Page 1

omega.com

®

®

FL-1900 Series

Rotameters

Operator’s Manual:

INSTRUCTION

SHEET

M0360/0201

®

6

4

6

0.5

SLMP AIR 70° 7 14.7 PSIA

SECTION 1 INTRODUCTION

1.1 GENERAL DESCRIPTION

OMEGA®Series FL-1900 Rotameters provide an

economical and efficient means of flow rate indication

when accuracy is not critical. Typical applications

include purging, seal oil systems, bearing lubrication,

and cooling water flow indication.

Engineering design makes them especially suitable

for use with corrosive liquids and gases, and

installation in corrosive atmospheres.

The Series FL-1900 Rotameters are furnished with a

control valve, but are available without the valve.

Indicator body and supported frame are constructed

from stainless steel. Sealing parts are manufactured

from vinylidene fluoride resin (Kynar). O-ring seals

are Viton-A. The meter is totally enclosed within a

cover of high impact polycarbonate (Lexan).

1.2 SPECIFICATION

The following specifications apply to all models.

CAUTION

Do not use this meter in excess of the specified values

PRESSURE RATINGS: 200 psig maximum

TEMPERATURE RATING: 250

°

F maximum

REPEATABILITY: ± 0.5 % of full scale

ACCURACY: Meter specified to have an accuracy

of ± 10 % of maximum scale from

100 % to 10% of scale reading.

Conforms to ISA R.P. 16.1,

Specification 10-S-10

DIMENSION: See Figure 1.1

METERING TUBE: Borosilicate glass

END FITTINGS: 316SS

WINDOW SHIELD: High Impact Plastic

FLOAT STOPS: Teflon

TUBE PACKING: Viton

O - RINGS: Viton

SCALE: 65mm direct reading for air or water

SECTION 2 INSTALLATION

2.1 RECEIPT OF EQUIPMENT

When the equipment is received, the outside packing

cases should be checked for any damage incurred

during shipment. If the packing case is damaged, the

local carrier should be notified at once regarding his

liability.

Remove the envelope containing the shipping list.

Carefully remove the equipment from the packing

case. Make sure spare or replacement parts are not

discarded with the packing material. Inspect for

damaged or missing parts.

2.2 RETURN SHIPMENT

Do not return any merchandise without an Authorized

Return (AR) number. Call OMEGACustomer Service

Department at (203) 359-1660.

CAUTION

It is recommended that this publication be read in its entirety before

performing any operation. Failure to understand and follow these

instructions could result in serious personal injury and/or damage

to the equipment

WARNING

Glass metering tubes are designed for operation up to the maximum operating pressures and temperatures as specified

herein. Due to the inherent brittle characteristic of glass and conditions beyond our control, tube breakage could result

below specified operating conditions. Possible glass tube breakage represents a potential hazard to operating personnel;

therefore, operator protection should be supplied where operating pressures may exceed 50 psig.. A safety shield constructed

of 1/2 inch acrylic plastic may be used or the glass tube meter maybe replaced with an all metal (armored) meter.

Figure 1.1 Dimension Diagram

Page 2

2.3 FILTER INSTALLATION

It is recommended that a filter with a rating of two (2) microns

be installed on the inlet side of the meter. This filter will reduce

the amount of foreign matter that could impair operation of

meter.

2.4 INSTALLATION OF METER

a. Check the control valve is fully closed.

b. Check the valve body is fully seated in meter

frame. Finger tighten if necessary.

c. Slowly tip meter back and forth and check that

float has freedom to move.

d. Remove dust covers from the inlet and outlet connections.

e. Install inlet and outlet line connections. Inlet

connection is at the zero end of the meter

.

2.5 CONTROL VALVE REPOSITIONING PROCEDURE

The user may desire to change the control valve from

the inlet side of the meter to the outlet side. If meter

is installed in the line, make sure that flow is stopped

to the meter. Failure to do this may result in a safety

hazard.

a. Disconnect inlet and outlet lines to meter.

b. Remove metering tube and seal spindle. Refer to

paragraph 4.3

c. Remove check ball from inside seal spindle.

Retain check ball for future use.

d. Install seal spindle in meter body. Refer to

paragraph 4.4

e. Turn meter 180

°

from original position so control

valve is now on outlet and seal spindle is on inlet.

f. Install metering tube. Refer to paragraph 4.4

g. Connect inlet and outlet lines to meter.

