Page 1

®

FL-X SERIES

FL-W Series

Water Meter Monitors

Water Meter Monitors

INSTRUCTION

SHEET

M0374/1098

INSTRUCTION

INTRODUCTION

The OMEGA FL-X Series Flowrate Indicators utilize fluid movement to actuate

a swinging vane, which drives the scale pointer attached to the vane shaft,

SHEET

and triggers the signal switch. These flowmeters are ideal for use on fresh or

sea water, deionized water, steam condensate, and a variety of organic and

inorganic liquids. The corrosion-resistant construction includes no breakable

tubes and a display that is unaffected by the opacity of the fluid.

SPECIFICATIONS

ACCURACY: + 5% full scale.

REPEATABILITY: + 1% of reading.

PRESSURE DROP: 2.2 psi, average

SIGNAL SWITCH: 3-wire SPDT. Rated 15 A @ 125 VAC, CSA/CE Rated

MAX. PRESSURE: 200 psig at 200 ˚F

HOUSING MATERIAL: PoIysulfone

INTERNAL WETTED PARTS: 316SS

SEALS: Viton

CONNECTIONS: 3/4" NPT, female, plastic

WEIGHT: 1 lb. 12 oz.

Flow Range Readout

Model No. (GPM Water) Increments

FL-X2 0-2 .5

FL-X3 0-3 1

FL-X4 0-4 1

FL-X5 0-5 1

FL-X6 0-6 1

FL-X7 0-7 1

INSTALLATION

This is an in-line device. To install, place wrench on fitting only, not meter

housing, to prevent cracking housing and/or fitting. Thread your piping into

the NPT ports, with flow going into the port marked “IN”. Mounting can be in

any position. See dimension diagram.

RECOMMENDED INSTALLATION PRACTICES

Water hammer and surges can be damaging to any flowmeter and must

always be avoided. Water hammer occurs when a liquid flow is suddenly stopped as with quick closing and solenoid operated valves. Surges

occur when flow is suddenly begun, as when a pump is turned on at full

power or a valve is quickly opened. Liquid surges are particularly damaging to flowmeters if the pipe is originally empty. To avoid damaging

surges, fluid lines should remain full (if possible) and pumps should be

brought up to power slowly and valves opened slowly. In addition, to

avoid both water hammer and surges, a surge chamber should be in-

stalled.

ADAPTER

FITTING

DIMENSION DIAGRAM

M0373/1097

6-1/2

3-1/2

3-5/16

5-7/8

4-3/8

2-5/8

ELECTRICAL

CONNECTION

3/4 NPT

4-1/2

6-1/2

5°

SWING

RADIUS

CONNECTING THE SWITCH

To connect the switch, refer to the switch diagram.

