Page 1

®

DWT1305D Series

Deadweight Tester

DWT1327D

Portable Pressure Test Set

Operator’s Manual

Deadweight Tester

Rev 1.1 9/02

®

®

®

®

®

®

®

®

®

®

®

®

®

®

An OMEGA Technologies Company

®

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: Tel: (95) TC-OMEGA

SM

FAX: (95) 203-359-7807

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

Czech Republic: Ostravska 767, 73301 Karviná

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

France: 9, rue Denis Papin, 78190 Trappes

Tel:: 33 (1) 30.62.14.00 FAX: 33 (1) 30.69.91.20

Toll Free in France: 05-4-OMEGA

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130-112166

United Kingdom: 25 Swannington Road, Broughton Astley, Leicestershire,

ISO 9002 Certified LE9 6TU, England

Te l: 44 (1455) 285520 FAX: 44 (1455) 283912

Toll Free in the United Kingdom: 0800-488-488

An OMEGA Technologies Company

OMEGAnetSMOn-Line Service Internet E-Mail

http://www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

CJS0296FSBA

®

Page 3

1.0 PURPOSE AND SCOPE OF MANUAL

This manual is provided to guide users of Model

DWT1305D and DWT1327D pressure testing devices in:

(1) installing the equipment

(2) Routine operations

The instructions in this manual are designed to be performed by qualified instrument maintenance personnel.

Omega Engineering does not recommend troubleshooting

or repairs beyond the scope of this manual. Problems that

cannot be remedied by following the instructions in this

manual should be referred to Omega. Immediate assistance can often be supplied by telephone. Defective components will be repaired or replaced as necessary.

Returned goods should be accompanied by information

requested in Section 6.

1.1 Safety Precautions

Pressure Testing Equipment must be selected and used in

accordance with recognized industry codes and safety

practices to avoid the possibility of misuse or misapplication which could result in personal injury or property damage. Personnel responsible for selection and installation

should also be familiar with the safety recommendations of

ASME B40.1 that apply to elastic pressure elements and

their application in general and specific services.

1. Pressure – Select a range so that the maximum

applied pressure will never exceed the upper range limit.

2. Vibration – Excessive vibration could cause a loosening of components and abnormal wear resulting in loss of

instrument accuracy or failure to provide valid data.

3. Temperature – Operation of the instrument in an environment where temperatures are in excess of design ratings may result in loss of accuracy and failure.

4. Process – Pressure boundary materials must be resistant to the process media. Failure to assure compatibility

may result in pressure boundary deterioration or failure.

Instruments operated at high pressure or with potentially

hazardous service, such as oxygen, should be carefully

selected in accordance with recognized industry codes

and the recommendations of ASME B40.1.

2.0 PRODUCT DESCRIPTION –

THEORY OF OPERATION – CONSTRUCTION

2.1.2 Product Description

2.1.3 Construction

The Omega Type DWT1305D Dual Range Deadweight

testers are precision built primary pressure standards,

used for testing, setting, calibrating or repairing pressure

measuring devices within the test points 15 psi (100kPa)

to 10,000 psi (70,000kPa).

The deadweight tester consists of a two stage hydraulic

pump containing a manifold which is pressurized during

operation. Integral to the pump is a shuttle valve that

allows the operator to regulate the speed of pressure

increase. One connection to the manifold includes a cylinder and a free-floating precision machined piston with a

plate for holding calibrated weights. A second connection

to the manifold accommodates a gauge or other pressure

measuring device to be calibrated or checked.

Incorporated into the manifold is a hand operated displacement valve that allows small adjustments in fluid volume to be made without further operation of the pump

handle or release valve.

The tester is dual range having two interchangeable piston

Omega

®

Installation and Maintenance Manual

for the Omega

®

Type DWT1305D Deadweight Tester

and Type DWT1327D Portable Pump

INDEX

Section Description

1.

