Page 1

1

Page 2

2

Page 3

TABLE OF CONTENTS

Quick Start Instructions 4

Introduction 6

Specifications 7

Symbol Explanations 7

Components and Terminology 8

Flow Meter Mounting Procedure 11

Electronic Connections 14

4-20mA Output Connections 16

Pulse Output Connections 18

Applying Power 20

Troubleshooting Guide 22

Drawings 23

Notes 24

3

Page 4

QUICK-START INSTRUCTIONS

This manual contains detailed operating instructions for the FDT-30 instrument.

The following condensed instructions are provided to assist an experienced

operator in basic operation of the instrument. If the operator is unfamiliar

with this type of instrument, refer to the detailed explanations located on

pages 10-32.

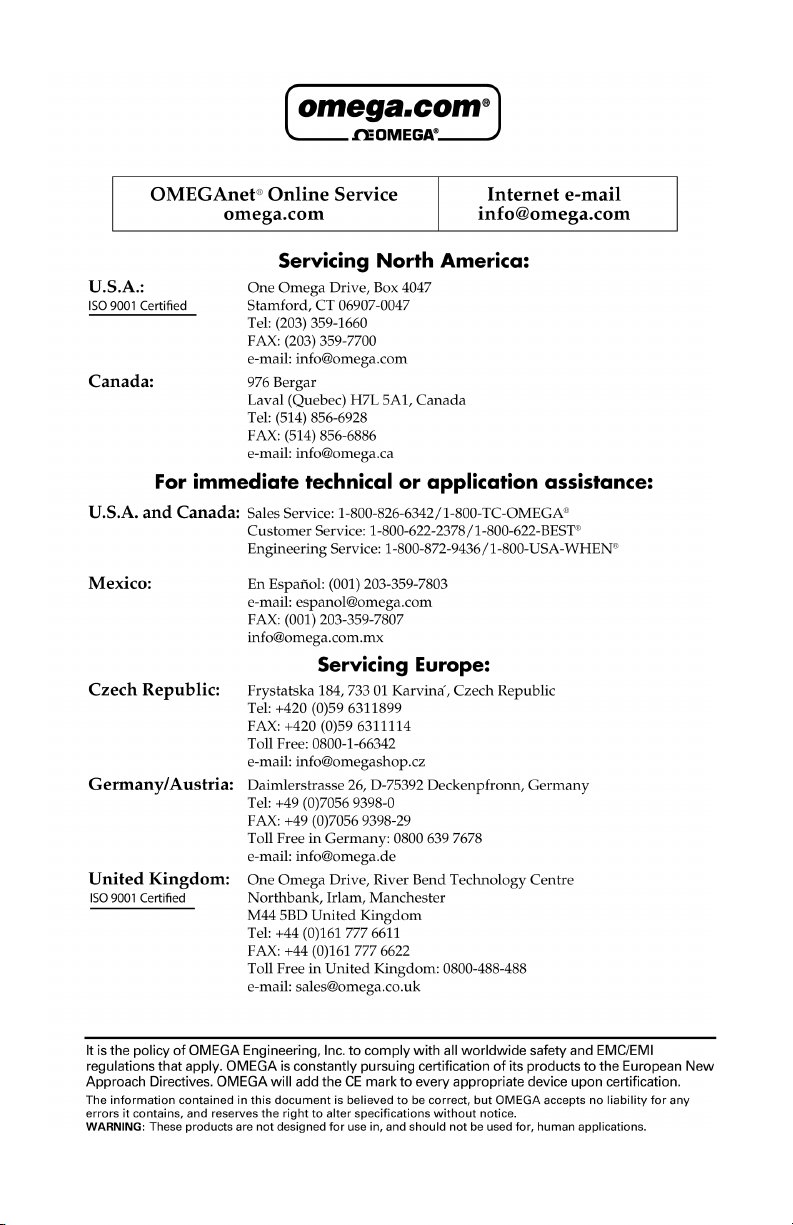

A. Select a flow meter mounting location with at least 10 pipe

diameters upstream and 5 diameters downstream from the

meter with no flow disturbances (i.e. elbows, tees, needle

valves, etc.). See Figure 1.

