Page 1

OMEGA

An

One Omega

Stamford,

Group Company

Drive, Box

CT 06907-0047

(203)359-1660

4047

Telex: 996404 Cable: OMEGA FAX: (203) 359-7700

FL-1600 SERIES

ROTAMETERS

)CAUTION/

It is recommended that this publication be read in its entirety before performing any operation. Failure to understand and follow these

irWUCtiOnS

could result in serious personal injury and/or damage to the equipment.

SECTION 1 INTRODUCTION

1.1

GENERAL DESCRIPTION

The OMEGA@ Series FL-1600 Rotameters are variable

area flowmeters designed for general in-line and by-pass

metering applications where operating conditions are

within the limitations of glass metering tubes.

A float is free to travel up and down within a tapered

borosilicate glass tube. As the float rises a greater flow

area exists: as it descends, flow area decreases. Fluid

flowing through the flowmeter (from bottom to top)

causes the float to rise to a point of dynamic balance,

which is a true indication of the flow.

1. 2

SPECIFICATIONS

CAUTiOq

1

Do not operate this instrument in excess of specifica-

tions listed below.

PRESSURE RATINGS:

FL-1604

FL-1605 100

FL-1606

L

FL-1607

NOTES:

1.

Pressure ratings are based on

2.

Above pressure

3. Maximum safe working pressures for glass tubes above 200 degrees F can be

calculated by

Caution: Do not use meters in excess of these pressures.

??

All plastic or

psig at 75 degrees F.

CONNECTIONS:

(

rattngs

using

non-metallic

Model

75

100

statrc

apply to rib or plain tapered tubes.

the pressure reduction given in the table above.

pressure applicable at 200 degrees

havea maximum safe pressure rating of 100

meters

&

Inlet

FL-1601

FL-1602

FL-1603

FL-1604

FL-1605

FL-1606 1

I

FL-1607

I

54

4L

%

%

1

400 0.45

400 0.33

400

Outlet

(NPTlHoriz.

”%

”

”

”

I

81

Outlet

Inlet

Vertical

?4

1”

‘/1

2”

0.25

(NPT)

”%

*

”

”1

F.

ACCURACY

*2%

INDUSTRIAL:

of full scale from 100% to 10% of scale

reading.

tl%

CALIBRATED:

of full scale from 100% to 10% of scale

reading.

%

% full scale.

t

REPEATABILITY: Within

MATERIALS OF CONSTRUCTION

METERING TUBE:

6OTOSiliCStS

glass

FLOATS: 316SS

FD-TINGS:

END

PACKING MATERIAL: Neoprene (brass meters); Teflon

Brass or 316SS

(316SS

meters)

O-RINGS:

Buna-N

SIDE PLATES: Aluminum

GLAND RINGS: Steel

GUIDE RODS, CARTRIDGES: 316SS

SAFETY GLASS WINDOWS: Aluminum Frames

GLAND

FOLLDWERS:

SCALE: 250 mm, detachable metal plate,

Aluminum

lo%-100% of FS

SECTION 2 INSTALLATION

RECOMMENDED INSTALLATION PRACTICES

Water hammer and surges can be damaging to any

flowmeter and must

always be avoided.

Water hammer occurs when a liquid flow is suddenly

stopped as with quick closing and solenoid operated

valves. Surges occur when flow is suddenlv begun, as

when a pump is turned on at full power or a valve is quick-

ly opened.

Liquid surges are particularly damaging to flowmeters if the

surqes.

pipe is originally empty. To avoid damaging

fluid

lines should remain full (if possible) and pumps should be

brought up to power slowly and valves opened slowly. In

addition, to avoid both water hammer and surges, a surge

chamber should be installed.

I

2.1

RECEIPT OF EQUIPMENT

When the equipment is received, the outside packing

case should be checked for any damage incurred during

shipment. If the packing case is damaged, the local car-

rier should be notified at once regarding his liability.

