Page 1

U

ser

’

s

Guide

Shop

e-mail: info@omega.com

For latest product manuals:

online

omega.com

omegamanual.info

at

FDT100 Series

Ultrasonic Flow Meters

Page 2

OMEGA

®

Onli

f

to

W

net

ne Service

omega.com info@omega.com

Ser

vicing North

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail:

info@omega.ca

For immediate technical or application assistance:

Internet e-mail

America:

U.S.A. and Canada: Sales Service:

Service:

Service:

1-800-826-6342/1-800-TC-OMEGA® Customer

1-800-622-2378/1-800-622-BEST® Engineering

1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Ser

vicing Eur

Czech Republic: Frystatska 184, 733 01 Karvin

TEL:

+

420 (0)59 6311899

+

FAX:

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

420 (0)59 6311114

ope:

á

, Czech Republic

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

+49

TEL:

FAX:

Toll Free in Germany: 0800 639 7678

e-mail:

(0)7056 9398-0

+49

(0)7056 9398-29

info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5BD United Kingdom

+44

TEL:

FAX:

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

(0)161 777 6611

+44

(0)161 777 6622

It is the policy o

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

contains, and reserves the right to alter specifications without notice.

ARNING: These products are not designed for use in, and should not be used for, human applications.

OMEGA Engineering, Inc.

comply with all worldwide safety and EMC/EMI

errors it

Page 3

Design, Assembly and Service Manual

Page 1 of 20

Ultrasonic water meter FDT100 series

Contents

1. APPLICATION...................................................................................................................................................2

2. MEASUREMENT METHOD ..............................................................................................................................2

3. TECHNICAL DESCRIPTION ............................................................................................................................2

3.1. Meter characteristics.................................................................................................................................................... 2

3.2. Meter design................................................................................................................................................................... 3

3.2.1. Compact version – basic dimensions.................................................................................................................. 3

3.2.2. Remote version – basic dimensions.................................................................................................................... 3

3.2.3. Ultrasonic sensor unit ............................................................................................................................................ 4

3.2.4. Electronic unit.......................................................................................................................................................... 4

3.2.5. Separate sensor unit – terminal board ................................................................................................................ 6

3.2.6. Meter handling ........................................................................................................................................................ 7

4. TECHNICAL SPECIFICATIONS....................................................................................................................... 8

5. PROJECT DESIGN AND METER INSTALLATION......................................................................................... 9

5.1. Project design of systems including ultrasonic water meters.......................................................................... 9

5.2. Meter installation......................................................................................................................................................... 12

5.2.1. General recommendations.................................................................................................................................. 12

5.2.2. Mechanical fitting.................................................................................................................................................. 13

5.2.3. Electrical connections .......................................................................................................................................... 13

5.2.4. Seals on meters.................................................................................................................................................... 15

6. OPERATIONAL START..................................................................................................................................17

7. OPERATION....................................................................................................................................................18

7.1. Reading the measured quantities from the meter display ............................................................................... 18

7.2. Electrical outputs........................................................................................................................................................ 18

7.2.1. Pulse output .......................................................................................................................................................... 18

7.2.2. Current output ....................................................................................................................................................... 19

7.3. Error identification function..................................................................................................................................... 19

7.4. Battery life and replacement .................................................................................................................................... 19

8. CALIBRATION ................................................................................................................................................20

Page 4

Design, Assembly and Service Manual

Page 2 of 20

Ultrasonic water meter FDT100 series

1. APPLICATION

Battery-powered ultrasonic water meters of the FDT100 SERIES type series are intended for technological

measurements of instantaneous flow rate and consumption in water-supply networks, and archiving of the measured

data. Measurement of water pressure in piping is also possible. The technical capabilities including high measurement

accuracy and long-term stability over a wide range of measured values make it possible to use the meters, apart from

the conventional measurements, for monitoring leakage and the general condition of water supply networks. The

FDT100 SERIES water meters do not require external power, do not include any moving parts or filters to prevent

choking with mechanical impurities and, compared to conventional water meters, have significantly lower hydraulic

losses.. Flow meters shall be used in standard non-explosive environments.

Any installation of flow meter must be in conformity with technical conditions mentioned in this manual.

2. MEASUREMENT METHOD

The measurement method used is a single-beam pulse transit-time method based on determination of the time

needed for an ultrasonic pulse wave to cross the distance between two probes embedded in piping. Each of the probes

functions as the sender and receiver in turns so that the ultrasonic wave travels in turns in and against the water flow

direction. This arrangement allows for effective elimination of errors due to asymmetry in the probe locations.

3. TECHNICAL DESCRIPTION

3.1. Meter characteristics

The FDT100 SERIES ultrasonic water meter is an electronic device used to measure the water flow rate in a fully

flooded piping. It is manufactured and supplied in two versions: compact and remote. The compact version, designated

FDT100 .SERIES , has the electronic unit attached directly onto the flow sensor housing. The remote version,

designated FDT100-R .SERIES, has the electronic unit separated from the sensor and connected with it by means of a

cable ( length 6m). The electronic unit is accommodated in a separate box that can be fitted on a wall.

In the standard configuration, the meter software allows for measuring and display of the instantaneous flow rate

and total volume of water passed through the meter since the volume counter was last reset. The meter is provided

with a passive pulse output including an optocoupler. The pulse length is 40ms. The meter include passive current

output. The meter is supplied suitable for use in drinking-water supply systems.

Page 5

3.2. Meter design

ELECTRONIC

CONTROL UNIT

DN

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

5,35"(136mm)

ULTRASONIC

SENSOR

S/N 22686/06

ANSI

2"

