Page 1

Percent of free chlorine in protonated form (HClO)

0

10

20

30

40

50

60

70

80

90

100

5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10

pH

percent

FCLTX-100 Series

SECTION 1.0

THEORY OF OPERATION

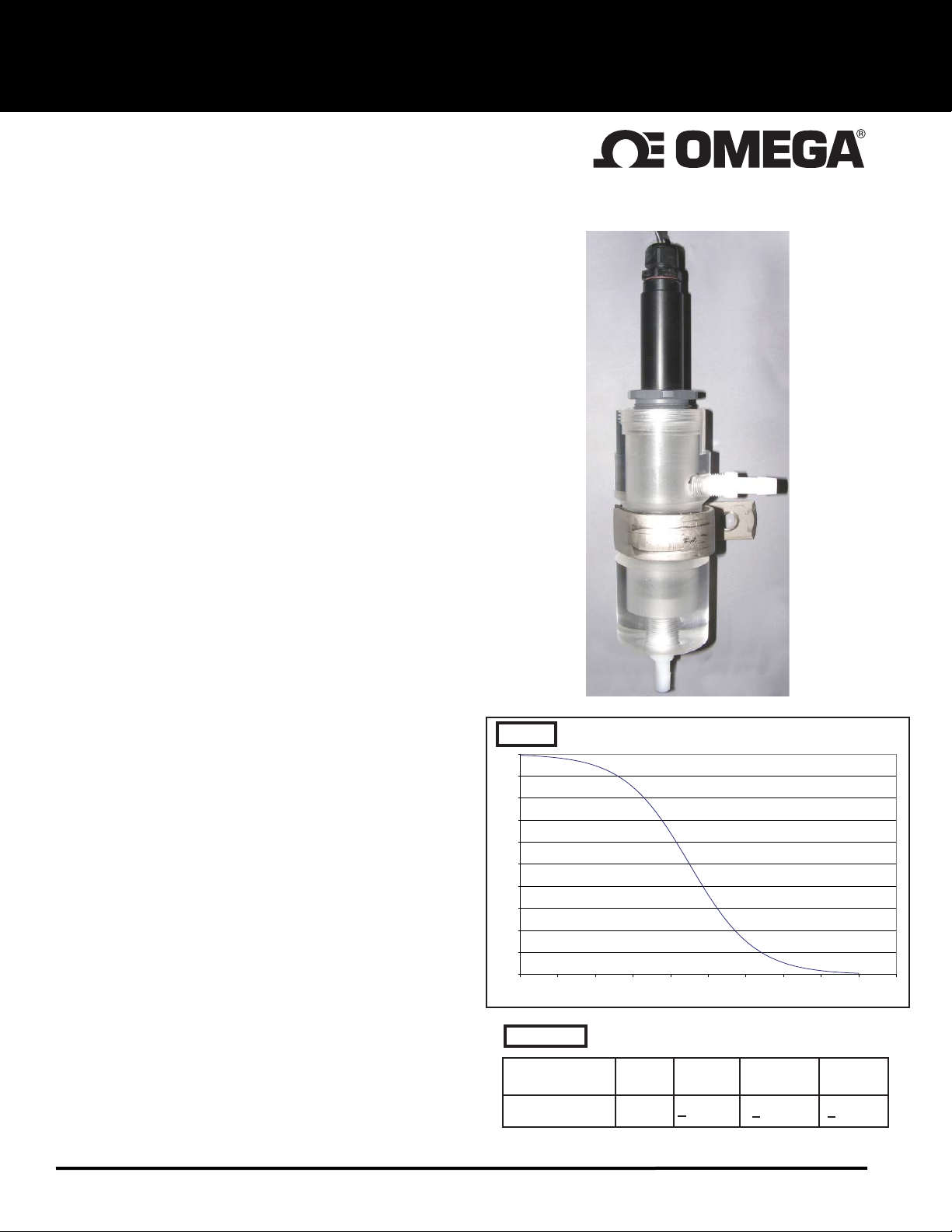

1.0 FREE CHLORINE DEFINED. Free Chlorine or "freely active chlorine"

is defined as the sum of molecular chlorine (Cl2), hypochlorous acid

(HOCl) and hypochlorite ions (OCl-). Molecular chlorine occurs at

pH values <pH4. Hypochlorus acid and hypochlorite ions are in pH

dependent equilibrium with one another as shown in FIG 1.