SECTION 3 OPERATION

3.1 GENERAL

After the meter has been installed it is ready for

operation. During operation make sure that meter

temperature and pressure specifications are not exceeded,

as stated in paragraph 1.2

When the valve stem knob is turned counterclockwise to

the stop, the valve is fully open. Flow indication is

measured using the center of the float as the reference

point. A check valve is incorporated within the seal

spindle. The check valve prevents reverse flow through

the meter when upstream flow is stopped. When the

control valve is installed on the outlet of the meter, the

check valve is not included.

SECTION 4 MAINTENANCE

4.1 GENERAL

No periodic maintenance, oiling, or cleaning is required

for the meter or meter components when it is used in

normal applications. It may be necessary to remove the

metering tube and components for cleaning when various

liquids have stained or left a deposit.

It is recommended that the meter and meter components

be ultrasonically cleaned if possible. If ultrasonic cleaning

is not available, use a suitable solvent. Tube and float may

be cleaned with a pipe cleaner or similar accessory.

4.2 SERVICE INFORMATION

Should this equipment require repair or adjustment,

contact OMEGA ENGINEERING Customer Service

Department at (203) 359-1660.

It is important that servicing be performed only by

trained and qualified service personnel. If this

equipment is not properly serviced, serious personal

injury and/or damage to the equipment could result.

4.3 DISASSEMBLY PROCEDURE (SEE FIGURE 5.1)

a. Remove shield (8) by squeezing sides at top and

bottom, and pulling forward.

b. Hold metering tube (1), and rotate seal spindle (4)

to the right until the stop is reached. Remove

metering tube.

c. Using tweezers, remove outlet float stop (2).

Remove float from metering tube. Be careful not

to drop float. Remove inlet float stop (2). If float is

stuck in metering tube, a rod (wooden dowel or

pipe cleaner preferred) may be inserted through

the inlet end of the tube, and the float pushed

through. Care must be taken not to score or

scratch the tube.

d. Depress seal spindle retainer tab. Rotate seal

spindle (4) to the left until it is disengaged from

the meter. Be careful not to drop the check ball (6)

from inside the seal spindle. Remove check ball.

e. Remove control valve (9) from meter body.

4.4 ASSEMBLY PROCEDURE (SEE FIGURE 5.1)

After the meter and the meter components have been

cleaned or checked, the following assembly procedures

should be followed. A separate assembly procedure

for the control valve is given in paragraph 4.6

a. Insert control valve body into meter frame and

finger tighten to secure.

b. Insert check ball (6) into seal spindle (4). Check for

freedom of movement.

c. Depress seal spindle retainer tab. Insert seal

spindle (4) into end fitting, and turn to the right

until fully seated. Release seal spindle retainer.

