Page 1

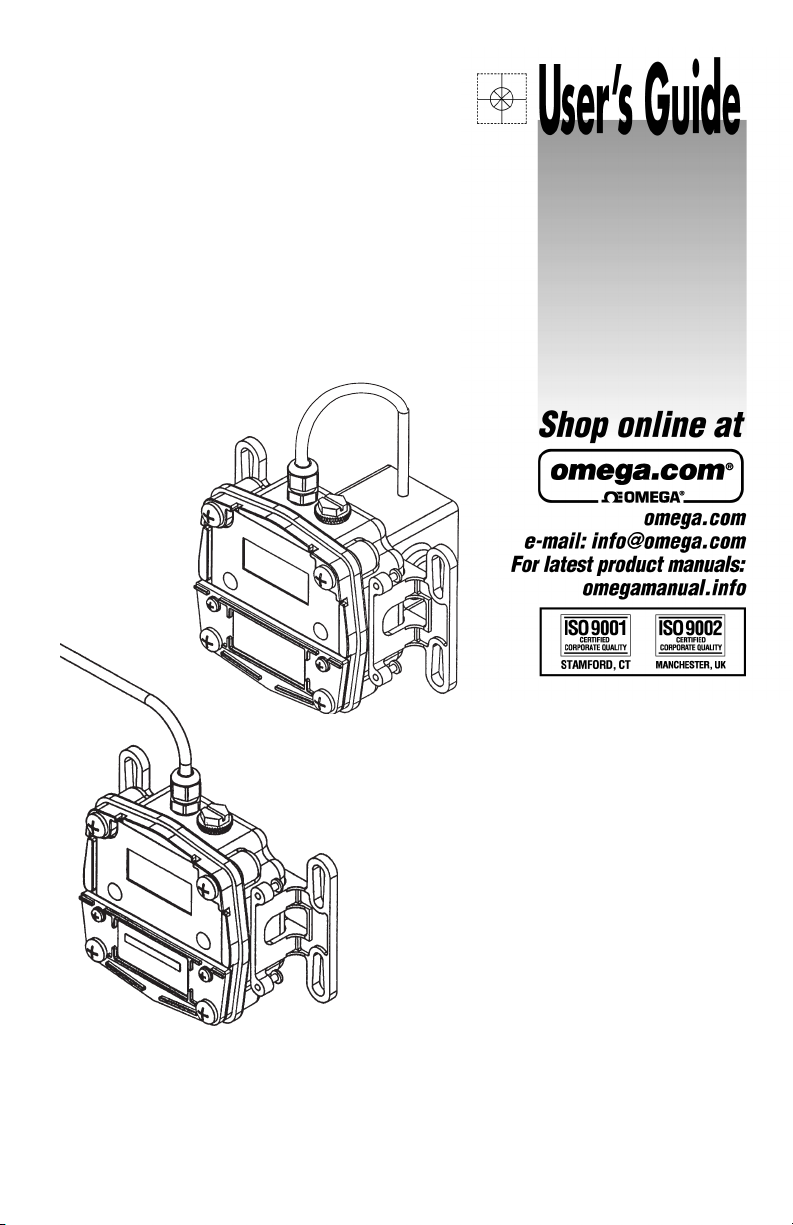

Local Model

Remote Model

FPD1000D-BAT

Battery Powered Display

Local and Remote Models

Page 2

Page 3

GENERAL INFORMATION

Use the OMEGA Standard Display in indoor

or outdoor applications where occasional

exposure to moisture is common. This

manual covers two models:

• Standard Display – Local (mounted to

the meter)

• Standard Display – Remote (where

remote monitoring is required)

Product differences in this manual are

identified by either, Local or Remote as

necessary.

Both models are battery powered; no external power source is required.

SAFETY INSTRUCTIONS

• When measuring flammable liquids,

observe precautions against fire or

explosion.

• When working in hazardous environments, always exercise appropriate

safety precautions.

• Be sure O-rings and seals are kept in

good repair.

