Page 1

FPD1004 thru FPD1007,

FPD1034, FPD1105, FPD1204

and FPD1205

(includes -R Option)

SERIES HIGH FLOW

Positive Displacement Flowmeters

Page 2

Page 3

TABLE OF CONTENTS

Important Information ................................. 2

Installation .................................................. 2

Operation .................................................... 3

Electrical Connections ................................ 4

Service Instructions .................................... 5

Troubleshooting .......................................... 6

FPD1004 Aluminum Meter

Parts List ...............................................

FPD1204 Aluminum Meter

Parts List ...............................................

FPD1034 Aluminum Meter

Parts List ...............................................

FPD1105 PPS Meter

Parts List .............................................

FPD1005 Aluminum Meter

Parts List .............................................

FPD1205 Stainless Steel Meter

Parts List .............................................

FPD1006 Aluminum Meter

Parts List .............................................

FPD1007 Aluminum Meter

Parts List .............................................

7

7

9

11

13

13

15

17

To the owner:

Thank you for purchasing an OMEGA FPD

Series Flowmeter. Please take a few minutes to read through the manual before

installing and operating your meter. If you

have any problems with the meter, refer to

the Maintenance and Troubleshooting sections of the manual.

This manual contains connection and operating instructions for the OMEGA FPD

Series meters with pulse outputs. This includes the following models:

FPD1004 FPD1005

FPD1204 FPD1205

FPD1034 FPD1006

FPD1105 FPD1007

Part breakdowns for each model are located at the back of this manual. For models

with displays and/or 4-20 mA output, an

additional instruction manual is provided.

The OMEGA FPD Series flowmeter has

incorporated the oval rotor principal into its

design. This has proven to be a reliable and

highly accurate method of measuring flow.

Exceptional repeatability and high accuracy

over a wide range of fluid viscosities and

flowrates are features of the OMEGA FPD

Series flowmeter design. The low pressure

drop and high pressure rating, means the

OMEGA FPD Series flowmeters are suitable for both gravity and pump (in-line)

applications.

1

Page 4

IMPORTANT INFORMATION INSTALLATION

Please read this information

!

▲

carefully before use!

Before use, confirm the fluid to be used is

compatible with the meter or consult with

OMEGA for advice.

To prevent damage from dirt or foreign

matter, OMEGA recommends a Y or basket type 60 mesh strainer be installed as

close as possible to the inlet side of the

meter. (If required, contact OMEGA for further information.)

NOTE: When a strainer is installed it should

be regularly inspected and cleaned.

Failure to keep the strainer clean will

dramatically effect flowmeter performance.

To prevent damage to the meter, slowly fill

the system with fluid. This will prevent damage caused by air purge.

NOTE: Failure to do this could damage the

meter.

Maintenance can be performed on the liquid crystal display and pulse units without removing or isolating the meter from

the line. When maintenance to any other

part of the meter is required, the meter must

be isolated and the line pressure reduced.

The Reed Switch pulse unit can cause inaccurate rate counts when used with high

speed counters. It is advised that a debounce circuit be used or alternatively use

the Hall Effect sensor option.