NC

C

NO

3-Wire SPDT

SWITCH DIAGRAM

F

INCREASING

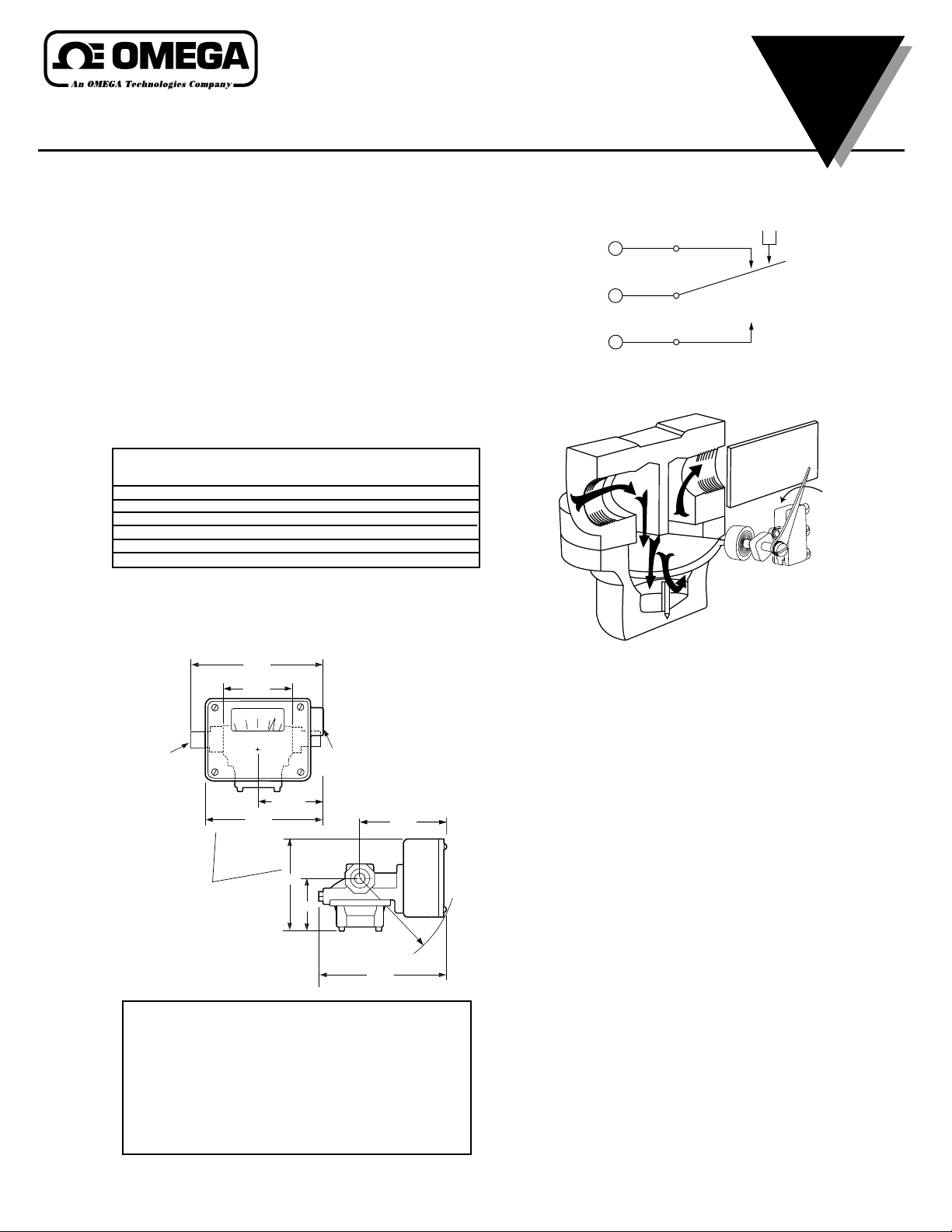

THEORY OF OPERATION

2

1

3

C

4

A

B

D

G

E

Fluid enters at A, passes around the semi-circular swinging vane B, and exits

at outlet C. The vane resists the fluid passage because of the constant-torque

spring D. As the vane is pushed farther down, the passage E gets larger to

accommodate the larger flow at no increase in pressure drop. The pointer F is

mounted on the vane shaft, as is an adjustable cam G, to trigger an electric

switch H.

0

F

H

SETTING THE SWITCH POINT

The cam that actuates the switch is located on the dial assembly. The position

of the cam dictates the switch point, i.e., the flow rate at which the cam throws

the switch. (Usually, the switch point is initially set at OMEGA.) To set or reset

the switch point, proceed as follows:

Warning: Shut off the electric power to the control box before opening it.

1. Remove the nameplate, window, and gasket from the control box.

2. The cam that actuates the switch is located just under the pointer. The

position of the cam dictates the flow rate at which the cam will trip the

switch.

3. Turn the pointer so that it points at the desired flow rate on the scale.

Against the low spring forces of the small Vane style models you can do this

by grasping the pointer itself (and holding it in position while you adjust the

cam).

4. While holding the pointer in the desired position, depress the cam ring

fully (approx. 1/16 inch) and rotate it until the switch actuates (clicks).

Release your downward pressure and the cam ring will lock at that position.

5. If you can’t hear the switch click, you can determine contact closure with

an ohmmeter connected across the switch terminals. Connect to the

common and normally open or normally close on the switch.

6. To check the setting, direct the pointer again to the desired flow rate,

noting where the switch actuates. Make adjustments as necessary. If the

bowl was removed please place on guide roll pins and firmly tighten, in a X

motion.

7. It’s much easier to set the switch point if you can do it with actual flow

present. Adjust the flow to the desired point where you want a signal to

occur and turn the cam to actuate the switch as outlined above.