Remove the envelope containing the shipping list.

Carefully remove the equipment from the packing case

and inspect for damaged or missing parts. Be sure the

float is not accidentally discarded with the packing, as

some larger meters are shipped with the iioat

remcved

from the tube to prevent breakage

2. 2

RETURN SHIPMENT.

Do not return any merchandise without an Authorized

Return (AR) number. Call OMEGA Customer Service

Department at (203) 359-1660.

2. 3

I

INSTALLATION OF FLOAT

Some flowmeters are shipped with the float installed in

the metering tube; others are shipped with the float

_.

I

.:

packed separately to prevent possible damage during

shipment and handling. In either case, remove the wrap-

pings and/or other protective material. Take great care to

avoid damaging the float. The accuracy of the meter

depends upon the float remaining dimensionally and

gravimetrically stable.

Page 2

!.4

It is advisable to insert the float before the flowmeter is

installed in the line Where the vertical inlet and outlet are

used for piping connections this is absolutely necessary.

Use reasonable care in inserting the float. Don ’t

justdrop

it in the glass metering tube. A sheet of paper slightly

coiled, forms a convenient chute so the float can be slid

into the metering tube avoiding high impact.

To install free or ribbed tube floats, remove the bottom

cleanout

plug (or flanged cover) and take out the bottom

float stop. Place the float in the tube with a paper chute,

as described above, and replace the float stop and

cleanout

plug.

With rod guided floats, take great care not to bend the

guide rod. Should the guide rod become bent, or its

polished surface become marred by burrs, scratches or

accumulation of foreign matter, it is advisable to replace

it with a new one. Never attempt to straighten a bent

guide rod.

Rod guided floats are inserted at OMEGA and are shipped

with a wooden dowel protector preventing undue move-

ment of the float while the rotameter is in transit. Be sure

to remove the wooden dowel before installing the

rotameter.

To install rod-guided floats, remove both top and bottom

cleanout

plugs. Remove the top nuts on the guide rod and

remove the guide rod and guide rod cartridge through the

bottom opening of the meter. Place the float on the guide

rod and put it back in the tube. Guide rod nuts should be

tightened until the guide rod is tensioned. If the guide is

not sufficiently tightened, there may be a tendency of the

float to whip under flow conditions. Replace the

cleanout

plugs (or flanged cover).

LOCATION OF CONTROL VALVE

Location of the control valve depends on many variables.

On most applications, the flowmeter will operate properly

with the control valve on either the upstream or

downstream side.

If the inlet and outlet valves adjacent to the flowmeter

are to be closed for any reason, the flowmeter must be

completely drained. Failure to do so may result in ther-

mal expansion of the liquid which can cause rupture of

the meter and possible personal injury.

HORIZONTAL

A

-

Inlet Valve

-

Outlet Valve

B

FIGURE 2.1 BY-PASS PIPING

SECTION 3 OPERATION

3.1

3. 2

PRE-OPERATIONAL CHECK

Prior to initial start-up and each time the flowmeter is re-

assembled, the zero alignment should be checked. The

zero line on the tube should coincide with the zero line

on the indicating scale. If these marks line up,

assured that the tube is correctly seated and

flowmeter is ready for accurate flow indication.

OPERATING PROCEDURE

WARNING

LINE

VERTICAL LINE

-

By-Pm

C

-

Control Valve

D

Valve

be

cm

it

the

2.5

INSTALLATION OF FLOWMETER

The flowmeter should always be mounted within

.

true vertical with the outlet connection (downstream

connection) at the top of the meter, and the inlet connec-

tion (upstream connection) at the bottom;

highest

scale graduation and largest part of the glass tube

at the top. Use a plumb-bob or other device to assure

perfect vertical positioning. Should the rotameter not be

mounted in a vertical position, both accuracy and sen-

sitivity may be affected.

