Page 1

FL9000-ACSERIES

Flowmeters

Operator’s Manual

Page 2

FLWOO-AC

SERIES INSTALLATION

OMEGA@

The

rugged proven technology of a direct reading,

type, variable area flowmeter, with a

solid state switching module This combination aids the

machine designer/troubleshooter by providing

taneous flow-rate

The

1.

plastic. Polysulfone is a strong

remains very stable to

precautions must be observed to ensure proper

performance.

a)

b)

cl

dJ

FL9000-AC

READ INSTRUCTIONS THOROUGHLY BEFORE INSTALLING FLOWMETER

FL9000-AC

The meter will melt, crack or distort if exposed to

an open flame or excessive heat. Therefore, DO

sweatfit

NOT

mounted to the plastic flowmeter body.

Pipe dope MUST NOT CONTACT the plastic

flowmeter body. Some pipe dope formulas will

react adversely with Polysulfone. If a sealing

material is necessary, use of Teflon tape is

recommended.

Do not over-tighten the threads on the plastic

flowmeter body. Overtightening NPT pipe

threads may cause fracturing of the plastic

flowmeter body.

Piping on the inlet and outlet of the flowmeter

must be aligned. Pay special attention to this

Flowmeter combines the

piston-

hermeticaiy

indrcation,

Flowmeter is made of polysulfone

brass fittings into a system while

coupled with the

?hermoplastic,

21O’F.

However, some

sealed,

instan-

IMPORTANT

and

s

electronic signal module, which automatically alerts the

operator. or controller if an incorrect flow rate is detected.

verification, pump testing, etc

2.

3.

4.

5.

.

Uses of this product include cooling

indication and verification, lubrication oil indication and

when high temperature, high pressure, or a

combination of both may be encountered.

e)

Check the compatibility of the fluid in the system

with the materials used in the flowmeter.

FL9000-AC

The

straight pipe at the inlet or outlet to stabilize the flow

through the meter.

FL9000-AC

The

orientation. Its design allows the designer/installer to

mount the flowmeter in horizontal piping, or vertical

piping, without affecting meter accuracy.

FL9000-AC

The

normally jam valves and other flow controls. If

particulate will be encountered, a 200 mesh or 74

micron filter is recommended.

Notice the “Flow Direction” arrow located on the

flowmeter scale The

valve to flow moving against the arrow.

