instruction manual for more details

OMEGA FPM-5800 Flow Indicator Instructions

CAUTION!

Follow instructions carefully to avoid personal injury.

1. Compatible Sensor Wiring

FPM-5800

Sensor

Input

Red

Blk

Shld

FP-5100

FP-5300

silver (shield)

black (AC signal out)

red (AC signal out)

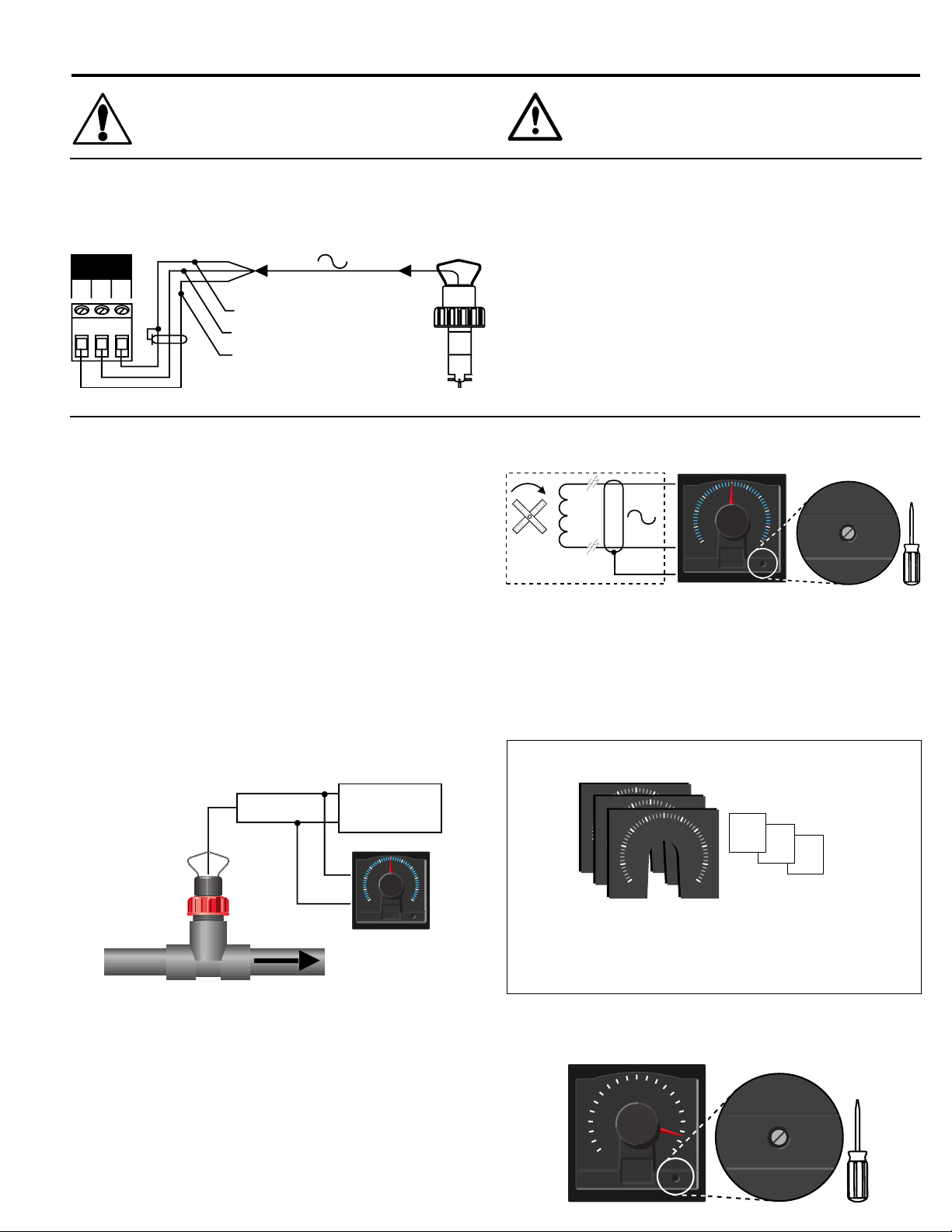

2. Calibration

The FPM-5800 flow metering system utilizes the AC signal amplitude

from the FP-5100 or FP-5300 sensor to drive the FPM-5800 meter.

The front panel meter movement adjustment (SPAN) is easily accessed

under the removable front window for simple calibration. A dial kit

with six dial ranges, assorted flow unit/multiplier decals, and dial

installation instructions is included for your convenience.