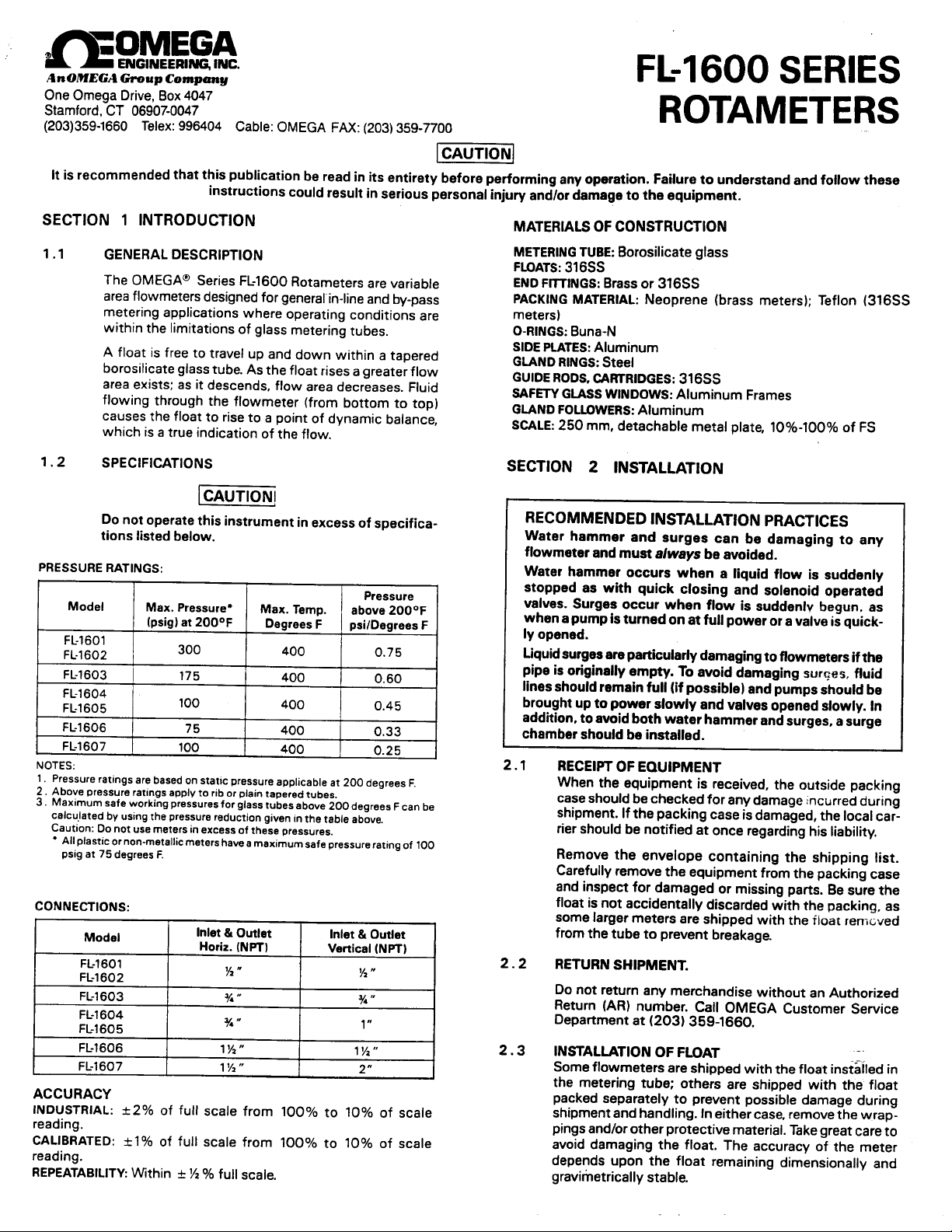

!.6

BY-PASS PIPING

It is strongly recommended to install a by-pass piping

rangement around the meter. By-pass piping permits the

meter to be isolated from the flow line for servicing or

cleaning.

