Omega Products FL-W01 Installation Manual

®

FL-W Series

Water Meter Monitors

INSTRUCTION

SHEET

M-0373/1206

INTRODUCTION

OMEGA ’s FL-W Series of Water Flow Monitors are rugged, vanable-area flowmeters that can be used with

flows from 1 gpm to 90 gpm. These flowmeters utilize

the fluid movement to actuate either a swinging vane

or piston, which drives the scale pointer and triggers

the signal switch. Models FL-W01, FLW02, FL-W05,

FL-W10, FL-W15 and FL-W20 use the piston design.

Models FL-W30, FL-W40, FL-W50, FL-W60, FL-W70,

FL-W80 and FL-W90 use the swinging vane design.

SPECIFICATIONS

ACCURACY: _+ 5% full scale / piston models;

± 2% full scale / vane models

REPEATABILITY: + 1% of reading

TEMPERATURE RA TING: 200 ˚F max.

PRESSURE RATING: 150 psig max. (piston models);

300 psig max. (vane models)

PRESSURE DROP: 2-5 psi (piston models);

2.2 - 3.8 psi (vane models)

SIGNALSWITCH: 3-wire SPDT, 15 A @ 125 V AC,CSA/CE rated

INTERNAL WETTED PARTS: 300 Series SS

SEALS: Buna and T eflon (piston models); Buna (vane models)