8. Replace window, nameplate, and gasket before turning on electric power.

1

Page 2

omega.com

TM

OMEGA

®

USA

MADE

IN

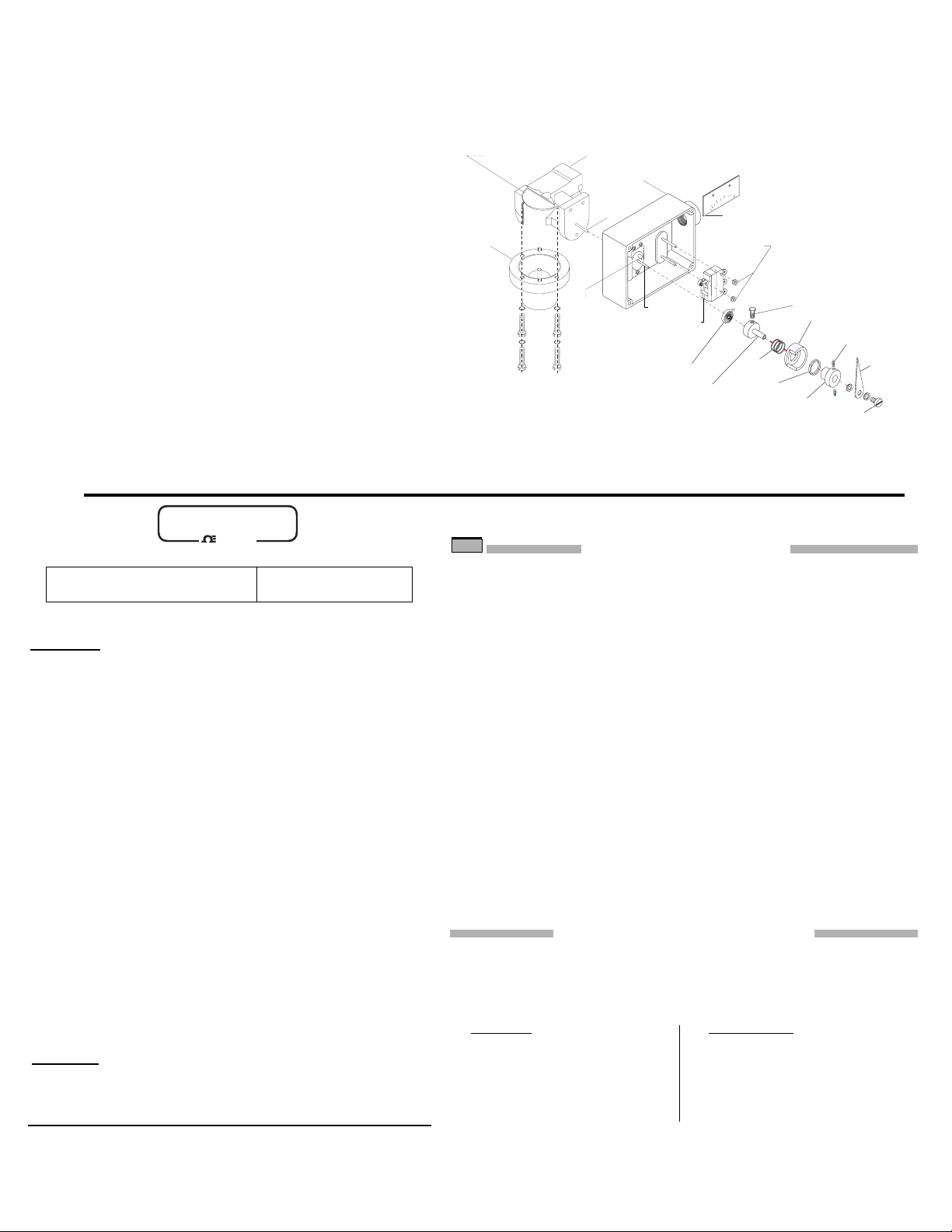

CHANGING THE SPRING (SMALL VANE STYLE)

Remove all parts attached to the shaft, from the spring to the pointer screw.

These parts will come off as an assembly by loosening the dial screw. The

cam screw may also have to be loosened so that the assembly will slide freely

off the shaft.

Remove the old spring from the assembly and replace. The new spring is

attached to the indicator dial by pressing the bent inside tip of the spring into

the slotted hub. If slot is too tight, run a knife through it.

Slide the assembly back onto the shaft and rotate it counterclockwise until the

outside spring loop engages the roll pin in the control box. (Flow direction can

be determined by noting “IN” and “OUT” marks on ports, looking from front of

unit). Pull the assembly back out slightly so that the spring is not sandwiched

and can move freely. Now rotate the assembly in the same direction until the

dial screw is at 12 o’clock (perpendicular to the top of the control box). This will

automatically bring the unit to its original calibration. Then tighten the dial screw.

PERIODIC MAINTENANCE

Using a valve to vary the flow, observe the pointer tracking the flow rate. If the

flow monitor does not respond properly, it is probably due to foreign material

building up around the swinging vane and hanging it up. The vane can sometimes be jogged loose by manipulating the pointer. If it doesn’t free up, remove

the bowl and clean out the flow chamber around the swinging vane with a

knife or brush.

For replacement parts, contact OMEGA Engineering Customer Service Department at (203) 359 - 1660.

SWINGING VANE

BOWL

SMALL HOUSING

CONTROL BOX

SHAFT

ROLL

PIN

3 WIRE SPDT SWITCH

SHAFT

SPRING

INDICATOR DIAL

Parts Drawing

SCALE

HEX NUTS

SPRING

O RING

CAM RETAINER

DIAL SCREW

CAM RING

ALLEN SCREWS

POINTER

POINTER SCREW

OMEGAnetSMOn-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA:

ISO 9001 Certified

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: canada@omega.com

For immediate technical or application assistance:

USA and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

En Espan˜ol: (203) 359-1660 ext: 2203 e-mail: espanol@omega.com

SM

SM

SM

SM

FAX: (95) 203-359-7807

Servicing Europe:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Ostravska 767, 733 01 Karvina

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

e-mail: czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: 33 0130-621-400 FAX: 33 0130-699-120

Toll Free in France: 05-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

25 Swannington Road, P.O. Box 7, Omega Drive,

Broughton Astley, Leicestershire, Irlam, Manchester,

LE9 6TU, England M44 5EX, England

Tel: 44 (1455) 285520 Tel: 44 (161) 777-6611

FAX: 44 (1455) 283912 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or written

request. Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at

no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of being damaged as a result of excessive corrosion; or

current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior

written consent of OMEGA ENGINEERING, INC.

RETURN REQUESTS / INQUIRIES

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

2

WARRANTY/DISCLAIMER

Loading...

Loading...