Scope of Manual Safety Precautions

2. Product Description DWT1305

Theory of Operation

Construction

Specifications

Product Description DWT1327

Theory of Operation

Construction

Specifications

3. Inspection

Installation DWT1305

Operation DWT1305

Installation DWT1327

Operation DWT1327

4. Factors Affecting Operation of Deadweight

Testers

5. Maintenance Instructions

Shipping Instructions

List of Illustrations

Figure 1-1

Figure 1-2

Figure 2-1

Figure 5-1

Page 4

and cylinder assemblies. One is a low pressure piston

having an effective area five times larger than that of the

high pressure piston. The low pressure piston is used for

making measurements below 2,000 psi (14,000 kPa). The

high pressure piston, with an area 1/5 that of the low pressure piston, is used to measure pressure through 10,000

psi (70,000 kPa). The weight masses are pre-measured

and identified with the pressure values they produce when

operated with the interchangeable piston and cylinder

assemblies.

Pressure calibration points produced by the deadweight

tester are accurate to within ± 0.1% of the reading certified

traceable to the National Institute of Standards and

Technoogy (NIST). The tester provides consistent, repeatable accuracy, maintaining its pressure for an appreciable

length of time regardless of temperature changes, slight

leaks in the pressure system, or changes in volume of the

pressurized system due to movement of a Bourdon tube

or other device.

A hand jack set, three wrenches, spare O-rings, and a

special adapter for making connections to pressure outlets

that do not accommodate cone pipe seating, are included

with each unit.

All deadweight testers are supplied with lower and back

connection offset pipe assemblies, with pipe adapters for

1

⁄

4 NPT or

1

⁄

2 NPT connections.

An all metal, double-latched, top handle carrying case is

supplied with the complete tester for all fittings and attachments. Deadweights are packed in metal, double-latched

storage-carrying boxes.

2.1.2 Theory of Operation – DWT1305D

The theory behind a deadweight tester can be expressed

as simply as force acting upon a known area. Pressure

produced by the pump is distributed by the manifold, to the

base of a precision machined piston and to a device being

calibrated or checked. Pre-selected weights loaded onto

the piston platform are acted upon by gravity and develop

a force that is to be equally opposed by the fluid pressure

from the pump. When equilibrium is achieved, the pressure value is known, it being a direct result of the sum of

the forces from the weights, piston platform and the piston

divided by the effective area of the piston and cylinder

assembly.

With the DWT1305D two piston and cylinder assemblies

are supplied, one having an effective area 1/5 of the other.