Figure 1

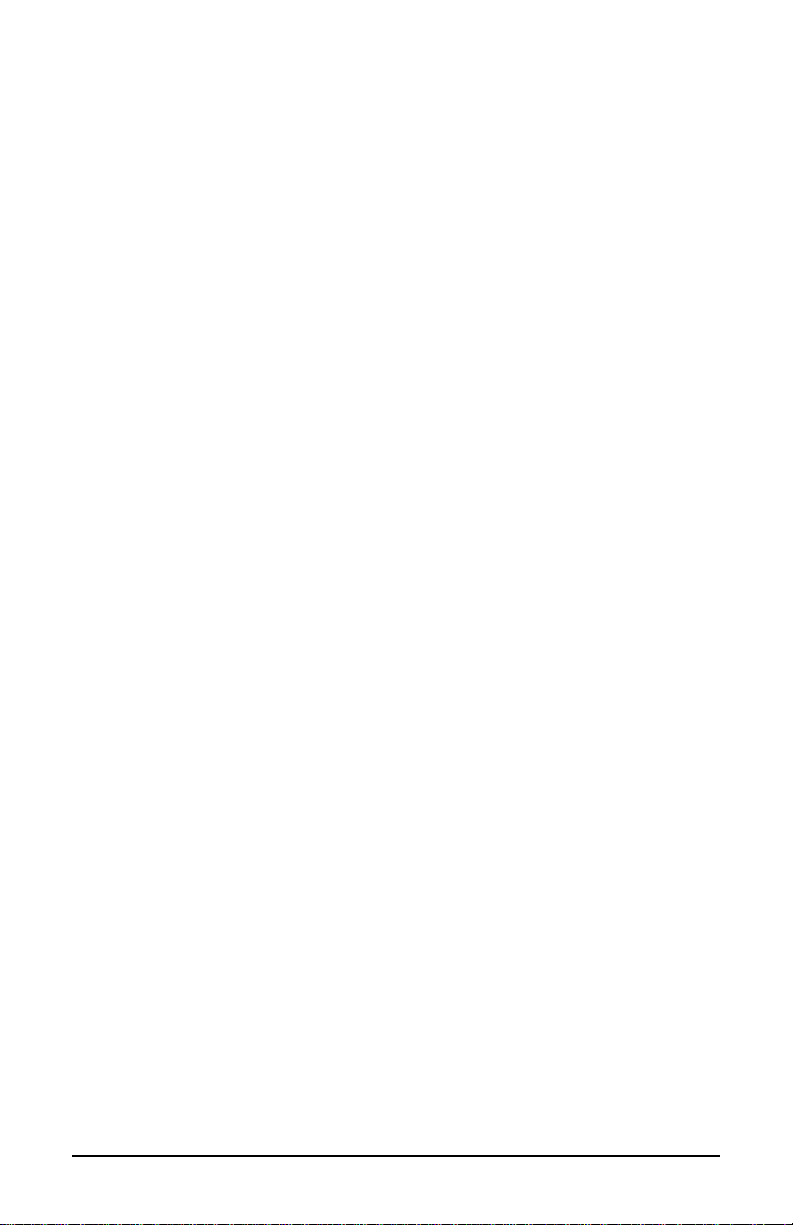

B. On horizontal pipe, choose a flow meter mounting location

within approximately 45-degrees of the side of the pipe. See

Figure 2. Locate the flow meter so that the pipe will be

completely full of liquid when flow is occurring in the pipe.

Avoid mounting on vertical pipes where the flow is moving in

a downward direction.

45°

NO

Figure 2

YES

4

YES

45°

NO

FLOW METER MOUNTING ORIENTATION

Page 5

C. Remove rust, scale and paint from the flow meter mounting

location. Clean to bare metal. Plastic pipes do not require

preparation.

D. Apply a thin, even layer of silicone grease to the two

transducer faces. Ensure that air bubbles are not present

over the two brown plastic sound-guides. Place the electronic

portion of the flow meter onto the prepared area of pipe,

making sure that the flow direction arrow is pointing in the

direction of flow. Place the clamp portion opposite the flow

meter and secure with the enclosed screws. Only moderate

torque is required on the screws—DO NOT OVER TIGHTEN

and DO NOT ROTATE the flow meter on the pipe once the

screws have been tightened.

E. Connect 11-30 Vdc to the power terminals within the FDT-30

transmitter. Ensure that the power supply is capable of

sourcing a minimum of 0.25 Amps. Observe polarity.

F. Connect either the 4-20mA, pulse output or both outputs to

the data acquisition or monitoring system as required.

G. Apply power.

H. If the pipe is full of liquid, a flow rate reading will appear. If

the pipe is empty or partially empty, a ERROR 0010 will be

shown on the display. The error will clear when flow resumes

and the pipe fills up with water.