BN 15 1,45psi

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

232

5

4-20

psi

G/imp

mA

r

r

a

n

t

y

w

a

o

i

f

d

i

v

e

m

o

v

e

d

r

S

D

Page 3 of 20

L

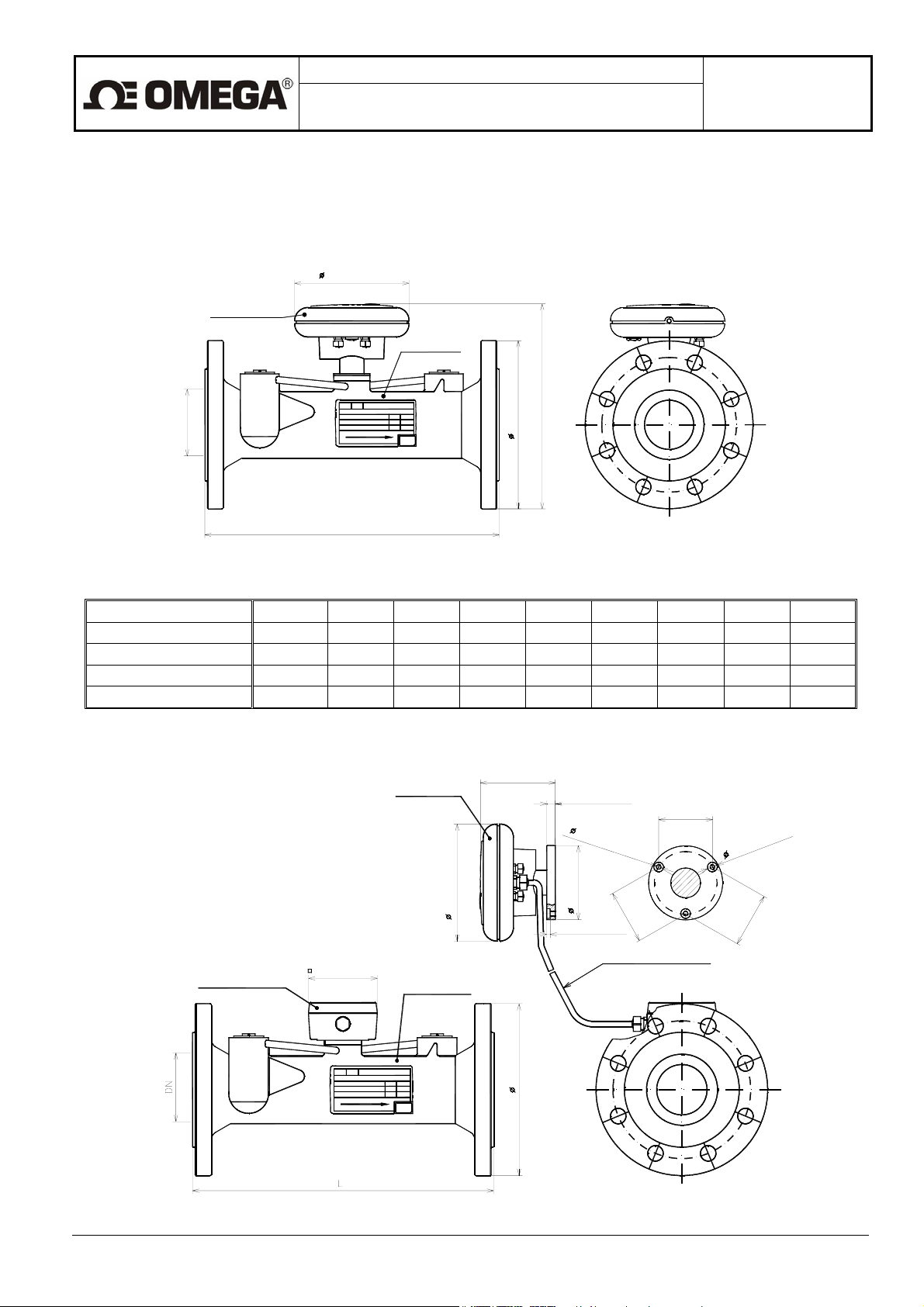

3.2.1. Compact version – basic dimensions

DN

L [inch] / [mm]

S [inch] / [mm]

D [inch] / [mm]

Weight [lb] / [kg]

1¼" (32) 1½" (40) 2" (50) 2½" (65) 3" (80) 4" (100) 5" (125) 6" (150) 8" (200)

10.2/260 11.8/300 11.8/300 11.8/300 13.8/350 13.8/350 13.8/350 13.8/350 13.8/350

7.5/190 7.8/198 8.2/208 8.9/225 9.3/237 10/253 11/280 12/307 14/352

5.5/140 5.9/150 6.5/165 7.3/185 7.9/200 8.7/220 9.8/250 11.2/285 13.4/340

10/4.5 15/7 22/10 24/11 33/15 39/17.5 50/22.5 57/26 80/36.5

3.2.2. Remote version – basic dimensions

3,54"(90mm)

ELECTRONIC

SENSOR

5,35"(136mm)

TERMINAL BOARD

3,15"(80mm)

ULTRASONIC

SENSOR

0,4"(10mm)

0

,

2

2

"

(

5

,

5

3,3"(84mm)

0,15"(4mm)

max. length 5m

m

2

,

m

)

4

"

(

6

1

2,4"(61mm)

)

)

m

m

1

1

(

"

3

4

,

0

)

1

6

(

"

4

,

2

S/N 22686/06

ANSI

2"

BN 15 1,45psi

232

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

psi

5

G/imp

4-20

mA

y

t

n

r

r

a

w

a

f

i

i

d

o

v

d

e

v

m

o

r

e

D

Page 6

Design, Assembly and Service Manual

Page 4 of 20

Ultrasonic water meter FDT100 series

DN

L [inch] / [mm]

D [inch] / [mm]

Weight [lb] / [kg]

1¼" (32) 1½" (40) 2" (50) 2½" (65) 3" (80) 4" (100) 5" (125) 6" (150) 8" (200)