INSTALLATION

CAUTION

Installation should be performed only by

qualified personnel, and in accordance

with local governing regulations.

Remote Installation

Choose a mounting location suitable for

the Standard Display. The ideal mounting

location is where the:

• FPD Series meter is as close as possible.

• mounting surface has minimal vibration.

• ambient temperature is 0°F to 140°F

(-18°C to 60°C) when using remote

display.

• cable lengths are minimal.

Avoid mounting locations where the Standard Display is:

• subject to constant exposure to water

or other liquids (occasional low-pressure splashing will not harm unit).

• subject to > 5g shock loading.

• facing the sun directly for long periods

of time.

Mount the OMEGA Standard Display Remote using standard U-bolts. Mounting

options include:

• Wall

• Pipe

This product comes with 20 feet of shielded

cable. OMEGA offers an optional cable kit

with 100 feet of cable (see spare parts list).

OPERATION

Computer Display

All operations are reflected in the LCD

readout. The large center digits indicate

amounts, where smaller words or “icons”

located above and below indicate specific

information regarding totals, flow, calibration

and units of measure.

Computer is on continuously and always

ready to perform. The computer is powered

by a field replaceable battery. When display

becomes dim, faded or the low battery

message appears (see below), the battery

needs to be replaced. Reference the

Maintenance Section for details.

1

Page 4

Batch and Cumulative Totals

The computer maintains two totals. The

Cumulative Total provides continuous measurement and cannot be manually reset. The

Batch Total can be reset to measure flow

during a single use. The Cumulative Total

is labeled TOTAL 1, Batch Total is labeled

TOTAL 2 BATCH.

When the Cumulative Total reaches a

display reading of 999,999 the computer

will highlight an X10 icon. This indicates to

the operator that a zero must be added to

the 6 digits shown. When the next rollover

occurs, the computer will highlight an X100

icon. This indicates to the operator that two

zeros must be added to the 6 digits shown.

Press the DISPLAY button briefly to switch

between the TOTAL 1, TOTAL 2 BATCH

and FLOWRATE. Press DISPLAY briefly

to display the TOTAL 2 BATCH. Hold the

DISPLAY button for 3 seconds to reset the

Batch Total to zero.

When fluid is flowing through the meter, a

small propeller icon is highlighted.

NOTE: Totalization counts total units

without differentiating between gallons,

liters or field calibrated units.

Flowrate Feature

To use this feature, press and release

DISPLAY until FLOWRATE icon appears.

The factory set time base will be highlighted

to the right of FLOWRATE (M = minutes,

H = hours, D = days). When FLOWRATE

is invoked, the display will be indicating

rate of flow.

Factory and Field Calibration

All calibration information is visible to the

user as icons on the top line of the display,

above the numeric digits.

All units are configured with a “factory”

calibration. Both gallons and liters are

available (“GL” or “LT” will be displayed).

While holding the CALIBRATE button, briefly

press DISPLAY to toggle between gallons

and liters. This factory calibration (indicated

with FAC) is permanently programmed into

the computer and is not user adjustable.

NOTE: Your computer may have other units

of measure programmed into it. If so,

holding the CALIBRATE button and momentarily pressing the DISPLAY button

will toggle through all factory set units.

Other possible units are: IGL (imperial

gallon), QT (quart), CF (cubic feet), CM

(cubic meter), BL (42 gal. barrel), CC

(cubic centimeter) or OZ (ounce).

Switching between different units will not

corrupt the Total’s contents. For example,

in GL mode, the computer totalizes 10.00

gallons, if the user switches to LT mode,

the display will read 37.85 liters (the same

volume, different unit).

The “field” calibration may be set by the

user, and can be changed or modified at

any time using the calibration procedure

described in the Calibration Section. Totals

or flowrate derived from the field calibration

are invoked when the FAC icon is no longer

visible on the top line of the display.