5

Page 6

INTRODUCTION AND OPERATING THEORY

FDT-30 transit time flow meters measure flow velocity by sending

pulses of ultrasound energy back and forth between two

piezoelectric devices. See Figure 3. The piezoelectric components

are located behind the oval-shaped, dark plastic sound guides that

are embedded in the flow sensor clamp. If the liquid inside of the

pipe is moving, the sound will travel faster when it is sent in the

Figure 3

FDT-30

Sound Path

difference in time between upstream and downstream time

measurements. The FDT-30 compensates for gas content in the

liquid and will remove gaseous content from flow rate and totalizer

readings. Outputs from the flow meter include 4-20 mA analog,

turbine frequency output/pulse output.

direction of liquid flow than it

will when it is sent against the

liquid flow. The FDT-30

microprocessor generates the

pulses and measures the

elapsed time required for the

sound to travel between the

piezoelectric devices. Liquid

velocity is proportional to the

6

Page 7

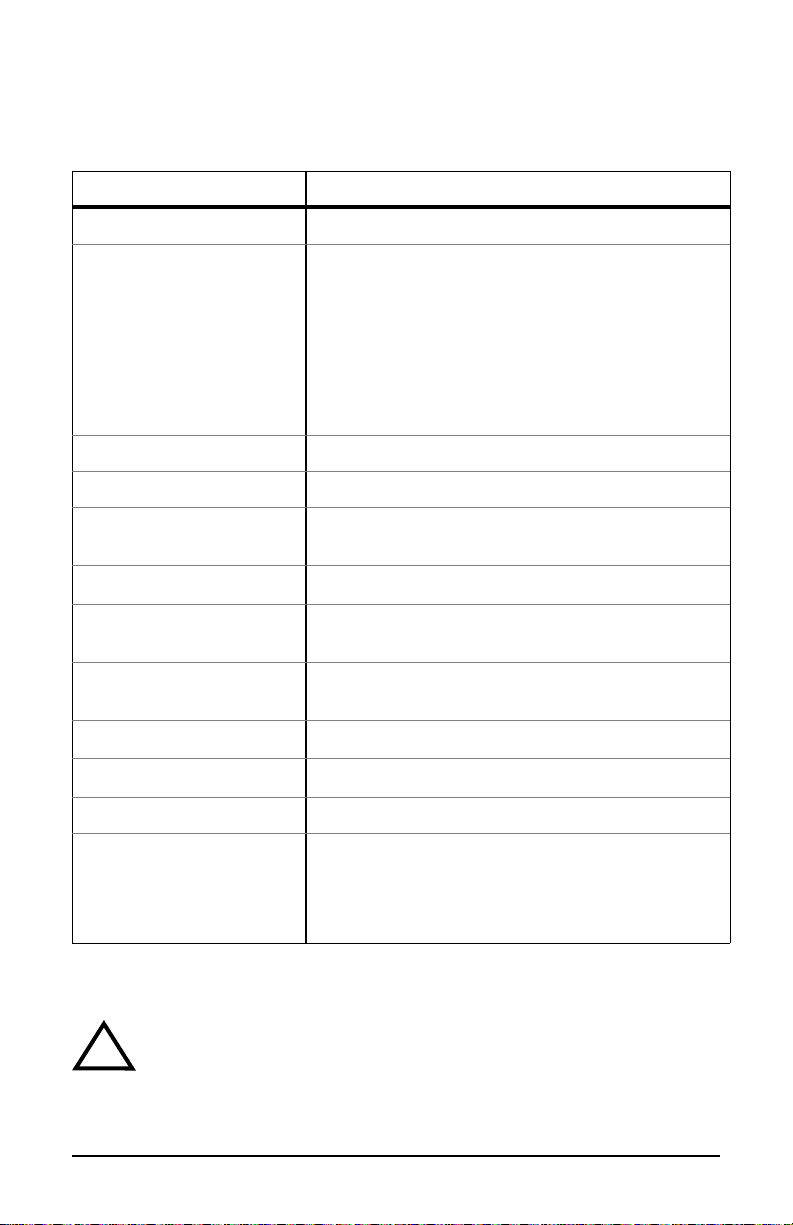

SPECIFICATIONS/OPERATING CONDITIONS

For a complete table of specifications, contact Omega.

Description Specification

Input Voltage

Flow Range Reference

Sch 40 ½” Pipe

Sch 40 ¾” Pipe

Sch 40 1” Pipe

Sch 40 1¼” Pipe

Sch 40 1½” Pipe

Sch 40 2” Pipe

Accuracy

Environment

Ambient Temperature

Altitude

Humidity

Transient

Overvoltages

Pollution Degree

Enclosure Material

11-30 VDC @ 0.25A

0.1 to 40 FPS [0.03 to 12.4 MPS]

0.5 to 25 GPM [20 to 850 BPD]

1.0 to 55 GPM [40 to 1800 BPD]

2.0 to 100 GPM [80 to 3400 BPD]

4.0 to 150 GPM [170 to 5000 BPD]

5.0 to 220 GPM [170 to 7500 BPD]

8.0 to 400 GPM [275 to 13500 BPD]

±1% of rate above 1 FPS [0.3 MPS]

Indoor use

General Purpose: 0 to +185°F [-20 to +85°C]

Hazardous Area: 0 to +105°F [-20 to +40°C

Up to 2000 meters

-20º to 31ºC; 80% max; decreasing linearly to

50% at 40ºC

According to installation category 1, in accordance with IEC 664

2 in accordance with IEC 664

ABS/Polycarbonate

4-20 mA Output

Pulse Output

12-bit, sourcing, DC ground referenced

Turbine Frequency Output/Pulse Output—

Switch Selectable, non-ground referenced AC/

Ground referenced square wave, 0-1,000 Hz,

100mVpp minimum/5VDC.

