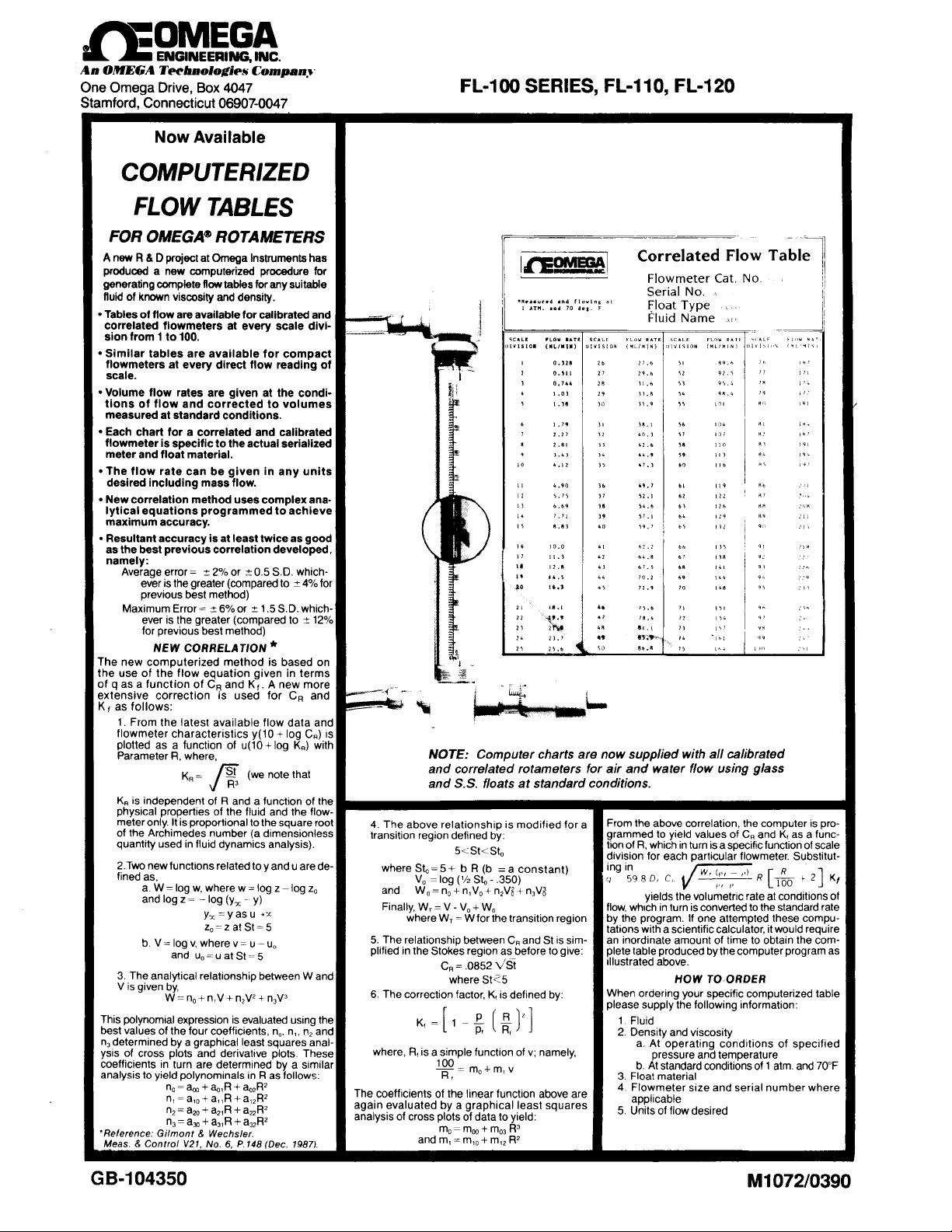

Now Available

COMPUTERIZED

FLOW TABLES

FL-1 00 SERIES, FL-1 10, FL-1 20

FOR OMEGA@

L

D

project at Omega Instruments has

R

A new

produced a new computerized procedure for

generating complete

fluid of known viscosity and density.

Tables of flow are available for calibrated and

correlated flowmeters at every scale divi-

sion from 1 to 100.

Similar tables are available for compact

flowmeters at every direct flow reading of

scale.

Volume flow rates are given at the

tions

of flow and corrected to volumes

measured at standard conditions.