2

Page 5

CONFIGURATION

Configuration determines what information is displayed on the screen. The configuration string is a 6-digit number that

programs the computer electronics to a

specific configuration. Using the information below, the end user can change the

information displayed on the screen by

changing the configuration string.

Local Mount Display

The factory calibration and display configuration features are preprogrammed and

further user programming is not required.

When replacing electronic displays, they

must be configured and calibration information entered before use. If desired, the

calibration or features can be changed in

the field using the procedures described

below.

Remote Mount Display

The default calibration and display configuration features may not be appropriate for

the user installation.

ATTENTION

ALL remote mount and replacement

displays must be configured AND calibrated before use!

Factory Default Configuration

The configuration strings below are the

default configurations for the local mounted

display and can be used for the final configuration for replacement displays or remote

mounted displays purchased separately.

NOTE: For replacement and remote elec-

tronics, this configuration does NOT

determine the K-factor for your specific

meter. That information must still be

entered using the calibration procedure. For replacement and remote

configurations, please see Calibration

Section for more information.

FACTORY CONFIGURATION STRINGS

MODEL CONFIGURATION STRINGS

FPD1001B

FPD1002B

FPD1003B

FPD1102B

FPD1103B

FPD1201B

FPD1202B

FPD1203B

FPD1004

FPD1204

FPD1105

FPD1005

FPD1205

FPD1006

FPD1007

B 2 2 0 1 3

B 1 2 0 1 3

3

Page 6

User Configuration

The flow computer has been programmed

with many features, most of which can

be enabled by the end user through the

configuration process. By disabling unnecessary features, day-to-day flowmeter

operation can be greatly simplified, making

the unit easier to use. Alternately, there are

several features available not found in the

default configuration.

User configuration features include:

• 0 to 3 totals, either resettable (batch)

or non-resettable (cumulative).

• Flowrate or no flowrate. Available in

units per minute, hour or day.

• Three different field calibration methods: K-factor entry, Dispense/Display

or % Correction Factor.

• Various units of measure (some or all):

GL (gallon), LT (liter), IGL (imperial gallon), QT (quart), CF (cubic feet), CM

(cubic meter), BL (42 gal. barrel), CC

(cubic centimeter) or OZ (ounce).

Changing Configuration Settings

Access to the conf igur atio n process

requires entering the 6-digit pin code

“020748”. Configurations are entered and

stored as 6-digit codes where each digit

represents a setting for one of the configuration options. New configuration settings

are stored in the computers long-term

memory and will not be lost either in OFF

mode or during battery change.

Since there are security timeouts associated with the configuration changing process, you should determine ahead of time

what your new 6-digit configuration code

will be. Using the information below, create

the new code and write it down so that you

can refer to it during configuration.

NEW CODE CONFIGURATIONS

DIGIT 1 ENABLES

0 No Totalizing Registers

1 TOTAL 1 (Accumulative)

2 TOTAL 2 BATCH

3 TOTAL 1 & TOTAL 2 BATCH

7 TOTAL 1, TOTAL 2 BATCH & TOTAL 3 BATCH

8 Enables U.S. Gallons, No Totalization Registers

9 TOTAL 1 (Accumulative) & U.S. Gallons

A TOTAL 2 BATCH & U.S. Gallons

b TOTAL 1 & TOTAL 2 BATCH & U.S. Gallons

F TOTAL 1, TOTAL 2 BATCH & TOTAL 3 BATCH & U.S. Gallons

DIGIT 2 ENABLES

0 No Flowrate Mode

1 Flowrate in Units Per Minute

2 Flowrate in Units Per Hour

4 Flowrate in Units Per Day

8 Enables Imperial Gallons (IGL), No Flowrate Mode

9 Flowrate in Units Per Minute & Imperial Gallons Enabled

A Flowrate in Units Per Hour & Imperial Gallons Enabled

C Flowrate in Units Per Day & Imperial Gallons Enabled

4

Page 7

NEW CODE CONFIGURATIONS – CONT’D.