Where connections are interchangeable (for vertical

horizontal connections), it is recommended that the

horizontal connections be used if at all practical in the

overall piping arrangement. Horizontal connections per-

mit the plugged vertical openings to serve as convenient

cleanout

rotated in

ports. The design permits the end-fitting to be

90°

increments, allowing inlet and outlet con-

nections to be made at right side, left side, at the front or

at the back of the rotameter. Refer to Fiaure 2.1

that

6O

of

is, with

ar-

or

During operation of this instrument. do not exceed

temperature and pressure ratings as listed in

Specifications.

It is well to by-pass the original flow surge when the

meter is first put in the line Refer to Figure 2-l. First, open

(C)

the by-pass valve

fully and the control valve

slightly. Then, open the meter inlet and outlet valves

(D)

(A

and B respectively). After the inlet line has been purged

(C)

of air, close the by-pass valve

slowly. This method

brings the flowmeter on-stream smoothly; allows the

float to start indicating the flow without bouncing or

shooting up to the very top of the metering tube.

For best results, the meter inlet and outlet valves (A and

B) should remain fully opened,

(D)

valve

to be used for complete flow

permitt+

cc‘itror.

the

c-ntrol

T;IIS

ar-

rangement is consistent with good control practice and

provides steadiest float operation.

When it is necessary to clean or repair the meter, open

the by-pass valve

outlet valves

(C)

first. Then, close the meter inlet and

(A

and B).

If the by-pass arrangement is not used, the valves should

be opened with extreme caution to prevent damage to

the float and metering tube.

Page 3

SECTION 4 MAINTENANCE

4.1 CLEANING

When the recommended horizontal connections are us-

ed, the flowmeter may be cleaned in this manner:

1.

Remove top and bottom

2 .

Remove the float and float stops. Be careful not to

damage the float.

Swab out the metering tube and end fittings with a

3 .

suitable solvent.

Replace float, float stops. and

4 .

flanges).

4. 2

DISASSEMBLY

1.

Remove front and back windows and window

frames.

Completely unscrew gland bolts from top and bot-

2.

tom end fittings.

Remove cap screws from the side plates of the top

3.

end fittings.

4.

Loosen the cap screws in the bottom end fitting so

that the side plates may be spread apart to allow the

top and bottom end fittings to be removed.

The metering tube may now be removed.

5.

4. 3

REASSEMBLY

1.

Replace the tube, being careful to see that the outlet

(wide) end of the tube fits flush against the tube seat

gasket in the outlet (top) end fitting.

-

cleanout

plugs (or flanges).

cleanout

plugs (or

Replace the windows and window frames. The seal-

5.

ing gaskets on the windows should be placed face

down against the meter body. Tighten the shield

bolts on the window frame only until they are

“snug,” then tighten one-quarter additional turn.

After the flowmeter has been re-assembled, it is im-

6.

portant that it be hydrostatically tested at the liquid

pressure rating as shown in the Hydrostatic Test

Pressure Table.

Hydr&&ic

testing should be performed only by

trained and qualified personnel or serious

damage could result.

HYDROSTATIC

TABLE 4-l.

TEST PRESSURES

Max. Working

Model

FLil601, 1602

FL-1603

FL-1604,

FL-1

1605

606

Pressure (PSI)

200°F

at

300

175

100

FL1607 100

75

’

Hydrostatic Test

Pressure

(PSI)

450

260

150

110

150

NOTE

Because both Teflon hat gaskets are purposely tight

fitting, they can be more easily assembled from the

inlet (smaller) end of the tube The smaller (inlet end)

gasket is often difficult to place over the glass tube.

A suggested method is to place the hat gasket in the

gland ring on a horizontal surface and carefully force

the end of the tube through the gasket and ring. This

will stretch the gasket enough that it can be removed

and reassembled on the tube in the proper order.

