Page 1

OMEGAFILM® Platinum

RTD Sensors

"F" SERIES

In Multiples

of 100 Pieces

U Available in Various

Sizes, Resistances,

and Accuracies

U Single and Dual Element

Configurations

U Flat or Cylindrical

Shapes

U Response Times

Equivalent or Better

Than Wire Wound

Elements

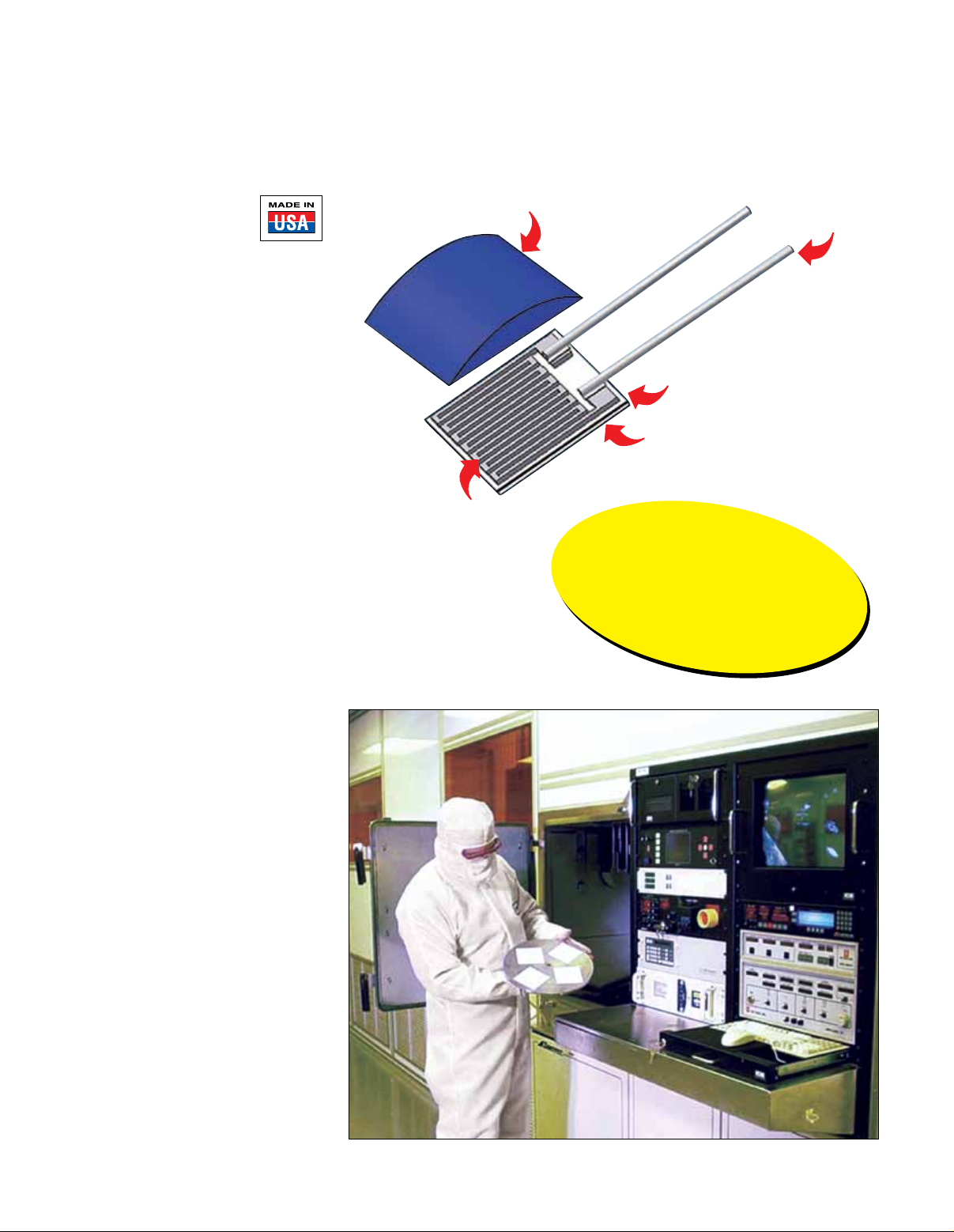

OMEGAFILM® platinum RTD

elements are manufactured using

materials and processes similar

to those employed in the

manufacture of integrated circuits.

This results in a rugged, reliable

sensing element that can be

produced in a wide range of sizes,

resistances, and accuracies to

meet even the most demanding of

applications.

The resistance vs. temperature

relationship of OMEGAFILM RTDs

conform to the internationally

accepted IEC60751 standard.

RTDs conforming to this standard

have a temperature coefficient

of resistance (also known as

Alpha) of 0.00385Ω/Ω/°C between

0 and 100°C.

As a result OMEGAFILM RTD

elements can be used worldwide

with a multitude of controllers and

instruments designed to function

within these requirements.