The graph shows % hypochlorous acid on the left of the curve.

Hypochlorous acid is a much stronger disinfecting agent (oxidizer) as

compared to hypochlorite ions.

1.2 SENSOR OPERATING PRINCIPLE. Both hypochlorous acid (HOCl)

and hypochlorite ion (OCl-) diffuse through the membrane between

the cathode and sample solution, even though the diffusion coefficients for each are different. At the applied potential, only hyphochlorous acid is electrochemically reduced. HOCl is reduced to chloride

ion at the gold cathode. At the same time, the silver anode is oxidized

to form silver chloride (AgCl). When the concentration of HOCl at

the cathode is dramatically decreased by electrochemical reduction,

hypochlorite ion will be transformed into hypochlorous acid , to some

extent, by proton transfer. The release of electrons at the cathode

and acceptance at the anode creates a current flow, which under

constant conditions, is proportional to the free chlorine concentration

in the medium outside the sensor. The resulting low current output

is then conditioned to 4-20mA current by the sensor's onboard electronic circuitry.

PRODUCT INSTRUCTION SHEET

SECTION 2.0

FACTORS INFLUENCING THE SENSOR

2.1 pH. Free Chlorine (FCL) exists as hypochlorous acid and hypochlorite anion (FIG 1). The acid-base dissociation of FCL has a pKa

of approximately 7.5. The FCL sensor responds to hypochlorous

acid and hypochlorite anion with different sensitivity. In combination, an increase in pH reduces the measured FCL and decrease in pH

increases the measured FCL. The need for automatic pH compensation depends on the pH value and the variation range of pH (Table

1). If pH variation of your sample is more than that listed in the table,

automatic pH compensation is required. pH compensation for the

sensors current (mA) reading is:

(sensor output in mA – 4)/(-0.0502pH3 + 0.867pH2 – 5.051pH + 12.43) + 4

2.2 Chemical Interferences. The sensors should not be used in water

containing surfactants, organic chlorine or stabilizers such as cyanuric

acid.

2.2 FLOW. The membrance covered free chlorine sensors (FCL series)

functions at any flow rate. To acheive reproducible measurements,

these free chlorine sensors require a specified constant flow rate. To

avoid complications (such as bubbles), it is best to operate the sensors at a flow rate of 0.2-0.6 gpm if using flow cell FC72 or FC70 (old

version).

Parts covered by this product instruction sheet include: FCLTX-100 Series

FIG. 1

-

HOCl

OCl

TABLE 1

pH Range <6.5 6.5-7.5 7.5-8.3 8.3-9.0

pH Variation N/A + 0.35 + 0.20 + 0.05

M4679/0708 page 1 of 6

Page 2

PRODUCT INSTRUCTION SHEET

SECTION 3.0

SENSOR PREPARATION

3.0 FREE CHLORINE SENSOR ASSEMBLY. The Free Chlorine

Sensor is shipped with the membrane cap pre-installed and

covered with a cap with water inside to keep the membrane

wet. Make sure to keep sensor cap, anode and cathode inside

the sensor body, away oily or greasy materials. Contact with oil

or grease will result in inaccurate measurements.

NOTE: IF SENSOR WILL BE STORED DRY OUT OF FLOW

CELL, SHAKE BODY DOWNWARD INTO A SINK TO REMOVE THE

FILL SOLUTION. TAKE THE MEMBRANE CAP AND IMMERSE IN A

CUP OF TAP WATER UNTILL READY TO REUSE. SEE

SECTION 9. REPLACE CAP AND ELECTROLYTE BEFORE INSTALLING INTO FLOW CELL (see SECTION 10 for cap and electrolyte

change. See SECTION 5 for sensor installation into flow cell).