When using the smaller piston and cylinder assembly, five

times more pressure is required to oppose the force of a

constant mass being acted upon by gravity. For this rea-

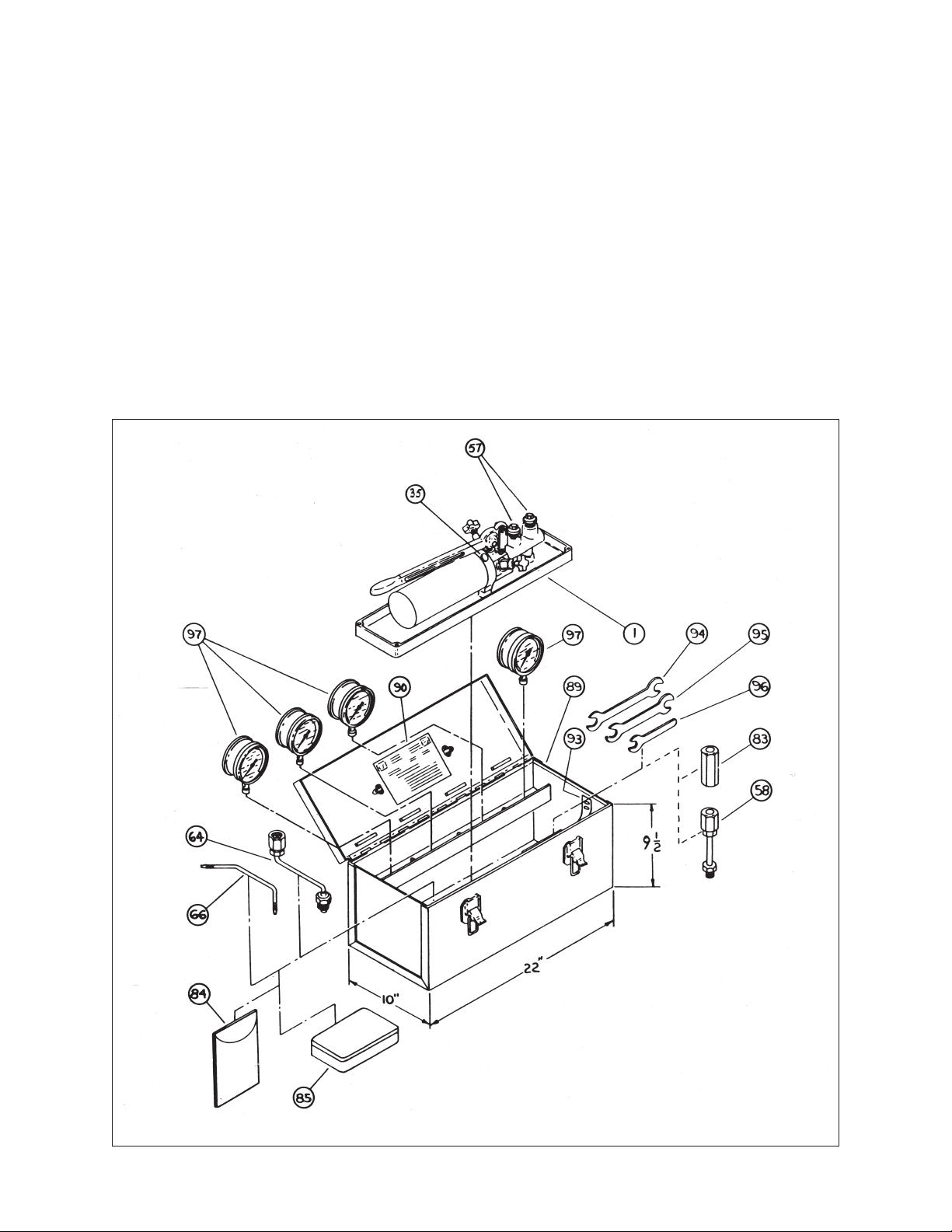

Figure 1-1 Omega Portable Dual Range Deadweight Tester – Type DWT1305

Page 5

son the masses supplied with the tester are stamped with

two pressure values, the value being contingent on the

effective area of the piston and cylinder assembly selected.

2.1.3 Specifications – DWT1305D

Accuracy:

Combined tolerance of weights and piston and

cylinder assemblies within 0.1% of reading. Weight tolerance within 0.05% of mass. Piston and cylinder is within

0.05% of rated mean effective area.

Deadweight: Non-magnetic die cast zinc alloy. Total

weight to produce maximum pressure of 10,000 psi

(70,000kPa) is 125 lbs. (56.7 kg).

Piston & Cylinder Assemblies: High strength stainless

steel piston and cylinder with brass collar and aluminum

weight platform.

Pump: Tw o stage, lever operated generates 10,000 psi

(70,000 kPa) with 28 pounds (12.7 kg) of force on lever

handle.

Pump Body: Aluminum, corrosion inhibited and coated

with baked blue epoxy finish.

Shuttle Valve: Stainless steel bypass valve that controls

rate of pressure increase and reduces operator effort

when working at high pressure.

Displacement Valve: A fine pitched threaded valve rod

permitting vernier adjustments to fluid volume and provide

precise pressure changes or adjustment of piston travel.

Limit stops prevent rod removal during normal operation.

Mounting: Four bench mounting holes located in base for

positive mounting to any level surface.

Instrument Connections: Tw o coned pipe assemblies

provide vertical calibration capability for back and lower

connected gauges. Standard

1

⁄4 inch internal NPT and 1⁄2

inch inter NPT fitting adapters are supplied.

Operating Fluid: DWT1305D – Light grade machine oils,

automotive petroleum base SAE 20 oils or other equivalent fluids suitable for use with Buna N O-ring materials.

1.5 pints required (.7 liters).

DWT1305DH – Most hydraulic oils of phosphate ester

base, brake fluids, skydrol, pydraul etc., suitable for use

with Butyl or Ethylene-Propylene O-ring materials. 1.5

pints required (.7 liters).

2.1.4 Certification:

Standard

– Certificate of NIST traceability

(accuracy/traceability statement only).

Optional (CAL-3) – Certification document includes actual

(as left) weight values for each weight and piston, piston

diameter values, environmental data and NIST test

numbers. Set includes numbered weights.