DIGIT 3 ENABLES

0 No Units of Measure from the below items

1 Enables Quarts (QT)

2 Enables Liters (LT)

3 Enables Quarts (QT) and Liters (LT)

4 Enables Cubic Feet (CF)

5 Enables Cubic Feet (CF) & Quarts (QT)

6 Enables Cubic Feet (CF) & Liters (LT)

7 Enables Cubic Feet (CF), Quarts (QT) & Liters (LT)

8 Enables Cubic Meters (CM)

9 Enables Cubic Meters (CM) & Quarts (QT)

A Enables Cubic Meters (CM) & Liters (LT)

b Enables Cubic Meters (CM), Quarts (QT) & Liters (LT)

C Enables Cubic Meters (CM) & Cubic Feet (QF)

d Enables Cubic Meters (CM), Cubic Feet (QF) & Quarts (QT)

E Enables Cubic Meters (CM), Cubic Feet (QF) & Liters (LT)

F Enables Cubic Meters (CM), Cubic Feet (QF), Liters (LT) & Quarts (QT)

DIGIT 4 ENABLES

0 No Units of Measure from the below items

1 Enables Barrels, 42 gallon (BL)

2 Enables Cubic Centimeter (CC)

3 Enables Barrels (BL) & Cubic Centimeters (CC)

4 Enables Ounces (OZ)

5 Enables Ounces (OZ) & Barrels (BL)

6 Enables Ounces (OZ) & Cubic Centimeters (CC)

7 Enables Ounces (OZ), Cubic Centimeters (CC) & Barrels (BL)

DIGIT 5 ENABLES

0 None of the below options enabled

1 Restore TOTAL 2 BATCH value after power loss, no filter

2 Restore TOTAL 3 BATCH value after power loss, no filter

3 Restore TOTAL 2 BATCH & TOTAL 3 BATCH values after power loss, no filter

8 Enable 8 Hertz input filter (recommended)

9 Restore TOTAL 2 BATCH value after power loss, with 8 Hz filter

A Restore TOTAL 3 BATCH value after power loss, with 8 Hz filter

b Restore TOTAL 2 BATCH & TOTAL 3 BATCH values after power loss, with 8 Hz filter

DIGIT 6 ENABLES

0 No Field Calibration allowed

1 Correction Factor method

3 K-Factor Entry method

7 Dispense/Display Entry method

5

Page 8

CONFIGURATION SETUP

Since there are security timeouts associated with the configuration changing process, you should determine ahead of time

what your new 6-digit configuration code

will be. Create the new code and write it

down so that you can refer to it before

beginning this procedure.

1. Temporarily disconnect power to the

display at any convenient point.

2. Allow at least 30 seconds before proceeding to allow all internal capacitance to discharge.

3. While the unit is still unpowered, press

and hold CAL. While holding the CAL

button, reapply power. Keep CAL button pressed for about a second after

applying power, then release.

4. While holding button, the display will

show “FLdCFG”.

5. The display should show “000000” with

the left-hand digit blinking. If you do not

see this, go back to Step 1.

6. Enter the Pin No. 020748.

a. To enter, use the CALIBRATE but-

ton to change the blinking digit

and/or use the DISPLAY button to

shift the blink to the next digit.

NOTE: You can use the buttons as

often as necessary. There is a long

timeout (about 4 minutes).

b. As an added security precaution,

if a valid password is NOT sensed,

within about 4 minutes, the computer will revert to normal operation, and you will have to repeat

the process from Step 1.

7. Briefly press and release BOTH buttons. If you have entered a valid Pin

number, the computer will immediately

display the current configuration code.

(For example: 922948). Display will

show “FLdCFG”.

NOTE: Once in configuration mode, the

computer will automatically revert to

normal operation if no button operation

is sensed for about 4 minutes.

If this happens, you have not com-

pleted the process. You will have to

repeat the entire process from Step 2.

8. Enter the 6-digit configuration code

number for your new configuration using the same method as used in Step

6a above.

9. When correctly entered, briefly press

and release BOTH buttons. The display

will briefly show “FLdCFG”, and then

the unit will return to normal operation.