SECTION 4.0

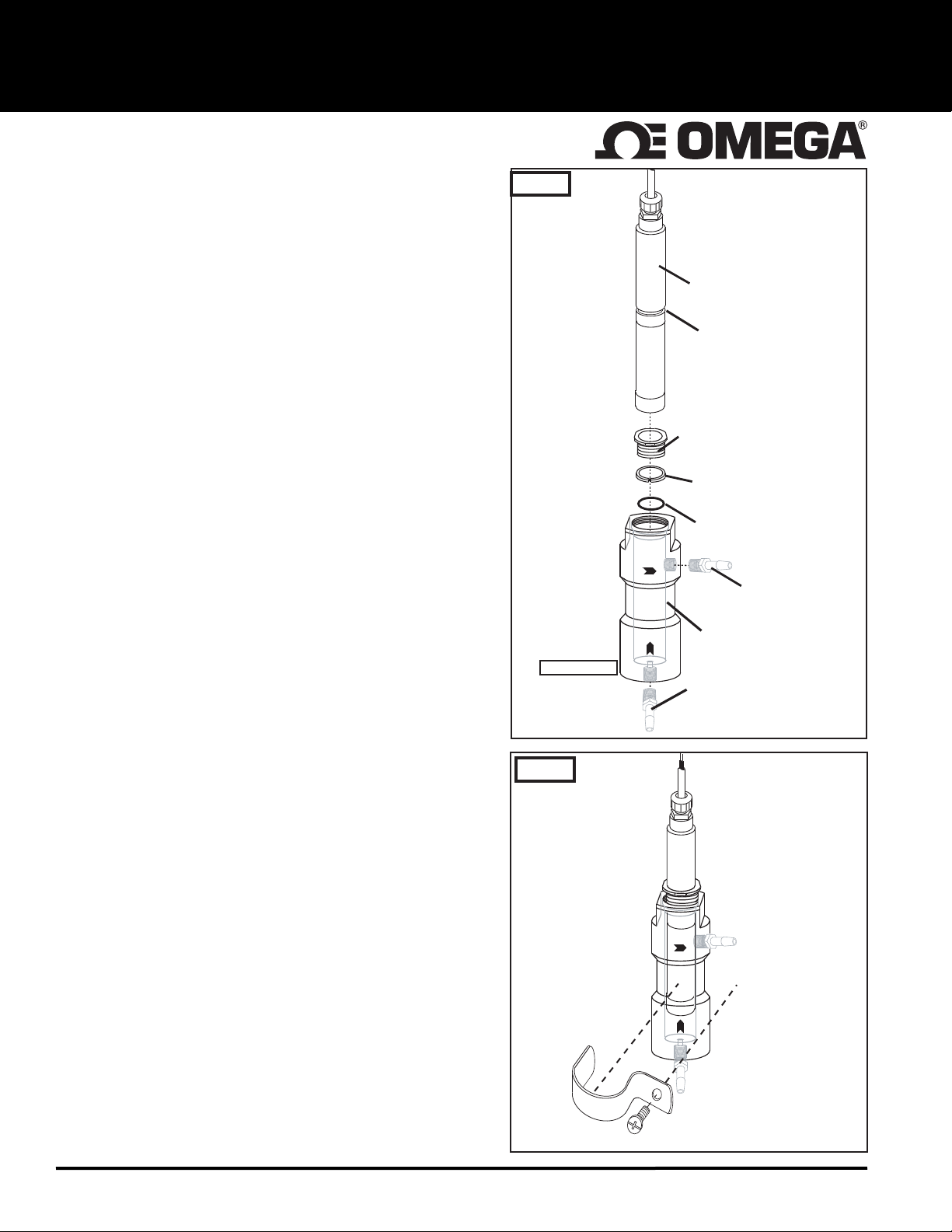

FLOW CELL INSTALLATION

4.0 FLOW CELL. To obtain accurate Free Chlorine reading,

the Sensor must be installed into the Flow Cell to prevent air

bubbles formation on the membrane, proper spacing between

the sensor and the installation wall, and laminar flow across

the membrane.