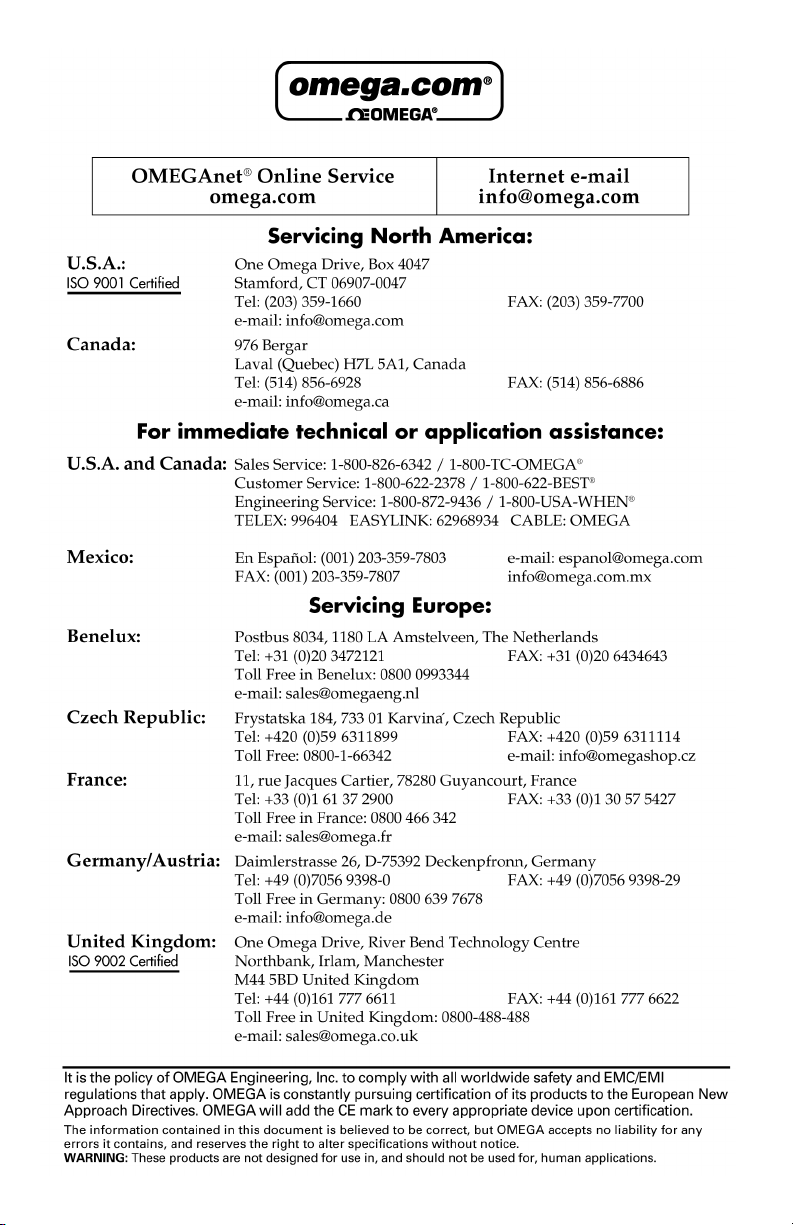

1. OMEGA recommends that when set

ting up pipework for meter installations,

a bypass line be included in the de-

sign. This provides the ability for a

meter to be removed for maintenance

without interrupting production. (See

Figure 1)

Figure 1

Bypass Line

Flow Outlet

2. Use thread sealant on all pipe threads.

3. For pump applications, ensure pipe

work has the appropriate working pressure rating to match the pressure output of the pump.

4. Install a wire mesh strainer (Y or bas-

ket type 60 mesh) as close as possible

to the inlet side of the meter.

5. Ensure that the meter is installed so

that the flow of the liquid is in the direction of the arrows embossed on the

meter body.

