Page 1

OMEGA

Tedinologl.a

An

L

Cmm,.myl/

FL2900/6900/7900/8900

FL2700B/6700B/7700B/87OOB

Serie s

Serie s

Pneumatic In-Line Flowmeters

Operator’s Manual: Ml

NOT use Aromatic

Do

guard. Do

Do NOT install this unit within 2 ft. of electrical transformers, high strength electric motors or other electro-magnetic devises

that could adversely effect the magnetic coupling between the Flow Indicator and the Piston Magnet.

The OMEGA’“’ Pneumatic In-Line Flowmeters monitor air flow rates

to determine optimum performance, flow regulator settings, or

pneumatic system performance. The

8700B Series feature direct reading scales for air flow. The

6900, 7900, and 8900 multi-pressure scales (from 40 to 130

mean accurate flow measurements can be made without the need

for conversion calculations for pressure variations.

INSTALLATION: The flowmeter can be mounted vertically or

horizontally in the flow line. Notice the flow arrow which is located

on the meter scale, showing the direction which the flow must

travel. The multi-pressure meter acts as a check valve in reverse flow.

CAUTION: The flowmeter contains a residual amount of petroleum

base test fluid. This fluid may be incompatible or hazardous with

some compressed gases.

All air meters must have a pressure gauge installed at the inlet port.

The gauge should have

than the actual pressure you are expecting to run. For example, if you

are running your pressure at 100

with a

PSIG

range of at least 125 PSIG. Flow straighteners are not

required at the inlet or exhaust ports. In fact, 90 degree elbows can

be at either end of the meter or both if necessary.

OPERATION: Inside the meter is a sliding piston moving against a

spring when the flow varies. This piston movement opens and

closes an orifice, which is followed on the outside of the meter by

a moving indicator ring, magnetically coupled to the internal piston.

The meter has a graduated scale calibrated for air in SCFM (standard

cubic feet per minute). The multi-pressure meters are calibrated for

inlet pressure ranges commonly used from 40

at

F.

The single pressure meters come standard with a single

70”

pressure scale calibrated for inlet pressure of 100

specified by customer.

NOT

PSIG

175/1094

,

CAUTION

use Loctite thread locker or liquid teflon as thread sealant.

Hydocarbons, Halogenated Hydrocarbons, Ketones or Ester-based fluids on (or near) polycarbonate

FL27OOB,

range capacity at least 25% higher

PSIG

you should have a gauge dial

IMPORTANT..... READ BEFORE INSTALLING!

67OOB,

77008, and

PSIG

PSIG

FL2900,

PSIG)