Configuration is now complete.

CALIBRATION

Local Mount Display

The factory calibration and display configuration features are programmed and further

user programming is not required. When

replacing electronic displays, they must

be configured and calibration information

entered before use. If desired, the calibration or features can be changed in the field

using the procedures described below.

Remote Mount Display

The default calibration and display configuration features may not be appropriate for

the user installation.

ATTENTION

ALL remote mount and replacement

displays must be configured AND cali-

brated before use!

6

Page 9

Field Calibration

Presently all computer electronics are

programmed with two different calibration

methods, only one of which is active at

a time. K-Factor Entry calibration is the

default method. This allows a calibration

point to be entered using numerical entry

of meter K-factors.

The alternate method is Dispense/Display

which requires that a specific volume of

fluid pass through the meter to determine

the correct K-factor. Dispense/Display

calibration can be selected using computer

electronics configuration.

The specific K-factor (ppg or pulses per

gallon) of your oval gear meter is shown in

the chart below, or refer to the nameplate

on the meter.

Field Calibration Procedure

(K-Factor Entry Method)

Because the oval gear meter is positive

displacement, it requires only one K-factor

and a single point calibration is sufficient.

1. To field calibrate, press and hold the

CALIBRATE and DISPLAY buttons for

about 3 seconds until you see FLdCAL.

Release both buttons and you will see

Kxxxx.x (where “x” represents the current field-cal k-factor value). You are

now in the field calibration mode.

2. The far left digit will be blinking. The

DISPLAY button can then be pressed

to select the digit location and the

CALIBRATE button can be pressed to

scroll the desired value at the blinking

position. Edit the K-factor shown to

the desired value. Acceptable K-factor

range is 0000.1 to 9999.9.

3. After the new value has been entered,

momentarily press and release both

buttons. “CALEND” will be momentarily

displayed. Unit is now ready for use.

4. Notice that the upper display line, the

“FAC” icon and all the units of measure

have disappeared.

Alternate units of measure are not selectable when meter is operating with field

calibration. This calibration is a unique

single point calibration for the meter and/

or application.

MODEL

FPD1001B 5855.4 0.132 GPH (0.5 LPH)

FPD1201B

FPD1002B 3785.4 0.53 GPH (2.0 LPH)

FPD1202B

FPD1102B

FPD1003B 1514.2 4.0 GPH (15.0 LPH)

FPD1203B

FPD1103B

FPD1004 424 0.25 GPM (1.0 LPM)

FPD1204

FPD1105 197 0.8 GPM (3.0 LPM)

FPD1005 136.3 1.6 GPM (6.0 LPM)

FPD1205

FPD1006 54.9 2.6 GPM (10.0 LPM)

FPD1007 25.3 4.0 GPM (15.0 LPM)

K-FACTOR (ppg)

MINIMUM FLOWRATE FOR

DISPENSE / DISPLAY CALIBRATION

7

Page 10

NOTE: To return to factory calibration

–

+

+

–

(FAC), press and hold both CALIBRATION and DISPLAY buttons for about

3 seconds, until FAcCAL is displayed.

Then release buttons. Unit should

return to normal operation and FAC

icon visible.

NOTE: If the field calibration mode is

entered and NO fluid is dispensed,

then upon leaving, the computer will

use data from the last successful field

calibration.

NOTE: A Field Calibration below the

minimum flowrate can adversely effect

accuracy.

The use of a uniformly dependable, accurate calibration container is highly recommended for the most accurate results. For

the most accurate results, dispense at a

flowrate which best simulates your actual

operating conditions. Avoid “dribbling”

more fluid or repeatedly starting and stopping the flow – these actions will result in

less accurate calibrations.

Make sure you meet the meter’s minimum

flowrate requirements.

For best results, the meter should be

installed and purged of air prior to Field

Calibration.

Field Calibration Procedures

(Dispense/Display Method)

1. To field calibrate, press and hold the

CALIBRATE and DISPLAY buttons for

about 3 seconds until you see FLdCAL.