2.2 Product Description DWT1327D

Page 6

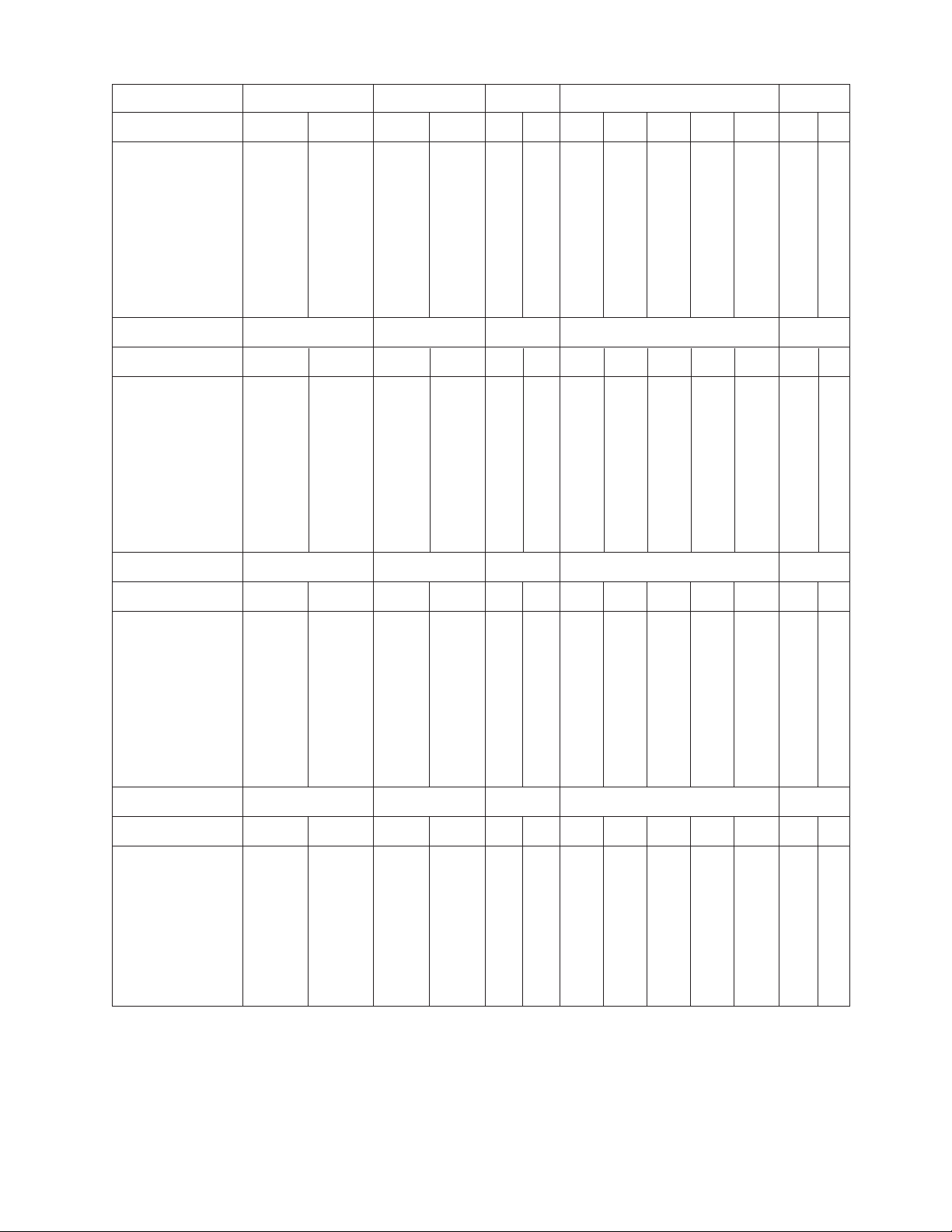

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

L-5 L-10 L-20 L-40 L-100

psi Type Low High Low High Low

High

H-25 H-50 H-100 H-200 H-500

lbs. kg.

DWT1305D-10

DWT1305DH-10 15/200 75/1000 5 25 1323--6027

DWT1305D-20

DWT1305DH-20 15/400 75/2000 5 25 132327032

DWT1305D-30 .

