Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

FPD2000 Series

Positive Displacement Flow Meters

Shop online at

Page 2

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

FPD2000 Series - Positive Displacement Flowmeters

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Fluid Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Flowmeter Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation and Technical Data Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

FPD2001 through FPD2004

FPD2011 through FPD2014

FPD2021 through FPD2024

Installation and Technical Data Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

FPD2005 through FPD2015

Installation and Technical Data Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

FPD2001-A through FPD2005-A

FPD2011-A through FPD2015-A

FPD2021-A through FPD2024-A

Maintenance Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

FPD2001 through FPD2004

FPD2001-A through FPD2004-A

FPD2011 through FPD2014

FPD2011-A through FPD2014-A

FPD2021 through FPD2024

FPD2021-A through FPD2024-A

Maintenance Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FPD2005

FPD2015

FPD2015-A

Page 4

Page 5

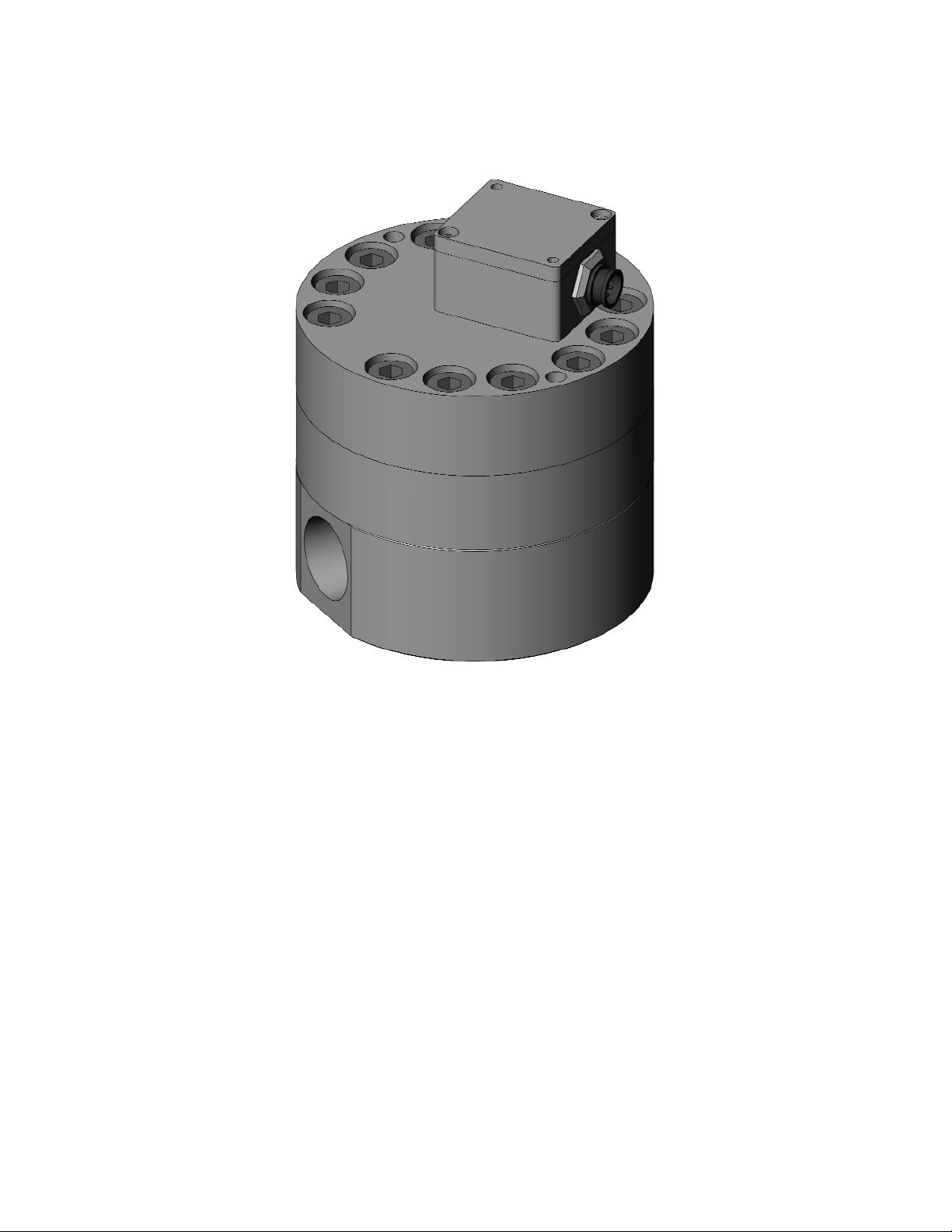

FPD2000 Series Positive Displacement Flow Meters

General Description:

Omega’s positive displacement gear flow meters are similar in design to a gear pump. The principle of

operation is reversed; instead of the gears driving the medium, the medium drives the gears. A nonintrusive hall-effect sensor detects the movement of the gear and as each gear tooth passes the sensor

a square wave pulse is produced and a discrete volume of liquid is measured. The resulting pulse train

is proportional to the actual flow rate and provides a highly accurate representation of the fluid flow. All

meters are designed with highly wear resistant moving parts to provide exceptionally long service life.