SYMBOL EXPLANATIONS

Caution—Refer to accompanying documents

!

7

Page 8

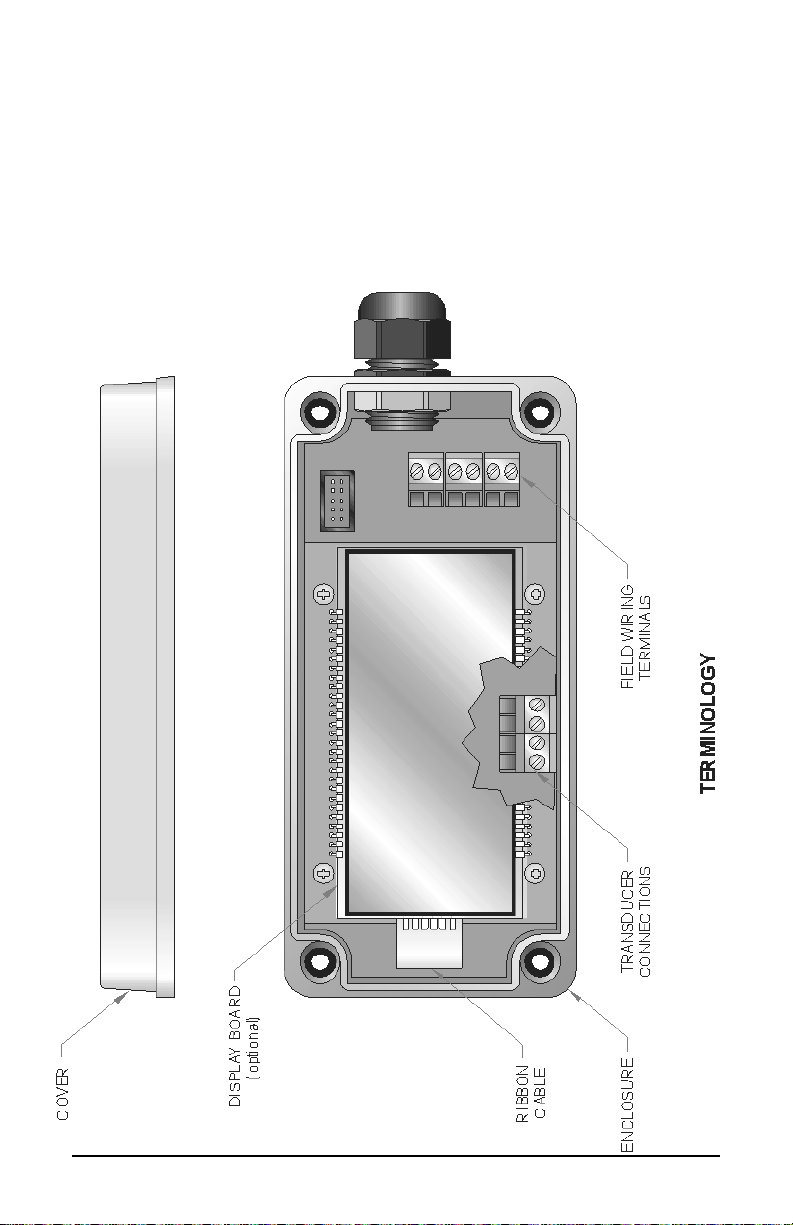

FLOW METER COMPONENTS AND TERMINOLOGY

The pictures on the following two pages reference key

components and their respective terminology of the FDT-30

flow meter. These terms are utilized throughout this manual.