to 130 PSIG,

or otherwise

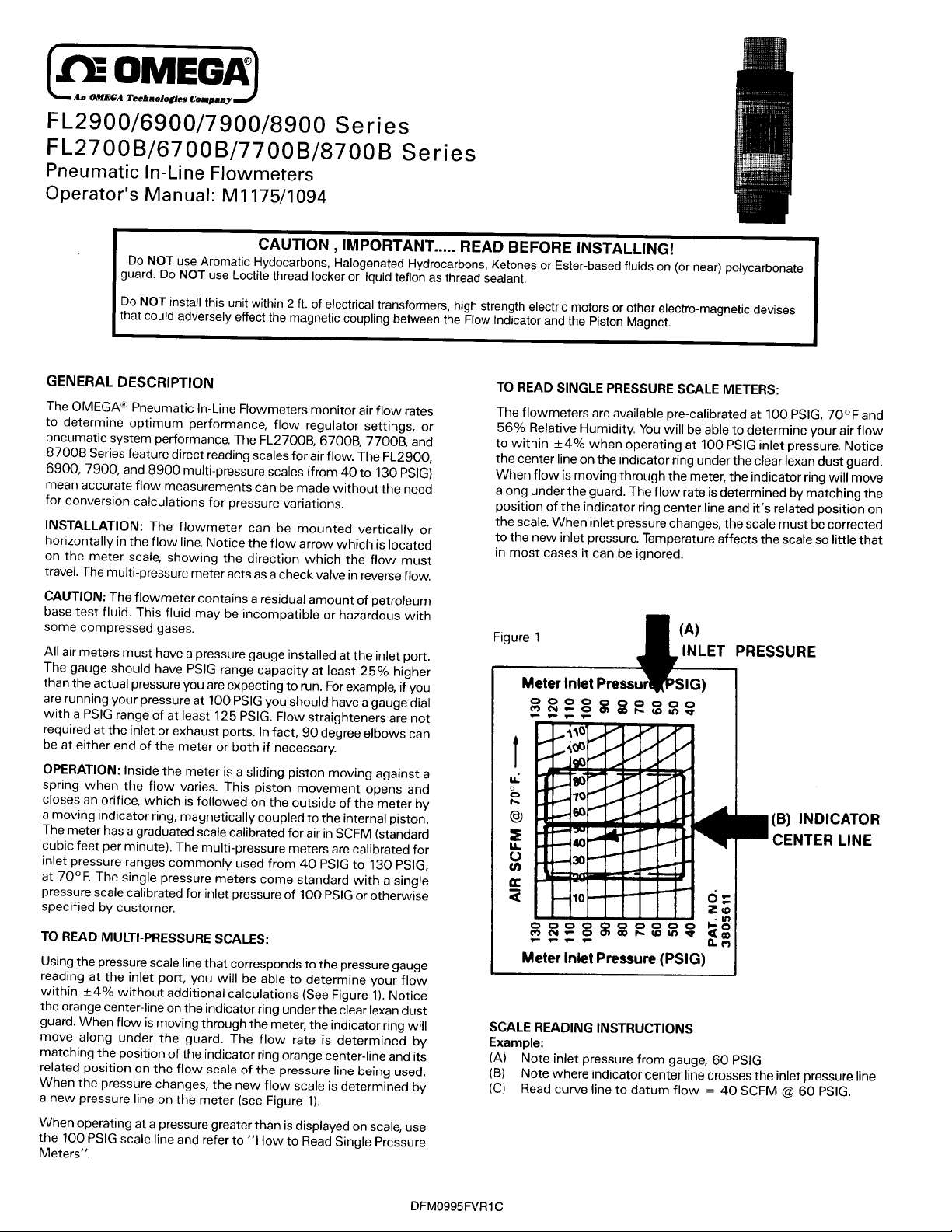

TO READ SINGLE PRESSURE SCALE METERS:

The flowmeters are available pre-calibrated at 100 PSIG,

56% Relative Humidity. You will be able to determine your air flow

to within

the center line on the indicator ring under the clear lexan dust guard.

When flow is moving through the meter, the indicator ring will move

along under the guard. The flow rate is determined by matching the

position of the indicator ring center line and it ’s related position on

the scale. When inlet pressure changes, the scale must be corrected

to the new inlet pressure. Temperature affects the scale so little that

in most cases it can be ignored.

Figure

t4%

when operating at 100

1

PSIG

inlet pressure. Notice

70°F

and

INLET PRESSURE

Meter Inlet Press

(B) INDICATOR

CENTER LINE

TO READ MULTI-PRESSURE SCALES:

Using the pressure scale line that corresponds to the pressure gauge

reading at the inlet port, you will be able to determine your flow

within

t_4%

the orange center-line on the indicator ring under the clear lexan dust

guard. When flow is moving through the meter, the indicator ring will

move along under the guard. The flow rate is determined by

matching the position of the indicator ring orange center-line and its

related position on the flow scale of the pressure line being used.

When the pressure changes, the new flow scale is determined by

a new pressure line on the meter (see Figure 1).

When operating at a pressure greater than is displayed on scale, use

the 100

Meters”.

without additional calculations (See Figure

scale line and refer to “How to Read Single Pressure

PSIG

I).