DOES NOT require lengths of

can be mounted in any plane of

will tolerate particles that will

FL9000-AC

water/Glycol

will act as a check

Page 3

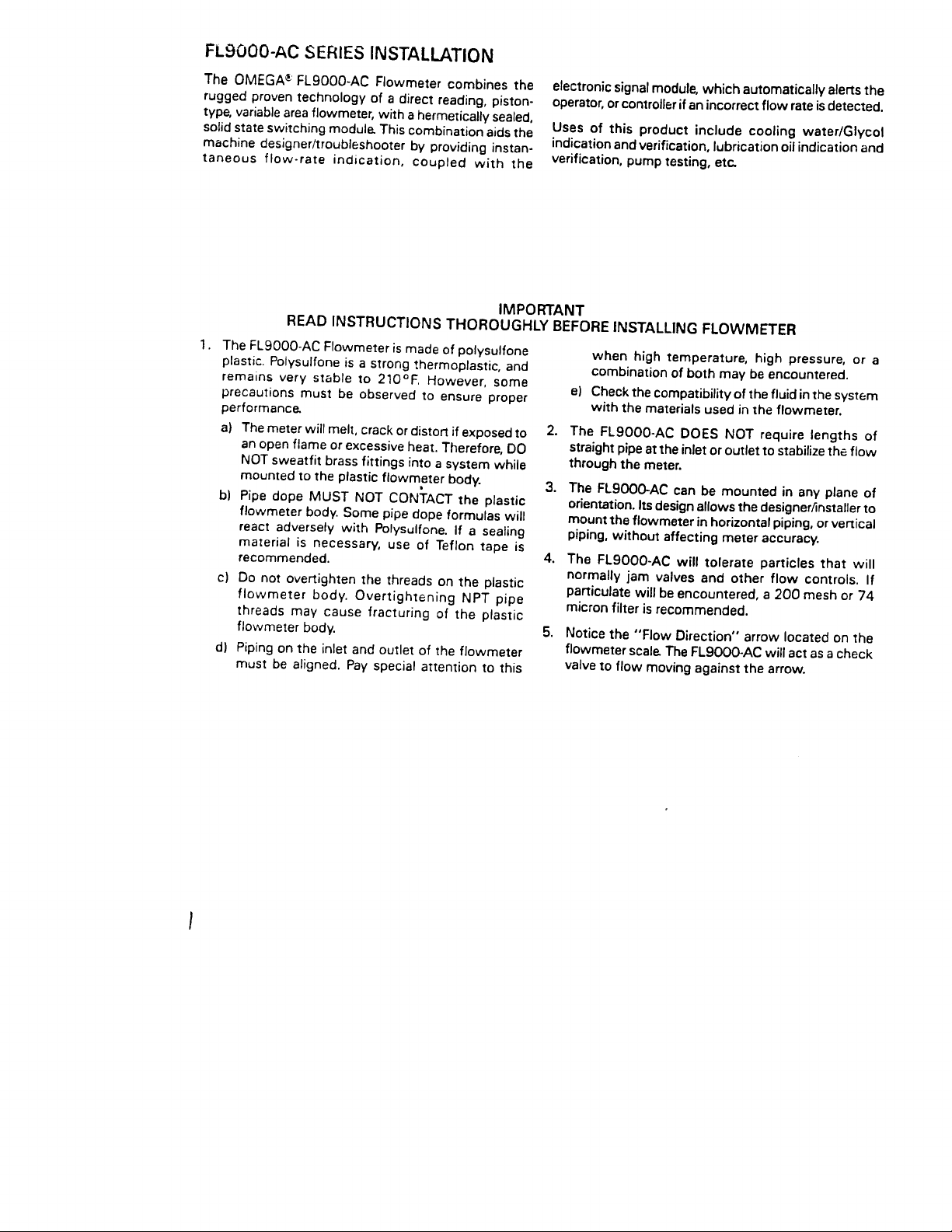

FLOW ALARM ASSEMBLY

RETAINING

(Fig. 1)