Model Flow Rate Readout Port Design

Number GPM Increments Size Type

FL-W01 0-1 0.2 3/4" PISTON

FL-W02 0-2 0.25 3/4" PISTON

FL-W05 0-5 1.0 3/4" PISTON

FL-W10 0-10 2.0 3/4" PISTON

FL-W15 0-15 3.0 3/4" PISTON

FL-W20 0-20 4.0 3/4" PISTON

FL-W30 0-30 5.0 1 1/2" VANE

FL-W40 0-40 5.0 1 1/2" VANE

FL-W50 0-50 10.0 1 1/2" VANE

FL-W60 0-60 10.0 1 1/2" VANE

FL-W70 0-70 10.0 2" VANE

FL-W80 0-80 10.0 2" VANE

FL-W90 0-90 10.0 2" VANE

INSTRUCTIONS FOR MODELS FL-W30,

FL-W40, FL-W50, FL-W60, FL-W70, FLW80 and FL-W90

THEORY OF OPERATION

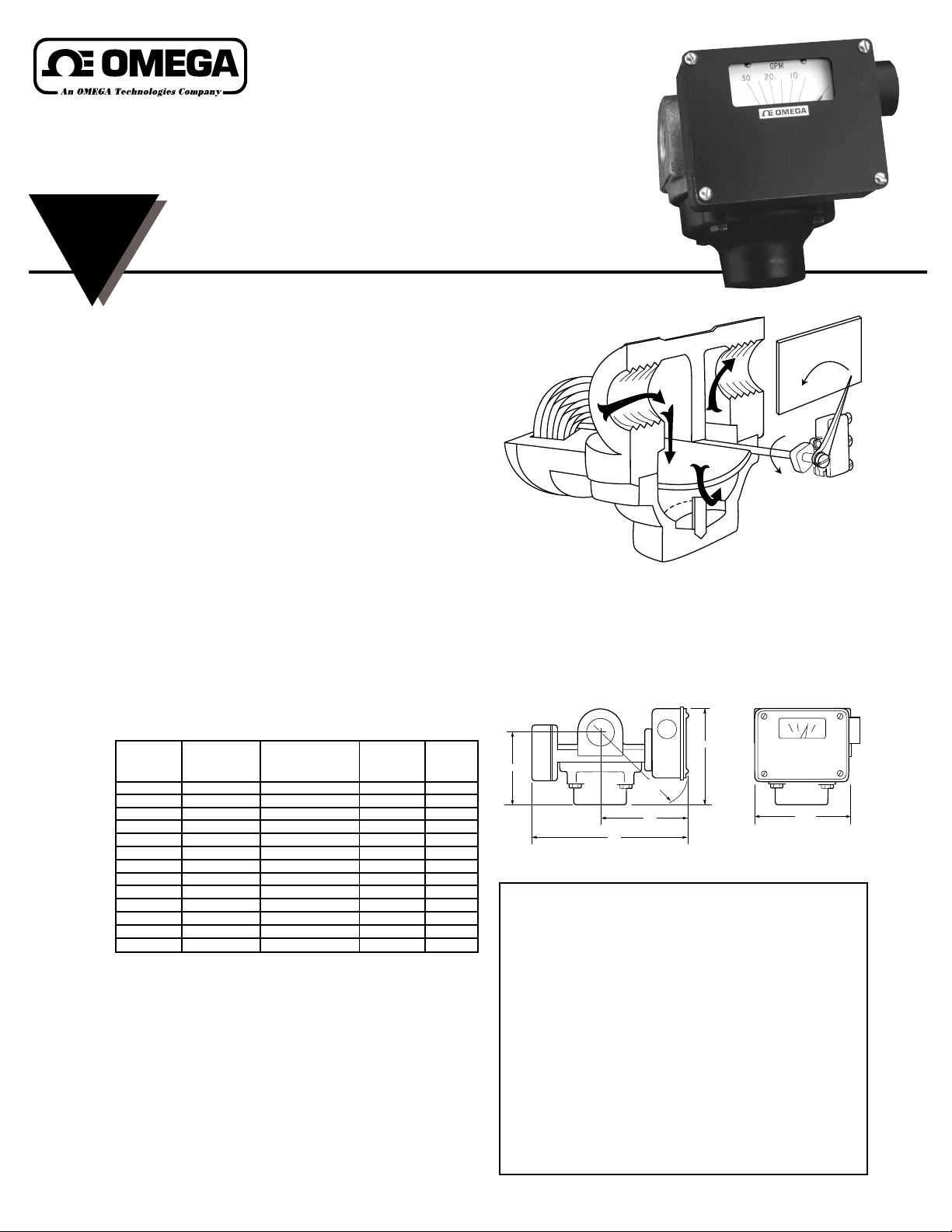

The FLW flow monitor utilizes the kinetic energy of a

flowing liquid to move a spring-biased swinging vane.

This action varies the orifice size in proportion to the

flow rate. The vane is mechanically linked to a pointer

which indicates the rate of flow on a scale. This mechanical output can also be used to trip electric

switches.

NPT

12

16

20

OPERATION DIAGRAM

INSTALLATION

This is an in-line device. To install, thread your piping

into the NPT ports, with flow going into the port

marked “IN”. Mounting can be in any position. See

dimension diagram.

4-1/2

4-1/2

RECOMMENDED INSTALLATION PRACTICES

Water hammer and surges can be damaging to

any flowmeter and must

Water hammer occurs when a liquid flow is suddenly stopped as with quick closing and solenoid

operated valves. Surges occur when flow is suddenly begun, as when a pump is turned on at full

power or a valve is quickly opened. Liquid surges

are particularly damaging to flowmeters if the pipe

is originally empty . To avoid damaging surges, fluid

lines should remain full (if possible) and pumps

should be brought up to power slowly and valves

opened slowly . In addition, to avoid both water hammer and surges, a surge chamber should be installed.

1

5-5/8

SWING

RADIUS

5

9

DIMENSION DIAGRAM

always

5-1/2

be avoided.