Each chart for a correlated and calibrated

flowmeter

meter and float material.

The flow rate can be given in any units

desired including mass flow.

New correlation method uses complex

lytical

maximum accuracy.

Resultant accuracy is at least twice as good

as the best previous correlation developed,

namely:

‘he new computerized method is based on

he use of the flow equation given in terms

!xtensive

cf

as follows:

is specific to the actual serialized

equations programmed to achieve

Average error =

ever is the greater (compared to

previous best method)

Maximum Error =

ever is the greater (compared to

for previous best method)

NEW

correction is used for

1. From the latest available flow data and

flowmeter characteristics

plotted as a function of

Parameter Ft. where,

ROTAMETERS

Row tables

-t

2% or

-t

CORRELATION *

CR

f

6% or

and If q as a function of

~(10

for any suitable

0.5 S.D. which-

K, A new more

~(10

-+

SD.

CR

+

log C,)

+

log K,) with

condi-

ana-

4% for

which-

2 1.5

-+

12%

and

IS

function of the

R

IS

independent of

KR

physlcal

properties of the fluid and the

meter only. It is proportional to the square root

of the Archimedes number (a dimensionless

quantity used in fluid dynamics analysis).

2.Two

new functions related toy and u are

fined as,

a. W = log

and log z

b.V=logv,wherev=u-u,

and

3. The analytical

V is given by,

This

best values of the four coefficients,

n3

determined by a graphical least squares anal-

ysis of cross plots and

coefficients

analysis to yield

‘Relerence:

Meas.

W =

polynomial expression is evaluated

In

turn are determined by a similar

n,=a,+q,R+q2R2

=a,,+a,,R+a,,RZ

n,

n3

= a, +

Gitmont

8

Control

and a

w.

where w = log z log

-

log (y, y)

=

y,=yasu

z,=zatSt=5

u,=uatSt=5

relatlonship between W and

n,

+

a,,R

aZO

n2 =

a,,R +

Wechster.8

V21,

No.

a=

n,V3

i n,V*

n,V +

derivattve plots These

R

as follows:

In

polynominals

a&+

+ +

aZ2RZ

6,

P.148 (Dec. 1987).

GB-104350

using

n,. n,.

n2

flow-

z0

the

and

de-

5. The relationship between

plified in the Stokes

6. The correction factor,

R,

is a simple function of

where,

The coefficients of the linear function above are

again evaluated by a graphical least squares

analysis of cross plots of data to yield:

and

region as before to

St<5

where

K,

m,=m,+m,,RJ

m,

mrp

=

is defined by:

namely,

v;

R2

m,, +

IS

give:

division

ingi;98D,

whfch

flow,

by the program. If one attempted these compu-

tations with a scientific calculator, it would require

an inordinate amount of time to obtain the

sim-

C, and St

plete table produced by the computer program as

illustrated above.

ordenng your specific computerized table

When

please supply the following information:

a. At

b. At standard conditions of 1 atm. and 70°F

3. Float material

4. Flowmeter

5.

Units of flow desired

particular flowmeter.