10.2/260 11.8/300 11.8/300 11.8/300 13.8/350 13.8/350 13.8/350 13.8/350 13.8/350

5.5/140 5.9/150 6.5/165 7.3/185 7.9/200 8.7/220 9.8/250 11.2/285 13.4/340

11/5 16.5/7.5 23/10.5 25/11.5 34/15.5 40/18 51/23 58/26.5 82/37

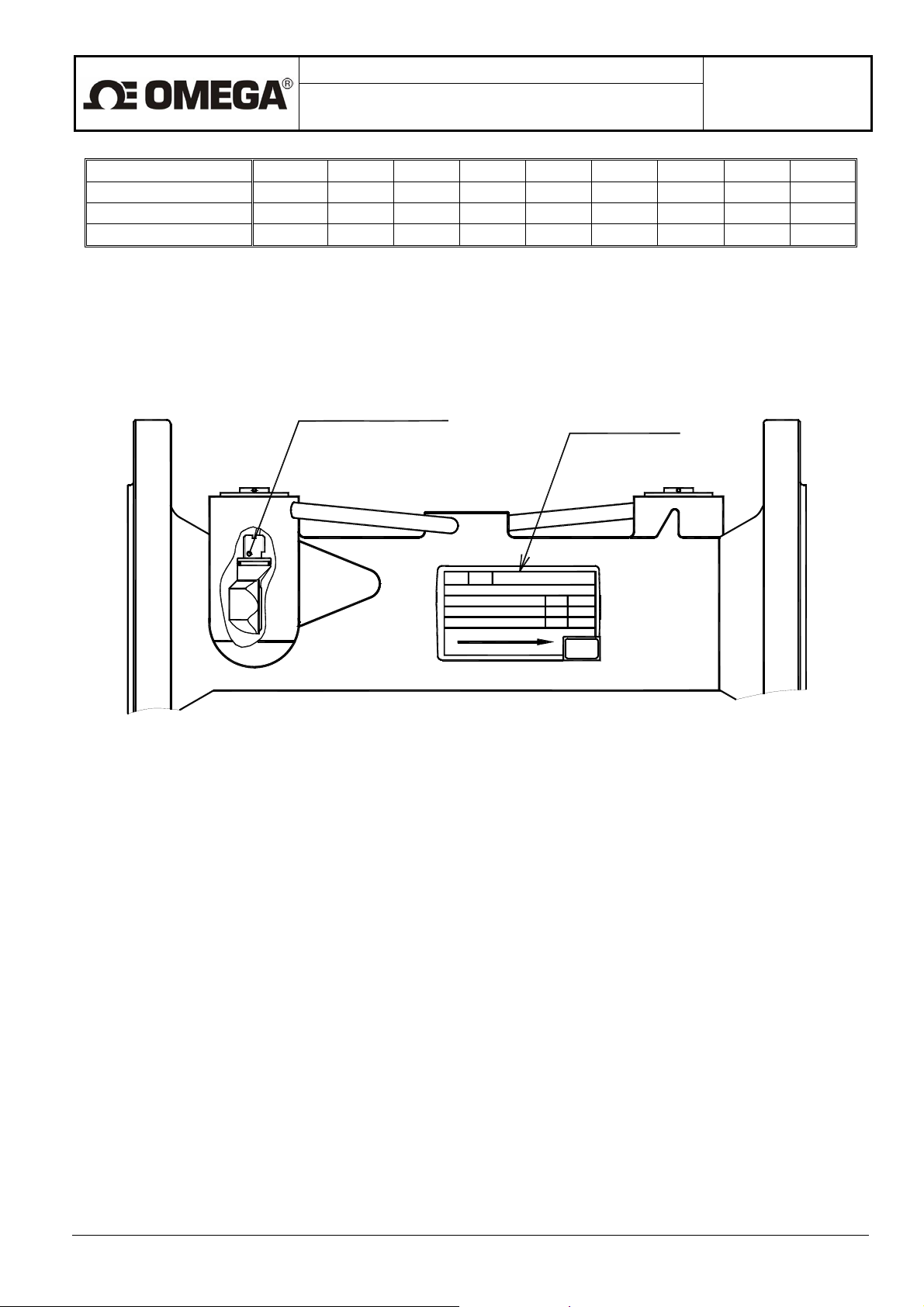

3.2.3. Ultrasonic sensor unit

The ultrasonic sensor unit comprises a housing made of ductile cast iron (material according to DIN GGG40) with

two flanges (according to 150# ANSI B) and two embedded ultrasonic probes. The sensor housing is painted with

surface finish of KOMAXIT E 2110 blue powder epoxy paint (RAL 5017). The rating plate attached to the sensor body

includes the basic meter specifications including the sensor size (DN), the accuracy class (B) and the rated constant

flow rate in gallons per minute (q

, the figure next to N) – see the picture below.

P

ULTRASONIC PROBE

ANSI

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

S/N 22686/06

2"