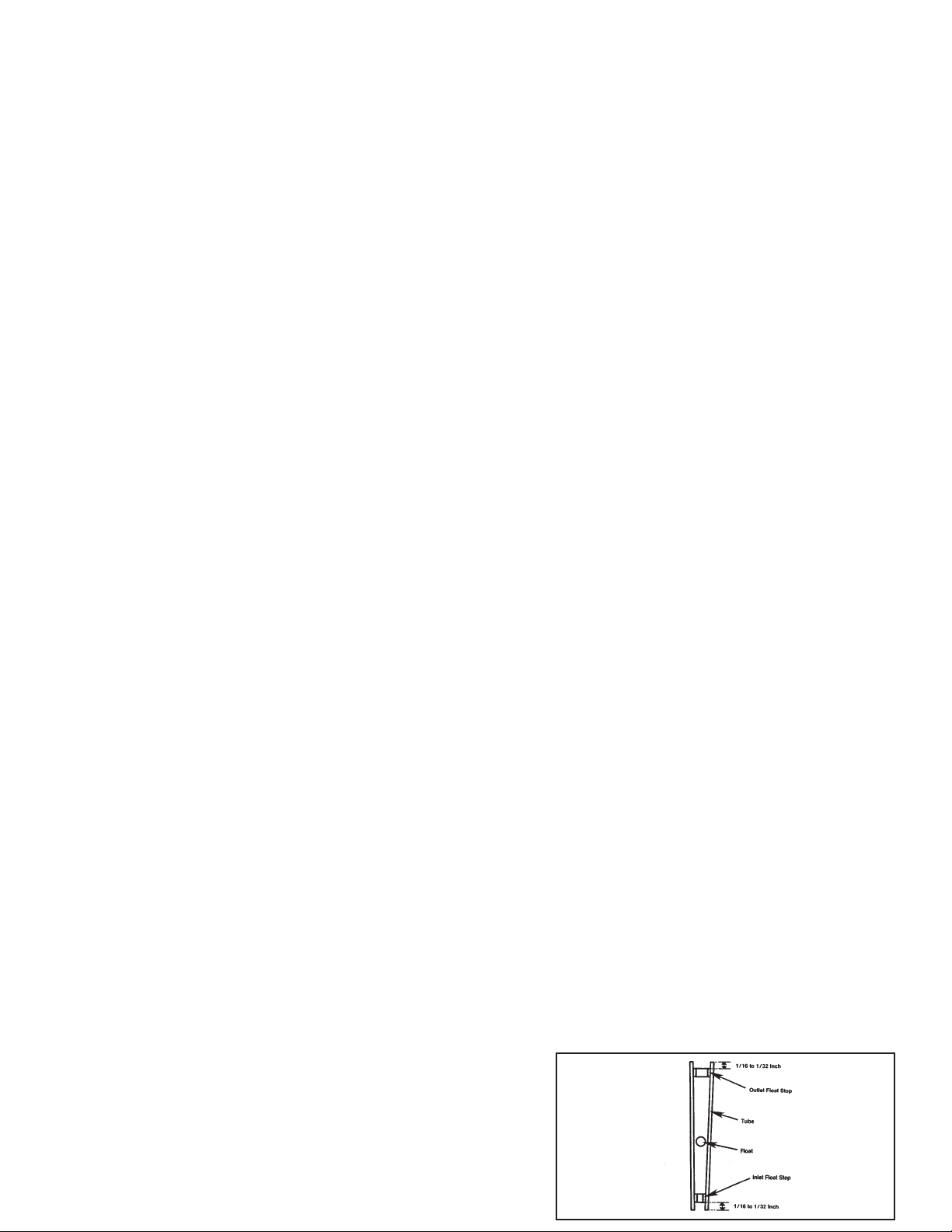

d. Insert inlet float stop (2) through outlet end of

metering tube. Using a rod (wooden dowel or

pipe cleaner preferred) push inlet float stop

through metering tube until it is approximately

1

/16 to 1/32 inch from end of metering tube.

(See Figure 4.2).

e. Insert float into metering tube.

f. Insert outlet float stop (2). Push float stop into

metering tube, until it is seated approximately

1

/16 to 1/32 inch from end of tubes. (See Figure 4.2).

Figure 4.2 Float Stop Installation Diagram

Page 3

g. Check the tubular inserts protrude from packings

approximately

1

/32 inch. if not, use tweezers and

reposition.

h. Insert metering tube into meter frame.

i. Center metering tube over the center of the

packings.

j. Rotate seal spindle to the left until a complete seal

between the metering tube and the packings is

accomplished.

k. After the flowmeter has been re-assembled, it is

important that it be hydrostatically tested at a liquid

pressure rating of 300 psig at room temperature.

4.5 CONTROL VALVE DISASSEMBLY PROCEDURE

When it is necessary to disassemble the control valve

for cleaning or to check components, the following

procedure should be followed. It is recommended that

the control valve be ultrasonically cleaned. If ultrasonic

cleaning is not available, use a suitable solvent.

a. Before removing control valve, stop all flow to meter.

b. Rotate valve stem knob to the left until valve is fully

open.

c. Rotate valve body to the left, and remove from meter

frame.

d. Make sure orifice and orifice o-ring are removed

from meter body.

e. Remove o-rings from valve.

f. Turn knob clockwise as far as possible.

g. Loosen set-screw in knob and remove knob.

h. Continue turning valve stem in a clockwise direction

to remove the stem from the bonnet.

i. Remove orifice from stem.

