Page 1

FPD1001B thru FPD1003B,

FPD1102B and FPD1103B,

FPD1201B thru FPD1203B

SERIES LOW FLOW

Positive Displacement Flowmeters

Page 2

Page 3

To the owner:

Red - Supply

Black - Ground

White - Output

X

V

cc

1 2 3

Please take a few minutes to read through

the manual before installing and operating

your meter. Always retain this manual for

future reference. If you have any problems

with the meter, refer to the Maintenance and

Troubleshooting sections of the manual.

This manual contains connection and operating instructions for the OMEGA FPD

Series meters. This includes the following

models:

FPD1001B FPD1202B-IP

FPD1201B FPD1003B

FPD1201B-IP FPD1203B

FPD1002B FPD1103B

FPD1202B FPD1203B-IP

FPD1102B

Part breakdowns for each model are located at the back of this manual. For models

with displays and /or 4-20 mA output, an

additional instruction manual is provided.

The flowmeter has incorporated the oval rotor principal into its design. This has proven

to be a reliable and highly accurate method

of measuring flow. Exceptional repeatability

and high accuracy over a wide range of

fluid viscosities and flowrates are features

of the oval rotor design. With low pressure

drop and high pressure rating, oval rotor

flowmeters are suitable for both gravity and

pump (in-line) applications.

NOTE: To prevent damage to the meter,

slowly fill the system with fluid (this will

prevent damage caused by air purge).

Failure to do this could damage the

meter.

To reduce pressure build up, turn off the

pump at the end of each day.

INSTALLATION

1. Use thread sealant on all pipe threads.

2. Ensure the meter is installed so that

rotor shafts are always in a horizontal

plane. Flow is bi-directional.

3. OMEGA recommends use of flexible

connections.

4. Extreme care must be taken when

installing the meter. Pipe strain or

overtightening the meter connections

can cause meter damage.

PULSER DETAILS

Your meter is equipped with both a Hall

Effect sensor and a Reed Switch sensor.

The equipment you are sending the pulse

signal to will determine which sensor you

use. The wires for the unused sensor will

not be used.

OPERATION

Please read this information

!

▲

carefully before use!

Before use, confirm the fluid to be used is

compatible with the meter. Refer to Industry

fluid compatibility charts or consult your

local representative for advice.

To prevent damage from dirt or foreign

matter it is recommended that a Y or basket type 200 mesh strainer be installed as

close as possible to the inlet side of the

meter. Contact your local representative

for advice.

Hall Effect Sensor Specifications:

•

4.5V to 24V (4.6 ~ 9 mA) operation

needs only an unregulated supply.

•

Open collector 25 mA output NPN

compatible with digital logic.