Filtration:

Depends upon model

Fluid Compatibility:

The materials of construction are stainless steel or high strength aluminum housing, stainless steel gears

and stainless steel bearings. The fluids should be compatible with these materials.

-1-

Page 6

Installation Instructions:

The preferred flow direction is etched or marked by an arrow on the meter as this is the flow direction

in which the meter was calibrated however; the flow meters have bi-directional flow capabilities. Damage

will not occur from reverse flow.

The preferred orientation is to mount the meter vertically although horizontal mounting is acceptable

if conditions deter vertical orientation. There is no need for straight run piping upstream or downstream

of the flow meter.

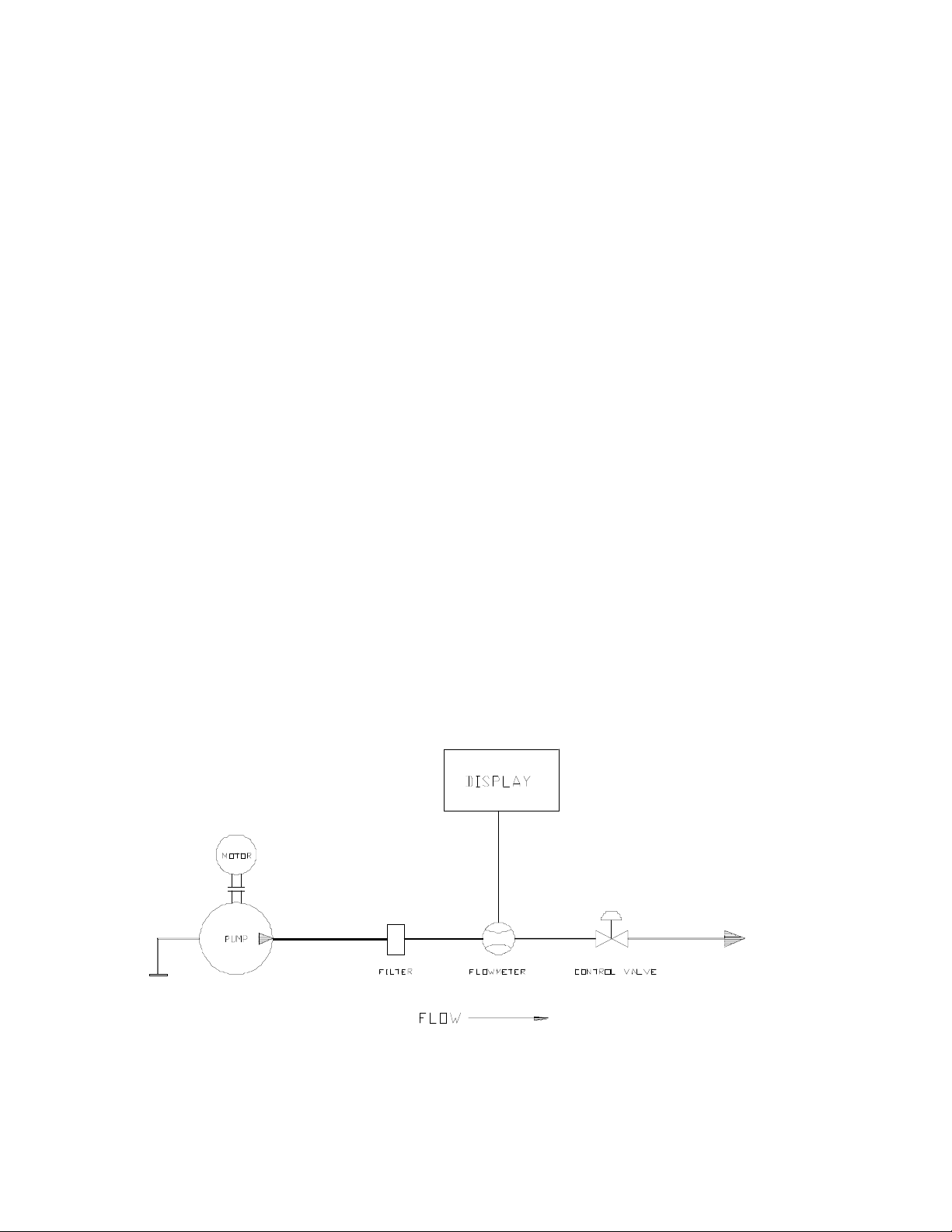

Install the meter upstream from control valves and fluid regulators if possible - see Fig.1. Back

pressure is necessary for stable running.