Im-

mersing the gaskets in warm water will further in-

crease their elasticity and help prevent damaging

them, particularly in cold weather. If the outlet

gasket on the larger tubes seems unable to be mov-

ed into position when being driven by the packing

ring, a small amount of silicone lubricant may be

used.

2. Since the dowel-pin construction assures perfect

alignment of the frame assembly, merely tighten the

cap screws to attach the side plates to the end

fittings.

3. Insert the packing gland bolts. Tighten the gland

follower on the “seating end fitting” before tighten-

ing the gland follower on the other end fitting. The

“seating end fitting” is always the outlet (top) end

fifing. If this procedure of tightening the seating end

first is not followed, the tube may be pulled away

from the seat gasket and the zero line on the tube

may not show above the inlet gland follower. In

tightening the packing bolts, tighten them

diagonally.

Check the zero line on the metering tube and on the

4.

scale for exact alignment.

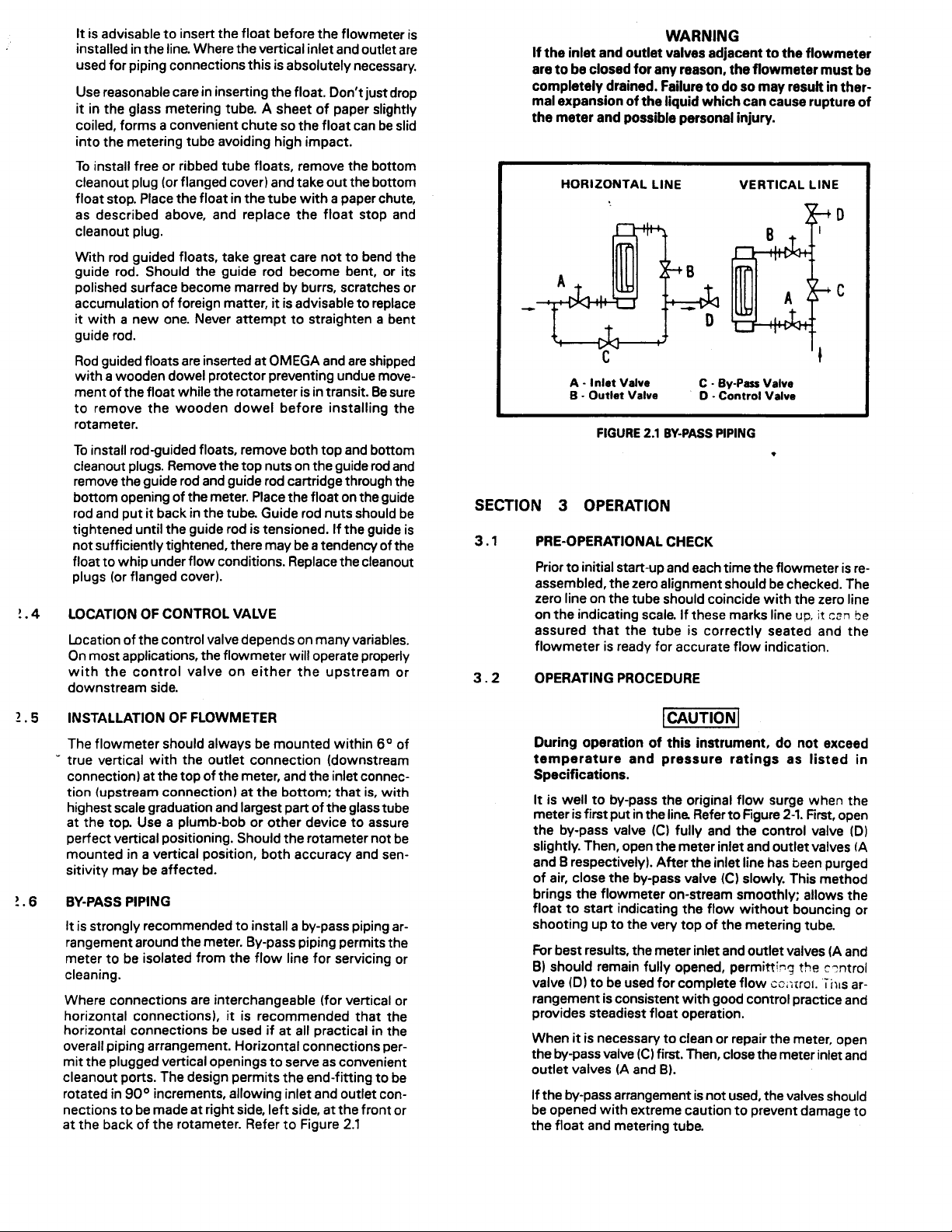

Type

(rib-guided)

Spherical

Aumb-Bob

Figure 3-1. Float Types

SECTION 5 PARTS LIST

When ordering replacement parts be sure to specify the

following: SERIAL NUMBER, Complete model number,

part description and quantity. Refer to Figure 5-2.

Glass metering tubes are designed for operation up to

the maximum operating pressures and temperatures as

specified herein. Due to the inherent brittle characteristic

of glass and conditions beyond our control, tube

breakage could result below specified operating condi-

tions. Possible glass tube breakage represents a poten-

tial hazard to operating personnel; therefore, operator

protection should be supplied where operating pressures

