Page 1

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

FLC Series

Clear In-Line Flowmeters

M-4402/1207

Shop online at

Page 2

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds

an additional one (1) month grace period to the normal one (1) year product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by the company will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1)

as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or

activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or

with any nuclear installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from

any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2007 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espanol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

FLOWMETERS

FLC Series – Clear In-Line Flowmeters

Basic Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Basic Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warning and Precautionary Areas . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Reading the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Specific Gravity or Density Effect . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Recommended Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Stabilized Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Contamination Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Page 4

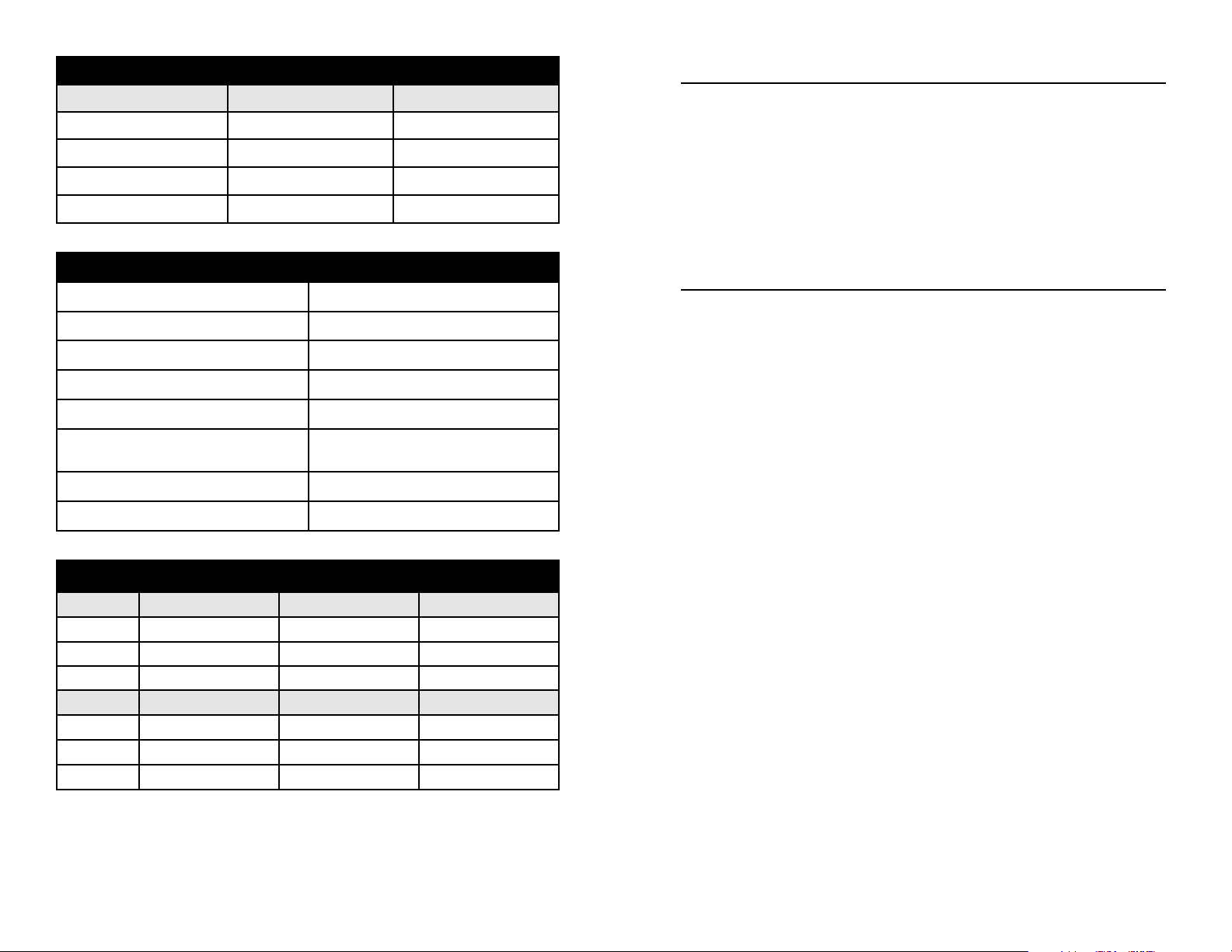

Mechanical Dimensions

DIM ½" Male ¾" Male 1" Male

A 2-7/16" (62mm) 2-7/16" (62mm) 2-7/16" (62mm)