Eliminate all dirt, debris and metal shavings from the piping as the liquid must be free from any particles larger than allowed by the manufacturer's specifications. Any recommended filtration should be

installed before operation as potential plugging most often occurs at startup.

If possible install a bypass around the meter and flush existing piping with the appropriate solvent

before first use - see Fig.1.

Review the pickup instructional guide prior to installation. Locate the pickup & wiring away from

A/C motors, actuators, heaters, relays etc. Use only shielded cable and do not take power from the same

circuits as other devices. Ensure clean power supplies which utilize a true earth ground. Intrinsic Safety

Barriers must be installed if the circuit is intended to be intrinsically safe.

The pickup sensor should only be installed hand tight… do not use wrenches or channel locks.

Over tightening may cause a dimple to protrude into the meter chamber beneath the pickup and interfere with the free gear rotation.

Figure 1

-2-

Page 7

Operation & Maintenance Instructions:

Maintenance Guides are provided with the meter - these should always be reviewed by personnel prior

to attempting any maintenance work. The overwhelming majority of down time & repairs are the result

of breakages due to improper maintenance actions, lack of training or rough handling.

Never run the meter dry or spin with air only - Gear flow meters are precision engineered flow devices

- they should always be maintained in a clean, lubricated condition with the internals wet at all times. Air

and water should not be allowed in contact with the internal parts except in short (1-2 second) cycles as

part of an automated flush.

Don't use water for flow testing - the viscosity of water is too low to produce accurate results unless

the flow rate is elevated and the internals would then have to be dried and lubricated to avoid corrosion

or scaling. Using a fluid with a viscosity of approximately 30 cSt such as mineral oil or thinned glycerin

is recommended if calibration of the system is necessary - the preferred calibration fluid would be the

actual fluid to be metered.

Don't ramp-up flow to a full flow condition instantaneously - Gear flow meters are rugged yet precise instruments which will respond almost instantaneously to changes in fluid flow. Normal pulsating

flows will not damage the meter and will merely cause the output to be unsteady however, if flow is

repeatedly cycled from zero to full flow instantaneously, fluid shock forces may be significant and may

produce premature damage or wear over time. To avoid damage to the system ramp-up to max flow over

a few seconds rather than instantaneously & do not inject high flow speeds into an empty meter.

Filtration is recommended to prevent contaminants from entering the meter. Should the meter

become plugged, a reduced flow may still be observed from the outlet as fluid pressure will squeeze

fluid through the meter - visual flow does not necessarily mean that the meter's gears are turning. If plugging is caused by contaminants then filtering should be installed….if plugging is repeatedly caused by

particle build up then review the cleaning and maintenance procedures in the following section. Because

of the vast differences in fluid types and in-plant procedures there may be some trial and error involved

in determining the ideal flushing or cleaning regimen.

A calibration factor (K Factor) is established at the factory on a preferred calibrating fluid - this number

is usually accurate for a wide variety of fluids and should not usually be changed - it is provided with the

meter either on a Calibration Data Sheet or on a tag attached to the meter. Should it be lost, a copy can

be obtained from the factory. A calibration verification procedure is detailed later in this document.

Storage - when the flow meter is idle or stored for any extended period of time the internals should be

thoroughly cleaned with the appropriate solvent, lubricated with a light oil and the ports capped or

plugged to prevent drying.

-3-

Page 8

Flow Meter Guidelines:

DO: Leave flushing solvent in the lines overnight or during extended off-times.

This keeps internals wet, preventing residual paint from drying, helping start ups.

DO: Follow the Maintenance Guide instructions when opening and cleaning a meter.

During cleaning separate the gears from the shafts. On carbide bearings, clean inside the

center of the gear bearing and on the outer surface of the shafts at the point where the gear

rotates on the shaft. Apply a suitable lubricating fluid before closing the meter. After tightening

the bolts, a short squirt of shop air will briefly spin the gears which should be easily audible.

DO: Install and maintain filters.

The recommended filter should be installed to eliminate potential plugging. Should plugging

occur, the meter will still pass fluid but with no signal output.

DO:

Check electrical compatibility between the meter's output signal and the input of the PLC.

If signals are not being detected at start up, first check wiring and electrical compatibility.

DO: Verify reliable grounding of electrical parts, as per installation guidelines, and a

dedicated power supply is recommended.

Volt age spikes on shared power lines, negligent grounding and sloppy wiring will likely produce

erratic readings and chronic maintenance

The control valve will provide back pressure which is beneficial to stable flow control.

DO: Install the meter immediately upstream of the regulator or control valve.