Notice

SCALE READING INSTRUCTIONS

Example:

(A)

(B)

(C)

DFMO995FVRl C

Meter Inlet Pressure (PSIG)

Note inlet pressure from gauge, 60

Note where indicator center line crosses the inlet pressure line

Read curve line to datum flow = 40 SCFM

I

PSIG

@

60 PSIG.

Page 2

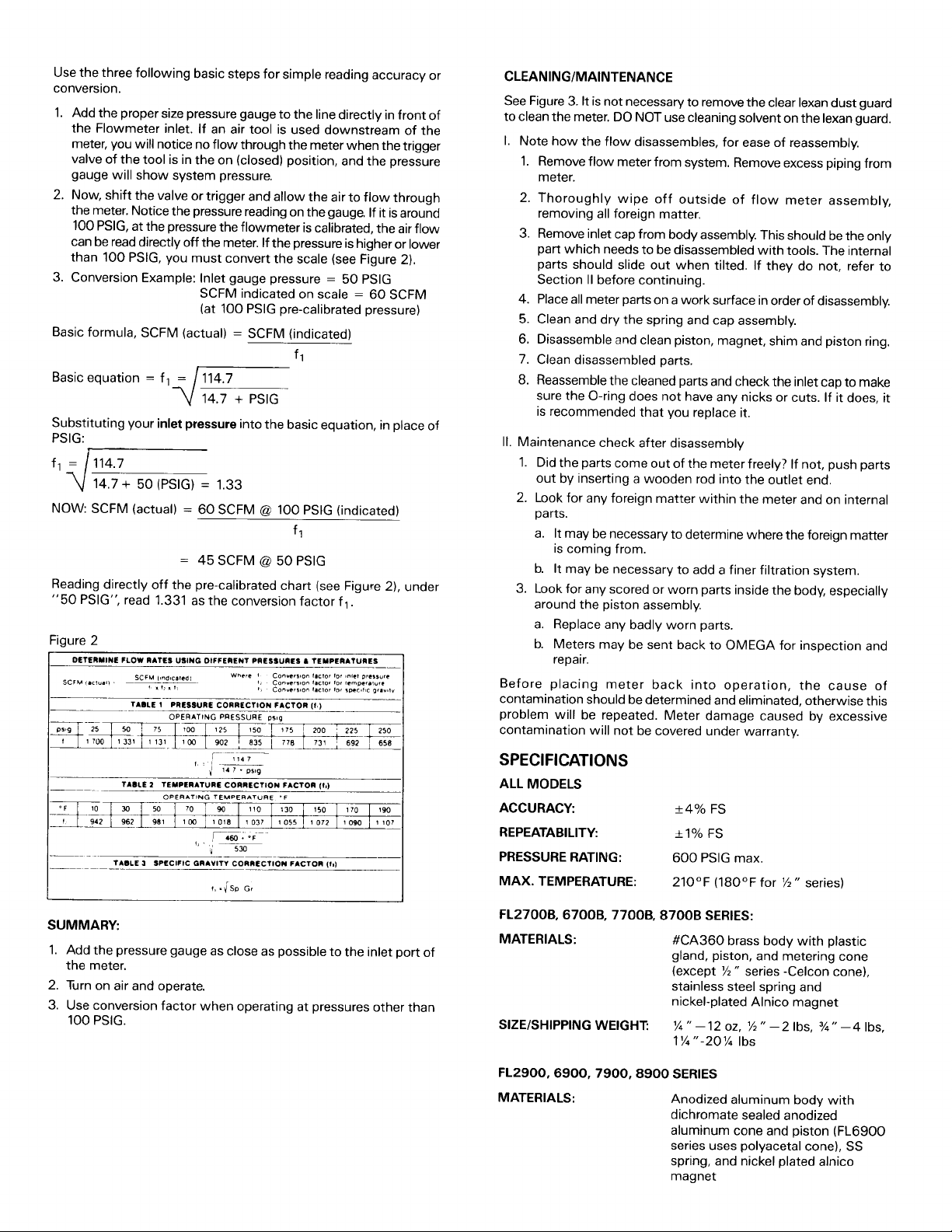

Use the three following basic steps for simple reading accuracy or

conversion.

Add the proper size pressure gauge to the line directly in front of

the Flowmeter inlet. If an air tool is used downstream of the

meter, you will notice no flow through the meter when the trigger

valve of the tool is in the on (closed) position, and the pressure

gauge will show system pressure.