FIG. 2

SENSOR

SNAP RING

GROOVE

THREADED FITTING

SNAP RING (INSTAL L S

INTO PROBE GROOVE)

O-RING

BARBED TUBE

FITTING

FLOW CELL

4.1. Using two 1/4” NPT Tube fittings, connect the FC72 Flow

Cell into your system, noting the inlet (bottom) and outlet

(side) orientation. (see FIGURE 2)

4.2. Install clamp with rubber backing as shown in FIG. 2A.

4.3 Drill 3/8" diameter hole on the panel.

4.4 Insert bolt as shown in FIG 2A

4.5 On back of panel attach lock washer and nut to secure

clamp and flow cell to panel.

SECTION 5.0

SENSOR INSTALLATION

5.0 SENSOR INSTALLATION INTO FLOW CELL.

a. First install threaded fitting onto sensor body

(remove fitting if pre-installed in flow cell)

b. Install snap-ring into groove on sensor body

c. Next, slide o-ring onto body of sensor until it

reaches bottom of threaded fitting.

d. Thread sensor assembly into top of flow cell as

shown in FIGURE 2.

d. Turn on flow and verify the flow through the Flow

Cell is at least 0.2gpm (45 liters/hour and no

more than 0.6gpm (135 liters/hour).

FC72 Flow cell

BARBED TUBE

FITTING

FIG. 2A

Parts covered by this product instruction sheet include: FCLTX-100 Series

M4679/0708 page 2 of 6

Page 3

PRODUCT INSTRUCTION SHEET

SECTION 6.0

ELECTRICAL INSTALLATION

6.0 ELECTRICAL INSTALLATION. The sensor produces an approximate output of 4 mA in air and 20mA at the top range of

free chlorine output (0-2ppm, 0-5ppm, 0-10ppm).

NOTE: The supply voltage to the Sensor must be 12-24 V DC with

minimum of 250 mA. Maximum load is 1 Watt. The sensor has 3 wires,

red (+) , black (-) and clear (shield). Twist together or solder black

and clear if instrument does not have separate ground. If a separate

ground is available such as for PLC’s connect clear (shield) to it.

Attach the red wire to the power supply positive terminal (+)and the

black wire to the PLC or DVM positive (+) terminal. Connect a wire

(customer supplied) from the power suppy negative (-) and the PLC or

DVM (-). See FIG 3. The Sensor will require several minutes to stabilize

after power is supplied to it.

SECTION 7.0

SENSOR CONDITIONING

7.0 SENSOR CONDITIONING The sensor requires conditioning

prior to generating stable values.

a. For new Sensors, allow the Sensor to run for at least

4 hours before calibration.

b. If the Sensor will be un-powered for 2 hours or

more, run for 3 hours prior to use.

c. After membrane/electrolyte replacement, allow the

Sensor to run for at least 4 hours.

FIG. 3

Power Supply

sensor red wire

sensor

black wire

PLC, DVM,...

Parts covered by this product instruction sheet include: FCLTX-100 Series

M4679/0708 page 3 of 6

Page 4

PRODUCT INSTRUCTION SHEET

SECTION 8.0

CALIBRATION

IMPORTANT NOTE: SENSORS ARE SUPPLIED FACTORY CALIBRATED WITH A

4-20mA SIGNAL OUTPUT CORRESPONDING TO THEIR SPECIFIC RANGE (0-2,

0-5 OR 0-10ppm). SPAN CALIBRATION IS NECESSARY WHEN RECEIVING A

NEW SENSOR SINCE YOUR CONDITIONS MAY VARY FROM THOSE USED AT

THE FACTORY FOR SPAN CALIBRATION. THE ZERO POINT CALIBRATION IS

NOT NECESSARY SINCE THE ZERO SETTING IS VERY STABLE.

PERIODIC CALIBRATION ( ABOUT ONCE PER WEEK) IS RECOMMENDED. THIS

IS USEFUL IN TRACKING SENSOR FAILURES AS WELL.

8.1 Removal of cord grip to access ZERO and SPAN

potentiometers inside the sensor body:

a. Remove top nut of cord grip as shown in FIGURE 4.

b. Remove remaining cord grip as shown in FIGURE 5. A wrench

may be required.