The control valve provides back pressure which stabilizes the flow.

DON'T: Allow air into the flow meter.

Always keep the meter internally wet.

DON'T: Dry paint lines using pressurized air.

Flow meters are designed to flow liquids. Meters should be closed to air except when air is part

of an automated purge cycle. Do not dry lines after purging.

DON'T: Allow materials to dry inside the meter.

When a meter is removed from the line during maintenance the internals should be cleaned

immediately, lubricated and the fluid ports capped.

DON'T: Over tighten the pickup sensor beyond hand tight.

When installing the pickup sensor turn it in lightly to a hand tight torque. Do not use a wrench

on the pickup as over tightening may cause a dimple of metal under the sensor nose to

protrude into the gear cavity & interfere with the gear's rotation.

DON'T: Use water or solvent for calibration or test purposes.

Water or solvent may not turn the gears at low flow and may leave the impression that the

meter is not functioning. Acalibration factor (k-factor) is issued with the flow meter which is valid

for most fluids except water or equivalent viscosities.

-4-

Page 9

Calibrations

Each flow meter is calibrated and given a 'K Factor' using a standard calibrating fluid at the factory. This

number is accurate for all fluids, with most viscosities, except the most water-like. There should be no

need to change this except for the very lowest viscosities close to 1.0 cP.

If flow readings are too high:

If the display shows significantly more than the volume actually dispensed or shows flow when there is

definitely no flow - this most likely indicates an electrical noise problem. In such cases turn off nearby

motors or heaters or relays, check cable shielding and establish a clean ground independent of other

electrical devices before repeating accuracy tests. If the problem continues it may be necessary to relocate the offending device

If flow readings are too low:

If the display shows significantly less than the volume actually dispensed then most likely the meter has

a high slippage factor and the fluid is by-passing the gears and the k-factor may require adjustment.

If it is necessary to adjust the existing k-factor:

Trigger at least 500ml of your sample fluid, in a steady stream, at approximately the desired flow rate,

into a graduated beaker. Compare the volume in the beaker to the volume on the display. Do not time

the operation merely measure the volume dispensed. Repeat the sample 3 times and take an average.

If the result is outside an acceptable margin, adjust the K Factor by the % difference between the average beaker sample and the average displayed total. If the error is not corrected clean the meter thoroughly and repeat the procedure. Do not use water for this test.

If it is necessary to re-calculate a new k-factor:

You will first need a data collecting instrument to count pulses produced by the meter. An Omega display

may be used in totalizer mode provided the KFT is set to count each pulse (KFT = 10000). Trigger at

least 500ml of your sample fluid, in a steady stream, at approximately the desired flow rate, into a graduated beaker. Divide the number of pulses by the volume dispensed and the result is your new k-factor

in the units of your sample…in the example above the k-factor units would be impulses/ml.

-5-

Page 10

Trouble Shooting Guide:

TROUBLE POSSIBLE CAUSE SOLUTION

Viscosity of fluid is <30cst. Decrease the K-factor by percent error.

Meter indicates Excessive pressure differential

lower than actual across meter causing gears to bind. Reduce flow rate, reduce fluid viscosity.

Debris in measuring chamber. Clean meter, change or add filter.

Upper housing has dimple from

over tightening sensor. Replace upper housing.

Air in lines. Add air eliminator.

Meter indicates Electro-magnetic interference. Ground flow meter and all electronics.

higher than actual.

Reverse fluid flow. Add check valve.

Indicator shows Fluid oscillates. Check pump, add check valve, increase

flow when there is back pressure.

no flow.

Electro-magnetic interference. Ground flow meter and all electronics.

Use shielded cable and relocate away

from electrical noise.

No fluid flow. Check pump.

Debris in measuring chamber or

gears. Clean meter, change or add filter.

Sensor not installed properly. Check sensor is installed to hand tight.

No flow indication. Review sensor guide.

Faulty wiring. Check sensor connection and readout

connection.

Faulty sensor. Replace sensor.

Upper housing has dimple from

over-tightening sensor. Replace upper housing.

Erratic system Ground loop in shielding. Ground shield one place only. Re-route

indication. cables from electrical noise.

Pulsating fluid flow. Add pulse dampener.

-6-

Page 11

FPD20x1 to FPD20x4 Dual Hall Effect Pickup

Installation and Technical Data Guide

Description:

The Dual Hall Effect Pickups are microprocessor-based sensors for use with the FPD2000 series of positive displacement flow meters. The DH sensors can detect both uni- and bi-directional flow. The sensors’ mode of operation is determined by an output selection switch located inside the housing. The DH

detects the rotation of the flow meter’s gears and emits a frequency signal proportional to flow. The output signal is a square wave pulse which has a duty cycle of approximately 50%.