Release both buttons and you will

see dd000.0. You are now in the field

calibration mode.

2. Dispense a known amount of fluid at a

flowrate representative of the application. Any amount between .1 and 999.9

units can be used. Display will count up

while fluid is flowing through the meter.

3. The DISPLAY button can then be

pushed to select the digit location and

the CALIBRATE button can be pushed

to scroll the desired value at the blinking

position. Edit the amount shown with

the value that was dispensed above.

Values from 000.1 to 999.9 can be

entered.

4. When satisfied with the value, press

both CALIBRATE and DISPLAY buttons simultaneously. CALEnd will be

displayed and unit will go back to

normal operation, less the FAC (factory

calibration) icon.

5. The meter will now be operating with

a custom calibration number unique to

the above dispense procedure. No unit

of measure (gallon, liter, etc.) icon will

be highlighted.

NOTE: To return to factory calibration (FAC),

press and hold both CALIBRATE and

DISPLAY buttons for about 3 seconds,

until FAcCAL is displayed. Then release

buttons. Unit should return to normal

operation and FAC icon visible.

NOTE: If the field calibration mode is en-

tered and NO fluid is dispensed, then

upon leaving, the computer will use data

from the last successful field calibration.

Connecting the Standard Display

Pulse output and external power are the

connections located on the interface PCB.

Solder a 1K resistor between the ( + ) voltage of the external power input and the ( + )

of the pulse output to use this output. (Wiring Diagram 1) Pulse signal represents the

output cabling to the receiving instrument.

WIRING DIAGRAM 1

M

Brown

Black

White

E

T

E

R

1KR (2 watt 1%)

EXT

PWR IN

Optional External Power (10-16 VDC 100mA)

PULSE

OUT

Optional Pulse Signal to Instrument

Blue

REED IN

8

Page 11

Connecting an External

Power Supply

An external power supply can be used

with or without the supplied 9-volt battery.

Power supply must be 10-12 VDC; 100 mA

if using the 9-volt battery as a backup, or

5-12 VDC; 100 mA if removing battery (e.g.,

if using both external power and optional

pulse out.

Follow the steps below to connect an external power supply.

1. Remove the four large screws from the

front of the coverplate.

2. Disconnect the battery.

3. Solder the external power leads to the

terminal marked “EXT PWR IN” on the

registers printed circuit board. Make

note of the voltage polarity “+” and

“–”.

4. Reassemble register onto the coverplate, replace the four screws and

tighten firmly.

MAINTENANCE

Replacing the Battery

Replace the battery when the readout

becomes dim, blank or “LobAtt” appears.

Replace the battery with a 9-volt lithium

battery.

To replace the battery:

1. Remove the two large screws and two

small screws from the battery coverplate.

2. Remove the battery coverplate and

gasket.

3. Remove the battery and clean any corrosion from the terminals.

NOTE: Coat the terminals with petroleum

jelly to protect against corrosion.

4. Install the new battery.

5. Check the gasket for damage and replace as needed. Position gasket and

coverplate to align, insert screws and

tighten.

NOTE: Batch and Cumulative Total values

as well as the factory calibration is

retained in the computer permanently

and will display when the battery is

replaced.

Store at temperatures between 0° F to

+140° F (–18° C to +60° C).

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

LCD REGISTER 1. Battery not connected Check battery connections.