Equipment Required

• Frequency counter

• OMEGA FP-5100 or FP-5300 Sensor installed in the process line

• Maximum (stable) flow rate induced in the process line

• Standard and phillips head screwdriver

Procedure

1. Induce the maximum (stable) flow rate in your process line.

2. Using the frequency counter, monitor and record the FP-5100 or

FP-5300 sensor frequency output (Hz), see diagram below:

Red

Frequency

counter

Black

10

Technical Notes:

• Use 2-conductor shielded cable for sensor cable splices up to 60 m

(200 ft)

• Maintain cable shield through cable splice.

• Route sensor cable away from AC power lines.

FP-5100 or FP-5300 Circuit

Rotor

w/magnets

red

black

Shield

FPM-5800

5

4

3

2

1

0

GPM

X 100

6

7

8

9

10

SPAN

SPAN

4. Install the appropriate dial face and flow unit/multiplier decal

covering your flow system's maximum flow rate (step 3). Refer to

dial installation instructions included with dial kit.

Your instrument dial kit (included) contains the following:

Assorted

6 Dials:

0-2

0-4

0-6

0-8

0-10

0-100

1

1

5

6

4

5

6

4

3

3

2

2

0

1

1

0

0

0

7

7

2

2

SPAN

10

10

SPAN

m3/h

8

8

9

9

SPAN

SPAN

GPM

x 10

LPM

x 1,000

Unit/

multiplier

Decals:

X 10

X 100

X 1,000

X 10,000

Sensor Frequency = ___________________________ Hz

Technical note:

Sensor frequency MUST be greater than 45 Hz for full scale needle

deflection.

3. Calculate the actual maximum flow rate in your process line as

follows:

Maximum flow rate = Sensor frequency (step 2) X A-Factor

(Section 6)

Example: A flow system's maximum flow rate is 18.3 GPM. The

proper dial and flow unit/multiplier decal for this flow system is:

0 - 2 dial + GPM X 10 decal

5. Disconnect frequency counter, then access and adjust the "SPAN"

potentiometer to match the calculated maximum flow rate (step 3).

After adjustment, calibration is complete.