8

4

0

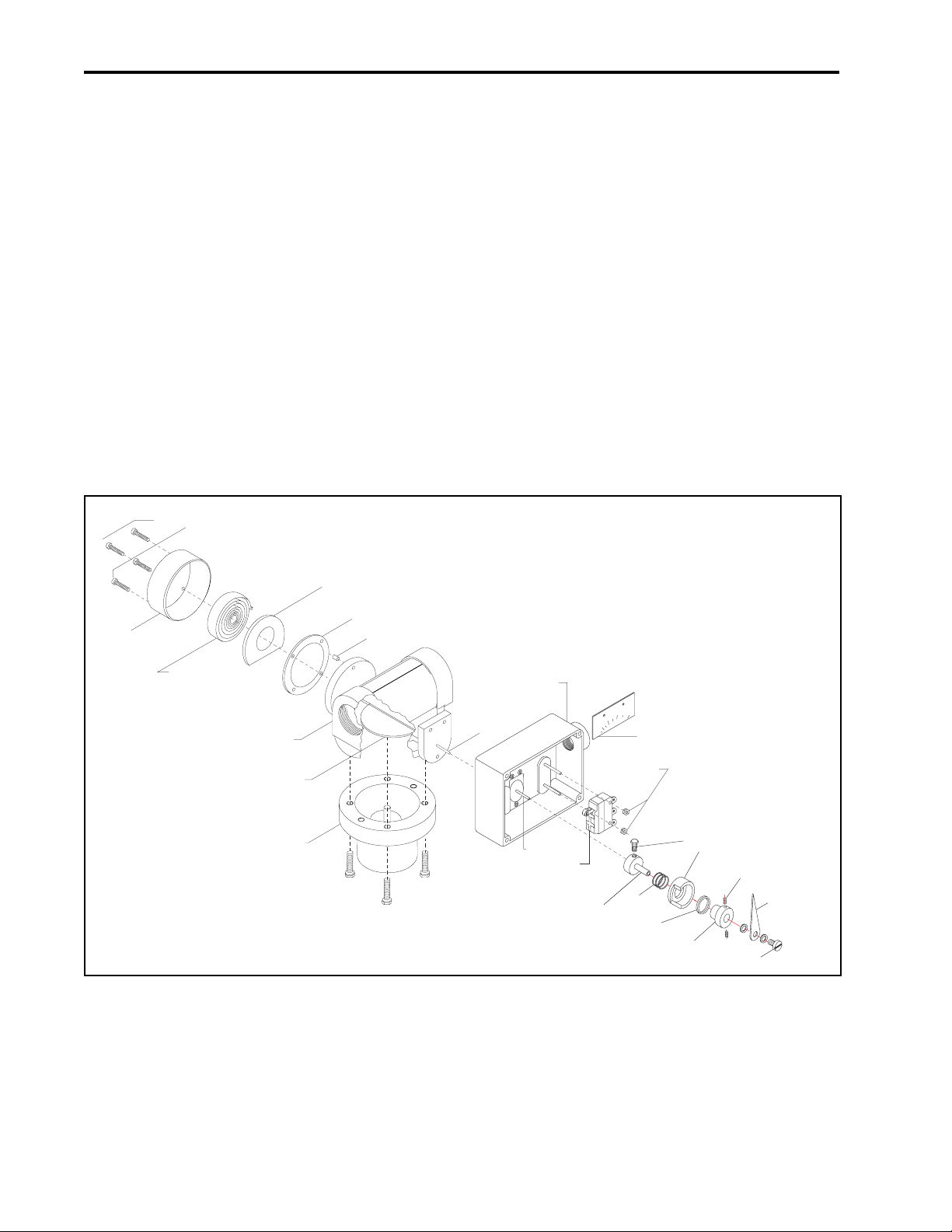

CHANGING THE SPRING (VANE STYLE)

Remove the spring cover and the main spring. Place

the new main spring onto the shaft and attach it by

sliding the hole in the inside loop of the coil over the flat

head rivet, and then place the outside loop over the roll

pin with only 1/4 turn of the spring counter clockwise.

SOCKET HEAD CAP SCREWS

PERIODIC MAINTENANCE

Using a valve to vary the flow, observe the pointer

tracking the flow rate. If the flow monitor does not

respond properly, it is probably due to foreign material building up around the swinging vane and hanging it up. The vane can sometimes be jogged loose

by manipulating the pointer. If lt doesn’t free up, remove the bowl and clean out the flow chamber around

the swinging vane with a knife or brush.

For replacement parts, contact OMEGA Engineering

Customer Service Department.

SPRING COVER

MAIN SPRING

MEDIUM SPRING PLATE

MEDIUM HOUSING

SWINGING VANE

BOWL

GASKET

ROLL PIN

CONTROL BOX

SHAFT

3 WIRE SPDT SWITCH

PARTS DIAGRAM FOR VANE MODELS

SHAFT

INDICATOR DIAL

SCALE

HEX NUTS

INDICATOR DIAL

SPRING

O RING

CAM RETAINER

SCREW

CAM RING

ALLEN SCREWS

POINTER SCREW

POINTER

2

Loading...

Loading...