for each

4-R

C,

in turn is converted to the standard rate

TO,ORDER

IiOW

operating

pressure and temperature

conditions of

condltlons ofvolumetnc rate at yields the

072/0390

Ml

Substitut-

21

K ,

+

[A

com-

specified

wheresize and serial number

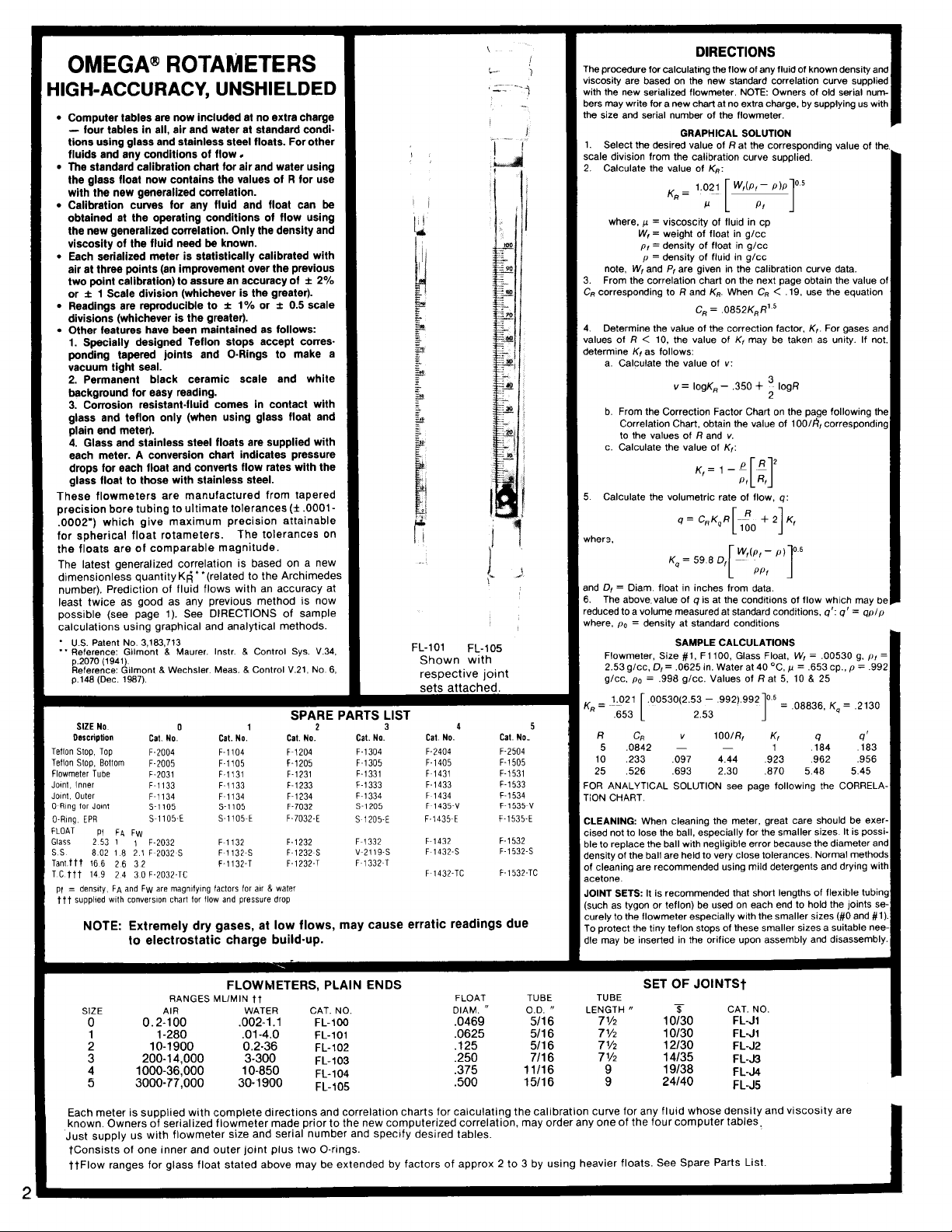

OMEGA@

ROTARilETERS

iIGH-ACCURACY, UNSHIELDED

??

Computer tables are now included at no extra charge

-

four tables in ail, air and water at standard condi-

tions using glass and stainless steel floats. For other

fluids and any conditions of flow.

??

The standard calibration chart for air and water using

the glass float now contains the values of

with the new generalized correlation.

??

Calibration curves for any fluid and float can be

obtained at the

operating

conditions of flow using

the new generalized correlation. Only the density and

viscosity of the fluid need be known.

??

Each serialized meter is statistically calibrated with

air at three points (an improvement over the previous

two point calibration) to assure an accuracy of

f

1 Scale division (whichever is the greater).

or

. Readings are reproducible to

divisions (whichever is the greater).

??

Other features have been maintained as follows:

1. Specially designed Teflon stops accept cones.

ponding tapered joints and O-Rings to make a

vacuum tight seal.

2. Permanent black ceramic scale and white

background for easy reading.

3. Corrosion resistant-fluid comes in contact with

f

1% or

glass and tefion only (when using glass float and

plain end meter).

4. Glass and stainless steel floats are supplied with

each meter. A conversion chart indicates pressure

drops for each float and converts flow rates with the

glass float to those with stainless steel.

These flowmeters are manufactured from tapered

precision bore tubing to ultimate tolerances

.0002’)

which give maximum precision attainable

for spherical float rotameters.

The tolerances on

the floats are of comparable magnitude.

The latest generalized correlation is based on a new

dimensionless

number). Prediction of fluid flows with an accuracy at

least twice as good as any previous method is now

possible (see page 1). See DIRECTIONS of sample

calculations using graphical and analytical methods.