8.2 Slope Calibration:

a. Determine the free chlorine content using a diethyl-p phenylenediamine (DPD) colorimeter test kit (see FIGURE 9.),

not included with ClO2 sensor and flow cell.

b. Measure Free Chlorine content with sensor. Make sure that

calibration flow rate and pH matches flow rate when

measuring sample since probe output is flow rate and pH

dependent. Make sure pH is within 5.5-8.0 range.

c. Adjust the span potentiometer to the desired mA (see

FIGURES 9 & 9A)

c. Repeat this slope calibration one day after sensor is

initially installed.

d. Repeat the slope calibration monthly.

FIG. 4

FIG. 6

FIG. 5

FIG. 7

Left

potentiometer

(Zero adjust)

Right

potentiometer

(Span adjust)

Cable

SECTION 9.0

SENSOR STORAGE

9.0 STORAGE. Store sensor at 5o C- 50o C ONLY and maximum

humidity of 90% (non-condensing).

a. Short Term Storage (1 week or less): Store in Flow cell

with water to prevent the probe from drying out.

b. Intermediate Term (1 week to 1 month): Store in cap,

bottle, or beaker with water to keep membrane wet.

c. Long Term (1 month or longer): Remove Membrane

Cap and store completely immersed in tap water. Turn

sensor upright and shake it to remove fill solution from

inside the sensor.

d. Electrolyte bottle shelf-life = 1 year from date of

manufature(see expiration date on bottle)

FIG. 9

Free Cl

C

L

O

FIG. 8

to Increase

output

to Decrease

output

2

ZERO

Free Cl

ClO2

READ

Note: The DPD method

for Free chlorine measurement is not selective

for free chlorine alone.

Other oxidants in the

water can also be measured as free chlorine.

Parts covered by this product instruction sheet include: FCLTX-100 Series

M4679/0708 page 4 of 6

Page 5

PRODUCT INSTRUCTION SHEET

SECTION 10.0

SENSOR MAINTENANCE/RECONDITIONING

10.1 GENERAL MAINTENANCE. Service the sensor regularly

(weekly is suggested)

10.2 MEMBRANE CAP REPLACEMENT. If membrane replacement is required, a new cap with preinstalled membrane must

be used. Order FCLA-2016 replacement membrane cap and

FCLA-2015 refill solution. To change membrane cap (do the

following over a sink or washbasin):

a) turn sensor upside down with cap facing upward

b) rotate cap counter-clockwise to remove (see FIG 10).

c) fill sensor body with electrolyte using needle and bottle of

refill solution (see FIG. 11)

d) install a new membrane cap by threading cap onto sensor

rotating cap clockwise (opposite of FIG 10)

10.3 MEMBRANE CAP/SENSOR CLEANING. Rinse cap with

water only. If cap does not clean, replace with new one.

SECTION 11.0

SENSOR TROUBLESHOOTING

11.1 CALIBRATION PROBLEMS

a) Sensor output HIGHER than DPD test

1) Run in time too short

2) Membrane cap damaged

3) Interference from water

contaminants (see Specifications,

"Cross Sensitivity")

4) Cable short circuit or damage

5) pH value less than pH 5.5

b) Sensor output LOW ER than DPD test

1) Run in time too short

2) Deposits on Membrane cap

3) Flow rate too low

4) Air bubbles on membrane

5) Surfactants in water

6) pH value more than pH 8.0

7) No electrolyte in membrane cap

c) Sensor ouput is 4mA (zero ppm)

1) Run in time too short

2) Only bound chlorine present

3) Chlorine content below detection

limit

4) Sensor not wired correctly (See

SECTION 6.0 of this manual)

5) Defective sensor

d) Sensor output UNSTABLE

1) Air bubbles on membrane

2) Membrane damage

3) Non-sensor problem

FIG. 10

FIG. 11

INJECT UNTIL SOLUTION

LEAKS OUT OF FILL HOLE

TROUBLESHOOTING CHART

Symptom Possible Cause Solution/Remedy

The sensor 1) Run in time too short 1) See Sec 5.0 -CONDITIONING

cannot be 2) Membrane cap damaged 2) Replace cap - See Sec 8.0

calibrated- 3) Interference from contaminants 3) See SPECIFICATIONS

ouput is 4) DPD chemicals bad 4) Use new DPD kit

HIGHER than 5) pH value < pH 5.5 5) Increase pH (5.5-8.0)

DPD Test See SPECIFICATIONS

6)Temperatue increased since cal 6) Match calibration temp.