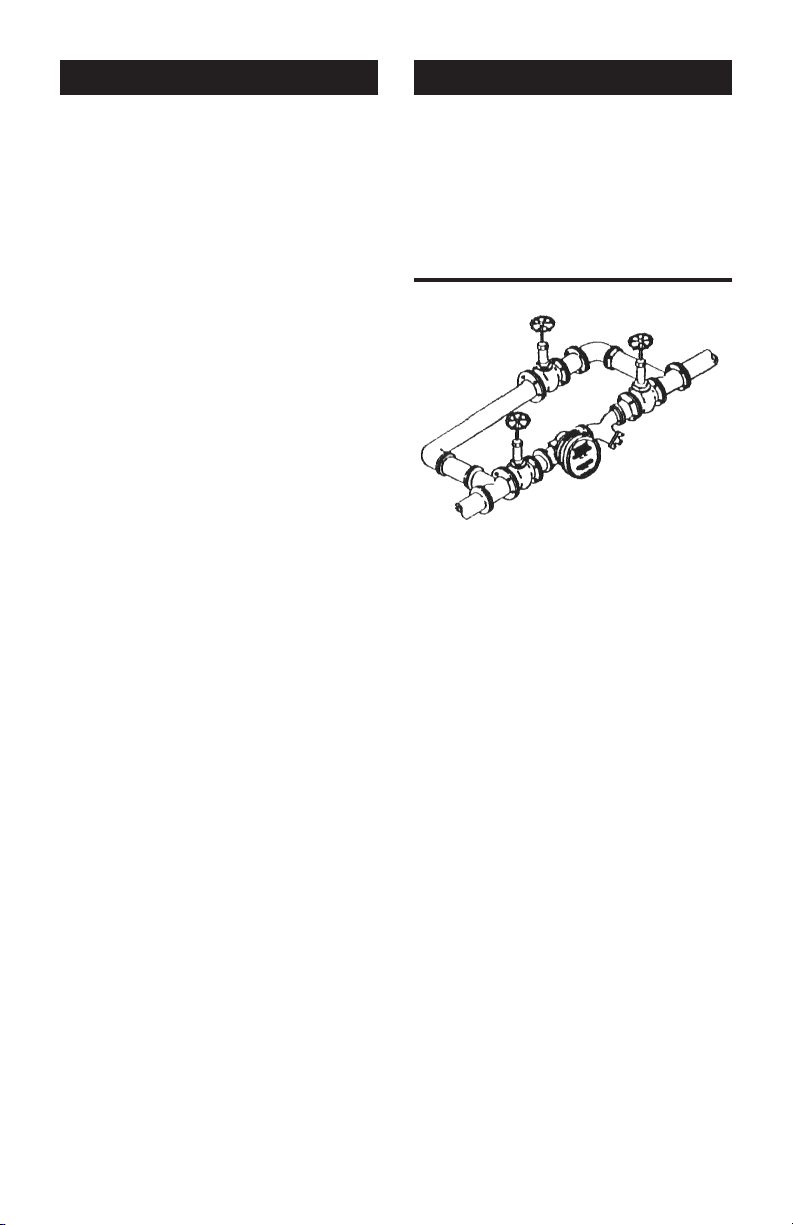

6. The meter can be installed in any orien

tation as long as the meter shafts are in

a horizontal plane. (See Figure 2) The

register assembly may be oriented to

suit the individual installation.

Flow Inlet

Strainer

-

-

2

Page 5

➧

R I G H T

Figure 2

OPERATION

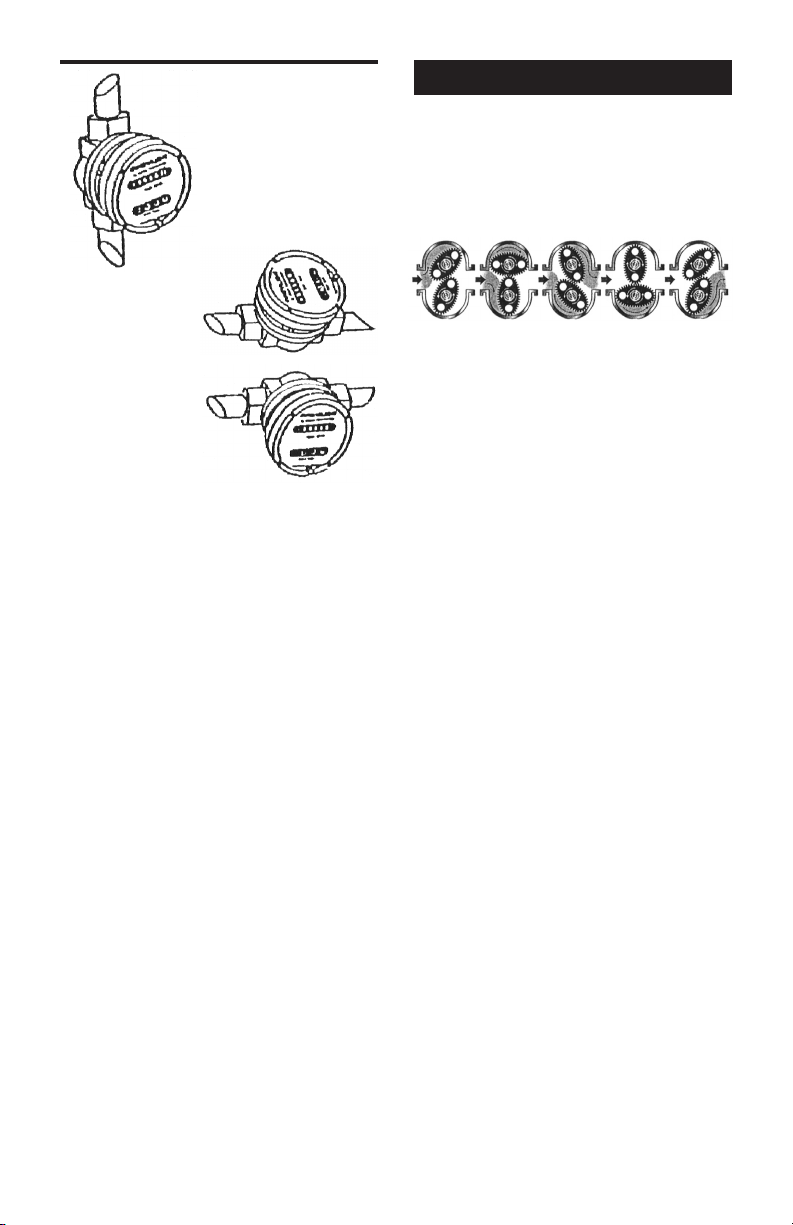

When fluid passes through the meter, the

rotors turn. The magnets which are located

in the rotors will pass across the pulser

circuit board (containing either Reed Switch

or Hall Effect sensors).