After the Flow Meter is installed, loosen the cap screw

on the electronic alar m assemb ly (see Figure 1). Adjust

the assembly so that the retaining band centers

approxi ma tely at the desired flow alar m position. Then,

retighten

cap screw securely. The module turns “on” as

BAND

flo w exceeds preset. The

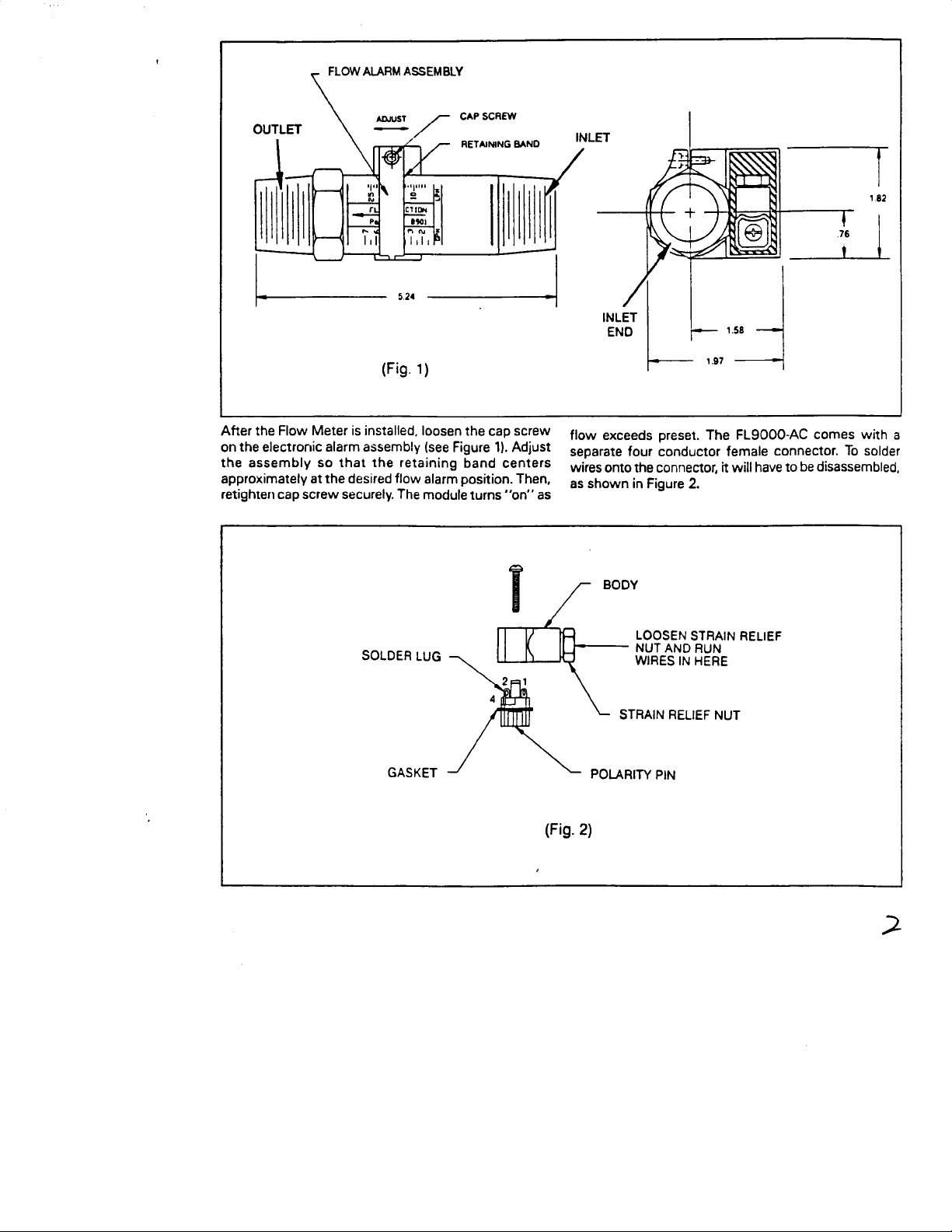

separate four conductor female connector. To solder

wires onto the connector, it will have to be disassembled,

as shown in Figure 2.

J

FL9000-AC comes w ith a

SOLDER LUG

GASKET

(Fig. 2)

LOOSEN STRAIN RELIEF

NUT AND RUN

W IRES IN HERE

STRAIN RELIEF NUT

2

Page 4

The connector has four

On the FL9000

3 and 4 are not used. On the

unit with the VAC flow alarm, terminals

flow alarm, terminal

solder lugs labeled

FL9DCKl

3 is not used. It should be noted

1.2.3

and 4.

unit with the VDC

before reassembly, which wire is connected to which

-

solder lug.

see

Color coding, or labeling the

6gures

3a

and

3b

wires is advised.

STRAIN RELIEF NUT

POlARlPl

(Fig.

After securing wires to solder lugs, a determination of the

orientation that the body of the connector should face.

needs to be

into the connector body, see Figure 4 below,

mada

PIN

3al

Before snapping the conductors back

4

After choosing orientation A, B or C, snap connector

back together, pull excess wires out of strain relief, and

tighten strain nut. Plug into electric housing and secure

with screw.

r

INLET OF FLOWMETER

-

ELECTRONIC

STRAIN RELIEF NUT

POLARITY PIN

(Fig.