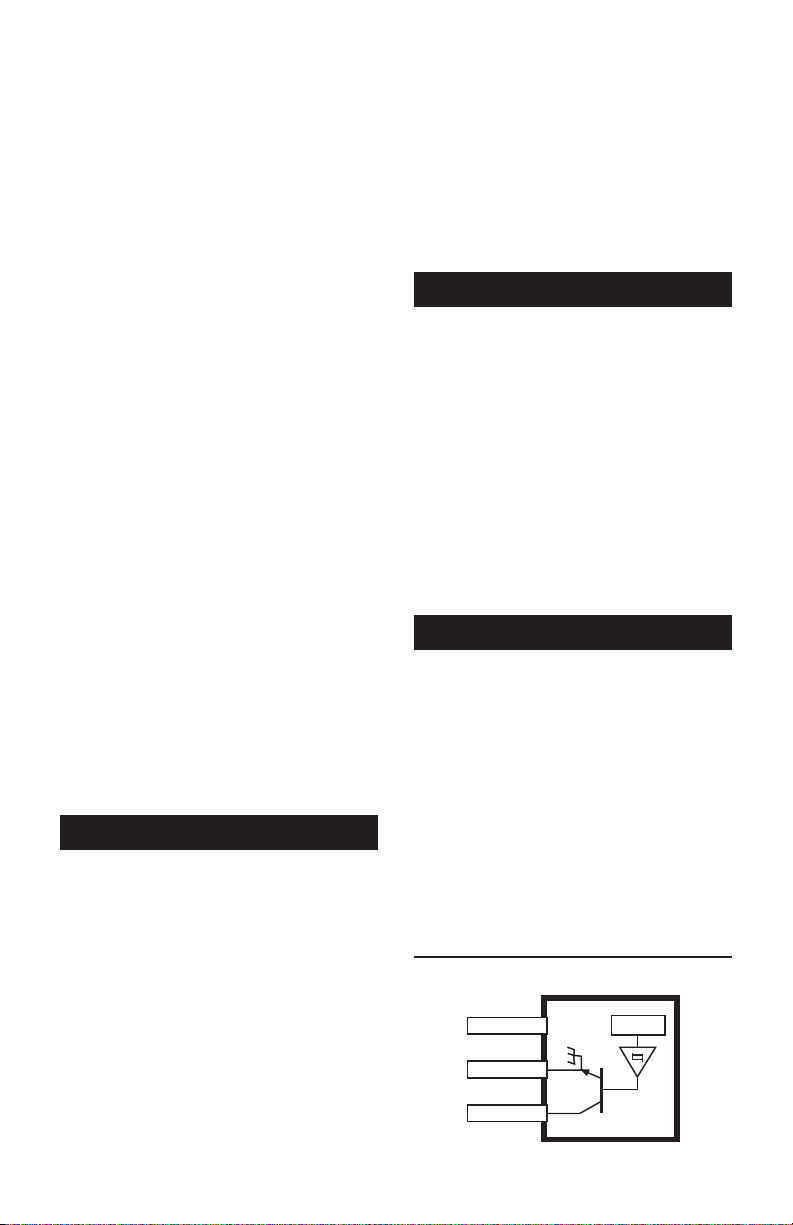

Figure 1

Hall Effect Sensor Wiring Details

1

Page 4

Reed Relay Specifications:

Alignment Marks

Body

Rotors

O-Ring

Inner Plate &

PCB Assembly

O-Ring

Meter

Cap

Screws

Inner Plate &

PCB Assembly

Wire

Clip

Seal

•

Wiring: Yellow wire / Green wire.

•

Two wire SPST N/O.

•

Switching voltage: 30 VDC; Maximum

current: 0.5 AMPS.

MAINTENANCE

CAUTION

Ensure the fluid is isolated from the

meter to be repaired.

CAUTION

Ensure the fluid line is depressurized

before commencing repairs.

CAUTION

Ensure electrical wiring is isolated

and disconnected before commencing repairs.

CAUTION

To prevent damage to the meter during re-commissioning, slowly fill the

piping system with fluid before starting the pumping system.

CAUTION

Refer to the Sensor Wiring section for

details.

Pulse Meter Disassembly

1. Loosen and remove four Phillips head

or cap head screws (see Figure 2).

2. Remove the meter cap and O-ring.

3. Remove the inner plate and PCB assembly. Refer to the PCB Removal

section for additional details.

4. Remove the O-ring.

5. Remove the rotors. Note the position

of the rotor with the magnet or grub

screws.

6. Clean and inspect all components,

replace as necessary.