W R O N G

R I G H T

NOTE: Incorrect installation can cause pre-

mature wear of meter components

7. Do not overtighten meter connections.

8. It is important that after initial installa

tion you fill the line slowly, high speed

air purge could cause damage to the

rotors.

9. Test the system for leaks.

10. Check the strainer for swarf or foreign

material. After the first 200 liters, check

periodically – particularly if the flowrate

decreases.

➧

➧

A signal is received which is then sent by

the Pulse Circuit Board (PCB) to the relevant LC display or receiving instrument.

-

3

Page 6

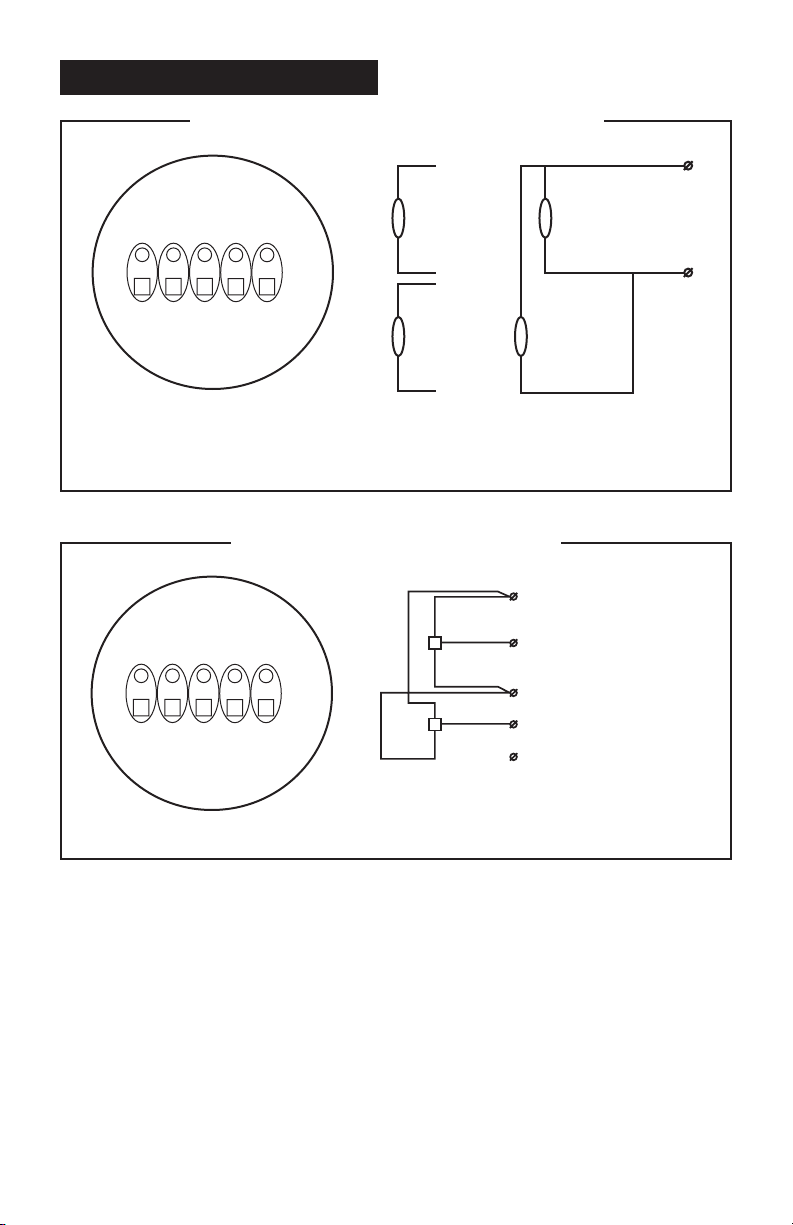

ELECTRICAL CONNECTIONS

1 2 3

4 5

Ground

1

2

3

4

1

2

3

4

1 2 3

4 5

1

2

3

4

5

Figure 3: Reed Switch Connections for PCB Terminals

Contact Rating 15 VA

Maximum Voltage 150 VDC

Figure 4: Hall Effect Sensor Connections

Configuration 1

2 x Pulse Outputs

Double Pulse Output

Hall Effect Voltage 4.5 to 24 VDC

Current Draw Minimum 4.6 mA

Output NPN Open Collector 25 mA

Configuration 2

Link 2 & 3 for

1 – HE Supply +

2 – HE 1 Signal

3 – HE Common –

4 – HE 2 Signal

5 – HE Ground

4

Page 7

SERVICE INSTRUCTIONS

Disassembly:

Ensure that the fluid supply to the meter is

disconnected, and the line pressure is released before disassembly. This step

is not required if you need to repair or

perform maintenance on the display or

PCB. In this case, there is no need to

isolate the meter from the flow. Refer to

the exploded parts diagram for your meter.