BN 15 1,45psi

LABEL SENSOR

232

psi

5

G/imp

4-20

mA

y

n

a

t

r

w

r

a

f

i

d

i

o

v

d

e

o

v

m

e

r

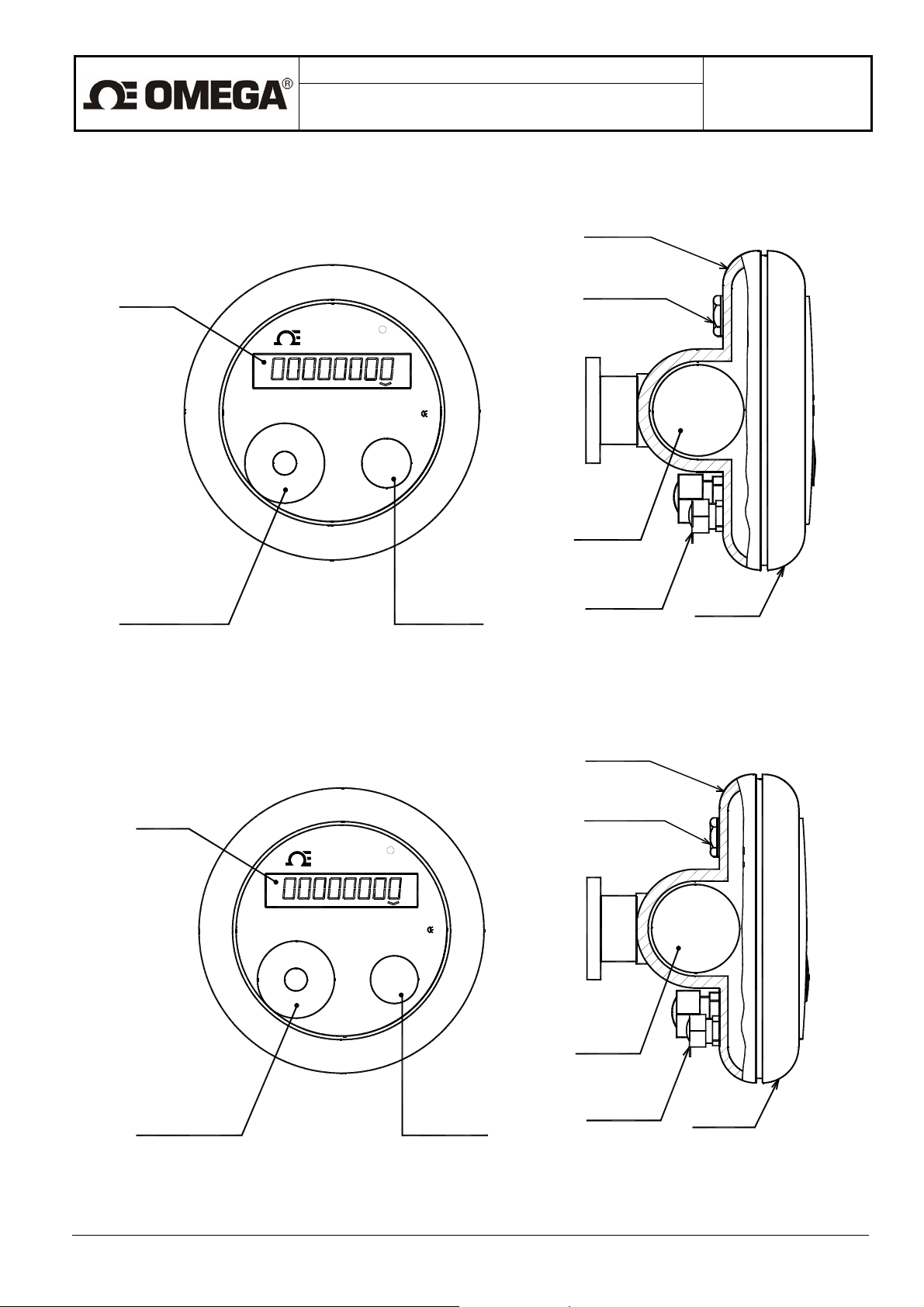

3.2.4. Electronic unit

The electronic unit and battery are placed in an aluminium box with a plastic lid. The box is provided with a special

valve preventing moisture condensation inside the box and up to three grummets for cables of circular cross-section.

The surface finish is by paint of orange hue (RAL 1017).

Two M8 grummets are intended for cables of outside diameter 3.5 to 5mm to be connected to the selected output

signal terminals. On delivery, these grummets are blinded. The third grummet (M12) is provided only in the case of the

remote meter version and is intended for the cable of diameter 6.5 to 8mm connecting the sensor and the remote

electronic unit. The connecting cable is supplied attached to the electronic unit with the other end ready to be

connected to the sensor terminal board.

The meter display is located under the transparent plastic cover. The push-button on the unit box is used to select

the desired display mode: either instantaneous flow rate (in gallons per minute GPM or m

(in thousands of gallons or m

3

) passed through the meter sensor since the volume counter was last reset, or the fluid

pressure (in bar). The actual quantity displayed is indicated at the bottom line by the symbol j. In the case of a meter

failure, the respective error message (E1 through to E5) will be indicated by the same symbol j - see the picture

below. A recess in the unit box is for an optical probe to be applied onto the recessed surface to read the stored data.

Also found under the box lid is the meter rating plate:

3

/hour), the total fluid volume

Page 7

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

Plate including rated parameters in G.10

3

a GPM

Page 5 of 20

ALUMINIUM

HOUSING

DISPLAY

R

OMEGA

E1 E2

FDT 103 XA

RECESS FOR

OPTICAL PROBE

Plate including rated parameters in m3 and m3/hour

3

E4 E5 G.10 GPM

E3

DC 3,6V

IP 67

T 32...122°F

PUSH-BUTTON

CONDENSATION

VALVE

BATTERY

BUSHINGS

ALUMINIUM

HOUSING

PLASTIC

COVER

DISPLAY

R

CONDENSATION

VALVE

OMEGA

E1 E2 E3 E4 E5 m m/h

FDT 103 XA

RECESS FOR

OPTICAL PROBE

IMPORTANT NOTICE: Prior to operational start, check proper tightening of the grummets and blinding of the

unused ones.

3 3

IP 67

T 32...122°F

DC 3,6V

PUSH-BUTTON

BATTERY

BUSHINGS

PLASTIC

COVER

Page 8

Design, Assembly and Service Manual

Page 6 of 20

Ultrasonic water meter FDT100 series

3.2.5. Separate sensor unit – terminal board

In the case of the remote version of the FDT100 SERIES water meter, attached to the sensor housing is a terminal

board in an aluminium box with a sealed lid. The terminal box is provided with a M12 grommet for a cable of diameter

6.5 to 8mm, a valve preventing moisture condensation inside the box and four spring-loaded WAGO terminals to which

the ultrasonic probes signals are brought. Connected to these terminals are the wires of the cable leading to the remote

electronic unit.