8

Page 9

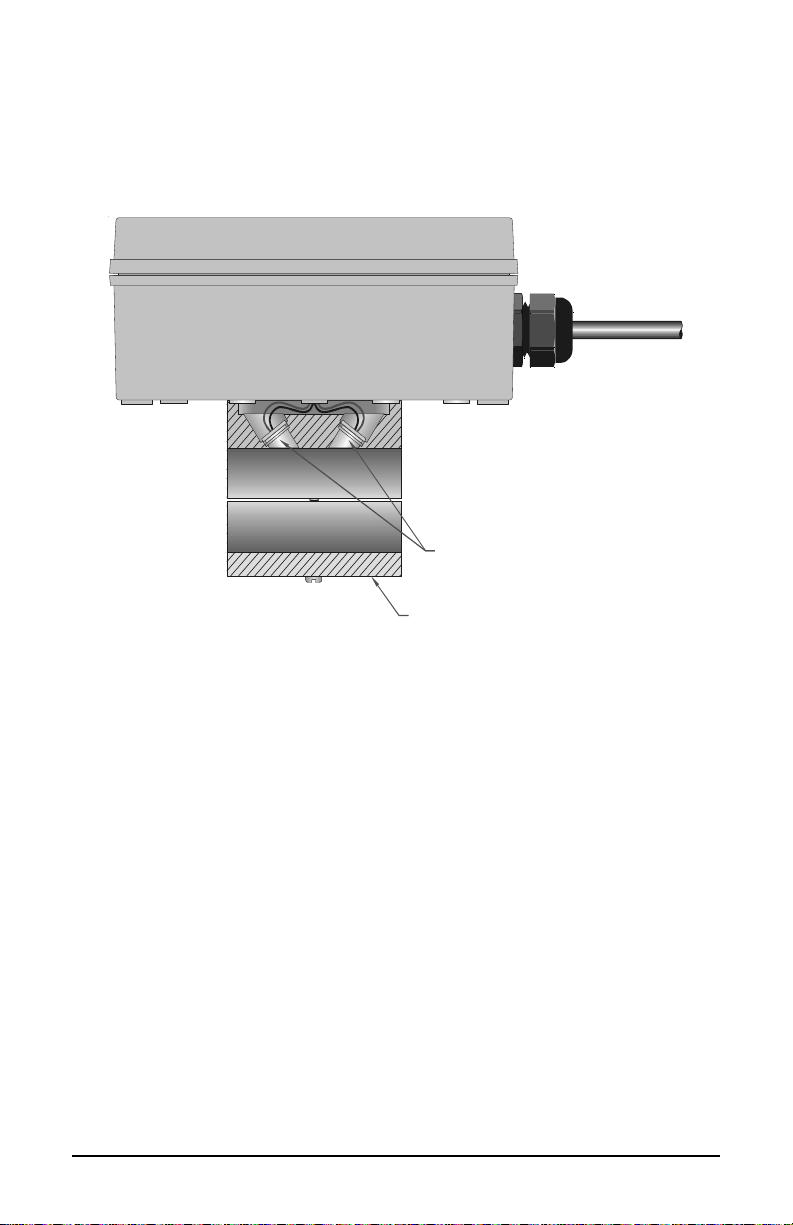

SOUND GUIDES

CLAMP

9

Page 10

FLOW METER INSTALLATION

!

!

!

IMPORTANT NOTE:

Not following instructions properly may impair

safety of equipment and/or personnel.

IMPORTANT NOTE:

Must be operated by a power supply suitable

for the location.

IMPORTANT NOTE:

Do not connect or disconnect either power or

outputs unless the area is known to be nonhazardous.

10

Page 11

A. FLOW METER LOCATION

The first step in the installation process is the selection of an

optimum location for the flow measurement to be made. For this

to be done effectively, a basic knowledge of the piping system

and its plumbing is required.

An optimum location would be defined as a piping system that is

completely full of liquid when measurements are being taken and

has lengths of straight pipe such as those described in Figure 4.

The optimum straight pipe diameter recommendations apply to

pipes in both horizontal and vertical orientation.

Note: If adequate straight plumbing cannot be provided the FDT30 will operate repeatably

accuracy

.