Units with Pulse Caps – Undo the con-

1.

duit connector, remove pulse cap and

remove the wires from the pulse terminal board.

Standard LC Display – Unscrew the four

large screws on top of the LC Display.

Carefully separate the LC Display from

the plastic housing and disconnect the

wires from the pulse terminal block.

2. Loosen the four cap screws and nuts

that hold down the meter cap. Remove

the screws and nuts and lift off the cap.

3. Remove the O-ring from the O-ring

groove in the meter cap.

4. Remove rotors.

Reassembly:

1. Before reassembling, check the condition of the rotors. Replace if necessary.

2. Rotors must be replaced in the proper

orientation (see list that follows). There

is no difference between rotor one or

rotor two.

1/2 in. Meters:

FPD1004 – Plugs Down

FPD1204 – Plugs Down

3/4 in. Meters:

FPD1034 – Plugs Up

1 in. Meters:

FPD1005 – Plugs Up

FPD1105 – Plugs Down

FPD1205 – Plugs Up

1-1/2 in. Meters:

FPD1006 – Plugs Up

2 in. Meters:

FPD1007 – Plugs Up

Figure 5

Rotor #1

Rotor #2

Rotors must be at 90° to each other

3. Replace the rotors onto the shafts at 90

degrees to each other. (See Figure 5)

Check their operation by turning either

of the rotors. If the rotors are not in mesh

correctly or do not move freely, remove

one of the rotors and replace correctly

at 90 degrees to the other rotor. Recheck the operation of the rotors.

4. Replace the O-ring back into the groove

in the meter cap. If the O-ring has grown

or is damaged in any way, replace it with

a new one.

5. Replace the meter cap. Insert the cap

head screws and fix nuts and tighten

in the sequence 1, 3, 2 and 4. Torque

screws to the appropriate pressure per

the chart that follows:

Body Screw

Material Torque

1/2 in. Meters:

FPD1004 Aluminum 31 in./lbs.

FPD1204 S.S. 80 in./lbs.

3/4 in. Meters:

FPD1034 Aluminum 31 in./lbs.

1 in. Meters:

FPD1005 Aluminum 31 in./lbs.

FPD1105 PPS 80 in./lbs.

FPD1205 S.S. 80 in./lbs.

1-1/2 in. Meters:

FPD1006 Aluminum 75 in./lbs.

2 in. Meters:

FPD1007 Aluminum 150 in./lbs.

6. The replacement of cables and connectors are a reversal of the disassembly

procedure. Replace conduit fitting if re-

quired.

5

Page 8

7. Test the meter by turning the rotors with

a finger or by applying very low air pres

sure (a good breath) to one end of the

meter, before returning the meter to the

line.

Pulse Circuit Board (PCB) Notes:

The PCB board is fastened to the meter

cap by two screws and stand off’s. All care

and caution should be taken when removing or handling the PCB as both the Reed

Switch and Hall Effect sensors are fragile.

Individual Reed Switches or Hall Effect sensors are not available as replacement parts

and are only available with the PCB.

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

FLUID WILL NOT 1. Foreign matter blocking Dismantle meter, clean rotors. Strainer must

FLOW THROUGH rotors be fitted in-line.

THE METER

2. Line strainer blocked Clean strainer.

3. Damaged rotors Replace rotors. Strainer must be fitted in-line.

4. Meter connections over- Re-adjust connections.

tightened

5. Fluid is too viscous See specifications for rated viscosity.

REDUCED FLOW 1. Line strainer partially Clean strainer.

THROUGH THE blocked

METER

2. Fluid is too viscous See specifications for rated viscosity.

METER READING 1. Fluid flowrate is too low See specifications for flow range.

INACCURATE or too high

2. Fluid is too viscous See specifications for rated viscosity.

3. Excess wear caused by Check meter body and rotors. Replace as

incorrect installation required.

METER NOT 1. Faulty Hall Effect sensor Replace PCB Board.

GIVING A PULSE

SIGNAL 2. Faulty Reed Switch Replace PCB Board.

3. Magnets failed Replace rotors.

6

Page 9

METER PARTS LISTING

Models: FPD1004 - Aluminum

FPD1204 - Stainless Steel

1

2

3

4

5

6

7

8

9

u = Recommended Spare

Parts to stock.