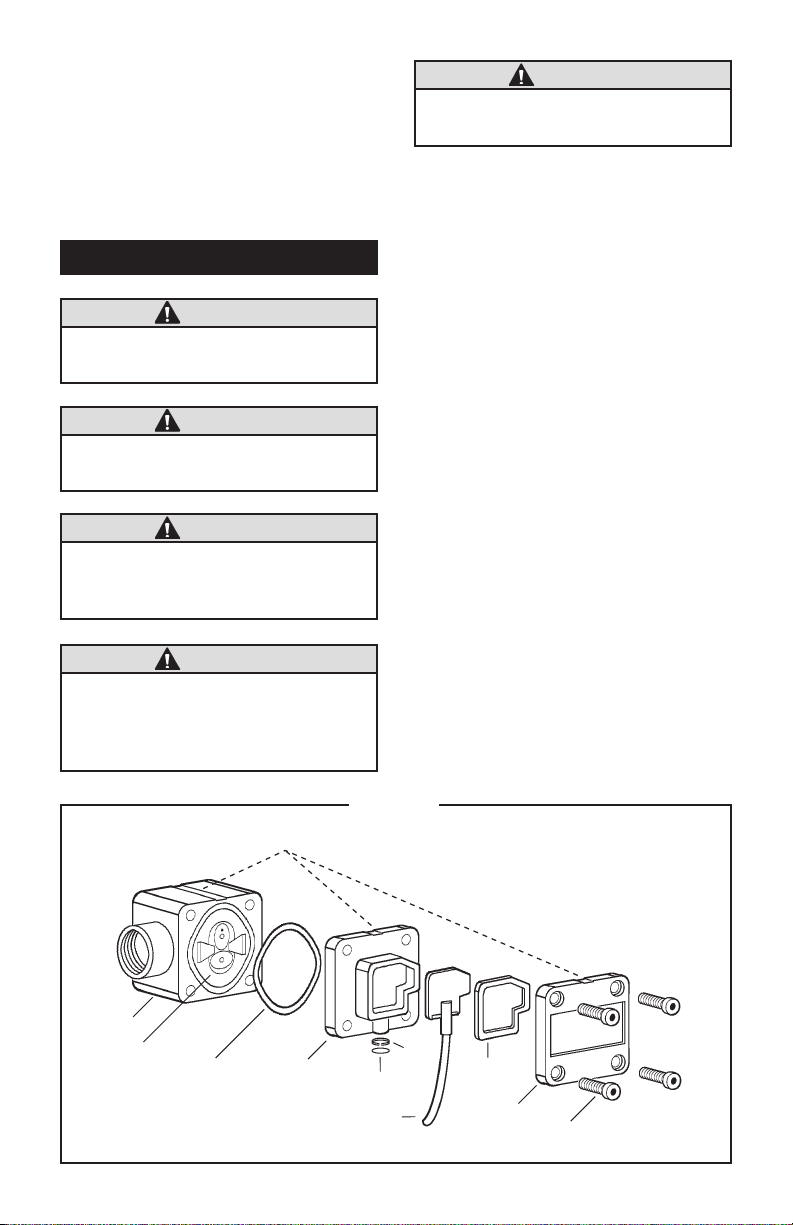

Pulse Meter Reassembly

1. Replace the rotors. Refer to Figure 3 or

Figure 4 for correct orientation. Rotate

the rotors by hand to ensure correct

engagement.

Figure 2

2

Page 5

Figure 3

Rotors with

Magnets

Alignment Marks

Magnets

NOT Visible

Magnets

Visible

GM001 Meters

Figure 4

GM002 & GM003 Meters

Models: FPD1001B & FPD1201B Models: FPD1002B, FPD1003B, FPD1102B,

2. Fit the O-ring into the O-ring groove in

the meter body.

3. Combine the inner plate assembly

(Items 4-7). Form the O-ring into the inner plate and replace the meter cap.

NOTE: Ensure all the alignment marks are

lined up with the mark on the body

(see Figure 2).

4. Replace and tighten the four bolts

to the required torque. Refer to Bolt

Torque in the Specifications section

for details.

5. Check meter function using low air

pressure.

6. Restore the fluid and reconnect the

wiring as detailed in the Installation and

Pulser Details sections.

PCB Removal

CAUTION

The PCB contains components that

are sensitive to static shock. Ensure

all items and maintenance staff are

grounded before working on the PCB.

1. Using a thin blade or similar tool, remove

the wire clip and seal (see Figure 2).

2. While lifting the PCB with the blade

inserted near the alignment marks,

carefully push the cable into the inner

plate. Continue to lift the back of the

PCB until all components on the PCB

clear the inner plate.

FPD1103B, FPD1202B & FPD1203B

3. Grasp the cable near the PCB and pull

the cable through the opening in the

inner plate until the cable ferrules are

near the inner plate opening.

4. Push the cable ferrules into the PCB

opening, one at a time, and remove

the cable.

PCB Replacement

CAUTION

The PCB contains components that

are sensitive to static shock. Ensure

all items and maintenance staff are

grounded before working on the PCB.

1. Feed the cable ferrules, one at a time,

through the cable opening in the inner

plate.