BUSHING

CONNECTING CABLE

TO ELECTRONIC UNIT

WAGO TERMINALS

X2 4 3 2 1

X1

4 3 2 1

CONDENSATION

VALVE

ALUMINIUM

BOX

BOX

LID

Page 9

Design, Assembly and Service Manual

Page 7 of 20

Ultrasonic water meter FDT100 series

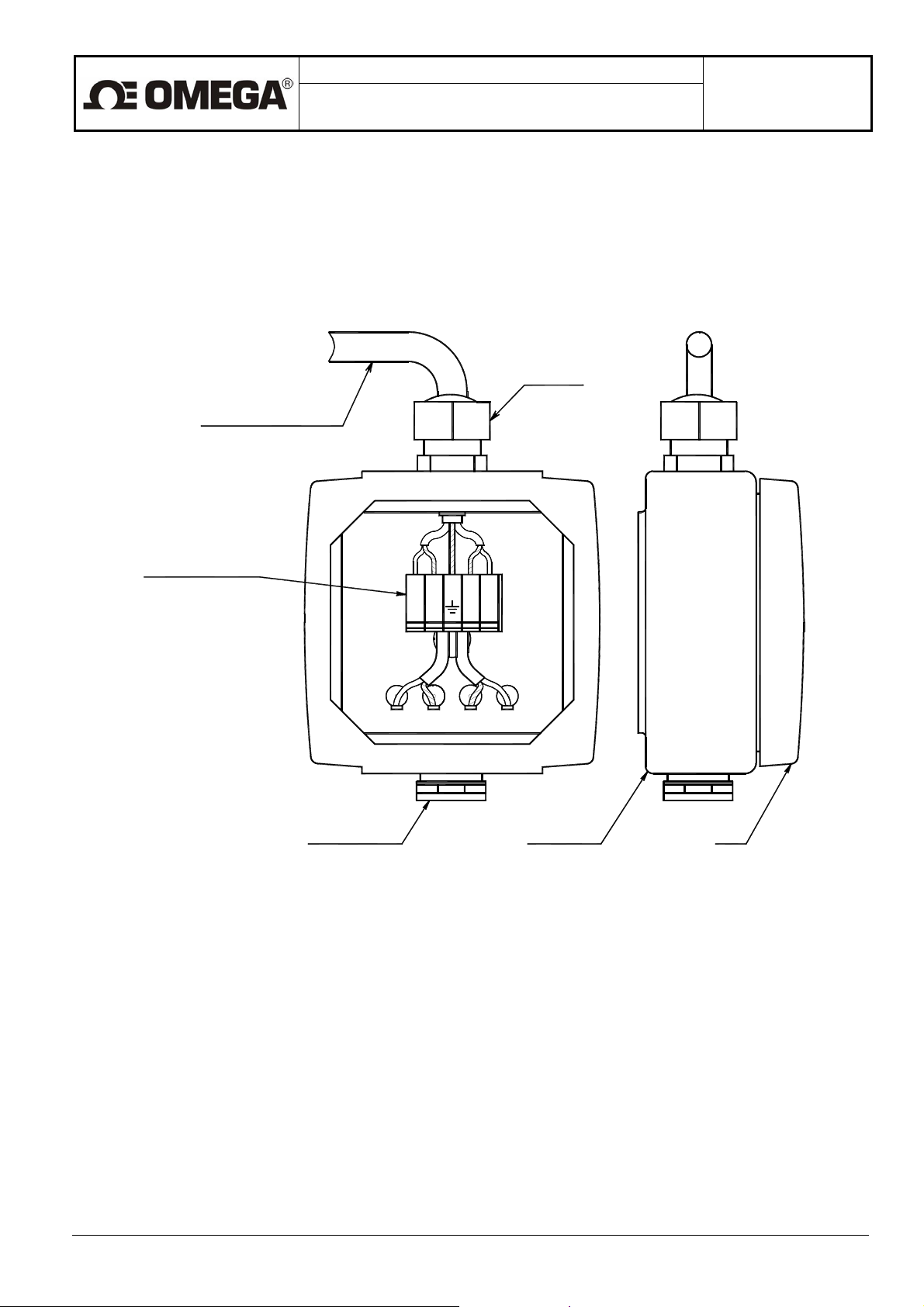

3.2.6. Meter handling

The arrows indicate incorrect grips on the meter assembly. Do not lift the meter holding it by the electronic unit or

the protection tubes – see the figure.

S/N 22686/06

ANSI

2" 2"

BN 15 1,45psi

232

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

psi

5

G/imp

mA

4-20

t

n

a

y

r

r

w

a

f

d

i

i

o

v

d

e

v

m

o

e

r

S/N 22686/06

ANSI

BN 15 1,45psi

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

232

5

4-20

psi

G/imp

mA

t

n

a

y

r

r

w

a

o

f

d

i

i

v

d

e

v

m

o

e

r

The arrows indicate the correct grips on the meter assembly. To lift the meter, hold it by the flanges or meter body.

ANSI

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

S/N 22686/06

2"

BN 15 1,45psi

4-20

232

psi

5

G/imp

mA

y

t

n

a

a

r

w

r

i

i

o

d

f

v

v

e

d

o

r

m

e

Page 10

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

4. TECHNICAL SPECIFICATIONS

Page 8 of 20

Rated internal diameter DN

Overloading flow rate qs

Continuous flow rate qp

Transient flow rate qt

Minimum flow rate q

Pulse output constant k

min

i

1¼"

(32)

GPM 52 90 130 220 350 530 880 1,320 1,585

3

m

/h 12 20 30 50 80 120 200 300 360

GPM 26 45 65 110 175 265 440 660 1,100

3

m

/h 6 10 15 25 40 60 100 150 250

GPM 2.1 3.5 13.2 22 35 53 88 132 220

3

m

/h 0.48 0.8 3 5 8 12 20 30 50

GPM 0.52 0.9 2 3.3 5.3 7.9 13.2 19.8 33

3

/h 0.12 0.2 0.45 0.75 1.2 1.8 3 4.5 7.5

m

G/imp 2 5 5 10 10 15 30 30 30

l/imp 10 25 25 50 50 100 100 100 100

1½"

(40)

2"

(50)

2½"

(65)

3"

(80)

4"

(100)

5"

(125)

Rated pressure РN 16

Accuracy class +/- 2% of reading, +/- 5 % below minimum transition rate

Temperature of measured fluid 32 to 122°F (0 to 50°С)

Ambient temperature 32 to 122°F (0 to 50°С)

Display unit single-line 8-character LC display

Li battery 3.6V/3.6Ah, type LSH 14 light lifetime 1 year from the day

Power

of production (standard "transport" battery)

Li battery 3.6V/16Ah, type LS 33600, minimum lifetime 6 to 8 years

since a date of production ( customer supplied)

Protection class IP 67

Pressure loss less than 0.1 bar at q

Outputs passive pulse U = 5 to 30V, I

passive current output 4 to 20mA, U

p

= 10mA, pulse length 40ms

max

= 24V

max

Optional accessories

remote meter version, maximum cable length 5m (-R)

6"

(150)

8"

(200)

Page 11

Design, Assembly and Service Manual

Page 9 of 20

Ultrasonic water meter FDT100 series

5. PROJECT DESIGN AND METER INSTALLATION

Compliance with standards ISO 4064-1, ISO 4064-2 and strict observance of the recommendations in this Manual

are required in all project-design work regarding application and installation of the FDT100 SERIES ultrasonic water

meters in water-supply networks. .

5.1. Project design of systems including ultrasonic water meters

In water supply and distribution systems, water meters should be located so as to ensure maximum measurement

accuracy. In the case of the FDT100 SERIES meters, the lengths of the required straight piping sections on the input

5 DN

ser.no

DN 80 PN16

BN40 0,1

bar

50

Meter constant

l/imp.

mA

4÷20

Current output

Pressure range

bar 1÷10

FLOW DIRECTION

3 DN

5 DN

80DN

ser.noPN16

bar

BN40 0,1

50

Meter constant

l/imp.

mA

4÷20

Current output

Pressure rang e

1÷10 bar

FLOW DIRECTION

3 DN

and output sides are at least 5xDN and 3xDN, respectively.

Minimum lengths of straight piping sections

If there is any pump nearby, it should be located on the output side of the meter at the distance of at least 20xDN.

20 DN

DN 80 PN16 v.è.

BN40 0,1

barù

Konstanta mìøidla 50l/imp.