Bold Text = Indicates Stainless Steel

model parts.

Item Rec. Part or Set

No. Qty. Parts

1 1 MS298N Meter Body 1/2 in. NPT (Aluminum)

1 1 MS337N Meter Body 1/2 in. NPT (Stainless Steel)

2 1 u BS145TE O-Ring (PTFE)

2 1 u BS145V O-Ring (Fluorocarbon)

3 2 u MS342S Rotors PPS (Polyphenylene Sulfide Resins)

3 2 u MS342HS High Viscosity Rotors (PPS)

4 1 MS297 Meter Cap (Aluminum)

4 1 MS338 Meter Cap (Stainless Steel)

5 1 u MS344-R PCB (Standard Reed Switch)

5 1 u MS344-HE PCB (Hall Effect Sensor)

6 2 MS284S PCB Board Screws

7 4 u MS346S Meter Cap Screws (Standard)

7 4 u MS350S Meter Cap Screws (Stainless Steel)

8 1 u MS340S Pulser Cap Gasket

9 1 MS296 Pulser Cap (Aluminum) 20mm Conduit Thread

9 1 MS296N Pulser Cap (Aluminum) 1/2 in. NPT Thread

9 1 MS339 Pulser Cap (S/Steel) 20mm Conduit Thread

9 1 MS339N Pulser Cap (S/Steel) 1/2 in. NPT Thread

10 2 MS347S Pulser Cap Screw (Stainless Steel)

(Order from this column only) Part Description

10

7

Page 10

SPECIFICATIONS

FPD1004 & FPD1204

Flow Ranges (LPM or GPM)

Above 5 centipoise

Below 5 centipoise

Accuracy of Reading

Maximum Viscosity* 1000 Centipoise

Maximum Operating Pressure

Maximum Operating Temperature

Pulse Type

Pulses per Liter/Gallon

Single Sensor (K-factor)

1 to 30 / 0.26 to 8

3 to 25 / 0.8 to 6.60

± 0.5%

5500 kPa / 800 PSI / 55 Bar

80°C / 176°F (Stainless Steel 120°C / 248°F)

Reed Switch Sensor or Hall Effect Sensor

112 PPL / 424 PPG

* Unless High Viscosity Rotors are fitted.

DIMENSIONS

8

Page 11

METER PARTS LISTING

Model: FPD1034 - Aluminum

1

2

3

4

5

6

u = Recommended Spare

Parts to stock.

Bold Text = Indicates Stainless Steel

model parts.

Item Rec. Part or Set

No. Qty. Parts

1 1 MS779NS Meter Body 3/4 in. NPT (Aluminum)

2 1 u BS235TE O-Ring (PTFE)

2 1 u BS235V O-Ring (Fluorocarbon)

3 2 u MS370S Rotors (PPS) (Polyphenylene Sulfide Resins)

4 1 MS150 Meter Cap (Aluminum)

5 1 u MS28-R PCB (Standard Reed Switch)

5 1 u MS28-HE PCB (Hall Effect Sensor)

6 4 MS111S PCB Board Screws

7 6 u MS114S Meter Cap Screws (Standard)

8 1 u MS300 Pulser Cap Gasket

9 1 MS160 Pulser Cap (Aluminum) 20mm Conduit Thread

9 1 MS160N Pulser Cap (Aluminum) 1/2 in. NPT Thread

10 4 MS115S Pulser Cap Screw (Stainless Steel)

(Order from this column only) Part Description

7

8

9

10

9

Page 12

SPECIFICATIONS

FPD1034

Flow Ranges (LPM or GPM)

Above 5 centipoise

Below 5 centipoise

Accuracy of Reading

Maximum Viscosity

Maximum Operating Pressure

Minimum Operating Temperature

Maximum Operating Temperature

Pulse Type

Pulses per Liter/Gallon

Single Sensor (K-factor)

3 to 60 / 0.8 to 15.85

8 to 53 / 2.1 to 14

± 0.5%

1000 Centipoise

5500 kPa / 800 PSI / 55 Bar

-10°C (+14°F)

+80°C (+176°F)

Reed Switch Sensor or Hall Effect Sensor

52 PPL / 197 PPG

DIMENSIONS

126mm

10

133mm

86mm

112mm

18mm

21.5mm

Page 13

METER PARTS LISTING

1

2

3

Model: FPD1105 - PPS

4

5

6

7

8

9

10

u = Recommended Spare

Parts to stock.

Bold Text = Indicates Stainless Steel

model parts.