, but will most likely not achieve ideal

Figure 4

Straight Pipe Recommendations

11

Page 12

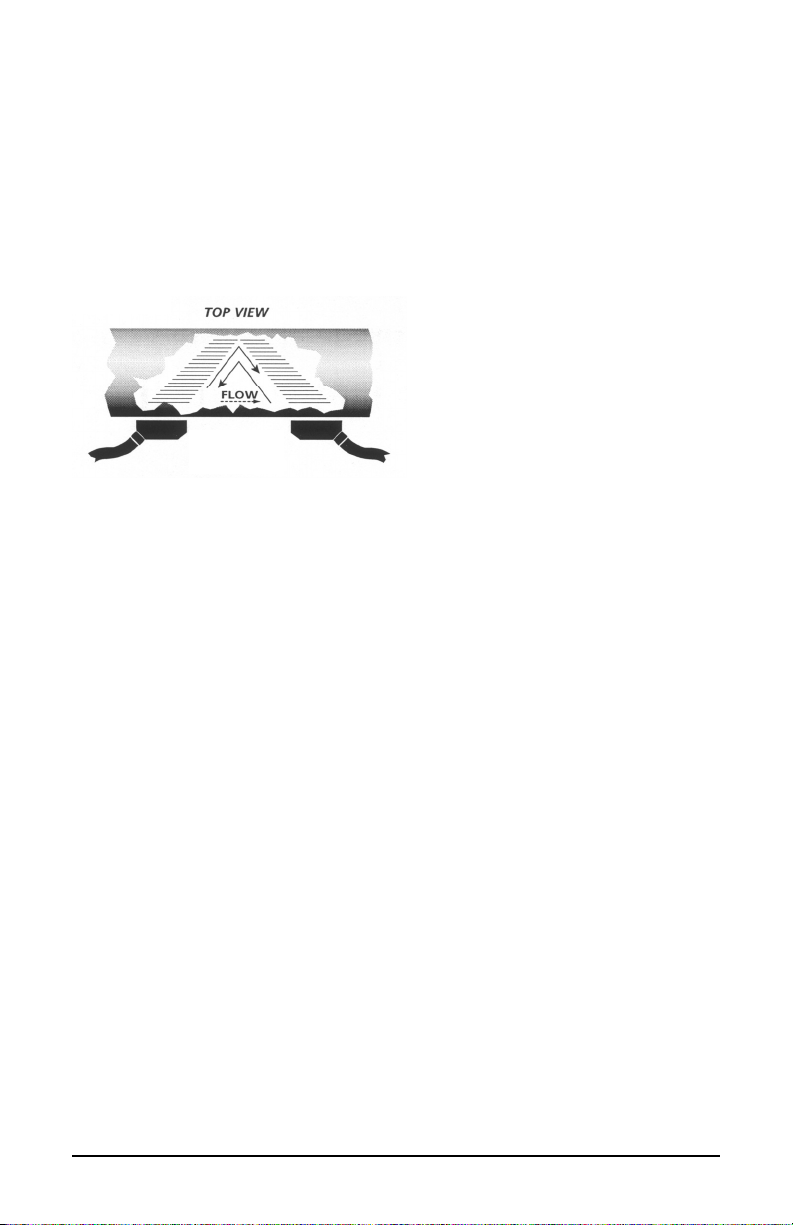

B. MOUNTING ORIENTATION ON THE PIPE

If the flow meter is applied to horizontal pipe, choose a mounting

position within approximately 45-degrees of 3 o’clock or 9 o’clock

on the pipe, assuming 12 o’clock to be to top of the pipe. These

positions provide optimum acoustic penetration into the moving

liquid. As illustrated in Figure 5, placement at the top or bottom

of the pipe can result in poor sound penetration due to air

pockets (on the top of the pipe) or sediment (at the bottom of the

pipe).

NO

45°

Figure 5

YES

YES

Mounting

Orientation on

45°

NO

Horizontal Pipes

FLOW METER MOUNTING ORIENTATION

It is best to plumb and orient the piping system so that it will be

completely full of liquid at all times—whether the liquid is flowing

or not. Typically, by slightly sloping the pipe in the upward

direction or orienting the check valve judiciously within the piping

system this can be accomplished.

If the flow meter is applied to vertical pipe with flow moving in an

upward direction, radial orientation does not matter.

12

Page 13

C. PIPE PREPARATION

Before the transducer face can be coupled to a pipe surface, an

area slightly larger than the flat surface of the transducer must be

cleaned to bare metal on the pipe. Remove all scale rust and

paint. Thoroughly dry and clean the mounting surface.

Note: For plastic pipes, such as PVC or PVDF, pipe

preparation is typically not required.

D. APPLYING ACOUSTIC COUPLANT

To assure an acoustically conductive path between the

transducer face and the prepared pipe surface, a coupling

compound is employed. Enclosed with the FDT-30 flow meter is

a tube of silicone based grease. This grease is adequate for the

majority of installations. If an alternate grease is utilized, the

grease must be specified not to flow at the temperature of the

pipe surface or the ambient conditions.

Apply an even layer of grease, approximately 1/16" [1.5 mm]

thick to the entire inside surface of the transducer. See Figure 6.

Figure 6

Applying

Acoustic Couplant

Apply silicone grease

to both surfaces

13

Page 14

E. MOUNTING THE FLOW METER

Place the flow meter on the prepared area of the pipe, observing

the flow direction arrow on the side of the flow meter enclosure.

Place the flow meter clamp on the backside of the pipe and

secure with the two enclosed screws. Tighten only enough to

hold the flow meter in place and to squeeze some of the acoustic

couplant from the mounting faces. Over tightening may strip the

threads and is unnecessary for flow meter operation.

IMPORTANT NOTE: Do not rotate the FDT-30 flow meter on

the pipe once the screws have been tightened, as the acoustic

grease may be disturbed. If the grease layer between the sound

guides and the pipe obtains an air pocket, the flow meter signal

strength and, hence, operation may be compromised.

If upon power up the flow meter indicates ERROR 0010 and the

pipe is full of liquid, reapplication of the acoustic grease will be

necessary.

F. FIELD WIRING—GENERAL

The FDT-30 is equipped with a single conduit hole located in the

flow meter enclosure that should be suitable for most

installations. A sealed cord grip or conduit connection should be

utilized to retain the NEMA 3 integrity of the flow meter

enclosure. Failure to do so will void the manufacturer’s warranty

and can lead to product failure.