2. Gently pull the cable through the inner

plate opening until the PCB almost

touches the inner plate.

3. While pulling the cable, tilt the PCB into

the recess in the inner plate. Ensure

components underneath the PCB do

not come into contact with the inner

plate.

4. Pull the cable until the cable ties contact the inner plate. Gently push the

PCB down into the housing.

5. Press the seal into the inner plate cable

entry, followed by the wire clip. Ensure

they both are seated correctly.

3

Page 6

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

FLUID WILL NOT 1. Foreign matter blocking Dismantle meter, clean rotors. Strainer must

FLOW THROUGH rotors be fitted in-line.

THE METER

2. Line strainer blocked Clean strainer.

3. Damaged rotors Replace rotors. Strainer must be fitted in-line.

4. Meter connections over- Readjust connections.

tightened

REDUCED FLOW 1. Line strainer partially Clean strainer.

THROUGH THE blocked

METER

2. Fluid is too viscous Maximum viscosity 1000 centipoise.

METER READING 1. Fluid flowrate is too low See specifications for minimum and maximum

INACCURATE or too high flowrates.

2. Air in fluid Bleed air from system.

3. Excess wear caused by Check meter body and rotors.

incorrect installation

METER NOT 1. Faulty Hall Effect sensor Replace meter cap.

GIVING A PULSE or Reed Switch

SIGNAL

2. Faulty magnet Replace rotors.

3. Rotors installed in wrong Refer to correct rotor positioning and

position assembly instructions.

4

Page 7

WETTED MATERIALS

Component Wetted Materials

Body:

FPD1001B, FPD1002B & FPD1003B Aluminum

FPD1102B & FPD1103B PPS

FPD1201B, FPD1202B & FPD1203B 316L Stainless Steel

Shafts:

FPD1001B, FPD1002B, FPD1003B, 316 Stainless Steel

FPD1201B, FPD1202B & FPD1203B

FPD1102B & FPD1103B Hastalloy (optional)

Rotors:

FPD1001B, FPD1002B, FPD1003B, PM Stainless Steel

FPD1201B, FPD1202B & FPD1203B

FPD1102B & FPD1103B PPS

Bushings:

FPD1001B & FPD1002B Sapphire

FPD1002B, FTB1003B, FPD1102B, Zirconia

FPD1103B, FPD1202B & FPD1203B

Inner Plate / Meter Cap:

FPD1001B, FPD1002B & FPD2003B PPS

FPD1102B & FPD1103B

FPD1201B, FPD1202B & FPD1203B Stainless Steel

Magnet:

All models Samarium Cobalt

5

Page 8

DISPLAY PARTS LISTING

Models: FPD1001B

FPD1201B

FPD1201B- IP

1

4

5

2

3

u = Recommended Spare Parts (See Figure 2).

Bold Text = Indicates Stainless Steel model parts.

Item Rec. Part or Set

No. Qty. Parts (Order from this column only) Part Description

1 1 MS600NS Meter Body & Shafts NPT Stainless Steel

1 1 MS605NS Meter Body & Shafts NPT Aluminum

2 1 MS427S Inner Plate

2 1 MS427-1S Inner Plate, Stainless Steel

3 4 MS98S Screws, Aluminum

3 4 MS113S Screws, Stainless Steel

3 4 MS277S Screws, Stainless Steel - I.P.

4 1 MS810S(SS) Rotor Assembly Stainless Steel

5 1 BS029VS O-Ring (Viton)

5 1 BS029TES O-Ring (Perfluoroelastomer)

1 u N359S O-Ring (NBR)

1 u N359S Wire Clip

1 u MS271AS PCB Assembly

1 u MS428S Meter Cap (FPD1001B)

1 u MS248-1S Meter Cap (FPD1201B & FPD1201B-IP)

6

Page 9

SPECIFICATIONS

Stainless Steel Models Aluminum Models

Port Size 1/8 in. 1/8 in.