Item Rec. Part or Set

No. Qty. Parts

1 1 MS352N Meter Body 1 in. NPT (PPS) & Hastalloy C Shafts

2 1 u BS235TE O-Ring (PTFE)

2 1 u BS235V O-Ring (Fluorocarbon)

3 2 u MS370S Rotors (PPS)

4 1 MS405R Meter Cap (PPS)

5 1 u MS368-R PCB (Standard Reed Switch)

5 1 u MS344-HE PCB (Hall Effect Sensor)

6 2 MS284S PCB Board Screws

7 4 u MS350S Meter Cap Screws (Stainless Steel)

8 1 u MS340S Pulser Cap Gasket

9 1 MS406R Pulser Cap (PPS) 16mm Conduit Thread

9 1 MS406R-N Pulser Cap (PPS) 1/2 in. NPT Thread

10 2 MS347S Pulser Cap Screw (Stainless Steel)

33 1 MS111S Earthing Screw

34 4 MS497S Nut (S/Steel) - not shown, recessed in body

(Order from this column only) Part Description

33

11

Page 14

SPECIFICATIONS

FPD1105

Flow Ranges (LPM or GPM)

Above 5 centipoise

Below 5 centipoise

Accuracy of Reading

Maximum Viscosity

Maximum Operating Pressure

Maximum Operating Temperature

Pulse Type

Pulses per Liter/Gallon

Single Sensor (K-factor)

3 to 80 / 0.8 to 21

8 to 70 / 2 to 18.5

± 0.5%

1000 Centipoise

1000 kPa / 150 PSI / 10 Bar

80°C / 176°F

Reed Switch Sensor or Hall Effect Sensor

52 PPL / 197 PPG

DIMENSIONS

12

Page 15

METER PARTS LISTING

Models: FPD1005 - Aluminum

FPD1205 - Stainless Steel

1

2

3

4

5

6

u = Recommended Spare

Parts to stock.

Bold Text = Indicates Stainless Steel

model parts.

Item Rec. Part or Set

No. Qty. Parts

1 1 MS187N Meter Body 1 in. NPT (Aluminum)

1 1 MS185N Meter Body 1 in. NPT (Stainless Steel)

1 1 MS187F Meter Body 1 in. ANSI 150 lb. Flange (Aluminum)

1 1 MS185F Meter Body 1 in. ANSI 150 lb. Flange (S/Steel)

1 1 MS185T Meter Body 1 in. Tri-Clover

2 1 u BS235TE O-Ring (PTFE)

2 1 u BS235V O-Ring (Fluorocarbon)

3 2 u MS50-1S Rotors (Stainless Steel)

3 2 u MS50-1HS High Viscosity Rotors (Stainless Steel)

4 1 MS150 Meter Cap (Aluminum)

4 1 MS250 Meter Cap (Stainless Steel)

5 1 u MS28-R PCB (Standard Reed Switch)

5 1 u MS28-HE PCB (Hall Effect Sensor)

6 4 MS111S PCB Board Screws

7 6 u MS114S Meter Cap Screws (Standard)

7 6 u MS200S Meter Cap Screws (Stainless Steel)

8 1 u MS300 Pulser Cap Gasket

9 1 MS160 Pulser Cap (Aluminum) 20mm Conduit Thread

9 1 MS160N Pulser Cap (Aluminum) 1/2 in. NPT Thread

9 1 MS170 Pulser Cap (S/Steel) 20mm Conduit Thread

10 4 MS115S Pulser Cap Screw (Stainless Steel)

(Order from this column only) Part Description

7

®

Flange (S/Steel)

8

9

10

13

Page 16

SPECIFICATIONS

FPD1005 & FDP1205

Flow Ranges (LPM or GPM)

Above 5 centipoise

Below 5 centipoise

Accuracy of Reading

Maximum Viscosity* 1000 Centipoise

Maximum Operating Pressure

Maximum Operating Temperature

Pulse Type

Pulses per Liter/Gallon

Single Sensor (K-factor)

Double Sensor (K-factor)

6 to 120 / 1.6 to 32

10 to 100 / 2.6 to 26

± 0.5%

NPT – 5500 kPa / 800 PSI / 55 Bar or Flange Rule

80°C / 176°F (Stainless Steel 120°C / 248°F)

Reed Switch Sensor or Hall Effect Sensor

36 PPL / 136.3 PPG

72 PPL / 272.6 PPG

* Unless High Viscosity Rotors are fitted.

DIMENSIONS

14

Page 17

METER PARTS LISTING

Model: FPD1006 - Aluminum

1

2

3

4

5

6

u = Recommended Spare

Parts to stock.