OMEGAFILM RTDs are available

in flat, round, and specialty shapes

for maximum flexibility. They are

also available in resistances at 0°C

that include 100, 500, and 1000 Ω

depending on the element style (the

resistances available for each style

will be shown on their individual

pages).

Glass coating over

wire bonds pattern

Platinum thin

film layer

Connection

wires

Connection pad

Ceramic base

OMEGAFILM

Can Be Used As-Is, or Packaged

in a Wide Variety of Sensor Styles. Custom

Packaging Options Are Also Available,

Contact Omega’s Applications

Engineering Department to Discuss

Your Specific Needs.

®

Sensing Elements

C-115

Page 2

Thin Film Interchangeability in °C

Temp °C Class B Class A 1⁄3 DIN (AA)

-50 0.55 — —

-30 0.45 0.21 —

OMEGAFILM

®

elements are manufactured to meet

the requirements of IEC Standard 60751. This

standard uses “Classes” to define the accuracy

and interchangeability for the elements, the

basic resistance vs. temperature characterisitcs,

temperature ranges and other technical

information relating to the OMEGAFILM RTD

elements. Key portions of these requirements

are summarized below.

0 0.30 0.15 0.10

100 0.80 0.35 0.27

150 1.05 0.45 0.36

200 1.30 0.55 —

300 1.80 0.75 —

400 2.30 — —

500 2.80 — —

Accuracy Classes

There are three accuracy “Classes” defined in IEC60751 for film type RTDs, they are: “Class A”, “Class B”,

1

⁄3 DIN (also known as AA).

and

These “Classes” are defined as follows:

Tolerance (°C)

Class A = ±(0.15 + 0.002t)

Class B = ±(0.30 + 0.005t)

Class AA (was

1

⁄3 DIN) = ±(0.1 + 0.0017t)

Temperature Range*

(-30 to 300°C)

(-50 to 500°C)

(0 to 150°C)

t = Temperature °C

C

Note: There is also an industry standard

* Note: The temperature ranges shown are not the temperature ratings for the sensors. Temperature ranges for each product have been

provided, please see the applicable page.

1

⁄10 DIN accuracy not available in film style RTDs.

Equations

Platinum RTD resistance can be calculated using the Callendar-Van Dusen Equation as follows:

For temperatures below 0°C:

Rt = R0 [1 + At + Bt2 + C(t-100)t3]

For temperatures above 0°C, this simplifies to:

Rt = R0 (1 + At + Bt

2

)

where: A = 3.9083 x10-3 (C-1)

B = -5.775 x10-7 (C-2)

C = -4.183 x10

-12

(C-4)

R0 = Resistance at 0°C

t = Temperature in degrees celsius

Maximum Operating Current

The maximum operating current is determined by the amount of electrical current that can be passed through

the element without significant self heating occuring. OMEGA recommends a maximum operating current of 1

milliamp for all of the 100 ohm elements and sensors we supply. Higher or lower currents may be suitable for other

resistances or sensor products, OMEGA recommends testing, for self heating effects before use.

Resistance vs. Temperature Values per IEC60751

Temp Resistance Temp Resistance Temp Resistance

(°C) (Ω) (°C) (Ω) (°C) (Ω)

-200 18.52 150 157.33 450 264.18

-150 39.72 200 175.86 500 280.98

-50 80.31 250 194.10 550 297.49

0 100.00 300 212.05 600 313.71

50 119.40 350 229.72 650 329.64

100 138.50 400 247.09 700 345.28

C-116

Page 3

OMEGAFILM® RTD Elements

(0.008)

Flat Profile Thin Film Platinum

Most

Economical!

for OEM Applications

“F” Series, Sold in Multiples of 100 Pieces

U Very Low Cost

U Flat, Small Profile

U Resistance Meets Requirements of IEC60751

U Temperature Range (See Tolerance Table)

Glass coating over

wire bonds pattern

Connection

wires

U Temperature Coefficient a = 0.00385 Ω/Ω/°C

U 100, 500, and 1000 Ω Configurations

1

U Class A, B, and AA (

⁄3 DIN) Tolerances

U Long-Term Stability—Max R0 Drift 0.4% after

1000 Hours at 500°C

U Vibration Resistance at Least 40 g Acceleration

at 10 to 2000 Hz

(932°F)

Platinum thin

film layer

Connection pad

Ceramic base

U Shock Resistance at 100 g Acceleration with

8 ms Half Sine Wave

Insulation Resistance >10 MΩ at 20°C, >1 MΩ at 500°C

U

U Self Heating 0.4 K/mW at 0°C

U Response Time Water Current (v = 0.4 m/s)

t0.5 = 0.2 s, t0.9 = 0.4 s; Air Stream

(v = 1 m/s) t0.5 = 3.0 s, t0.9 = 9.0 s

U Platinum Clad Nickel Wire Leads

10 L x 0.2 mm D (0.39 x 0.008")

Discount Schedule

1-4 packs .......... Net 10-24 packs .........10%

5-9 packs .......... 5% 25 or more packs .....15%

Tolerance

Tolerance of Temperature

Class Tolerance (°C) resistance at 0°C (V) Range

AA

(1⁄3 DIN)