B 7-11/16" (195mm) 8-1/32" (204mm) 8-3/32" (206mm)

Port Size NPTF ½", SAE #8 NPTF ¾", SAE #12 NPTF 1", SAE #16

DIM ½" Female ¾" Female 1" Female

A 2-7/16" (62mm) 2-7/16" (62mm) 2-7/16" (62mm)

B 7-5/32" (182mm) 7-9/16" (192mm) 7-9/16" (192mm)

Port Size NPTF ½", SAE #8 NPTF ¾", SAE #12 NPTF 1", SAE #16

Performance

Measuring accuracy: ±5% of full-scale

Repeatability: ±1% of full-scale

Flow Measuring Range: 1-30 GPM (5-110 LPM)

Turn Down Ratio (All Ranges:) 10:1

Maximum operating pressure: 325 PSIG (22.4 bar)

Maximum operating temperature:

FLC-W Series: 200°F (93°C)

FLC-H Series: 250°F (121°C)

Pressure Differential: See graph on right.

Filtration requirements: 74 Micron (200 U.S. mesh) min.

Materials of Construction (Wetted Components)

FLC-W Series FLC-H Series

End Ports Polysulphone Polysulphone

Seals Buna-N Buna-N

Spring Stainless Steel Stainless Steel

Indicator and Casing Polycarbonate Polysulphone

Page 4

Stabilized Contamination

The goal of filtration is to create effective protection from system

contamination. Proper filtration stabilizes contamination to allow fluid

components to function properly. A fluid system is considered

stabilized when, “contamination in” equals “contamination out”. Proper

filtration must reduce initial contamination to a stabilized level within

an acceptable time period. the system should be stabilized in time to

prevent premature wear or damage to meter components.

Contamination Sources

Fresh Fluid

When fresh fluid is stored in holding tanks, it may be contaminated

with scale or metal flakes from inside the tank. To prevent this type of

contamination, be sure to filter fresh fluid before adding to the system.

New Machinery Contamination

When building new machines, a certain amount of built-in

contamination is unavoidable. Typical built-in contamination consists

of dust, dirt, chips, fiber, and sand, flushing solutions, moisture, weld

splatters and pipe sealants. Flushing the system before operation can

reduce contamination, but cannot eliminate it totally.

Unless the system is flushed at a high velocity, some contamination

will not be dislodged until the system is in operation. System

contamination can cause fluid component malfunction.

Environmental Contamination

When performing routine maintenance, the system's fluid is

commonly exposed to environmental contamination. Exercise caution

during routine maintenance to prevent this type of contamination. Be

sure to change breather filter and systems air filter regularly.

Self-Generation Contamination

Self-generated contamination is a product of wear, cavitation, fluid

breakdown and corrosion. Systems that are carefully flushed,

maintained, and have fresh fluid added, mainly have self-generated

contamination. In this case, proper filtration can prevent fluid

component malfunction.

Page 9

Page 5

Basic Application Information

The flow meter can be installed directly in the fluid line without flow

straighteners or special piping. The meter is used to measure the flow

rate of most liquids which do not contain particles greater than 74 micron.

1) The casing and union retainers are made of either Polycarbonate

or Polysulphone materials permitting use with a variety of media.

Use of mild detergent to clean the meter body is encouraged to

prevent damaging the label or associated components.

2) The meter may be mounted in the most convenient location, in any

orientation to allow easy access for reading and maintenance.

3) The Meters should NOT be mounted near hot pipes or

equipment which can cause damage to the pressure vessel.

4) The Meters should not be mounted in a manner such

that piping misalignment or other system components can exert

force or produce a bending moment on the pressure vessel.

5) To retain accuracy and repeatability, internal moving parts are

closely toleranced and require filtration of at least 74 micron or a

200 mesh screen.