Proudový výstup 4-20mA:

FLOW DIRECTION

Pump placement

In cases where full flooding of the piping cannot be guaranteed at all times, the meter sensor should be fitted in

such piping section where these conditions will always be met.

Page 12

Design, Assembly and Service Manual

Page 10 of 20

Ultrasonic water meter FDT100 series

N

D

3

N

5

D

.

è

.

ù

v

r

a

b

.

p

6

m

i

1

N1

/

l

,

P

0

0

5

A

a

m

l

0

0

0

d

4

i

8

2

ø

N

-

:

ì

N

B

4

m

D

p

a

u

t

t

n

s

ý

a

t

v

s

ý

n

v

o

Ko

d

u

o

r

P

W

O

L

F

N

O

I

T

C

E

R

I

D

Meter placement to ensure full flooding

Should the meter need be installed in a vertical piping section, the water flow direction shall be upwards.

5 DN

DN 80

PN16 v.è.

BN40 0,1

barù

Konstanta mìøidla 50l/imp.

Proudový výstup 4-20mA:

FLOW DIRECTION

3 DN

barù

BN40 0,1

DN 80 PN16 v.è.

Proudový výstup 4-20mA:

Konstanta mìøidla 50l/imp.

FLOW DIRECTION

Vertical sensor position

Page 13

Design, Assembly and Service Manual

Page 11 of 20

Ultrasonic water meter FDT100 series

To ensure reliable and accurate measurements under all circumstances, the measured fluid shall fill the internal

cavity of the sensor at all times. Therefore the sensor should not be placed at the highest piping section or in a

vertical piping section where the flow direction is downwards, in particular in cases where a piping outlet to open

tanks is anywhere near.

DN 80

PN16 v.è.

BN40 0,1 barù

Konstanta mìøidla 50l/imp.

Proudový výstup 4-20mA:

FLOW DIRECTION

Proudový výstup 4-20mA

Konstanta mìøidla 50l/imp.

DN PN16

80

BN40 0,1

:

v.è.

barù

FLOW DIRECTION

Examples of incorrect sensor placement

There are no limitations regarding sensor position in piping; however, consideration should be given to the ease of

reading the display data and access to the optical probe contact point (see the picture below).

360°

The above recommendations regarding the meter/sensor placement and installation apply to both the compact and

remote meter versions.

Page 14

Design, Assembly and Service Manual

Page 12 of 20

Ultrasonic water meter FDT100 series

5.2. Meter installation

5.2.1. General recommendations

In the basic arrangement (flow direction from left to right and the sensor installed into a horizontal piping section),

the electronic unit is fitted onto the sensor body as shown in the following picture.

OMEGA

E1

E2 E3 E4 E5

FDT 103 XA

R

3

G.10 GPM

DC 3,6V

IP 67

T 32...122°F

FLOW DIRECTION

In the case of vertical mounting, or the flow direction from right to left, the electronic unit can be rotated with respect

to the sensor body by 90 or 180° in both ways; 180° rotation is a limit to avoid straining the connecting wires. The unit

can be rotated upon loosening the arresting screw M5 at the unit base using an Alien wrench, size 2.5mm. The 90°

positions on the unit base are marked by recesses for the arresting screw..

°

0

8

1

OMEGA

1

8

0

°

VIEW P

R

E1 E2 E3 E4 E5 G.10 GPM

FDT 103 XA

3

DC 3,6V

IP 67

T 32...122°F

P

lock screw

FLOW DIRECTION

To prevent signal interference, the meter wiring shall be placed at least 25cm away from any live power cables.

Page 15

2

n

Design, Assembly and Service Manual

Page 13 of 20

Ultrasonic water meter FDT100 series

The interconnection between the meter sensor and electronic unit (the remote meter version) is made by a shielded

cable with the shielding connected to the earth potential at the sensor terminal board. It is recommended that all output

signals (the pulse and current outputs) be connected using shielded cables with the shielding connected to the earth

potential on the side of the plant control system. The meter sensor shall also be carefully grounded. To do that, connect

the grounding bolt on the sensor flange with the piping flanges using an grounding conductor of cross-section of at

least 4mm

2

.

min 4mm -green and yellow wire insulatio

3

G.10 GPM

IP 67

T 32...122°F

R

DC 3,6V

OMEGA

FDT 103 XA

5.2.2. Mechanical fitting

The ultrasonic sensor shall be fitted into the water piping across piping flanges matching the meter flanges ANSI.

5.2.3. Electrical connections

The compact meter version (FDT100 SERIES): the electrical interconnection operation consists of connecting the

output signal cables to the respective terminals on terminal board in the electronic unit. The terminal board can be

accessed upon removal of the plastic lid at the top of the unit box. The lid is secured in position by means of two M4

screws with hexagonal socket heads for Alien wrench size 2mm.

At the bottom side of the plastic lid there are two slots 8mm wide where a flat tool can be inserted to help lift the lid

from the box. It is recommended to insert a screwdriver into one of the slots and slightly pry upwards. The locations of

the slots are shown in the picture below. Prior to replacing the lid, apply a thin layer of glycerine or silicon oil on the

sealing O-ring.

When replacing the lid, the 3mm hole at the bottom side of the plastic lid should be fitted onto the guide pin of

diameter 2.5mm press-fitted at the box bottom.

Page 16

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

Page 14 of 20

y

t

an

r

r

f

i

a

ed

d

w

i

v

o

o

v

em

r

-RS

y

t

n

a

d

r

f

e

i

r

v

a

d

o

i

w

o

m

v

e

r

X2

X1

9876

42315

-I

-IMP

TX

RX

+I

+RS

+IMP

OUTPUT TERMINAL

BOARD CONNECTIONS

Communication

interface RS 232

Impulse output

Current otput

(external power supply)

(external power supply)

FDT 100 series

654

-I

7

98

Not used

1-30k

+

U=5-25V

Imax.=10mA

-

Impulse output

+IMP

-IMP

+I

Current otput

(exter.power supply)

Impulse output

(exter.power supply)

power supply

X1

321

-RS

Communication

interface RS 232

+RS

RX

TX

Current output power

supply

U=10-24V

-

+

I=4-20 mA

The remote meter version (FDT100 SERIES ): the free end of the signal cable from the electronic unit is to be

connected to the respective spring-loaded WAGO terminals at terminal board in the sensor unit assembly. The lid on

the terminal box is held in position by means of four M4 screws with hexagonal socket heads for Alien wrench size

3mm.