Accuracy of Reading ± 1% ± 1%

Maximum Viscosity 1000 Centipoise 1000 Centipoise

Flow Ranges (LPH or GPH)

Above 5 centipoise 0.5 to 50 / 0.132 to 13.2 0.5 to 50 / 0.132 to 13.2

Below 5 centipoise 2 to 50 / 0.528 to 13.2 2 to 50 / 0.528 to 13.2

K-Factor (Pulses per Litre/Gallon) 1552 / 5875.32 1552 / 5874.32

Max. Operating Pressure SS = 1000 kPa / 150 PSI / 10 Bar 500 kPa / 75 PSI / 5 Bar

I.P. = 5500 kPa / 800 PSI / 55 Bar

Strainer Size (Recommended) 200 Mesh 200 Mesh

Bolt Torque SS = 44 in-lb. 17.7 in-lb.

I.P. = 80 in-lb.

Min. Operating Temperature -10°C / +14°F -10°C / +14°F

Max. Operating Temperature 120°C / 248°F 60°C / 176°F

Pulse Type Hall Effect Sensor/Reed Switch Hall Effect Sensor/Reed Switch

Cable Length 1 meter / 3.28 feet 1 meter / 3.28 feet

Weight 602 g / 21.23 oz. 308 g / 10.86 oz.

Dimensions (W x D x H) 60mm x 50mm x 50mm 60mm x 50mm x 50mm

Face to Face 67mm / 2.63 in. 60mm / 2.36 in.

7

Page 10

DISPLAY PARTS LISTING

Models: FPD1002B

FPD1202B

FPD1102B

FPD1202B-IP

1

2

5

4

3

u = Recommended Spare Parts (See Figure 2).

Bold Text = Indicates Stainless Steel model parts.

Item Rec. Part or Set

No. Qty. Parts (Order from this column only) Part Description

1 1 MS1S-2S Meter Body & Shafts NPT Stainless Steel

1 1 MS1AL-2S Meter Body & Shafts NPT Aluminum

1 1 MS1R-2S Meter Body & Shafts NPT PPS

1 1 MS1R-2C Meter Body & Hast Shafts NPT PPS

2 1 MS812S (SS) / MS811S (PPS) Rotor Assembly Stainless Steel (FPD1202B)

2 1 MS812S (SS) / MS811S (PPS) Rotor Assembly Stainless Steel (FPD1202B-IP)

2 1 MS810S (SS) Rotor Assembly Aluminum (FPD1002B)

2 1 MS811S (PPS) / MS812S (SS) Rotor Assembly PPS (FPD1102B)

3 4 MS98S Screws, Aluminum/PPS

3 4 MS113S Screws, Stainless Steel

3 4 MS277S Screws, Stainless Steel - I.P.

4 1 MS427S Inner Plate

4 1 MS427-1S Inner Plate Stainless Steel

5 1 BS029VS O-Ring (Viton)

5 1 BS029TES O-Ring (Perfluoroelastomer)

1 u N359S Wire Clip

1 u MS271AS PCB Assembly

1 u N359S O-Ring (NBR)

1 u MS428S Meter Cap

1 u MS428-1S Meter Cap

8

Page 11

SPECIFICATIONS

Stainless Steel & PPS Models Aluminum Models

Port Size 1/4 in. 1/4 in.

Accuracy of Reading ± 1% ± 1%

Maximum Viscosity 1000 Centipoise 1000 Centipoise

Flow Ranges (LPH or GPH)

Above 5 centipoise 2 to 100 / 0.53 to 26.4 2 to 100 / 0.53 to 26.4

Below 5 centipoise 5 to 100 / 1.32 to 26.4 5 to 100 / 1.32 to 26.4

K-Factor (Pulses per Litre/Gallon) 1000 / 3785 1000 / 3785

Max. Operating Pressure SS = 1000 kPa / 150 PSI / 10 Bar 500 kPa/ 75 PSI / 5 Bar

I.P. = 5515 kPa /800 PSI / 55 Bar

PPS = 500 kPa / 75 PSI / 5 Bar

Strainer Size (Recommended) 200 Mesh 200 Mesh

Bolt Torque SS = 44 in-lb. 17.7 in-lb.

PPS = 8.8 in-lb.

I.P. = 80 in-lb.