HOUSING

3b)

3

POLARITY PIN

(Fig. 4)

Page 5

FL9000-AC

The

variety of different

is designed to turn “on” or “off” a

115VAC

loads. Examples of loads

include: Solenoid valves, warning lights and AC relay

coils. The module can only switch loads that consume

between 2.5 and 90 watts, or have 5000R to 150R

impedance respectively. If the load draws less than 2.5

watts, a loading capacitor is required. The capacitor ’s

value and connection is demonstrated in Figure 5. If the

load draws greater than 90 watts, a power relay is

necessary. Figs. 6 and 7 show typical relay connections.

Wiring Configurations:

Conventional Connection: See Fig. 5

1.

3 Load limited by relay contacts

3.

The Schematic in Fig. 5 will provide conduction over

15-20% of full scale above, or below the flow rate set

point.

LOADS CAP. MUST BE

RATED

XS’OOV

INWCT lVE

WITH

Fig. 5

foad

1

must draw between 2.5 and 90 watts. For

loads smaller than 2.5 watts, see

#2.

For loads

greater than 90 watts, see Figs. 6 and 7.

2 Loads consuming less than 2.5 watts require a

0.47

PF

capacitor connected as shown. This

capacitor will increase the power consumption and

ensure complete conduction.

2. Conventional Relay Connections: See Fig. 6

Fig. 6 demonstrates a SPDT relay with a 115 VAC coil

integrated with a flow alarm module. This

combination allows switching of loads up to the

rating of the relay contacts.

VW

11s

RELAY

1

Y

3

:

RELAY CONTACT

RI

I

I

I

4

I

Fig. 6

latching Relay Systems: See Fig. 7

The Flow Alarm Module can be integrated with

latching type relays, or a simple latching system can

be connected as in Fig. 7.

DPDT

RELAY

W

BUT

f

-1

I,

0

TON

“LLA,

0

RELAY CONTACT

LUNIACI

Y,

IF--- -

The module will turn the relay “on” as flow either

exceeds, or falls below the flow rate set point. The

relay will remain activated until the reset button is

depressed.

Page 6

Wiring Configurations for VDC Flow Alarm:

1. For relay output:

al Relays with coil voltage

between 7 and 24 VDC.

b)

Relays with coil voltage

between 4 and 60 VDC.

TTL/CMOS interface:

2. For

FROM

CONNECTOR

3. Other loads (eg. lamp, buzzer,

.

etc)

The load must draw less than

0.5 amps at 7-24 VDC. If the

load uses in excess of 0.5

amps or 24 VDC, section 1

wiring must be used.

Note: See specifications to avoid damage to FET (transistor).

CAUTION: To protect the FET from damage due to inductive

collapse, use a “catch” diode, as demonstrated in section 1 of wiring

configurations, when switching inductive loads such as solenoids

and relay coils. Connection of Terminal 1 directly to a voltage source

will destroy the unit.

VCLTAGE

Page 7

SPECIFICATIONS

ACCURACY:

REPEATABILITY:

MAX. TEMP./PRESSURE:

MAXIMUM PARTICLE SIZE:

SIZE:

CONNECTION:

MATERIAL:

f

7% full scale

f

1% full scale

7ooF;@

220 PSI

60

PSI at

74 microns for standard

units; 400 microns for

ribbed piston water

meters

3h”

1

FL-9200- ‘/(a”

FL-9000 and

Length

(‘A”

(1’/6”

Copper Tubing. FL-9000

and

Male

Polysulfone

210°F

across flats,

Length;

9100-5%

%”

O.D.) or 1” Nominal

O.D.)

Type M

FL9100-1”

NPT,

*

NominalFL9200-Fits

WETTED PARTS:

ALARM

SETPOINT:

RELAY:

Polysulfone,

steel,

barium ferrite

Proximity switch

triggering a

1 amp

over 25% of span, and

drops out above and

below that. Includes

mating connector. Relay

not field installable

Adjustable

stainless

Buna-N,

and

110

Relay pulls in

triac.