The output signal cable connections the terminal board are made in the same way as shown above for the case

of the compact meter version.

Page 17

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

Page 15 of 20

P

VIEW P

of the electronic unit with the top cover removed

y

t

X2

n

a

r

r

f

i

a

d

e

w

d

v

i

o

o

v

m

e

r

X1

876

9

42315

-I

-IMP

-RS

RX

TX

+I

+IMP

+RS

y

t

n

a

d

r

f

e

i

r

v

a

d

o

i

w

o

m

v

e

r

(external power supply)

Current otput

Communication

brown white

X2 4 3 2 1

(external power supply)

interface RS 232

Impulse output

X1

4 3 2 1

CONNECTIONS BETWEEN ELECTRONIC UNIT AND FLOW SENSOR

FDT 100

series

AUXILIARY ELECTRONIC UNIT

1234

PROBE 1

1234

PROBE 1

white

X1

PROBE 2

brown

X2

PROBE 2

FLOW SENSOR TERMINAL BOARD

5.2.4. Seals on meters

The water meters used as technological meters shall be provided with clamp-on and stick-on company and

assembly seals as shown in the following illustration pictures.

The compact meter version, type FDT100 SERIES

Page 18

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

Page 16 of 20

R

Clasp-on seals

P

Stick-on assembly seal

on terminal board cover

VIEW P

ANSI

PRESSURE

IMPULSE OUTPUT CONS T.

CURRENT OUTPUT

Stick-on seals

S/N 22686/06

2"

BN 15 1,45psi

232

psi

5

G/imp

mA

4-20

n

t

y

a

r

r

a

w

f

i

v

o

d

i

e

d

o

m

v

r

e

VIEW R

( with top cover removed)

y

t

n

a

r

r

f

i

a

e

w

d

i

v

o

o

v

m

e

r

X2

d

X1

X1

21

6 7 8 9

3

54

The remote meter version, type FDT100 SERIES

-I

-IMP

RX

TX

+I

-RS

y

t

an

f

r

i

ar

d

i

ov

w

o

m

v

e

r

+RS

d

e

+IMP

Page 19

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

Clasp-on assembly seals

on connecting cable housing

Page 17 of 20

FLOW SENSOR

Clasp-on seal

DATA-PROCESSING ELECTRONIC UNIT

R

Clasp-on seal

ANSI

PRESSURE

IMPULSE OUTPUT CONST.

CURRENT OUTPUT

S/N 22686/06

2"

BN 15 1,45psi

232

5

4-20

w

v

r

Stick-on seals

psi

G/imp

mA

a

r

o

i

d

e

m

t

y

n

r

a

f

i

o

v

e

d

VIEW R

( with top cover removed)

y

t

X2

n

a

r

r

f

i

d

a

e

w

d

v

i

o

o

v

m

e

r

X1

132

-RS

y

t

n

a

d

f

r

i

e

r

v

a

d

o

i

w

o

m

v

e

r

9

678

4

5

-I

-IMP

TX

RX

+I

+IMP

+RS

Stick-on assembly seal

on terminal board cover

6. OPERATIONAL START

The water meter is delivered calibrated and in a fully operative condition. Once it is fitted into the selected metering

point in the piping, bled and filled with the technological fluid, it is ready for operation. The condition of readiness to start

is indicated by disappearance of the error messages j at the bottom of the meter display unit. Using the control pushbutton, check the selection of measurement modes: the instantaneous flow rate, total volume passed and pressure (if

applicable).

Page 20

Design, Assembly and Service Manual

Page 18 of 20

Ultrasonic water meter FDT100 series

7. OPERATION

7.1. Reading the measured quantities from the meter display

The eight-character display unit can show either the instantaneous flow rate in gallons per minute (or m3/hour), the

total volume of the fluid passed through the meter sensor since the reading was last reset, in G.10

reading of instantaneous flow rate has a certain delay as the displayed value is determined as the arithmetic average of

the six latest measurements (each taken in 1-second intervals). So calculated values also appear at the meter outputs.

The delay becomes noticeable in the cases of rapidly changing (growing or falling) flow rate. Meter errors will be

indicated on the display. Due to the limited power capacity of the meter, the various display modes can only be

selected in intervals of 1 second or longer. It is therefore recommended that the display mode selection push-button be

always depressed for at least one second, and the next selection command be given after another 1 second or longer.

Depending on the reading of the total fluid volume passed, the decimal point on the display will move as shown in the

following picture.

3

Displayed data in G.10 (m )

3

3

(or m3). The

Decimal point position for

total volume less than

100,000 G.10 (m )

Decimal point position for

total volume between

100,000 G.10 (m ) and 1,000,000 G.10 (m )

3

3

3

3

3

3

Decimal point position for

total volume greater than

10,000,000 G.10 (m )

Decimal point position for

total volume between

1,000,000 G.10 ( m ) and 10,000,000 G.10 ( m )

3

3

3

3

3

3

7.2. Electrical outputs

7.2.1. Pulse output

An pulse output is found on all FDT100 SERIES water meters irrespective of their version or configuration. In

includes an optocoupler connected to terminals 7 and 8 (terminal board X1); the permitted current loading is 10mA, the

pulse length 40ms. On a customer’s request the pulse length can be set at 2ms. If voltage pulses are required, use an

external power source of 5 to 25V DC connected in series with a limiting resistor so that the maximum current would

not exceed 10mA. The interconnection of external power source and limiting resistor is shown in the picture illustrating

the interconnections at the output terminal board (Section 5.2.3 above).

The pulse length can also be modified on site; for 40ms pulses, use jumper J5 to connect terminals J5:2 and J5:3

(X1), for 2ms pulses, connect terminals J5:1 and J5:2 (see the figure below).

J5

1

23

12

34 5

X1

678

9

Page 21

Design, Assembly and Service Manual

Page 19 of 20

Ultrasonic water meter FDT100 series

7.2.2. Current output

The current output 4 - 20mA is connected to terminals 5 and 6 at the output terminal board. Upon attaining the

output current level of 20mA (corresponding to Qmax), the current will not exceed this value and the error message E4

will appear on the display (see Section 7.5. below). To utilize the output current function, use an external power source

of 10 to 24V DC and the interconnection at the output terminal board as described in Section 5.2.3. The maximum

permitted resistance (the ohm resistance of the cable + input resistance of the co-operating equipment) of the current

output circuit shall be determined using the following formula:

R

[Ω] =

s

.