The sensor 1) Run in time too short 1) See Sec 7.0 -CONDITIONING

cannot be 2) Deposits on membrane cap 2) Remove deposits or replace

calibrated- cap if cleaning ineffective.

output is 3) Flow rate too low 3) increase fl ow - See

LOWER than SPECIFICATIONS

DPD Test 4) Air bubbles on membrane 4) Remove and re-install sen

sor to remove bubbles.

5) Surfactants in water 5) Remove surfactants and

replace cap

6) pH > pH 8.0 6) Lower pH (5.5-8.0)

See SPECIFICATIONS

7) No electrolyte in cap 7) Add new electrolyte, run in

sensor and re-calibrate

8) Temperature decreased since cal 8) Increase temp to match cal

9) Organic chlorination agents 9) Use chlorinating agents

present in water per DIN 19643

Sensor output 1) Only bound chlorine present 1) Check for Chloramine with

is 4mA (0 ppm) NO FREE CHLORINE appropriate DPD test.

Replace water/ Rechlorinate.

2) Run in time too short 2) See Sec 7.0 -CONDITIONING

3) Chlorine content below limit 3) Add chlorine and repeat

calibration

4) No electrolyte in cap 4) Refi ll electrolyte

5) Sensor electrical connection 5) See SECTION 6.0

wrong

Unstable output 1) Air bubbles on sensor membrane 1) Tap to remove bubbles

from sensor 2) Membrane damaged 2) Replace membrane, run in

sensor and recalibrate.

3) Non-sensor problem 3) check PLC or I/O device

Parts covered by this product instruction sheet include: FCLTX-100 Series

M4679/0708 page 5 of 6

Page 6

SECTION 12.0

SENSOR SPECIFICATION

12.1 OPERATING SPECIFICATIONS. Follow all operating specifications,

especially for pH and flow rate as noted in the specification tables

below.

TECHNICAL SPECIFICATIONS

SENSOR

Dimensions: 8.2"L x 1" dia

Body Material: Black PVC

Membrane Material: polyethersulfone

O-ring material: Viton

Cathode: Gold

Anode: Silver chloride (AgCl)

Cable: 2 -conductor shielded, 10ft (3mtr)

tinned wire leads

FLOW CELL

Dimensions: 5.58"H x 2.25"DIA

Material: Acrylic

Connections: 1/4" NPT inlet and outlet

OPERATING SPECIFICATIONS

Operating temperature range: 0-45 degC

Maximum operating pressure: 1 bar/14.7 psi/1atm

Flow rate minimum: .20 gpm

Flow rate maximum: 0.6 ppm

pH range: 5.5-9.0

Output signal: 4.0+/- 0.2mA in air (zero)

20mA +/- 0.2mA at high range

(2, 5 or 10ppm)

Power Requirement: 12-24 VDC, 250 mA minimum

Cross-Sensitivity: ClO2, ozone, bromine

Chemical Compatibility: up to 50% ethanol/water or

up to 50% glycerol/water

R

PRODUCT INSTRUCTION SHEET

FC72 FLOW CELL DIMENSIONS

SENSOR AND FLOW CELL INSTALLATION DIMENSIONS

MAINTENANCE/REPLACEMENT PARTS

FC72 Flow Cell, 1/4 inch FNPT inlet and outlet, includes:

2 each 1/4" barbed tube fittings, clamp, threaded

flow cell installation fitting

FCL-ES Free Chlorine sensor fill solution, 30mL, 1 each

FCL-RM FCL Replacement premembraned cap, 1 each

Parts covered by this product instruction sheet include: FCLTX-100 Series

M4679/0708 page 6 of 6

Loading...

Loading...