For hazardous area installation, see the drawing at back of this

manual. For non-hazardous location installations, flow meter

power and output signals can be carried by a single cable with

multiple conductors. Select a 20-24 AWG shielded cable with an

external jacket suitable for the installation environment and either

2, 4, or 6 conductors—dependent on the electronic output

requirements.

Wiring methods and practices are to made in accordance with

the NEC—National Electrical Code

ordinances that may be in affect. Consult the local electrical

inspector for information regarding wiring regulations.

When making connections to the field wiring terminals inside of

the flow meter, strip back the wire insulation approximately 0.25

14

®

and/or other local

Page 15

inches [6 mm]. Stripping back too little may cause the terminals

to clamp on the insulation and not make good contact. Stripping

back too much insulation may lead to a situation where the wires

could short together between adjacent terminals. Wires should

be secured in the Field Wiring Terminals using a screw torque of

between 0.5 and 0.6 Nm.

G. FIELD WIRING—POWER

!

!

IMPORTANT NOTE:

Must be operated by a power supply

suitable for the location.

IMPORTANT NOTE:

Do not connect or disconnect either power

!

or outputs unless the area is known to be

non-hazardous.

Power for the FDT-30 flow meter is obtained from a direct current

DC power source. The power source should be capable of

supplying between 11 and 30 Vdc at a minimum of 0.25 Amps or

250 milliamps. With the power from the DC power source

disabled or disconnected, connect the positive supply wire and

ground to the appropriate field wiring terminals in the flow meter.

See Figure 7. A wiring diagram decal is located on the inner

cover of the flow meter enclosure.

If the flow meter is only to be utilized as a flow rate indicator or

totalizer, no further wiring will be required. Skip to step J.

DC Ground

11 to 30 Vdc

11- 30 VD C

Figure 7

DC Power Connection

15

Page 16

H. CONNECTING THE 4-20 mA OUTPUT

The FDT-30 is equipped with a ground-referenced 4-20 mA

output—the output shares a common ground with the power

supply. The output transmits a continuous current output that is

proportional to liquid flow rate. The output was scaled at the

factory and the scaling information is recorded on the label

located on the side of the FDT-30 enclosure. To ensure that the

instrument or data acquisition system that is receiving the 4-20

mA signal responds properly, it must be spanned identically to

the FDT-30.

The 4-20 mA output is designed to source current across a loop

resistance that is typically located within a data acquisition

system or other receiving instrument. The maximum resistance

that the FDT-30 can accommodate is directly related to the DC

power source that is powering the flow meter and the 4-20 mA

loop. Chart 1 illustrates the range of load resistance that can be

used with a given power supply voltage. Ensure that the loop

load resistance is within the shaded region of the graph, or nonlinearity and transmitting errors will occur.

16

TFXL Loop Re sistance

FDT-30 Loop Resistance

1400

1200

1000

800

600

400

Loop Load: Ohm s

200

0

15 17 19 21 23 25 27 29

Supply: Vdc

Operate in the

Shaded Region

Chart 1

4-20 mA Loop Load

Page 17

The 4-20 mA output is polarized and since the output shares the

DC common with the power supply, reversing the connections

can cause a short circuit in the DC power circuit. Figure 8

shows a block diagram of how the 4-20 mA interfaces with the

receiving device.

FDT-30 Flow Meter Receiving Device

Meter Power 11 to 30 Vdc

4-20 mA Output

4-20 mA Ground

4-20 mA

Loop Resistance

Power Supply

Ground

Figure 8

4-20 mA Block

Diagram

Connect the wires to the appropriate Field Wiring Terminals

within the FDT-30 enclosure. See Figure 9.

4-20 mA Ground

4-20 mA Output

Figure 9

4-20 mA Connections

17

Page 18

I. CONNECTING THE PULSE OUTPUT

The FDT-30 is equipped with a circuit that outputs a pulse

waveform that varies proportionally with flow rate. The quantity

of pulses per unit volume of liquid is described by the K-factor

that is recorded on the side of the flow meter enclosure. To

ensure that accurate readings are being recorded by the

receiving instrument, the FDT-30 and the receiving instrument

must have identical K-factor values programmed into them.

Two pulse output options are available with the FDT-30:

Turbine meter simulation (SW1 ON) — This option is utilized

when a receiving instrument is capable of interfacing directly

with a turbine flow meter’s magnetic pickup. The output is a

relatively low voltage AC signal that is not ground referenced.

The minimum AC amplitude is approximately 500 mV peak-to

-peak.

This option is selected by placing SW1 in the ON position.

See Figure 10.

TTL pulse frequency (SW1 OFF) — This option is utilized

when a receiving instrument requires that the pulse voltage

level be either of a higher potential and/or referenced to DC

ground. The output is a square-wave with a peak-to-peak

voltage swing of 5 volts.