Basic Installation Information

The meters are mounted in-line and are direct reading. The meters

can be mounted in a vertical or horizontal position as long as the fluid

is flowing in the direction of the arrow on the flow scale. No straight

pipe is required before or after the meter. In fact, 90° elbows can be

installed on both ends without any noticeable flow variation. When

installing a meter, apply “Teflon Tape” on pipe threads. DO NOT apply

pipe dope or Teflon paste. If tape is used, be sure to leave 1/8" (3 mm)

of pipe thread exposed on end of pipe. Position filter in front of meter

and in a location that allows easy access for routine maintenance.

Refer to “Warnings and Precautionary Areas” for additional information.

INSTALLATION DOS AND DON'TS

To obtain satisfactory operation from the flow meter, the following

points should be considered:

Page 5

Reading the Meter

Notice the black reference line which runs 360° around the metering

poppet. This reference line moves under the scale in direct relation to

the movement of the poppet. When fluid is flowing, the flow rate

through the meter is read by lining up the black reference line with

the closest rate line on the flow scale.

Specific Gravity or Density Effect

Standard meters are calibrated for either WATER with a specific gravity of 1.0 or OIL with a specific gravity of .873. The floating disk meter

is affected by fluid density as are most other similar type meters.

Omega’s meters have less of this effect because of the sharpness of the

floating orifice disks being used. The indicated flow reading will read

high for heavier fluids and low for lighter fluids. A corrective factor can be

applied to the standard scale or a special scale can be added at a slight

additional costs. When measuring fluids with other specific gravities, the

basic equations below can be used to develop corrected readings.

CONTAMINATION AND FILTRATION

Recommended Filtration

The manufacturer recommends system filtration of at least 74 micron filter or a 200 mesh screen. It has been found that if inadequate filtration

has caused meter failure, it will normally fail in the open position. Some

systems may require a magnetic filter. IMPORTANT: Meter damage

caused by excessive contamination is not covered under warranty.

Page 8

Page 6

DO:

install a pressure gauge near the inlet of the meter

place throttling valves at the outlet of the meter

use pipe sealer on the connections

install solenoid valves at meter outlet (as far downstream as

possible)

mount in any orientation: vertical, horizontal or upside down

DO NOT:

place restrictions between the meter's pressure gauge meter inlet

use in systems where reverse flow is possible

place meter in non-aligned piping

over-flow the meter by more than 150% of maximum reading

operate at pressures and temperatures greater than specified

Warning and Precautionary Areas

1) The meters are designed to operate in systems that flow in only

one direction: the direction of the arrow on the flow scale.

Attempting operation in the reverse direction may cause damage

to the meter or other system components.

2) The pressure vessel and its associated components are made of

Polycarbonate on the FLC-W meters. Polycarbonate can

be safely cleaned with soap and water. However, many other

cleaning agents can damage Polycarbonate, causing discoloration

or crazing.

3) When installing onto threaded pipe, caution should be taken not to

over tighten the pipe connections or introduce torque on the main

body of the meter. The meter main body may rupture if overtightened.

4) Meter should not be used in systems where the assembled piping

is not supported. Externally applied piping forces may cause the

meter to rupture or malfunction.

5) Operating Temperature: In standard meters, several components

have a maximum temperature rating (see specifications).

Page 6

6) Operating Pressure: All meters are tested at a burst pressure three

times that of operating pressure. Meters should not be used over

the operating pressure rating.

7) Teflon tape: Caution should be used when using Teflon tape on

pipe thread joints. Leave at least 1/8" (3mm) of pipe thread

exposed from end of pipe when applying tape.