DH signal outputs are protected with a self-resetting fuse. This fuse has a 50mAnominal trip point. When

a trip occurs, turn off power to the sensor and remove output load to reset fuse. The sensor has two different output configurations: sinking output and sourcing output.

The DH sensor circuit board is equipped with a red and green LED. The red LED is a status LED which,

when the sensor is operating properly, will flash once every 6 seconds, a fast flash will indicate a failure

of one or both of the pick-ups. The green LED indicates the pulse of the input signal. Note that signals

above 20Hz will look as solid green.

Installation:

• Ensure that the flowmeter sensor cavity is free of debris prior to installing pickup

• Make sure the sensor mounting screws line up with the sensor mounting holes. If they do not,

remove and rotate the sensor 180°

• Sensor is equipped with an output test feature for readouts before initial running of your system

TEST FEATURE:

Note: Power must be cycled for new setting to take effect

• Switch setting 8 will cause the pick-up to output a 10 Hz (+/- 20%) Phase = +90 deg pulse output,

simulating low flow conditions without flow through your meter.

• Switch setting 9 will cause the pick-up to output a 250 Hz (+/- 20%) Phase = -90 deg pulse output,

simulating medium flow conditions without flow through your meter.

NOTE: WIRING SHOULD BE INSTALLED BY A QUALIFIED INSTRUMENTATION TECHNICIAN

Pin Number Wire Color

Signal 2: 2 Green

Signal 1: 4 White

Ground: 5 Black

Supply Voltage: 6 Red

Wiring Color Code:

Pin Number Function

1 NC

2 Output 2

3 NC

4 Output 1

5 Ground

6 Supply

Electrical Connection for Pin Connector

1 3 5

6

Pinout looking at male

connector on sensor

Switch Output 1 Output 2

0 Direction Signal 2

1 Signal 1 Signal 2

2 Direction Signal 1 + 2 (2x frequency)

3 Signal 1 Signal 1 + 2 (2x frequency)

4 Signal 1 (both outputs in phase)

5 Signal 2 (both outputs in phase)

6 Signal 1 + 2 (both 2x frequency & both outputs in phase)

7 Reserved

8 Test: S1 & S2 == 10 Hz (+/- 20%) Phase = +90 deg.

9 Test: S1 & S2 == 250 Hz (+/- 20%) Phase = -90 deg.

Operating Modes

Top view of circuit board with

view of LED’s and switch

Note: Power must be cycled for new

setting to take effect

-7-

Page 12

FPD20x1 to 20x4 Dual Hall Effect Pickup

Installation and Technical Data Guide

Sourcing Output Circuit

~40 Ohm

SUPPLY

OUTPUT

GROUND

Analog

Switch

• Signal output square wave :

V

high

= Supply -1V @ no output load

V

low

= 0.1V

• Max sourced output voltage: Supply -0.5V

• Max current sourcing capabilities: 50mA

Supply Voltage: +10 to 27 Volt DC

Supply Current: 18 mA @ 12 VDC, 25 mA @ 24 VDC

Duty Signal: 50% ± 15%

Minimum Signal: 0.5 Hz

Frequency Output: Flow dependent, up to 2,000 Hz

Driving Capacity: 50 mA Max resistive load

Output Impedance: ~ 40 Ohm - analog switch and self-resetting fuse

Temperature Range: -40° F to 185° F (-40° C to 85° C)

Technical Data:

1.19"

DH-X: (2.12")

DH-XX: (2.39")

Part number configuration:

DH Sensors can be used with all Aluminum, 303

Stainless Steel and 316 Stainless Steel body flow meters

FPD20x1,2,3: (2.12”)

FPD20x4: (2.39”)

-8-

Page 13

Switch Output 1 Output 2

0 Flow Direction Signal 2

1 1x frequency +90 deg phase

2 Flow Direction 2x frequency

3 2x frequency +90 deg phase

4 Flow Direction 4x frequency

5 Both outputs 4x frequency in phase

6 Reserved

7 Forward pulses Reverse pulses

8 Test: S1 & S2 == 10 Hz (+/- 20%) Phase = +90 deg.

9 Test: S1 & S2 == 250 Hz (+/- 20%) Phase = -90 deg.

FPD2005 and 2015 Hall Effect Pickup

Installation and Technical Data Guide

NOTE: WIRING SHOULD BE INSTALLED BY A QUALIFIED INSTRUMENTATION TECHNICIAN

Pin Number Wire Color

Signal 2: 2 Green

Signal 1: 4 White

Ground: 5 Black

Supply Voltage: 6 Red

Wiring Color Code:

Pin Number Function

1 NC

2 Output 2

3 NC

4 Output 1

5 Ground

6 Supply

Electrical Connection for Pin Connector

1

Pinout looking at

male connector

on sensor

Operating Modes

Top view of circuit

board with view of

LED’s and switch

Description:

The 4-Hall Effect Pickups are microprocessor-based sensors for use with the FPD2000 series of

positive displacement flow meters. The sensor can detect both uni- and bi-directional flow, and

sensors’ mode of operation is determined by an output selection switch located inside the housing. The

sensor detects the rotation of the flow meter gears and emits a frequency signal proportional to flow.