NOT WORKING properly

2. Battery flat Replace battery.

3. Faulty wiring connections Check wiring for loose or faulty connections.

4. Faulty LCD Replace computer assembly.

5. Faulty connection from Check wiring connections.

computer to Pulse PCB

9

Page 12

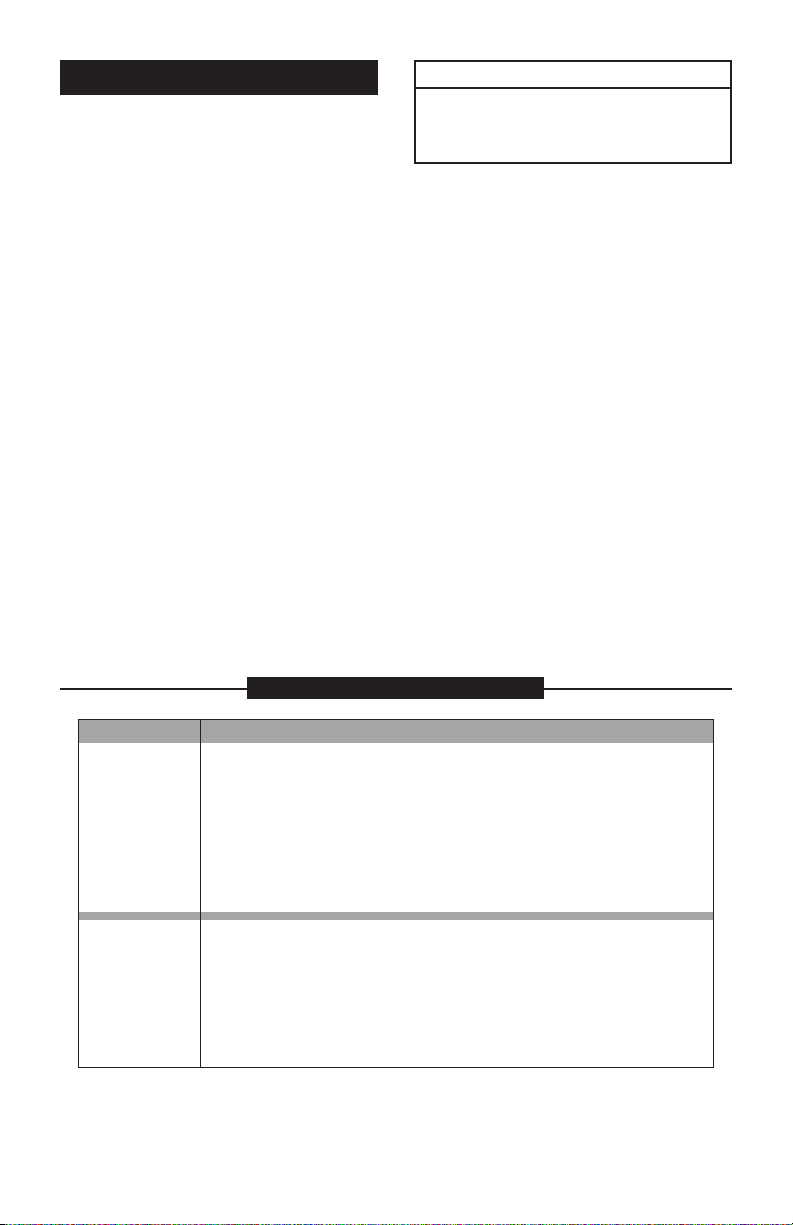

DISPLAY PARTS LISTING

20

14

15

16

17

18

11

12

13

10

19

10

21

5

7

6

4

3

2

Item No.

1

No. Part No. Description Req’d.