U source [V] - 7

0.02

7.3. Error identification function

Meter errors shall be identified as E1 through to E5 by symbol j shown at the bottom of the display unit.

Error identification symbols: E1 - the ultrasonic signal cannot freely propagate in the sensor cavity (due to the

presence of air or mechanical particles)

E2 - too great a difference between the signal travel times in and against the fluid

flow direction (possibly due to the presence of air at one of the probes, which

may be a temporary condition during the operation of filling the piping with

fluid, or due to contamination of the face part of one of the probes)

E3 - A/D converter error (e.g. due to strong interference)

E4 - flow rate in excess of q

E5 - flat meter battery

Should the display go completely blank, check the battery condition (the voltage should be over 3V). Replace

defective battery using the procedure described in Section 7.6. Should the battery replacement fail to restore the

correct meter function, send the meter for repair to the manufacturer’s service centre.

s

7.4. Battery life and replacement

Electronic unit is equipped with battery SAFT LITHIUM 3,6V /3,6Ah LSH 14 "light" (size C) containing less than 1g

of lithium and is equipped with plastic case capable of using of either C and D size battery. Lifetime of LSH 14 "lite"

battery is 1 year since date of production and can be replaced by battery LITHIUM 3.6V / 16Ah LS 33600 (size D) with

lifetime up to 8 years, with using of communication functions up to 6 years. Plastic case is not used for D size battery

LSH 14 "light" battery is used as a "transport battery," because it is non-restricted to transport/non-assigned to Class

9 according Lithium battery transport regulation (Ref. TC-LSH 14"light"-09/03-1).

To replace the meter battery, first remove the plastic lid on the electronic unit box held in position by two M4 screws

with hexagonal socket heads (use Alien wrench, size 2mm), see Section 5.2.3., then loosen three M3 screws holding

the electronic module in the aluminium box and pull the module outside the box. While doing that, make sure you do

not damage any metrological or company seals. The electronic module can only be removed as far as probe

conductors and output signal cables permit. The battery is located in a holder at the bottom of the unit; pull the battery

free and replace it with a new one. Mind the correct polarity as indicated on a plate on the battery holder. Push the

electronic module back into the box, tighten the holding bolts, replace the box lid, fix its position with screw and apply

assembly seal on one of them.

Page 22

Design, Assembly and Service Manual

Ultrasonic water meter FDT100 series

Page 20 of 20

BATTERY HOLDER

PLATE SHOWING

BATTERY POLARITY

y

t

n

a

r

r

f

a

i

d

e

w

d

i

v

o

o

v

m

e

r

BATTERY

DIRECTION OF REMOVING

BATTERRY FROM HOLDER

MOUNTING SCREWS M3

ELECTRONIC UNIT ASSEMBLY

y

t

n

a

d

r

f

i

e

r

v

a

d

o

i

w

o

m

v

e

r

STICK-ON SEALS

The electronic module removed from its box

8. CALIBRATION

The standard calibration is done with respect to the pulse output. In that case the measurement error at the current

output will be approx. 1% higher than that at the pulse output. If the customer requires calibration for the current output,

it can be done and the additional error of about 1% will then appear at the pulse output.

Page 23

W

R

g

W

s

p

f

,

ARRANTY/

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

examination by OMEGA, if

OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including

but not limited to mishandling, improper interfacing, operation outside of design limits,

or unauthorized modification. This W

with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER W

REPRESENTATIONS OF ANY KIND WHA

OF

TITLE, AND ALL IMPLIED W

MERCHANT

DISCLAIMED. LIMITATION OF

exclusive, and the total liability of

OMEGA with respect to this order,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential,

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor sh

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity,

as set forth in our basic W

OMEGA and hold OMEGA har

Product(s) in such a manner.

ABILITY

incidental or special damages.

medical application, used on humans, or misused in any way,

customers receive maximum coverage on each product.

the unit is found to be defective, it will be repaired or replaced at no

ARRANTY is VOID if the unit shows evidence of

control. Components in which wear is not warranted, include but are not

TSOEVER,

ARRANTIES

AND FITNESS FOR A PARTICULAR

LIABILITY:

whether based on contract, warranty,

ARRANTY/DISCLAIMER language, and, additionally,

mless from any liability or damage whatsoever arising out of the use of the

DISCLAIMER

EXPRESSED OR

INCLUDING ANY W

The remedies of purchaser set forth herein are

OMEGA assumes no responsibility

Customer Service

improper repair

having been tampered

ARRANTIES

IMPLIED, EXCEPT THA

ARRANTY OF

PURPOSE

all it be used: (1) as a “Basic

purchaser will indemnify

ARE HEREBY

negligence,

Upon

charge.

OR

T

,

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBT

(AR) NUMBER FROM OMEGA’S

A

VOID

return

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breaka

FOR

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

2. Model and serial number of the product under

3. Repair instructions and/or specific problems

OMEGA’s policy is to

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent o

PROCESSING DELA

package and on any correspondence.

ARRANTY RETURNS, please have the

PURCHASED,

warranty,

relative to the

and

roduct.

make running changes, not model changes, whenever an improvement is possible. This affords

OMEGA ENGINEERING

YS). The assigned AR number should then be marked on the outside of the

CUSTOMER SER

wa

INC.

VICE DEPARTMENT (IN ORDER TO

FOR NON-WARRANTY REPAIRS, consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

AIN AN AUTHORIZED RETU

Page 24

W

Industria

here Do I Find Ever

Pr

ocess Measurement and Contr

OM

EGA…Of Course!

Shop online at omega.com

TEMPERA

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators

Recorders,

Infrared

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load

Displacement

Instrumentation

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based

Plug-in

Datalogging

Recorders, Printers & Plotters

HEA

TERS

Heating Cable

Cartridge & Strip Heaters

Immersion

Flexible

Laboratory Heaters

ENVIRONMENT

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

TURE

&

Controllers & Process Monitors

Pyrometers

Cells & Pressure Gages

Ice Point References

Transducers

&

Accessories

&

Batch Controllers

Acquisition Systems

Cards for Apple, IBM & Compatibles

Systems

&

Band Heaters

Heaters

AL

l Water

&

Wastewater Treatment

ything I Need for

ol?

M-4268/0406

Loading...

Loading...