Min. Operating Temperature -10°C / +14°F -10°C / +14°F

Max. Operating Temperature SS = 120°C / 248°F 80°C / 176°F

PPS = 80°C / 176°F

I.P. = 120°C / 248°F

Pulse Type Hall Effect Sensor/Reed Switch Hall Effect Sensor/Reed Switch

Cable Length 1 meter / 3.28 feet 1 meter / 3.28 feet

Weight SS = 240 g / 8.5 oz. 310 g / 11 oz.

PPS = 600 g / 21.2 oz.

Dimensions (W x D x H) 60mm x 50mm x 50mm 60mm x 50mm x 50mm

Face to Face SS = 67mm / 2.63 in. 60mm / 2.36 in.

PPS = 64mm / 2.52 in.

9

Page 12

DISPLAY PARTS LISTING

1

4

5

2

Models: FPD1003B

FPD1203B

FPD1103B

FPD1203B-IP

u = Recommended Spare Parts (See Figure 2).

Bold Text = Indicates Stainless Steel model parts.

Item Rec. Part or Set

No. Qty. Parts (Order from this column only) Part Description

1 1 MS2S-2S Meter Body & Shafts NPT Stainless Steel

1 1 MS2AL-2S Meter Body & Shafts NPT Aluminum

1 1 MS2R-2S Meter Body & Shafts NPT PPS

1 1 MS2R-2C Meter Body & Hast Shafts NPT PPS

2 1 MS427S Inner Plate

2 1 MS427-1S Inner Plate Stainless Steel

3 4 MS98S Screws, Aluminum

3 4 MS113S Screws, Stainless Steel

3 4 MS277S Screws, Stainless Steel - I.P.

4 1 MS814S (SS) / MS813S (PPS) Rotor Assembly Stainless Steel (FPD1203B &

FPD1203-IP)

4 1 MS810S (SS) Rotor Assembly Aluminum (FPD1003B)

4 1 MS813S (PPS) / MS814S (SS) Rotor Assembly PPS

4 1 MS814HS Rotor Assembly Stainless Steel High Viscosity

5 1 BS029VS O-Ring (Viton)

5 1 BS029TES O-Ring (Perfluoroelastomer)

1 u N359S O-Ring (NBR)

1 u N359S Wire Clip

1 u MS271AS PCB Assembly

1 u MS428S Meter Cap

1 u MS428-1S Meter Cap

3

10

Page 13

SPECIFICATIONS

Stainless Steel & PPS Models Aluminum Models

Port Size 1/4 in. 1/4 in.

Accuracy of Reading ± 1% ± 1%

Max. Viscosity 1000 Centipoise 1000 Centipoise

High Viscosity Option Yes Yes

Flow Ranges (LPH or GPH)

Above 5 centipoise 15 to 500 / 4 to 32 15 to 500 / 4 t o 32

Below 5 centipoise 25 to 500 / 6 to 132 25 to 500 / 6 to 132

K-Factor (Pulses per Litre/Gallon) 400 / 1514 400 / 1514

Max. Operating Pressure SS = 1000 kPa/150 PSI/10 Bar 500 kPa/75 PSI/5 Bar

PPS = 500 kPa/75 PSI/5 Bar

I.P. = 5515 kPa/800 PSI/55 Bar

Strainer Size (Recommended) 200 Mesh 200 Mesh

Bolt Torque SS = 44 in-lb. 17.7 in./lbs.

PPS = 8.8 in-lb.

I.P. = 80 in-lb.

Min. Operating Temperature -10°C / +14°F -10°C / +14°F

Max. Operating Temperature SS = 120°C / 248°F 80°C / 176°F

PPS = 80°C / 176°F

I.P. = 120°C / 248°F

Pulse Type Hall Effect Sensor/Reed Switch Hall Effect Sensor/Reed Switch

Cable Length 1 meter / 3.28 feet 1 meter / 3.28 feet

Weight 240 g / 8.5 oz. 320 g / 12 oz.

600 g / 21.2 oz. (PPS)

Dimensions (W x D x H) 60mm x 50mm x 50mm 60mm x 50mm x 50mm

Face to Face SS = 67mm / 2.63 in. 60mm / 2.36 in.

PPS = 64mm / 2.52 in.

11

Page 14

Page 15

Page 16

M-4 686 / 0808

Loading...

Loading...