*

U.S.

Patent No.

**

Reference:

p.2070

Reference:

p.148

SIZE N

Description

.etlan

Stop, Top

retIon

Stop. Bottom

:lowmeter

Tube

klmt,

inner

loIni.

Outer

101 Ring 1

I-Ring

EPR

-LOAT

;1ass

;?I

166

lCttt

149 24

density,

ttt suppled

(1941).

(Dec.

O

JOl",

253

8

02

26 32

FA

and

= pf

wlfh

Gilmont

Gllmont

1987).

FwFC Pf

1

i

1 F-2032 S

18

conversion

1

3OF-2032.TC

quantityKi”(related

3,183,713

Maurer.

8

0

Cat. No.

F-2004 F-1104

F-2005 F-1105 F-1205

F-2031 F-1131

F-1133

F-1134

S-1105

S~l105-E

F-2032

magmfylng

for

char,

&

Control Sys. V.34.

Instr.

&Control V.21, N

Meas.

8 Wechsler.

Cat. No.

F-1133 F-l 233

F-1134

S-1105

S-ll05~E

F~ll32

F-1132-S

F-1132-T F-1232-T

factors far Fw are

flow and pressure drop

NOTE: Extremely dry gases,

to electrostatic charge build-up.

R

for use

f

2%

*

0.5 scale

.OOOl-

(-t

to the Archimedes

SPARE I

1

Cat.

No.

2

F~l204

F-1231

F-i 234

F-7032

F-7032-E

F-1232

F-1232~s

wakr

& ar

at low flows, may cause erratic readings due

DIRECTIONS

The procedure for calculating the flow of any fluid of known density and

viscosity are based on the new standard correlation curve supplied

with the new serialized flowmeter. NOTE: Owners of old serial

bers may write for a new

the size and serial number of the flowmeter.

1.

Select the desired value of Rat the corresponding value of

scale

division from the calibration curve supplied.

2.

Calculate the value of

where,

W,

p,

p

W,

and

note,

3.

From the correlation chart on the next page obtain the value

28

corresponding to

chart

at no extra charge, by supplying us with

GRAPHICAL SOLUTION

KR:

W ,(p:j-pipl ”l

,.;,

K,=

viscoscity

= weight of float in g/cc

=

density of float in

=

density of fluid in

P,

[

of fluid in cp= p

g/cc

Kn.

When

glee

.19.

use the equation

<

C,

are given in the calibration curve data.

R

and

.0852K,R’5C, =

4.

Determine the value of the correction factor.

<

10, the value of R values of

K, as

letermine

a. Calculate the value of

follows:

v

b. From the Correction Factor Chart on the page following thr

Correlation Chart, obtain the value of

to the values of

c. Calculate the value of

5

Calculate the volumetric rate of flow,

whers,

Kq

D, snd

= Diam. float in inches from data.

above.value of

3.

The

.educed

to a volume measured at standard conditions,

=

density at standard conditions

p0

Nhere.

O

6,

JAR1

rs LIST

Cat. No.

F-1304

F-1305

F-1331

F-1333

F-1334

S-1205

S 1205-E

F~l332

2119-S

1332-Trantttt

Shown with

resDective

3

FL-105

ioint

4 5

Cat. No.

F-2404 F-2504

F-1405 F-1505

F

1431

F-1433 F-1533

F

1434 F-1534

F

1435-v

F-1435E

F~l432

F

1432-S

F

1432.TC

Cat. No.

F-1531

F-1x35~”

F-1535-E

F-1532

F-1532-S

F-1532.TC

Flowmeter, Size

2.53

g/cc.

=

Ry

,653

R

.0842

5

,233

10

25

-OFI

ANALYTICAL SOLUTION see page following the

I!

r:ON CHART.

CLEANING:

sised not to lose the ball, especially for the smaller sizes It is

318

to replace the ball with negligible error because the diameter

density of the ball are held to very close tolerances. Normal method:

3f cleaning are recommended using mild detergents and drying witt

acetone.

JOINT SETS: It is recommended that short lengths of flexible

[such as tygon or teflon) be used on each end to hold the joints se

To protect the tiny teflon stops of these smaller sizes a suitable nee

dle may be inserted in the orifice upon assembly and disassembly

SAMPLE CALCULATIONS

.0625

= 0,

glee.