The output signal is a square wave pulse which has a duty cycle of approximately 50%.

Signal outputs are protected with a self-resetting fuse. This fuse has a 50mAnominal trip point. When a

trip occurs, turn off power to the sensor and remove output load to reset fuse. The sensor has two

different output configurations: sinking output when jumpers JP1 & JP2 are removed and sourcing

when jumpers JP1 & JP2 are shorting pins.

Sensor circuit board is equipped with a red and green LED. The red LED is a status LED which, when

the sensor is operating properly, will flash once every 4 seconds, a fast flash will indicate a failure of

one or more of the pick-ups. The green LED indicates the pulse of the input signal. Note that signals

above 20Hz will look as solid green.

Installation:

• Ensure that the flowmeter sensor cavity is free of debris prior to installing pickup

• Install flow meter and sensor - CYCLE POWER - or sensor will not function properly!!

• Sensor is equipped with an output test feature for readouts before initial running of your system

TEST FEATURE:

Note: Power must be cycled for new setting to take effect

• Switch setting 8 will cause the pick-up to output a 10 Hz (+/- 20%) Phase = +90 deg pulse output, simulating low flow conditions without flow through the meter.

• For sourcing outputs remove shorting block from JP1 & JP2

For sinking outputs place shorting block across JP1 & JP2 (factory default)

• Switch setting 9 will cause the pick-up to output a 250 Hz (+/- 20%) Phase = -90 deg pulse output,

simulating medium flow conditions without flow through the meter.

Note: Power must be cycled for

new setting to take effect

-9-

RED LED

GREEN LED

SWITCH

JP2

JP1

Page 14

FPD2005 and 2015 Dual Hall Effect Pickup

Installation and Technical Data Guide

Sinking Output Circuit

~40 Ohm

SUPPLY

OUTPUT

GROUND

Analog

Switch

Sourcing Output Circuit - Default from Factory

~40 Ohm

SUPPLY

OUTPUT

GROUND

Analog

Switch

• Output selection jumper off: remove shorting

block from JP1 & JP2

• User may need to add external components

to interface to displays or other instruments

• User must limit output voltage to Supply -1V

• Max current sinking capability: 50mA

• Output selection jumper on: place shorting

block across JP1 & JP2

• Signal output square wave :

V

high

= Supply -1V @ no output load

V

low

= 0.1V

• Max sourced output voltage: Supply -0.5V

• Max current sourcing capabilities: 50mA

Supply Voltage: +10 to 27 Volt DC

Supply Current: 75 mA @ 24 VDC

Duty Signal: 50% ± 15%

Minimum Signal: 0.5 Hz

Maximum Signal: 1,000 Hz

Frequency Output: Flow dependent, up to 2,000 Hz

Driving Capacity: 50 mAMax resistive load

Output Impedance: ~ 40 Ohm - analog switch and self-resetting fuse

Temperature Range: -40° F to 185° F (-40° C to 85° C)

Technical Data:

-10-

To Secure Sensor to Flow Meter:

Use a 9/64 hex key to tighten

internal screws.

1.38

Page 15

FPD20xx-A Analog Output Sensor

The FPD20xx-A is a microprocessor based, meter mounted, analog output sensor. Each unit has a sensor, amplifier and converter module built into an Ex housing. The FIP is designed to handle frequencies

up to 5,000 Hz. The operational frequency range is user defined via four BCD rotary switches, where the

high flow rate in frequency is set to 20 mA and the output signal is automatically scaled. End connection

is a 3-pin male connector.

NOTE: This is a 3 wire hookup and is not suitable for a 2 wire installation.

Technical Specifications:

Supply Voltage: 10-30 VDC

Supply Current: 60 mAmax

Signal Output: 4-20mA or

Maximum Load

Impedance (Vcc/0.02): 275 ohm (for mA out)

Temperature Range: 0-185° F

Jumper Settings:

J1 AB: Analog Output

BC: Frequency Output

J2 AB: Housing Ground

CB: Signal ground

Response Time: 1/F + 25 msec

Frequency Input: 5 KHz max

Diagnostics: A glowing LED indicates the

unit is working. The LED will

blink to show an active

frequency.