1

1.2

0.8

0.6

0.4

0.2

0

GPM

X 100

1.4

1.6

1.8

2

SPAN

SPAN

Page 2

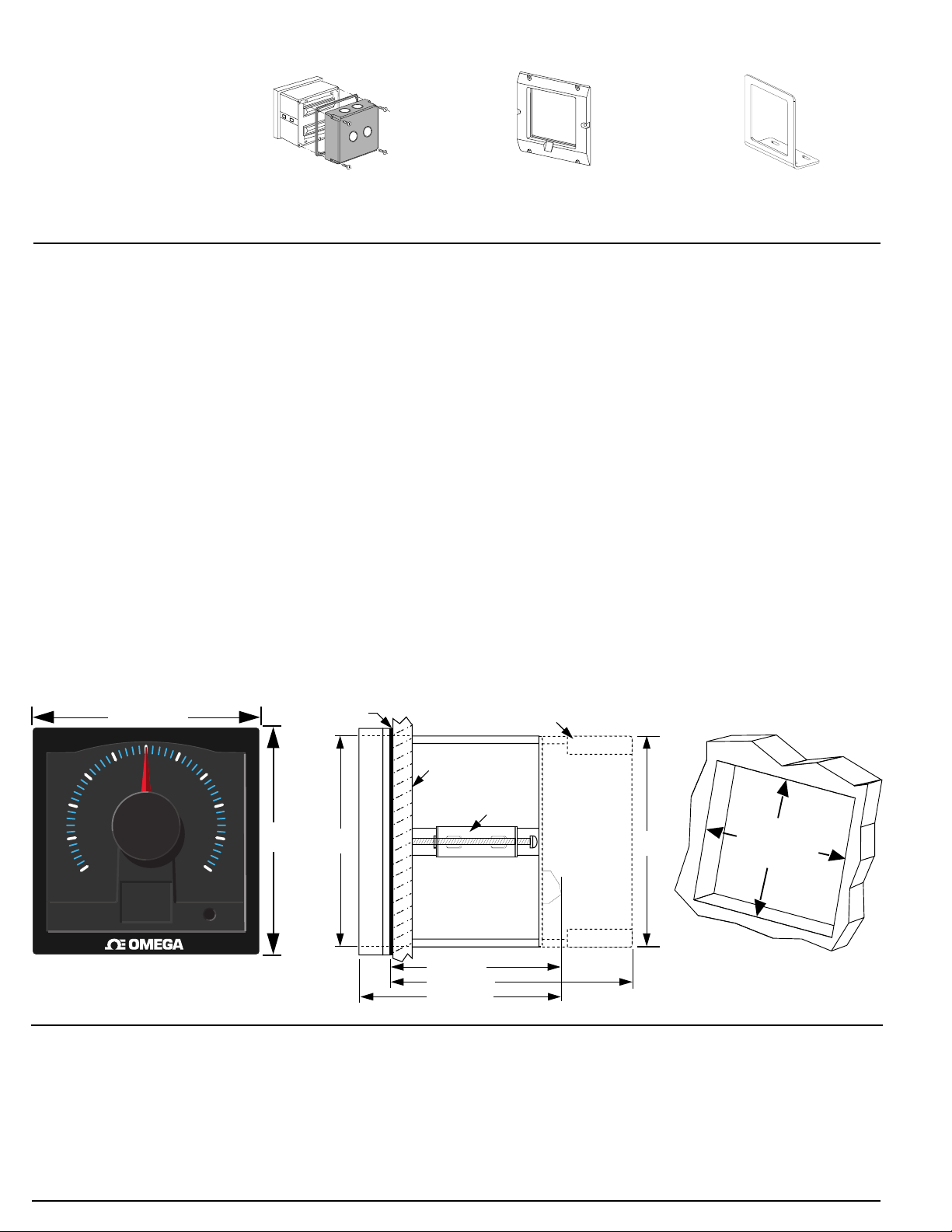

3. Parts and Accessories

There are no user replaceable

components in the FPM-5800.

Unauthorized repair attempts may

void warranty.

Splashproof rear cover,

FPM-5000-SBCK

4. Specifications

General

Sensor compatibility: OMEGA FP-5100 & FP-5300 series only

Minimum full scale range: 7 fps

Enclosure:

• Rating: NEMA 4X/IP65 front

• Dimensions: 1/4 DIN, 96 x 96 x 88 mm (3.8 x 3.8 x 3.5 in.)

• Case: ABS plastic

• Weight: Approximately 450 g (16 oz.)

Display:

• Type: Taut-band suspension meter movement, 250° deflection (not

suitable for prolonged exposure to vibration)

• Accuracy: ±2% of full scale

• Repeatability: ±1% of full scale

5 x 5 inch adapter plate

for OMEGA retrofit,

Optional surface mount bracket,

FPM-5000-MB

FPM-5000-RAK

Environmental

Operating temp.: -10 to 65 °C (14 to 149 °F)

Storage temp.: -15 to 80 °C (5 to 176 °F)

Relative humidity: 0 to 95%, non-condensing

Quality Standards

• FM, CSA, CE, UL listed

• Manufactured under ISO 9001

Electrical

Power: None

Noise immunity: EN50082-2

Noise emissions: EN55011

Safety: EN61010-1

Dimensions

91 mm

(3.6 in.)

Panel

Gasket

Mounting Panel

96 mm (3.8 in.)

3

2

1

0

5

4

6

7

8

9

96 mm

(3.8 in.)

10

GPM

X 100

SPAN

®

Front View

5. Maintenance

• Front window: Never wipe the front window with static retentive

cloths such as wool or polyester which may induce a static charge. If

a static charge develops on the window, the indication needle may

appear erratic or non-functional. When this occurs, clean the front

window with an anti-static cloth, or a soft cotton cloth and anti-static

spray, or a mild liquid soap solution to remove the static charge.

Optional Splashproof Rear Cover

Mounting Clamp (2 ea.)

88 mm

(3.5 in.)

92 x 92 mm

(3.62 x 3.62 in.)

SIDE VIEW

76 mm (3 in.)

96 mm (3.8 in.)

88 mm (3.5 in.)

Panel cutout

• Case: Clean the instrument case and front panel with a soft cotton

cloth dampened with a mild liquid soap solution.