may exceed 50 psig. A safety shield construction of

inch acrylic plastic may be used or the glass tube meter

may be replaced with an all metal (armored) meter.

RS

Type GV

(rod-gurcfed)

Spool

WARNING

GS

Type

(rod-guided)

LJ

Type

%

Page 4

9

10

11

17

._

1

13

1

14

17

IfI

I

Window

I

1

19

20

I

1

Scale Blank

21

-

Follower

_..-

-

Ring

Rina

___

Seat Gasket

Phi&d

1..

...”

.

. . . .

Outlet

___.

-

Inlet

-

Outlet

lasket

3lass

(

Packing

Side Plate

Scale Side Plate

Glrnd

_._..

Gland

Gland

Window Frame

Millnrl

-----~-

FrameGasket

Meter Gasket

Steel

Steel

steot

_...“.

,

-

,

1

1

1

Steel

Steel

1

Asbestos

Asbestos

Stn. Stl.

Stn. Stl.

Safety Felt

Cork

1

I

I

1 I Aluminum

Glass

Figure 5-2. Parts Drawing

WARNING

FLOWMETER OPERATION

If the inlet and outlet valves adjacent to the flowmeter are to be closed

”

for any reason, the flowmeter must be completely drained. Failure to do

so may result in thermal expansion of the liquid which can cause rupture

of the meter and possible personal injury.

HORIZONTAL LINE

No. 6 Plain

28

29

t 30 I Stuffino Box Aina

31

32

33

35

34

36 Cartridge Gasket

37

38

39

Scale Holder Screws

Hd. Self-Tapping

Scale Holder Screws

Hd. Self-Taopina

Stuffing

Guide Rod

Guide Rod

I

Cartridae

1

Cartridge

Cartridge Gasket.

Teflon Hat Gasket

Teflon Hat Gasket

80x

-

-

Outlet

Inlet

. .

Ring

VERTICAL LINE

_

-

inlet

-

Outlet

Inlet

-

Outlet

-

Inlet

-

Outlet

-

Oval

Rd.

2 Stn. Stl.

2

7

1

I

1

1

2

I

1

1

1

1

1

1

1

Stn. Stl.

Stn. Stl.

I

I

I

I

COPYRIGHT 1987 OMEGA ENGINEERING, INC. PRINTED IN U.S.A.

-

Inlet Valve

A

-

Outlet Valve

B

-

Bypass Valve

C

-

Control Valve

D

TYPICAL INSTALLATION

M379/097

Loading...

Loading...