-11-

"S" VERSION

CONNECTOR

(A) +10-30 VDC

C

A

(B) COMMON

B

(C) SIGNAL OUT

+10-30 VDC

COMMON

SIGNAL OUT

"E" VERSION

PIGTAIL LEADS

RED

BLACK

WHITE

S1 S2 S3 S4

1

1

0

2

9

3

8

4

7

5

6

J1

ABC

OUT

1

0

0

2

2

9

9

3

3

8

8

4

4

7

7

5

5

6

6

CBA

J2

1

0

2

9

3

8

4

7

5

6

Page 16

Scaling Analog Output:

On the front panel there are four rotary switches which are

adjustable with a small screwdriver. It is not necessary to

power the unit down to change the settings. The switches are

read from left to right in order of decreasing value as shown in

the figure to the right.

If the maximum frequency is known at which the resulting output should be 20mA, set the switches to

this frequency. The output will automatically scale itself. If the maximum frequency is not known, the correct

switch settings can be determined in 2 ways.

The following equation can be used to determine what the switch setting should be for any particular meter and

flow rate.

Switch Setting =

Where: K Factor is the flow meter scaling factor in pulses / volume (found on calibration sheet)

Max. Flow Rate is the flow rate at which the analog output should be at it's max.

Note: K-Factor and Max flow rate MUST have same units, ie: gallon/GPM, liter/LPM

60 is the scaling factor when max. flow rate is in volume/minute. Use 3600 for volume/hour

Ex: K Factor = 89,100 pulses/gallon (for a FPD2001-A), Max flow rate = 0.2 GPM

Switch Setting = = 297

If the numerical flow rate is not known, the unit can be calibrated in systems with the following:

1) Adjust system flow to the rate at which analog output should read 20 mA.

2) Set scaling switches to a value known to be above the maximum frequency (ex. 9, 49, 799, 2999) if unsure,

use 4999

3) If S1 is 0, go to step 4. Decrease S1 until output shows 20 mA. Then increase its setting by one unless value

is 4, in which case value should remain 4. If the switch value is 0 and the output is below 20 mA, leave switch

at 0 and go to next switch.

4) If S2 is 0, go to step 5. Decrease S2 until output shows 20 mA. Then increase its setting by one unless value

is 9, in which case value should remain 9. If the switch value is 0 and the output is below 20 mA, leave switch

at 0 and go to next switch.

5) If S3 is 0, go to step 6. Decrease S3 until output shows 20 mA. Then increase its setting by one unless value

is 9, in which case value should remain 9. If the switch value is 0 and the output is below 20 mA, leave switch

at 0 and go to next switch.

6) Decrease S4 until output shows 20 mA and leave setting. DO NOT increase this setting by one. The switches

are now set at the frequency which will result in a 20 mA output.

When setting switches in step 1, try to use numbers ending in 9 for example: 9, 39, 299 and 2999. Any switch

setting above 5000 Hz is read as 4999 Hz.

Example: Actual maximum input frequency is 538 Hz. Switches are set to 0999 Hz, a value known to be above

actual maximum input frequency. The output shows 12.64 mA.

Starting with the switch of highest order, in this case S2 since S1 is 0, its value is decreased until the output

shows 20 mA (S2 shows 4). The switch is then increased by 1 (S2 is set to 5). S3 is then decreased until the

output shows 20 mA (S3 shows 2). The switch is then increased by 1 (S3 is set to 3). Finally, S4 is decreased

until the output shows 20 mA and left as such (S4 set at 8) the switches are now set to 538 Hz, the frequency

which will cause maximum output current / voltage.

K Factor * Max Flow Rate

60

89,100 * 0.2

60

-12-

x1000 x100 x10 x1

1

0

2

9

3

8

4

7

5

6

1

0

2

9

3

8

4

7

5

6

1

0

2

9

3

8

4

7

5

6

S1 S2 S3 S4

1

0

2

9

3

8

4

7

5

6

Page 17

Maintenance Guide

For Flow Meter Series: FPD2001-2004, FPD2001-A - 2004-A, FPD2011 - 1014,

FPD2011-A - 2014-A, FPD2021 - 2024, FPD2021-A - 2024-A

Cleaning, inspecting or repairing a gear flow meter is easily accomplished by following the procedures

below.

1. Remove the Sensor (1) from the flow meter body Upper Housing (4).

Using a 3mm hex key, loosen the 2 mounting screws inside the sensor.

2. For the FPD20x3 size and smaller use M6 Bolts (2), loosen them using a

5mm hex key. The FPD20x4 uses M10 Bolts (2), loosen them using an

8mm hex key. Keep the 2 opposing bolts near the Locating Pins (7)

engaged by a few threads to avoid stress on the shafts and the locating

pins during housing separation. Please note the orientation of the

Upper and Lower housings with respect to each other so that the

meter is reassembled the same way.