Now, shift the valve or trigger and allow the air to flow through

the meter. Notice the pressure reading on the gauge If it is around

100 PSIG, at the pressure the flowmeter is calibrated, the air flow

can be read directly off the meter. If the pressure is higher or lower

than 100 PSIG, you must convert the scale (see Figure 2).

Conversion Example: Inlet gauge pressure = 50

PSIG

SCFM indicated on scale = 60 SCFM

(at 100

PSIG

pre-calibrated pressure)

Basic formula, SCFM (actual) = SCFM (indicated)

f l

ft

Basic equation =

= 114.7

?i

14.7 +

PSIG

Substituting your inlet pressure into the basic equation, in place of

PSIG:

.114.7

f,

=

(PSIG)

14.7 + 50

-J

NOW SCFM (actual) = 60 SCFM

= 1.33

@

100

PSIG

(indicated)

fl

PSIG

@

= 45 SCFM

Reading directly off the pre-calibrated chart (see Figure

“50 PSIG ”, read 1.331 as the conversion factor

50

2), under

fl.

Figure 2

CLEANING/MAINTENANCE

See Figure 3. It is not necessary to remove the clear lexan dust guard

to clean the meter. DO NOT use cleaning solvent on the lexan guard.

I.

Note how the flow disassembles, for ease of reassembly.

1.

Remove flow meter from system. Remove excess piping from

meter.

2. Thoroughly wipe off outside of flow meter assembly,

removing all foreign matter.

3.

Remove inlet cap from body assembly. This should be the only

part which needs to be disassembled with tools. The internal

parts should slide out when tilted. If they do not, refer to

Section II before continuing.

4. Place all meter parts on a work surface in order of disassembly.

5. Clean and dry the spring and cap assembly.

6. Disassemble and clean piston, magnet, shim and piston ring.

7. Clean disassembled parts.

8.

Reassemble the cleaned parts and check the inlet cap to make

sure the O-ring does not have any nicks or cuts. If it does, it

is recommended that you replace it.

II.

Maintenance check after disassembly

1.

Did the parts come out of the meter freely? If not, push parts

out by inserting a wooden rod into the outlet end.

2.

Look for any foreign matter within the meter and on internal

parts.

a.

It may be necessary to determine where the foreign matter

is coming from.

b.

It may be necessary to add a finer filtration system.

3. Look for any scored or worn parts inside the body, especially

around the piston assembly.

a. Replace any badly worn parts.

b. Meters may be sent back to OMEGA for inspection and

repair.

Before placing meter back into operation, the cause of

contamination should be determined and eliminated, otherwise this

problem will be repeated. Meter damage caused by excessive

contamination will not be covered under warranty.

SUMMARY:

1.

Add the pressure gauge as close as possible to the inlet port of

the meter.

2. Turn on air and operate.

3. Use conversion factor when operating at pressures other than

100 PSIG.

SPECIFICATIONS

ALL MODELS

*4%

ACCURACY:

REPEATABILITY:

PRESSURE RATING:

MAX. TEMPERATURE:

7700B.

FL2700B.

6700B.

8700B SERIES:

MATERIALS:

SIZE/SHIPPING WEIGHT:

FL2900,6900,7900,8900

MATERIALS: Anodized aluminum body with

FS

+I%

FS

PSIG

600

210°F

max.

(180°F

for

%”

series)

#CA360 brass body with plastic

gland, piston, and metering cone

(except

%

V

series

-Celcon

stainless steel spring and

nickel-plated Alnico magnet

1/4”-1202,

1%“-20%

%“-2lbs.

Ibs

?/4”-4lbs.

SERIES

dichromate

sealed anodized

aluminum cone and piston

series uses polyacetal cone), SS

spring, and nickel plated alnico

magnet

cone),

(FL6900

Page 3

Figure 3

l/2”

Style Meter

lnlel

FLOW

14”

314”

l/4”,

l-1

--_)

Cap Cone

Style Meter

(L

Cone Assembly

Cap

Style Meter

Piston

Piston

Magnet

Magnet Ring

Ring

SPdnO

Outlet

ato

Body Assembly

(L

Cone

Cap

Model No.