Page 3

6. OMEGA FP-5100 or FP-5300 Flow Sensor A-Factors

-------------------------------------------- AA--FFAACCTTOORRSS ----------------------------------------------PIPE OMEGA

SIZE FITTING U.S. GPM LP M m3/h

SCH 80 PVC TEES FOR SCH 80 PVC PIPE

1/2 IN. FP-5305 0.1250 0.4729 0.0284

3/4 IN. FP-5307 0.2328 0.8812 0.0529

1 IN. FP-5310 0.3435 1.3002 0.0780

1 1/4 IN. FP-5312 0.7195 2.7233 0.1634

1 1/2 IN. FP-5315 1.0242 3.8767 0.2326

2 IN. FP-5320 1.8473 6.9920 0.4195

2 1/2 IN. FP-5325 2.7481 10.4016 0.6241

3 IN. FP-5330 4.4310 16.7714 1.0063

4 IN. FP-5340 7.8681 29.7807 1.7868

SCH 80 CPVC TEES FOR SCH 80 CPVC PIPE

1/2 IN. FP-5305C 0.1250 0.4729 0.0284

3/4 IN. FP-5307C 0.2328 0.8812 0.0529

1 IN. FP-5310C 0.3435 1.3002 0.0780

1 1/4 IN. FP-5312C 0.7195 2.7233 0.1634

1 1/2 IN. FP-5315C 1.0242 3.8767 0.2326

SCH 80 PVC SADDLES FOR SCH 80 PVC PIPE

2 IN. FP-5320S 1.8473 6.9920 0.4195

2 1/2 IN. FP-5325S 2.7481 10.4016 0.6241

3 IN. FP-5330S 4.4310 16.7714 1.0063

4 IN. FP-5340S 7.8681 29.7807 1.7868

6 IN. FP-5360S 14.4152 54.5614 3.2737

8 IN. FP-5380S 25.3115 95.8039 5.7482

SCH 80 PVC SADDLE ON SCH 40 PVC PIPE

2 IN. FP-5320S 2.1938 8.3035 0.4982

2 1/2 IN. FP-5325S 3.1789 12.0321 0.7219

3 IN. FP-5330S 4.7477 17.9702 1.0782

4 IN. FP-5340S 8.9177 33.7536 2.0252

6 IN. FP-5360S 16.0871 60.8897 3.6534

8 IN. FP-5380S 27.8714 105.4932 6.3296

------------------------------------------------------ 11 HHzz == -----------------------------------------------------

-

-

PIPE OMEGA

SIZE FITTING U.S. GPM LPM m3/h

COPPER/BRONZE BRAZOLETS ON SCH 40 PIPE

2 1/2 IN. FP-5325BR 3.1915 12.0798 0.7248

3 IN. FP-5330BR 4.9302 18.6606 1.1196

4 IN. FP-5340BR 8.6207 32.6293 1.9578

5 IN. FP-5350BR 11.4068 43.1749 2.5905

6 IN. FP-5360BR 16.2602 61.5447 3.6927

8 IN. FP-5380BR 28.1690 106.6197 6.3972

10 IN. FP-5381BR 44.4444 168.2222 10.0933

12 IN. FP-5382BR 62.5000 236.5625 14.1938

SCH 80 IRON SADDLES ON SCH 80 PIPE

2 IN. FP-5320 1.8541 7.0179 0.4211

2 1/2 IN. FP-5325 2.7003 10.2205 0.6132

3 IN. FP-5330 4.4709 16.9225 1.0154

4 IN. FP-5340 7.8329 29.6475 1.7789

5 IN. FP-5350 10.2389 38.7543 2.3253

6 IN. FP-5360 14.6699 55.5257 3.3315

8 IN. FP-5380 25.7511 97.4678 5.8481

10 IN. FP-5381 39.2157 148.4314 8.9059

12 IN. FP-5382 56.6038 214.2453 12.8547

SCH 80 IRON SADDLE ON SCH 40 PIPE

2 IN. FP-5320GIS 2.2371 8.4676 0.5081

2 1/2 IN. FP-5325GIS 3.1915 12.0798 0.7248

3 IN. FP-5330GIS 5.0042 18.9408 1.1364

4 IN. FP-5340GIS 8.7591 33.1533 1.9892

5 IN. FP-5350GIS 11.2570 42.6079 2.5565

6 IN. FP-5360GIS 15.9574 60.3989 3.6239

8 IN. FP-5380GIS 28.1690 106.6197 6.3972

10 IN. FP-5381GIS 44.4444 168.2222 10.0933

12 IN. FP-5382GIS 62.5000 236.5625 14.1938

-------------------------------------------- AA--FFAACCTTOORRSS -----------------------------------------------

------------------------------------------------------ 11 HHzz == -----------------------------------------------------