3. Holding the Upper Housing (4), gently tap on the top of the 2 opposing bolt

heads to separate the Upper Housing (4) from the Lower Housing (9). Do

NOT use chisels or screwdrivers to split and pry apart the housings.

This can cause damage to the meter bodies and meter internal parts.

4. After separation, remove, clean and inspect the gear assemblies (6) and

shafts (5). Clean out the o-ring groove, shaft holes and meter cavity.

IMPORTANT: The gear assembly consists of two bearings (6a), the

Gear (6b), and a Bearing Spacer (6c. These parts are loosely fitted

and can fall out. These parts are matched together and careful

attention MUST be made to their orientation and location as they

MUST be replaced the exact way they were.

5. After cleaning all parts completely, the Gear Assemblies (6), Shafts (5) and

Locating Pins (7) can be reinserted. Check for free and easy rotation of

the gears.

6. Replace the O-Ring (8). Teflon o-rings should always be replaced. Viton

o-rings can be reused if they are not damaged.

7. During reassembly keep the meter housings as parallel as possible. Make

sure the housings are orientated the same way they were prior to

disassembly.

8. Replace the Washers (3) and the Bolts (2). Torque the bolts to 15Nm for

the12, 20 and 30 size meters and 30Nm for the 60 size meters. Do not

force the meter housings together. Do NOT use a hammer or other such

device. Over tightening will not cause damage to the meter, but may

fatigue the bolts and/or restrict the operation if internal surfaces are not

completely clean.

9. After reassembly, gently blow air through the meter so the gears spin. This

should be clearly audible given a moderate background noise level.

10. Clean any debris from the pickup holes before remounting the sensor (1)

to the Upper Housing (4). Use a 3mm hex key to tighten the mounting

screws in the sensor to mount the sensor on the housing. Note that there

is a correct and incorrect orientation for the sensor to be mounted on

the flow meter. Please see the Omega website for documentation if you

do not have it. The orientation is noted by the sensor's connector with

respect to the outlet port of the flow meter.

-13-

Page 18

Maintenance Guide

For Flow Meter Series: FPD2005, FPD2015, FPD2015-A

Cleaning, inspecting or repairing a FPD20x5 Series gear flow meter is easily accomplished by following

the procedures below.

1. Remove the Sensor (3) from the flow meter body Upper Housing

(5). Using a 9/64 hex key, loosen the 2 mounting screws inside

the sensor.

2. Remove the hex bolts (1) with a 3/8 hex key.

3. Turn 2 of the hex bolts into the extraction bolt holes (4) until they

make contact with the lower housing (10). Using these bolts for

separating the housings helps to reduce any stress on the

locating pins and gear shafts.

4. With the extraction bolts turned down to the lower housing, give

each bolt a half-turn, alternating them, until the housings have

separated enough to where you can lift the upper housing (5)

straight off the locating pins. CAUTION: When lifting the top

housing off, make sure the gears stay in the lower housing.

If they come out with the upper housing, they may fall off

and damage the lower housing or the gears themselves.

5. After separation, inspect the gears (7) and bearings (9). Carefully

remove the gears and thoroughly clean them with solvent.

Special care must be observed when cleaning or flushing either

the upper (5) or lower housing (10) as the bearing could dislodge

from the housing. NOTE: Do not remove the bearings. For

bearing repairs the meter should be returned to the factory.

6. After cleaning, add lubrication if possible. The gears can be

reinserted into their previous positions. Check for free and easy

rotation of the gears.

7. Replace the O-ring (6) if it is damaged or deformed.

8. Keep the meter housings parallel during reassembly and align

the index marks on the housings so they are on the same side.

NOTE: Do not force the housings together using a hammer

or other similar device. Make sure to turn out the bolts from

the extraction holes.

9. Replace the hex bolts and torque all the bolts to 50 ft/lbs, once

one bolt is torqued, move to the bolt that is opposite it and repeat

until all bolts have been torqued. Over tightening will not cause

damage, but may restrict operation if surfaces are not completely

clean.

10.After reassembly, gently blow air into the meter so the gears

spin. This should be clearly audible given a moderate

background noise level.

11.The bearings should be lubricated prior to storage. Never

allow contact with water without immediately drying and

lubricating after use.

Shown with Quad-4 Sensor.

-14-

Page 19

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13

months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal

one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive

maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will

issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if

the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to

defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing,

operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit

shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages

that result from the use of its products in accordance with information provided by OMEGA, either

verbal or written. OMEGA warrants only that the parts manufactured by the company will be as

specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

exclusive, and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of

the component upon which liability is based. In no event shall OMEGA be liable for consequential,

incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on

humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on

humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number

should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in

transit.

FOR W

ARRANTY RETURNS, please have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2007 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

Page 20

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺

⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M-4639/0408

Loading...

Loading...