.99d

g/cc. Values of

p.

=

.00530(2.53

L

CR

.097

,693

When cleaning the meter, great care should be

K, may be

taken as unity. If not

v:

3

,350 t

- IogK,

=

Y.

R and

K,:

K ,= ,-- P

q=

[

q

is at the conditions of flow which

FllOO,

#l.

in. Water at 40

.992).992

-

1.021

2.53

100/R,

1

4.44

2.30,526

IOQR

2

!T2

R,PI

[I

f.

+ 2 CRK4R

[

1

‘)

!%-

D, 6 = 59

PPt

1

Glass Float,

‘C.

at

5, 10

O5

1

K,

1

.923

,870

100/k?,

q:

K,

‘s

=

=

= W,

,653

p

&

25R

.06836.

.P64

,962

5.48 5.45

num

For gases

correspondin<

may be

qpfp

q ’

=

q’:

p, g,

.00530

.99i

= p

cp.,

.2130Kq =

.%33

,956

CORRELA.

exer.

POSSi.

tubin<

(#O

and curely to the flowmeter especially with the smaller sizes

I

the

o

antK,.

=

aru

#1)

IO%0

10130

12130

14135

19138

24140

JOlNTSt

CAT. NO.

FL-J1

FL-J1

FL-J2

FL-J3

FL-J4

FL-J5

FLOWUETERS,

MLlMlN

RANGES

SIZE

0

Each meter is supplied with complete directions and correlation charts for calculating the calibration curve for any fluid whose density and viscosity are

known. Owners of serialized flowmeter made prior to the new computerized correlation, may order any one of the four computer tables,

Just supply us with flowmeter size and serial number and

tconsists

ttFlow

ranges for glass float stated above may be extended by factors of approx 2 to 3 by using heavier floats. See Spare Parts List.

AIR

0.2-100 ,002-l

l-280

10-1900 0.2-36

200s14,000

l OOO-36,000

3000-77,000

of one inner and outer joint plus two O-rings.

tt

WATER

.Ol-4.0

3-300

1 O-850

30-l 900

.l

PLAIN ENDS

CAT. NO.

FL-100

FL-101

FL-102

FL-103

FL-104

FL-105

specify

FLOAT

DIAM.

.0469

.0625

.125

,250

,375

,500

desired tables.

TUBE

O.D.

u

5116

5116

5116

7116

11116

15/16

TUBE

n

LENGTH

SET OF

w

l/2

7

‘/2

7

‘/2

7

7

%

KR

t

r

10

ORRELA

C

T/ON CHART

Density

Gases

GAS

cetylene

.ir

.mmonia

.rgon

utane

(n)

(iso)

utane

:arbon

dioxide

:arbon

monoxide

:hlorine

thane

thylene

leiium

lydrogen

lydrogen chloride

lydrogen sulfide

.rypton

lethane

lethyl

chloride

leon

litric

oxide

litrogen

litrous oxide

)xygen

‘ropane

iulfur

dioxide

:enon

Density a Viscosity of

Liquids at

LIOUID

Acetic Acid

Acetone

Anilme

Benzene

Butyl Acetate

n-butanol

4

CCI

Chlorobenzene

Chloroform

Diethyl Ether

Ethyl Acetate

Ethanol

Ethylene Br

Ethylene Cl

Ethylene Glycol

Fluorobenzene

Heptane

Methyl Acetate

Methanol

Nitrobenzene

n-octane

Propanol

Toluene

o-xylene

m-xylene

p-xylene

Aqueous Solutions

10% HCI

30%

HCI

10%

HNO,

HNO3

40%

HzSO~

10%

HsSOa

60%

a

Viscosity of

a

at

70°F

p

in

1.087

1.200

.7155

1.655

2.510

2.481

1.035

1.160

2.989

1.259

1.170

.1657

.0834

1.522

1.429

3.382

.6653

2.139

.035a

1.244

1.161

1.836

1.326

1.075

2.717

5.307

TABLE II

In

1

atm

c1

g/Li

g/mlp

1.049 1.221

1.022 4.40

1.594

1.106

1.483

1.460

1.109 19.90

1.023

1.204 2 03

in cp

.OlOl

.0181

.00986

.0221

.0076

.0076

.0148

.0174

.0133

.00913

.OlOl

.0194

.0087

.0144

.0126

.02

514

.0109

.0107

.0312

.0188

.0175

.0144

.0203

.00803

.0125

.0226

8

1 atm70°F

in cp

p

by

weight)