0625 in.2.0125 in.

2

DWT1305DH-30 15/600 75/3000 (.4032) (.0806) 5 25 132348539

DWT1305D-50

DWT1305DH-50 15/1000 75/5000 5 25 1323810548

DWT1305D-100

DWT1305DH-100 15/2000 75/10000 5 25 13231817580

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

L-.5 L-1 L-2 L-4 L-5

kg/cm2Type Low High Low High Low High

H-2.5 H-5 H-10 H-20 H-25

lbs. kg.

DWT1305DM-20

DWT1305DMH-20 1/20 -- .5 2.5 112126329

DWT1305DM-100

DWT1305DMH-100 1/20 5/100 .5 2.5 112126530

DWT1305DM-150 .

0625 in.2.0125 in.

2

DWT1305DMH-150 1/30 5/150 (.4032) (.0806) .5 2.5 112147534

DWT1305DM-350

DWT1305DMH-350 1/70 5/350 .5 2.5 11211210548

DWT1305DM-700

DWT1305DMH-700 1/140 5/700 .5 2.5 21212617580

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

L-.5 L-1 L-2 L-4 L-5

bar Type Low High Low High Low High

H-2.5 H-5 H-10 H-20 H-25

lbs. kg.

DWT1305DB-20

DWT1305DBH-20 1/20 -- .5 2.5 112126329

DWT1305DB-100

DWT1305DBH-100 1/20 5/100 .5 2.5 112126530

DWT1305DB-150 .

0613 in.2.0123 in.

2

DWT1305DBH-150 1/30 5/150 (.3954) (.0791) .5 2.5 112147534

DWT1305DB-350

DWT1305DBH-350 1/70 5/350 .5 2.5 11211210548

DWT1305DB-700

DWT1305DBH-700 1/140 5/700 .5 2.5 21212617580

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

L-50 L-100 L-200 L-400 L-500

Pascal Type Low High Low High Low High

H-250 H-500 H-1000 H-2000 H-2500

lbs. kg

.

DWT1305DA-2000

DWT1305DAH-2000

100/2000 -- 50 250 112126329

DWT1305DA-10000

DWT1305DAH-10000

100/2000 500/10000 50 250 112126530

DWT1305DA-15000

.

0613 in.2.0123 in.

2

DWT1305-DAH-15000

100/3000 500/15000 (.3954) (.0791) 50 250 112147534

DWT1305DA-35000

DWT1305DAH-35000

100/700 500/35000 50 250 11211210548

DWT1305DA-70000

DWT1305DAH-70000

100/14000 500/70000 50 250 21212617580

Dimensions in ( ) are square centimeters

TABLE 2-1

Page 7

2.2.1 Construction

The Omega Type DWT1327D Portable Test Pumps are

rugged, versatile pressure transfer standards, used for

testing, setting, calibrating or repairing pressure measuring devices with ranges up to 10,000 psi (70,000kPa). A

selection of high accuracy test gauges, with a precision of

±0.25% of span, are available as the standard to which the

device under test is compared.

The main component to the tester is a two stage hydraulic

pump containing a manifold which is pressurized during

operation. Integral to the pump is a shuttle valve that

allows the operator to regulate the speed of pressure

increase. One connection to the manifold has a straight

pipe with a precision test gauge attached serving as the

reference standard. A second connection to the manifold

accommodates a gauge or other pressure measuring

device to be calibrated or checked. Incorporated into the

manifold is a hand operated displacement valve that

allows small adjustments in fluid volume to be made without further operation of the pump handle or release valve.

Pressure values produced by the pump are able to be

clearly read to within ±0.25% accuracy of the span of the

precision test gauge selected for testing. A hand jack set,

three wrenches, spare O-rings, and special adapter for

making connections to pressure outlets that do not accommodate cone pipe seating, are included with each unit.

Test pump accessories include lower and back connection

offset pipe assemblies, with pipe adapters for

1

⁄

4 and

1

⁄

2

NPT connections.

An all metal, double-latched, top handle carrying case is

supplied with the complete tester to hold all fittings and

attachments.