FL2904

FL2909

FL2918

FL2924

FL6920

FL6960

FL6911

FL6915

FL7918

FL7950

FL7990

FL791 5

FL7922

FL8925

FL8945

FL8960

FL8980

FL8910

Assembly

Pkton

Flow Range

(SCFM)

1- 4

2- 9

2-

18

4-2 4

2-2 0

lo-60

-

110

10

-

150

20

4-1 8

5-5 0

IO-9 0

15

-

150

20

-

220

20

-

250

25

-

450

50

-

600

50

-

800

50

-

1000

Magnet

Port Size

i

Ring

‘/2

3/i

‘/,

Aaaombly

Body

Spring

Dimensions

OD

”‘h

”

”

1

”

1.4” 4.8”

1.8”

2.3”

4.0” 12.2”

Length

6.6”

7.2”

i

Model No.

FL2704B

FL2709B

FL2718B

FL2724B

FL676OB

FL6711B

FL6715B

FL7750B

FL7722B

FL8745B

FL876OB

FL878OB

FL871OB

@

SCFM

PSIG, 70°F

1-4

2-9

2-18

4-24

IO-60

10-110

20-150

5-50

20-220

100 FNPT

Port Size O.D .

”

l/4

”

%

”

3/i

1.4”

1.8”

2.3”

Length

4.8”

6.6”

7.2”

Page 4

Servicing USA and Canada: Call OMEGA Toll Free

One

USA

Omega Drive, Box 4047 976 Bergar

Stamford, CT 06907-0047

Telephone: (203) 359-1660

FAX: (203) 359-7700

Sales Service: l-800-826-6342

Customer Service: l-800-622-2378

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Canada

Lava1 (Quebec)

Telephone: (514)

FAX: (514) 856-6886

l-800-TC-OMEGASM

/

l-800-622-BESTSM

/

I-SOO-USA-WHENSM

/

H7L

5Al

856-6928

Servicing Europe: United Kingdom Sales and Distribution Center

25

Swannington Road, Broughton Astley, Leicestershire

OMEGA warrants this unit to be free of defects

for a period of 13

period to the normal

that OMEGA ’s customers receive maximum coverage on each product. If the unit should malfunction, it must

be returned to the factory for evaluation. OMEGA ’s Customer Service Department will issue an Authorized

Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is

found to be defective it will be repaired or replaced at no charge. However, this WARRANTY is VOID if the

unit shows evidence of having been tampered with or shows evidence of being damaged as a result of

excessive

other operating conditions outside of OMEGA ’s control. Components which wear or which are damaged by

misuse are not warranted. These include contact points, fuses, and

OMEGA is

only warrants that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND ALL IMPLIED WARRANTIES INCLUDING

ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the total

liability of OMEGA with respect to this order. whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for consequential,

incidental or special damages.

Every precaution for accuracy has been taken in the preparation of this manual; however, OMEGA

ENGINEERING, INC. neither assumes responsibility for any omissions or errors that may appear nor assumes

liability for any damages that result from the use of the products in accordance with th e

information contained in the manual.

SPECIAL CONDITION: Should this equipment be used in or with any nuclear installation or activity, purchaser

will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of

the use of the equipment in such a manner.

months

porrosion;

glad

from date of purchase. OMEGA Warranty adds an additional one

(1)

one

or current, heat, moisture or vibration; improper specification; misapplication; misuse or

to

offer suggestions

year product warranty

on the use of its various products. Nevertheless, OMEGA

LE9

England

6TU.

In

materials and workmanship and to give satisfactory service

to cover handling and shipping time. This ensures

triacs.

(1)

month grace

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED

RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PRO-

CESSING DELAYS). The assigned AR number should then be marked on the outside of the return package

and on any correspondence.

FOR

FOR

MANn

following information available BEFORE contacting

OMEGA-

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

0

Copyright 1995 OMEGA ENGINEERING, INC. All rights reserved. This documentation may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in

whole or in part, without prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the

NON-WARRANTY

consult OMEGA for current

charges. Have the following information available

BEFORE

l.P.O. number to

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

contactina

caiibration,

relative to the product.

REPAIRS OR

reoair/calibration

OMEGA:

cover

the COST of the repair/

CALIBRATION,

Loading...

Loading...