± (0.1 + 0.0017t) ±0.04 0 to 150°C

A ±(0.15 + 0.002t) ±0.06 -30 to 300°C

B ±(0.3 + 0.005t) ±0.12 -50 to 500°C

To Order visit omega.com/f1500_f2000_f4000 for Pricing and Details

Dimensions in mm Size (mm) Nominal

Model Number (1 mm = 0.03937") W x L x H Resitance (Ω)

F2020-100-B 2.0 x 2.0 x 0.8 100

F2020-100-A 2.0 x 2.0 x 0.8 100

F2020-100-1/3B 2.0 x 2.0 x 0.8 100

F2020-1000-B 2.0 x 2.0 x 0.8 1000

F2020-1000-A 2.0 x 2.0 x 0.8 1000

F2020-1000-1/3B 2.0 x 2.0 x 0.8 1000

F2010-100-B 2.0 x 9.0 x 0.8 100

F2010-100-A 2.0 x 9.0 x 0.8 100

F2010-100-1/3B 2.0 x 9.0 x 0.8 100

F2010-500-B 2.0 x 9.0 x 0.8 500

F2010-1000-B 2.0 x 9.0 x 0.8 1000

F2010-1000-A 2.0 x 9.0 x 0.8 1000

F2010-1000-1/3B 2.0 x 9.0 x 0.8 1000

F4050-100-B 4.0 x 5.0 x 0.8 100

F4050-100-A 4.0 x 5.0 x 0.8 100

F4050-100-1/3B 4.0 x 5.0 x 0.8 100

F4050-500-B 4.0 x 5.0 x 0.8 500

F4050-500-A 4.0 x 5.0 x 0.8 500

F4050-1000-B 4.0 x 5.0 x 0.8 1000

F4050-1000-A 4.0 x 5.0 x 0.8 1000

F4050-1000-1/3B 4.0 x 5.0 x 0.8 100

F1540-100-B 1.5 x 4.0 x 0.8 100

F1540-100-A 1.5 x 4.0 x 0.8 100

F1540-100-1/3B 1.5 x 4.0 x 0.8 100

Sold in multiples of 100 pieces.

Due to the self heating error by the measuring conditions, the measuring current should be limited to a maximum value. We recommend 100 Ω max 1 mA;

500 Ω 0.7 mA; 1000 Ω max 0.3 mA.

Ordering Example: F2020-100-B-100, 100 pieces of 2 x 2 mm 100 Ω Class B tolerance thin film RTD element

(0.031

(0.078

(0.031

(0.078

(0.031

(0.157

(0.031

(0.059

±0.2

0.8

±0.007

)

±0.2

2.0

±0.007

)

(0.078

±0.2

0.8

±0.007

)

±0.2

2.0

±0.007

)

±0.2

0.8

±0.007

)

±0.2

4.0

±0.007

)

(0.196

ø = diameter

±0.2

0.8

±0.007

)

±0.2

1.5

±0.007

)

2.0

9.5

(0.374

5.0

4.0

±0.2

±0.007

±0.2

±0.2

±0.007

±0.2

10

±0.007

10

10

(0.157

±2

)

)

)

±2

10

±2

ø

(0.39

(0.39

ø

±2

(0.39

(0.39

0.2

±0.078

±0.007

C-117

0.2

(0.008)

±0.078

ø

(0.008)

±0.078

0.2

ø

(0.008)

±0.078

)

)

)

0.2

)

)

Page 4

Thin Film RTD Elements

“F” Series for OEM Applications

U Some as Small

as Thermistors

U Flat Packages (0.8 mm Thick)

U a = 0.00385, IEC60751 Curve

U Accuracy Equivalent to That

of Wire-Wound Units

U Better Response Than

Wire-Wound Units of

Equivalent Size

U 100, 500, and 1000 Ω

(See Table Below)

Actual size.

Sold in

Convenient Packs

of 100 Elements

F4050-100-B,

shown larger than actual size.

C

F4050

Actual Size

4.0 x 5.0 x 0.8 mm

F2020

Actual Size

2.0 x 2.0 x 0.8 mm

F4050-100-B, shown larger

than actual size.

F2020-100-B, shown larger

than actual size.

F2010

Actual Size

2.0 x 9.0 x0.8 mm

F1540

Actual Size

1.5 x 4.0 x 0.8 mm

Temp °C Class B Class A 1⁄3 DIN (AA)

-50 0.55 — —

-30 0.45 0.21 —

0 0.30 0.15 0.10

100 0.80 0.35 0.27

150 1.05 0.45 0.36

200 1.30 0.55 —

300 1.80 0.75 —

400 2.30 — —

500 2.80 — —

F2010-100-A, shown larger

than actual size.

F1540-100-1/3B, shown larger

than actual size.

Interchangeability in °C

C-118

Loading...

Loading...