4.6 CONTROL VALVE ASSEMBLY PROCEDURE

After the control valve components have been cleaned

or checked, the following assembly procedures should

be followed:

a. It is recommended the valve stem threads be

lubricated with a molybdenum disulfide type

lubricant and all 0-rings be lubricated with a

silicone lubricant.

b. Insert the valve stem into the bonnet and turn the

stem counterclockwise (viewed from knob end) as

far as possible.

c. Install knob on stem and align set-screw with

detent in stem. Tighten set-screw.

d. Install the small orifice o-ring on orifice and insert

orifice in end of bonnet. Place the orifice on a flat

surface and gently apply downward pressure

until the orifice is properly seated in the bonnet.

e. Install large o-ring on the bonnet.

SECTION 5 PARTS LIST

5.1 RECOMMENDED SPARE AND REPLACEMENT PARTS

When ordering parts be sure to specify the following:

SERIAL NUMBER, complete equipment model number,

part description and part number. Refer to

Figure 5.1 for part reference.

CAUTION

Hydrostatic testing should be performed only by

trained and qualified personnel or serious

damage could result.

NOTE

Do not remove the two small 0-rings from valve stem.

Model No. Model No.Float Float

Range

SCFH AIR*

Range

GPH WATER*

Pressure

Drop

Inches Water **

Pressure

Drop

Inches Water **

FL-1901

FL-1902

FL-1903

FL-1904

FL-1905

FL-1906

FL-1907

FL-1908

FL-1909

FL-1910

FL-1911

FL-1912

FL-1951

FL-1952

FL-1953

FL-1954

FL-1955

FL-1956

FL-1957

FL-1958

FL-1959

FL-1960

FL-1961

FL-1962

Glass

Glass

316SS

Glass

316SS

Glass

316SS

Glass

316SS

Glass

316SS

Carboloy

Glass

316SS

316SS

Glass

316SS

Glass

316SS

Glass

316SS

Glass

316SS

Carboloy

0.2 - 1.2

0.2 -2.0

0.5 - 5.0

0.5 - 6.0

1.0 - 10

1.2 - 12

2.0 - 18

5.0 - 45

10.0 -80

5.0 - 55

10.0 - 90

12.0 -120

0.01 - 0.14

0.05 -0.5

0.1 - 1.0

0.05 - 0.7

0.10 - 1.6

0.2 - 2.0

0.5 - 4.0

1.0 - 9.0

2.0 -17

1.0 - 11

2.0 - 20

3.0 -30

1

2.2

10.8

12.4

10.1

10.4

25

60

214

73

292

400

1.8

4.0

19.5

22.3

18.3

18.7

45

109

385

132

525

890

*Air Flow Given At 14.7 psia and 70

0

F **Pressure Drops Are Approximate

Figure 5.1 Exploded View, FL-1900

Page 4

Servicing North America:

USA:

One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux:

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: Rude´ arma´dy 1868, 733 01 Karvina´ 8

Tel: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: +33 (0)130-621-400 FAX: +33 (0)130 699 120

Toll Free in France: 0800 4 06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: germany@omega.com

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®On-Line Service Internet e-mail

www.omega.com info@omega.com

FOR WARRANTY RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. PurchaseOrder number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2001 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

WARRANTY / DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of

13 months from date of purchase. OMEGA’s Warranty adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers

receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue

an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is

found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design

limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been

tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control.

Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by it will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

exclusive, and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase

price of the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our

basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA

harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

WARNING

FLOWMETER OPERATION

If the inlet and outlet valves adjacent to the flowmeter are to be closed for any reason, the flowmeter must be completely drained.

Failure to do so may result in thermal expansion of the liquid which can cause rupture of the meter and possible personal injury.

RECOMMENDED INSTALLATION PRACTICES

Water Hammer and surges can be damaging to any flowmeter and must always be avoided.

Water hammer occurs when a liquid flow is suddenly stopped as with quick closing and solenoid operated valves. Surges occur

when flow is suddenly begun, as when a pump is turned on at full power or a valve is quickly opened.

Liquid Surges are particularly damaging to flowmeters if the pipe is originally empty. To avoid damaging surges, fluid lines

should remain full (if possible) and pumps should be brought up to power slowly and valves opened slowly. In addition, to

both water hammer and surges, a surge chamber should be installed.

* Recommended Spare Parts

omega.comomega.com

®

®

Loading...

Loading...