O-100%

VAC

FS

@

Page 8

ONLY

OUALlFlEO PERSONNEL. NO WARRANTY EXTENDED HEREIN WILL APPLY IF SUCH UNIT IS INSTALLED OR

U

SED BY

UNOUALIFIED PERSO

ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED. INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AN0 OF FITNESS FOR A PARTICULAR PURPOSE. OMEGA

ENGINEERING, INC IS NOT RESPONSIBLE FOR ANV DAMAGES OR LOSSES CAUSED TO OTHER

EOUIPMENT. WHETHER DIRECT. INDIRECT. INCIDENTAL. SPECIAL OR

PURCHASER MAY EXPERIENCE AS A RESULT OF THE INSTALLATION OR USE OF THE PRODUCT THE

BUYER ’S SOLE REMEDY FOR ANY BREACH OF THIS AGREEMENT BY OMEGA ENGINEERING. INC OR ANY

OF

ANY

BRV\CH

PAID BY THE

DIRECTLY AFFECTED BY SUCH BREACH.

EVERY PRECAUTION FOR ACCURACY HAS BEEN TAKEN IN THE PREPARATION OF THIS MANUAL.

HOWEVER, OMEGA ENGINEERING. INC. NEITHER ASSUMES

ERRORSTHAT

OF THE PRODUCTS IN ACCORDANCE WITH THE INFORMATION CONTAINED IN THE MANUAL.

WARRANTY BY OMEGA ENGINEERING, INC. SHALL NOT EXCEEDTHE PURCHASE PRICE

PURCnASER TO OMEGA ENGINEERING. INC. FOR THE UNIT OR UNITS OR

MAY APPEAR NOR ASSUMES

NNEL

. THERE ARE NO WARRANTIES EXCEPT AS STATED HEREIN. THERE

CONSEOUENTIAL. WHICH THE

LIABILITV FOR ANY DAMAGES THAT RESULT FROM THE USE

RESPONSIBILITV FOR ANY OMISSIONS OR

BYTHESE UNITS ARE INHERENTLY DANGEROUS AND ARE INTENDED TO BE INSTALLED AND USED

EOUIPMENT

=OMEGA

,,.

One Omega

Slamford,

‘,.“I%

ENGINEERING,INC.

‘rrrbu).“lo

I

Owe.

Box 4047

Connecncu:

““rpy,

ffi907-0047

Call OMEGA Toll Free ’.

Sales:

Customer Service: l-600-622-2378

Engineering Assistance:

CT:

(203)

‘In

And

Direct

telephone number (203)

CONTACT THE OMEGA CUSTOMER SERVICE DEPARTMENT TO OBTAIN AN AUTHORIZED

RETURN (AR) NUMBER. The designated AR number should then be marked on the outside of

the return package.

359.1660

lnlernabonal

all warranty and

To

1. Returnee ’s name,

2. Model end

Repalr

3.

OMEGA ’s policy is

Thai

possible.

OMEGA” is a

0

Copyright 1990 OMEGA ENGINEERING, INC. All rights reserved including illustrations.

in this manual may be reproduced

without

way our

regls:ered

writlen

1400-TGOMEGA

I

1-600-6246342

140047244361

repalr

delaya,

Serlal

Inrtructlons.

IO

make running changes, not model changes,

cuslomers

l-600-622-BEST

I

l-600-USA-WHEN

CABLE: OMEGA

TELEX: 996404

Return

requeats/lnqulriea

359.1660. BEFORE RETURNING ANY INSTRUMENT, PLEASE

alao please be

proceaalng rvold

address, and phone number.

numbem.

get the latest

EASYLINK: 62966934

FAX: (203) 3547700

Requests/lnqulrter

to OMEGA Customer Service Department,

sun, to Include:

in technology and

trademark of OMEGA ENGINEERING,

permission

In

any manner,

lrom

OMEGA ENGINEERING,

eflher wholly or

whenever an improvement is

engmeenng.

INC.

In

pan for any purpose whatsoever

INC.

Nolhing

Printed in U.S.A

M1174/0590

Loading...

Loading...