OPERATION

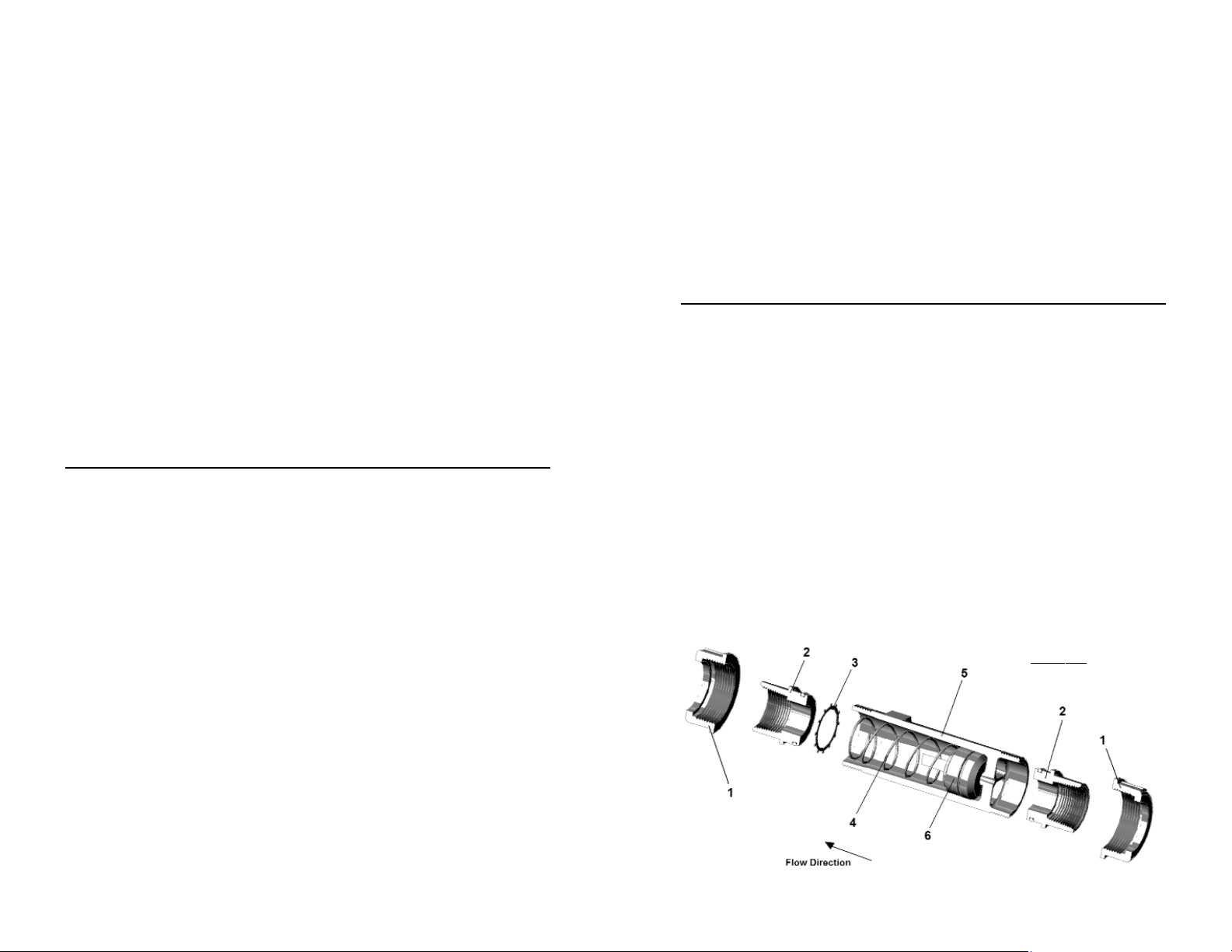

Operating Principles

Omega has developed a line of unique flow meters which combine

the simplicity of a sharp-edged orifice disk and a variable area flow

meter. See Figure 1 “Flow Meter Cross Section” below. The meters

are tubular, with all internal wetted parts sealed within the body

casing (5). Running through the center of the body casing is a

tapered center shaft which is centered in the bore. Encircling the shaft

is a sharp-edged, floating metering poppet (6). The metering poppet

is held in the “no flow” position by the biased return spring (4). As the

flow moves through the meter it creates a pressure differential across

the floating orifice disk, forcing the disk and transfer magnet against

the return spring. As flow increases, the pressure differential across

the metering poppet increases, forcing poppet to move along the

tapered center shaft. As flow decreases, the biased return spring

forces the poppet down the tapered center shaft, returning to the “no

flow” position.

Page 7

Figure 1:

Flow Meter Cross Section

Loading...

Loading...