.32

,652

2 946

,969

,799

.58

1 20

1.72

2 256

1.15<

1.04;

1 55E

1 22E

5 90:

,790

,879

,083

,610

,714

,900

,709

898

,684

,933

791

,703

,804

867

,880

.864

861

(%

1.048

1 149 1.70;

1.054

1.247

1.066

1.499

,732

,233

,455

.79

.598

409

381

,597

,542

,590

,810

,620

,648

0.2

FOR

CR

1.0

0.7

CR-

.0852

0.4

KRR’.~

= CR < 0.19,

0.3

0.5

1.

3

CORRECT/ON

FACTOR CHART

1.

ANALYTICAL SOLUTION OF FLUID FLOW

Same as step 1 of GRAPHICAL SOLUTION on previous page

2. Same as step 2 of GRAPHICAL SOLUTION

3. Calculate

4. Determine the region of flow as follows:

5. For the turbulent region, calculate the following:

6. For the transitional region calculate the following:

7. Calculate the

8.

9.

10.

the

following:

KR2R3

a) St =

St,, = 5 +

b)

a) If St < 5 region is Stokes, skip to step 9

b) If

c) If St >

a) V =

W ,=no+n,V+n2V2+~V3

b)

where,

a)

W,

b)

c)

zc

b)

yc = 10.040 -(l/z,)

C)

CR=

d)

Determine the value of

v

a)

where,

c)

K,

For the Stokes region calculate:

c,

q =

.777R

F

5 region is transitional, skip to step 6

.Sb

5 St

St0 region is turbulent, proceed to step 5

,350

+

1.5

-.197

no

=

n,

= 1.065

n2

=

n,V,

n,,

+

log-‘W,

(w,+

log-‘(y,-

100

m,

= 4.81

m,=

’- = 1

PI

.0852(St)05

[

1

- Kn

.00418R-

t

.0189R

-

.1510R+

-

,929

.06185R.

-

,542 = n3

n2V02

+

+

V (Vas calculated in Step V, - W0 W, =

followino:

-

0.1193)

10)

(

V from step

.138-

-2.62+

* Skip to step

R

R,

[I

+2

K,

R

100

001375R*

+

.004025R2

skip to step 7

(St,, from step

.350] - S10

log[O.5 log

n3V03

+

K,as

follows:

5a)

R3

1000

R2

,369

100

(m, from step

flow at the conditions of flow:

log[log

=

V,

=

= WC

a)

= log- ’

=

log-’ V

= a)

C,K,R

(KRfrom

.000155R2

(coeff.

the same as in 5b)

=

(K,

10

8b)

step 2)IogR]

1 for gases)

5a)

3b)

SAMPLE CALCULATIONS FOR

1.

R :

.08836

=

Y:

4:

=

.00781

:“0

:n,

:“2

:

:V,

:m,

.2130

for all values

for all values of

Kn

2.

3.

St =

sr:R3a)

b)

St,: 6.805

4.

Region: Stokes

5. a) v:

W,:b)

“3

6. a)

“‘;b)

w,:

c)

w,:

a)

7.

zc:b)

Yc:c)

C,:d)

8.

a)

b)

R,:

IQ:

K,:c)

c,:a)

9.

~;“i

b)

K,

10.

,975

.0842

4.79

5

,977

,180

ANALyrCAL SOLUTION

R

a’f

7.61

12.77

transitional

1

--.1707

1.0315

-.1785

-

0765

-.6923

-.9325

-1.061 3

-1.256 5

.0554

1.495

9.371

,235

.09632

22.54

R

25

122.0

24.4

turbulent

-.1592

-.4249

-.1894

1.4519

-.3304

-1.004 3

1

.3760

3.128

9.72

,525

931

E4

::

23

138

71

The above flow (q)

11.

conditions

q = q’

p

PO

(q’)

as follows:

where,

red&d

mky

be

p.

= density at std.

to a volume measured at standard

cond

,964

-9

(1

forfiquiisR;-3.55-51.5R+2.37R2

K,‘:

I

700

.179

x0

and S.S. size * NOTE: For

[l-(k)‘]

=

for gases

11.

q ’:

R,’

Where:

5.45

addatonal Float multiply by an

K,”facior

Loading...

Loading...