Bold Text = Indicates Stainless Steel

model parts.

Item Rec. Part or Set

No. Qty. Parts

1 1 MS191N Meter Body 1-1/2 in. NPT (Aluminum)

1 1 MS191F Meter Body 1-1/2 in. ANSI 150 lb. Flange (Alum.)

2 1 u BS243TE O-Ring (PTFE)

2 1 u BS243V O-Ring (Fluorocarbon)

3 2 u MS58S Rotors (PPS)

3 2 u MS58HS High Viscosity Rotors (PPS)

4 1 MS220 Meter Cap (Aluminum)

5 1 u MS201-R PCB (Standard Reed Switch)

5 1 u MS201-HE PCB (Hall Effect Sensor)

6 4 MS284S PCB Board Screws

7 6 u MS116S Meter Cap Screws (Standard)

8 1 u MS300 Pulser Cap Gasket

9 1 MS160 Pulser Cap (Aluminum) 20mm Conduit Thread

9 1 MS160N Pulser Cap (Aluminum) 1/2 in. NPT Thread

10 4 MS115S Pulser Cap Screw (Stainless Steel)

(Order from this column only) Part Description

7

8

9

10

15

Page 18

SPECIFICATIONS

FPD1006

Flow Ranges (LPM or GPM)

Above 5 centipoise

Below 5 centipoise

Accuracy of Reading

Maximum Viscosity* 1000 Centipoise

Maximum Operating Pressure** NPT – 5500 kPa / 800 PSI / 55 Bar

Maximum Operating Temperature

-10°C to 120°C (14°F to 248°F) (Stainless Steel)

Pulse Type

Pulses per Liter/Gallon

Single Sensor (K-factor)

Double Sensor (K-factor)

10 to 250 / 2.6 to 66

15 to 235 / 4 to 62

± 0.5%

-10°C to 80°C (14°F to 176°F) (Aluminum)

Reed Switch Sensor or Hall Effect Sensor

14.5 PPL / 54.9 PPG

29 PPL / 109.8 PPG

* Unless High Viscosity Rotors are fitted.

** Meter conforms to PED 97/23/EC CAT 1.

DIMENSIONS

16

Page 19

METER PARTS LISTING

Model: FPD1007 - Aluminum

1

2

3

4

5

6

u = Recommended Spare

Parts to stock.

Bold Text = Indicates Stainless Steel

model parts.

Item Rec. Part or Set

No. Qty. Parts

1 1 MS283F Meter Body 2 in. ANSI 150 lb. Flange (Alum.)

1 1 MS283N Meter Body 2 in. NPT (Aluminum)

2 1 u BS252TE O-Ring (PTFE)

2 1 u BS252V O-Ring (Fluorocarbon)

3 2 u MS147S Rotors (PPS)

3 2 u MS147HS High Viscosity Rotors (PPS)

4 1 MS230 Meter Cap (Aluminum)

5 1 u MS201-R PCB (Standard Reed Switch)

5 1 u MS201-HE PCB (Hall Effect Sensor)

6 4 MS284S PCB Board Screws

7 6 u MS243S Meter Cap Screws (Standard)

8 1 u MS300 Pulser Cap Gasket

9 1 MS160 Pulser Cap (Aluminum) 20mm Conduit Thread

9 1 MS160N Pulser Cap (Aluminum) 1/2 in. NPT Thread

10 4 MS115S Pulser Cap Screw (Stainless Steel)

(Order from this column only) Part Description

7

8

9

1

0

17

Page 20

SPECIFICATIONS

FPD1007

Flow Ranges (LPM or GPM)

Above 5 centipoise

Below 5 centipoise

Accuracy of Reading

Maximum Viscosity* 1000 Centipoise

Maximum Operating Pressure** NPT – 5500 kPa / 800 PSI / 55 Bar or Flange Rule

Maximum Operating Temperature

-10°C to 120°C (14°F to 248°F) (Stainless Steel)

Pulse Type

Pulses per Liter/Gallon

Single Sensor (K-factor)

Double Sensor (K-factor)

15 to 350 / 4 to 92

33 to 300 / 9 to 79

± 0.5%

-10°C to 80°C (14°F to 176°F) (Aluminum)

Reed Switch Sensor or Hall Effect Sensor

6.68 PPL / 25.3 PPG

13.4 PPL / 50.6 PPG

* Unless High Viscosity Rotors are fitted.

** Meter conforms to PED 97/23/EC CAT 1.

DIMENSIONS

18

Page 21

Page 22

Page 23

Page 24

M-4 102 / 0608

Loading...

Loading...