2.2.2 Theory of Operation – DWT1327D

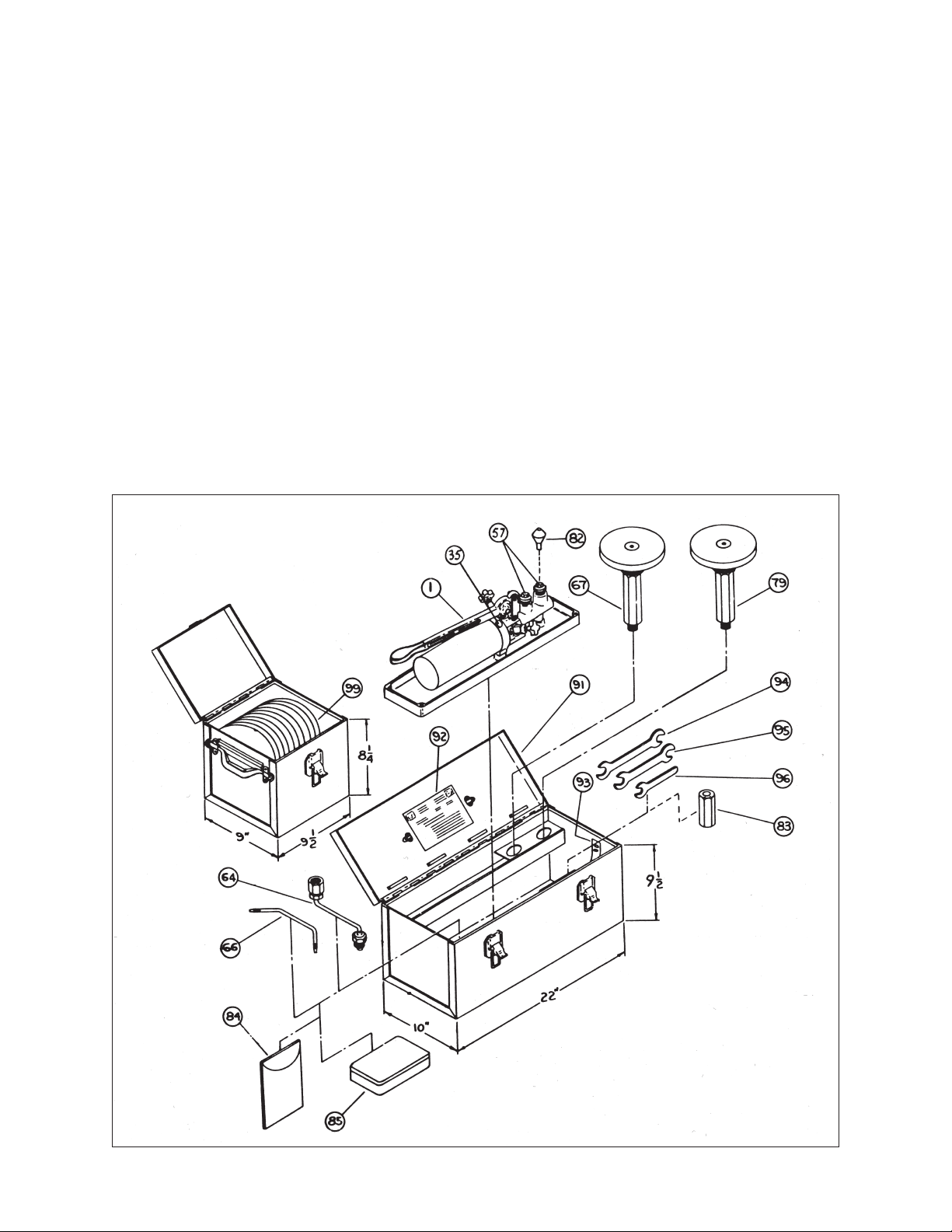

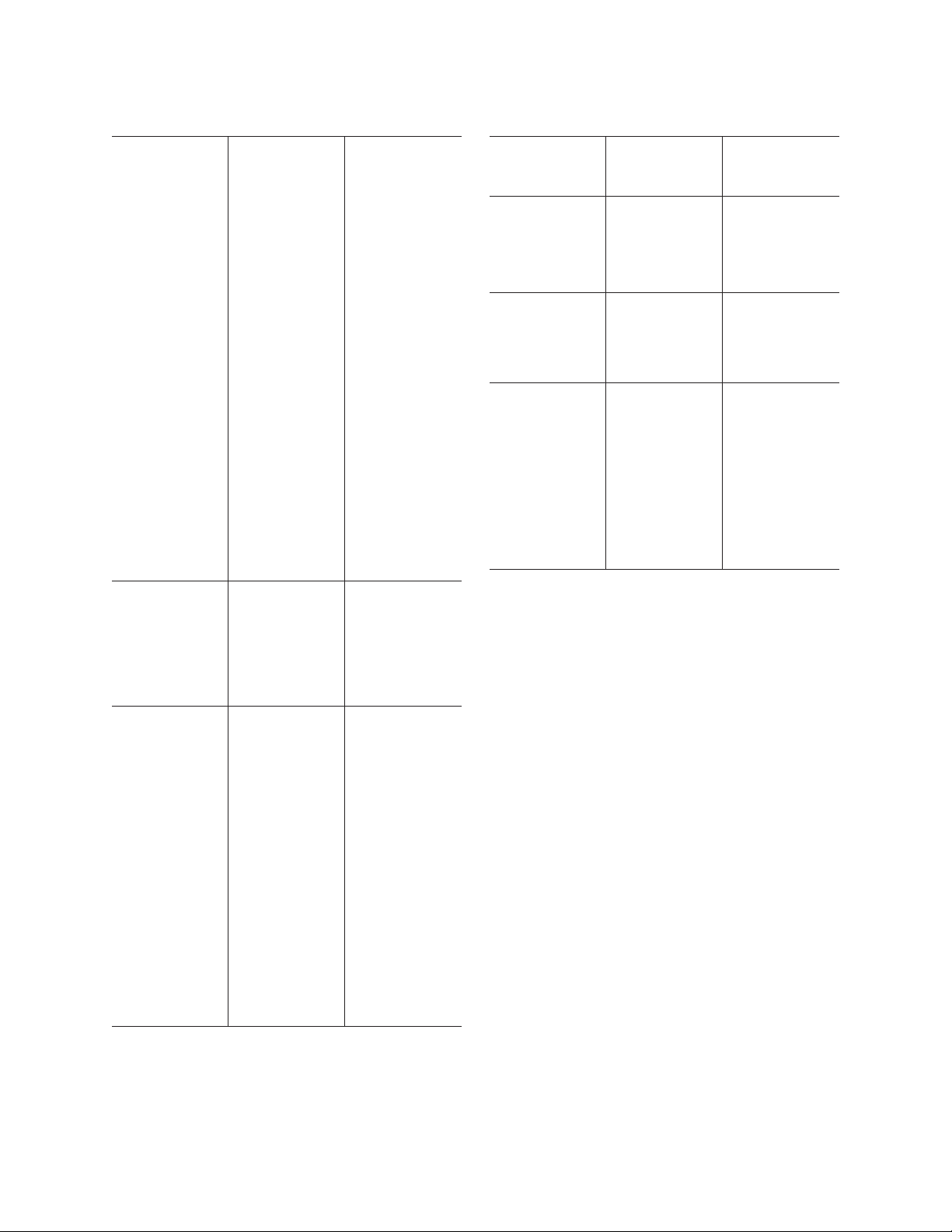

Figure 1-2 Omega Portable Test Pump – Type DWT1327

Note: (97) Gauges are not provided with

the set and may be ordered separately.

Page 8

The operating principle behind the DWT1327D Test Pump

is a simple form of comparison. Pressure produced by the

pump is equally distributed by the manifold to a test gauge

and to a device being calibrated or checked. The reading

of the test gauge serves as the reference to which other

device readings are compared.

Selection of the test gauge range is the determining factor

in establishing the precision to which a comparison check

is to be made. Test gauge accuracy is expressed as a percentage of its span.

Proper selection of the test gauge range must be made to

minimize the amount of the unit error. If a 5,000 psi

(35,000kPa) range test gauge were used to test devices

whose span values were less than a fourth of the test

gauge range, the unit error of 12.5 psi (87kPa) would be

greater than 1% of the test pressure. Therefore, it is important to select a test gauge that has a full scale range equal

to or only slightly in excess of the pressure value to be

measured.