1 120009-2 Battery Cover .......................................... 1

2 120028-1 Battery Gasket ........................................ 1

3 FPD-BATT Battery, 9-volt Lithium.............................1

4 120569-01 Computer Assembly ............................... 1

5 120035-1 PCB Assembly ........................................ 1

6 901002-82 O-Ring ....................................................1

7 120509-01 Adapter Kit .............................................. 1

8 120058-01 Bracket ...................................................1

9 904005-13 Screw, 6-32 x 1/2 in. (Remote Model) .... 4

10 904002-44 Screw, 8-32 x 5/16 in. ............................. 2

11 125066-20 Cable, 20 ft. (Remote Model) .................. 1

125066-3 Cable, 100 ft. (Remote Model) ................ 1

12 902005-9 Strain Relief ............................................ 1

13 901002-87 O-Ring .................................................... 1

14 906005-47 Threaded Plug ........................................ 1

15 906005-48 Seal ......................................................... 1

16 904005-63 Screw, 4-40 x 3/16 in. ............................. 2

17 902004-51 Terminal ..................................................4

18 904005-28 Sealing Screw, 1/4-20 x 5/8 in. ............... 4

19 904005-27 Sems Screw, 6-32 x 3/8 in. ..................... 2

20 902007-07 Strain Relief for FPD1000 Series

High Flow (sold separately)............... 1

21 904006-94 Screw, 10-16 x 5/8 in. (Local Model) ...... 2

9

8

Page 13

LOCAL MODEL

SPECIFICATIONS

Materials:

Acetal, Amorphous Nylon, PET Polyester, Polyester (decals), FKM (gasket

& seals), Stainless Steel (fasteners)

Power Source:

On-board, field-replaceable, 9-volt

Lithium battery

Battery Life:

Approximately 4 years

Configuration:

2-Totals (1 cumulative and 1 batch),

Rate, 2 Cals (Factory calibration in

gallons or liters; 2 field calibrations),

K-factor to match published K-factor

for each size meter

Input Signal:

Hall Effect or Reed Switch

Time Base:

Hours for FPD1000 Series Low Flow

Minutes for FPD1000 Series High Flow

Unit of Measure:

U.S. gallons or liters

Accuracy:

No additional error over coupled flow

meter’s accuracy

Frequency Range:

0 to 1000 hertz

Batch Total:

Up to 999,999 (x100)

Cumulative Total:

Up to 999,999 (x100)

Temperature:

0° F to +140 °F (–18° C to +60° C)

Cable:

N/A

Mechanical Connections:

Display is mounted directly to flow

meter body

Electrical Connections:

One strain relief port: PG7 (1/2-20)

thread. Grip range: .11 to .26 inches

One threaded port plugged (1/2-20)

Dimensions

(In addition to meter body size):

Width: 4.5 in. (11.4 cm)

Height: 6 in. (15.2 cm)

Depth: 4.5 in. (11.4 cm)

Shipping Weight: 1 lb. (.45 kg)

REMOTE MODEL

SPECIFICATIONS

Materials:

Acetal, Amorphous Nylon, PET Polyester, Polyester (decals), FKM (gasket

& seals), Stainless Steel (fasteners),

PVC (cable jacket)

Power Source:

On-board, field-replaceable, 9-volt

Lithium battery

Battery Life:

Approximately 4 years

Configuration:

2-Totals (1 cumulative and 1 batch),

Rate, 2 Cals (Factory calibration in

gallons or liters; 2 field calibrations),

K-factor must be programmed for

each size meter.

Input Signal:

NPN Open-collector, Hall Effect or

Reed Switch

Time Base:

Hours for FPD1000 Series Low Flow

Minutes for FPD1000 Series High Flow

Unit of Measure:

U.S. gallons or liters

Accuracy:

No additional error over coupled flow

meter’s accuracy

Frequency Range:

0 to 750 hertz

Batch Total:

Up to 999,999 (x100)

Cumulative Total:

Up to 999,999 (x100)

11

Page 14

Temperature:

0° F to +140° F (–18° C to +60° C)

Cable:

20 ft., 3-conductor (red, black & white),

tinned drain wire, 22 AWG, PVC jacket

.212 dia., (Reference Belden 9363 or

equivalent cable)

Mechanical Connections:

Wall or pipe mountable with standard

U-bolts

Electrical Connections:

One strain relief port: PG7 (1/2-20)

thread. Grip range: .11 to .26 inches

One threaded port plugged (1/2-20)

1 additional strain relief required on

the flow meter.

Dimensions:

Width: 4.5 in. (11.4 cm)

Height: 6 in. (15.2 cm)

Depth: 2.5 in. (6.4 cm)

Shipping Weight:

1 lb. (.45 kg)

12

Page 15

Page 16

M-4 128 / 1010

Loading...

Loading...