This option is selected by placing SW1 in the OFF position.

See Figure 10.

Figure 10

Pulse Output Switch Positions

18

Page 19

Turbine Meter Simulation Output Connection

Connection of the turbine meter simulation output is simply a

matter of connecting the two Field Wiring Terminals to the turbine

meter input terminals on the receiving instrument and verifying

that the K-factor listed on the side of the FDT-30 enclosure is

programmed into the receiving instrument. This output is not

referenced to DC ground and is not polarized, so wiring polarity

is not important. See Figure 11.

Turbine Output

Turbine Output

Figure 11

Turbine Meter Simulation Connections

TURBINE SIMULATIO N

19

Page 20

TTL Pulse Frequency Connection

Connection of the TTL pulse frequency output is a matter of

connecting the two Field Wiring Terminals to the frequency input

terminals on the receiving instrument and verifying that the Kfactor listed on the side of the FDT-30 enclosure is programmed

into the receiving instrument. This output is referenced to DC

ground and is polarized. Connect the TTL Pulse plus (+) field

terminal in the flow meter to the frequency input on the receiving

instrument. Connect the TTL Pulse negative (-) field terminal to

the frequency input negative or DC common connection in the

receiving instrument. See Figure 12.

TTL Output (+)

TTL Output (-)

Figure 12

TTL Pulse Output Connections

J. APPLYING POWER TO THE FDT-30

The FDT-30 flow meter requires a full pipe of liquid before a

successful startup can be completed. Do not attempt to make

adjustments or change configurations until a full pipe is verified.

1. Verify that all wiring is properly connected and routed as

described in Steps A though I of this manual.

2. Verify that the flow sensor is properly mounted and that the

acoustic grease is intact between the transducer faces and

the pipe.

3. Apply power. The display of the FDT-30 will display a display

test where all segments will illuminate in succession and then

the software version will be displayed. The meter will then

enter RUN Mode.

20

Page 21

4. Upon entering RUN Mode, the FDT-30 will provide one of the

following responses:

The display may indicate ERROR 0010, which indicates

low signal strength. Low signal strength is caused by one

of the following:

an empty pipe (gas locked)

gas content in the liquid that exceeds 10%

inadequate acoustic grease between the flow meter

transducer and the pipe

a broken connection between a transducer and the

main circuit board—check wire terminations under

the display.

The display may indicate a flow rate.

If 0.000 is indicated, it means that the meter is

operating properly, but that the liquid is not moving.

A negative value would indicate that flow is moving

backwards—against the flow direction arrow. A

standard FDT-30 will not output flow signals under

this condition.

The flow meter indicates flow rate. This verifies that

signal strength is adequate and that the flow is

moving in the direction that the flow arrow signifies.

21

Page 22

TROUBLESHOOTING GUIDE

Unit does not turn “ON”

when power is applied

Unit reads zero flow when

flow is actually running

ERROR 0010 is Displayed

on the Screen

Verify that voltage in the range of 11-

30 Vdc is present at the field terminals.

If the voltage is present and neither

LED on the main printed circuit board

is illuminated, return the flow meter to

the factory for evaluation.

Verify that the Maximum Flow Rate

value is not set to a very high value

and causing the Flow Cutoff percent

entry to drive the readings to zero.

Decrease Max Flow setting or

decrease Flow Cutoff percentage.

Verify that a zero was not entered on

page 3 of the calibration screen.

The flow meter is not mounted onto

the pipe using an acoustic couplant.

The acoustic couplant is not uniform

between the flow meter transducer

and the pipe.

The liquid contains more than 10%

suspended gas bubbles.

The pipe is full of gas—gas locked.

Flow Meter Reads

Negative Flow Readings

Flow Meter is Reading

Flow, But Output Is Not

Transmitting

22

Flow is running backwards when

compared to the FLOW DIRECTION

arrow located on the side of the flow

meter enclosure.

Verify that one of the LEDs on the

main printed circuit board is flashing—

if not, contact Omega.

Verify connections and polarity of

wiring.

Test output with a milliamp meter,

oscilloscope or other test instrument.

Verify that the output is configured for

RATE (Figure 16).

Page 23

INSTALLATION

FDT-30 HAZARDOUS AREA

OR EQUIVALENT

OR EQUIVALENT

(NEC) Article 500.

®

FDT-30 FLOW METER

1. Information shown on this drawing is provided to indicate wiring

2. Disconnect to be located near the FDT-30 Flow Meter. 3. Disconnect may not be required if FDT-30 Flow Meter is powered from

requirements to comply with National Electrical Code

a class 2 Power Supply.

4. Smaller gauge wire may be acceptable if overall system meets NEC

Requirement per Article 725 Part III.

23

Page 24

NOTES

24

Page 25

NOTES

25

Page 26

NOTES

26

Page 27

27

Page 28

28

Loading...

Loading...