-

-

CARBON STEEL TEES ON SCH 40 PIPE

1/2 IN. FP-5305CS 0.1621 0.6134 0.0368

3/4 IN. FP-5307CS 0.2829 1.0709 0.0643

1 IN. FP-5310CS 0.4251 1.6091 0.0965

1 1/4 IN. FP-5312CS 0.9892 3.7442 0.2246

1 1/2 IN. FP-5315CS 1.3230 5.0077 0.3005

2 IN. FP-5220CS 2.2416 8.4845 0.5091

STAINLESS STEEL TEES ON SCH 40 PIPE

1/2 IN. FMG-5305 0.1671 0.6327 0.0380

3/4 IN. FMG-5307 0.2961 1.1209 0.0673

1 IN. FMG-5310 0.4719 1.7862 0.1072

1 1/4 IN. FMG-5312 0.9691 3.6682 0.2201

1 1/2 IN. FMG-5315 1.4848 5.6199 0.3372

2 IN. FMG-5320 2.6906 10.1839 0.6110

GALVANIZED IRON TEES ON SCH 40 PIPE

1 IN. FP-5310GI 0.5740 2.1724 0.1303

1 1/4 IN. FP-5312GI 0.9527 3.6060 0.2164

1 1/2 IN. FP-5315GI 1.2851 4.8642 0.2919

2 IN. FP-5320GI 2.0367 7.7089 0.4625

A-Factor Conversion Formulas:

1 U.S. gallon =

0.83267 Imperial gallon

0.003785 cubic meters

0.000003069 Acre feet

8.3454 pounds of water

Page 4

-------------------------------------------- AA--FFAACCTTOORRSS ----------------------------------------------PIPE OMEGA

SIZE FITTING U.S. GPM LPM m3/h

BRONZE TEES ON SCH 40 PIPE

1 IN. FP-5310BR 0.5740 2.1724 0.1303

1 1/4 IN. FP-5312BR 0.9527 3.6060 0.2164

1 1/2 IN. FP-5315BR 1.2851 4.8642 0.2919

2 IN. FP-5320BR 2.0367 7.7089 0.4625

COPPER TEE FITTINGS ON COPPER PIPE

1/2 IN.SK K FP-5305CU 0.1354 0.5124 0.0307

1/2 IN. SK L 0.1448 0.5480 0.0329

3/4 IN.SK K FP-5307CU 0.2828 1.0704 0.0642

3/4 IN. SK L 0.3140 1.1885 0.0713

1 IN.SK K FP-5310CU 0.4718 1.7857 0.1071

1 IN. SK L 0.5007 1.8950 0.1137

1 1/4 IN.SK K FP-5312CU 0.6801 2.5743 0.1545

1 1/4 IN. SK L 0.7022 2.6577 0.1595

1 1/2 IN.SK K FP-5315CU 1.0533 3.9869 0.2392

1 1/2 IN. SK L 1.0878 4.1171 0.2470

2 IN.SK K FP-5320CU 2.0429 7.7325 0.4639

2 IN. SK L 2.0975 7.9391 0.4763

STAINLESS STEEL WELDOLETS ON SCH 40 PIPE

2 1/2 IN. FMG-5325 3.1915 12.0798 0.7248

3 IN. FMG-5330 4.9302 18.6606 1.1196

4 IN. FMG-5340 8.6207 32.6293 1.9578

5 IN. FMG-5350 11.4068 43.1749 2.5905

6 IN. FMG-5360 16.2602 61.5447 3.6927

8 IN. FMG-5380 28.1690 106.6197 6.3972

10 IN. FMG-5381 44.4444 168.2222 10.0933

12 IN. FMG-5382 62.5000 236.5625 14.1938

------------------------------------------------------ 11 HHzz == -----------------------------------------------------

-

-

CARBON STEEL WELDOLETS ON SCH 40 PIPE

2 1/2 IN. FP-5325CS 3.1915 12.0798 0.7248

3 IN. FP-5330CS 4.9302 18.6606 1.1196

4 IN. FP-5340CS 8.6207 32.6293 1.9578

5 IN. FP-5350CS 11.4068 43.1749 2.5905

6 IN. FP-5360CS 16.2602 61.5447 3.6927

8 IN. FP-5380CS 28.1690 106.6197 6.3972

10 IN. FP-5381CS 44.4444 168.2222 10.0933

12 IN. FP-5382CS 62.5000 236.5625 14.1938

A-Factor Conversion Formulas:

1 U.S. gallon =

0.83267 Imperial gallon

0.003785 cubic meters

0.000003069 Acre feet

8.3454 pounds of water

Loading...

Loading...