2.2.3 Specifications – DWT1327D

Accuracy:

1

⁄

4% of 1% of test gauge span.

Test Gauges: Omega PGT45L 41⁄

2˝ test gauges are

recommended.

Pump: Tw o stage, lever operated generates 10,000 psi

(70,000kPa) with 28 pounds (12.7kg) of force on lever

handle.

Pump Body: Aluminum, corrosion inhibited and coated

with baked blue epoxy finish.

Shuttle Valve: Stainless steel bypass valve that controls

rate of pressure increase and reduces operator effort

when working at high pressure.

Displacement Valve: A fine pitched threaded valve road

permitting vernier adjustments to fluid volume to provide

precise changes. Limit stops prevent road removal during

normal operation.

Mounting: Four bench mounting holes located in base for

positive mounting to any level surface.

Instrument Connections: Tw o coned pipe assemblies

provide vertical calibration capability for back and lower

connected gauges. Standard

1

⁄

4 inch internal NPT and

1

⁄

2

inch internal NPT fitting adapters are supplied.

Operating Fluid: DWT1327D – Light grade machine oils,

automotive petroleum base SAE 20 oils or other equivalent fluids suitable for use with Buna N O-ring materials.

1.5 pints required (.7 liters).

DWT1327DH – Most hydraulic oils of phosphate ester

base, brake fluids, Skydrol, Pydraul etc., suitable for use

with Butyl or Ethylene-Propylene O-ring materials. 1.5

pints required (.7 liters).

DWT1327DO – Distilled water with compatible corrosion

inhibitor. A .1% solution of sodium dichromate is a suitable

inhibitor. 1.5 pints required (.7 liters).

2.2.4 Certification:

Exclusively dependent upon certification provided with test

instrument.

3.0 SETTING UP THE TESTER

Page 9

3.1 Inspection

3.1.1 Component Check DWT1305D

The deadweight tester, as shipped from the factory, contains all of the components necessary for operation except

pump fluid and the test instrument(s). Figure 1-1 provides

an illustrated breakout of these items for quick verification.

3.1.2 Component Check DWT1327D

The portable test pump, as shipped from the factory, contains all of the components necessary for operation except

pump fluid. Figure 1-2 provides an illustrated break-out of

these items for quick verification.

3.1.3 Claim for Missing or Damaged Goods

In the event it is determined that an item is missing or

damaged, contact Omega Engineering immediately.

Disposition of damaged or missing goods will be provided

at that time.

3.2 Installation Type DWT1305D

3.2.1 Set-up Procedure (See Figures 1-1 and 2-1)

To remove the tester from the case, release the spring clip

(93), depressing the clip by hand, grasp the pump reservoir and lift up the back end of the pump assembly.

Having removed the pump assembly from its carrying

case (91), remove the two plastic shipping plugs (57).

Select a lower connection (64) or back connection (66) offset pipe and connect to inner pump body outlet as shown

in Fig. 2-1.

Remove the reservoir filler plug (35) and fill reservoir with

operating fluid.

3.2.2 Bench Space Required (See Figure 1-1)

Allow a space:

10 inches (25.4 cm) width

27 inches (68.6 cm) depth

22 inches (55.9 cm) height – allows for maximum load of

deadweights

3.2.3 Storage Space Required

One Tester Box:

101⁄

2 inch (2.6 cm); 22

1

⁄

2 inch (57 cm) depth; 10 inch (25

cm) height

One Weight Box:

10 inch (25 cm) width; 10 inch (25 cm); 10 inch (25 cm)

height

Storage space dimensions are larger than actual size of

tester carrying case and deadweight carrying case by

approximately _ inch, (1.3 cm), in order to facilitate ease of

handling in storage.

Note: For catalog numbers DWT1305D, DH-100,

DWT1305DM, DMH-150, DWT1305DB, DBH-700

and DWT1305DA, DAH-700 allow storage space for

two weight boxes.

Page 10

Figure 2-1 Omega Portable Deadweight Tester DWT1305D

Page 11

3.3 Operation DWT1305D

3.3.1 Piston and Cylinder Selection

The DWT1305D Tester is a dual range device in that most

models utilize two interchangeable piston and cylinder

assemblies for measurement of pressure throughout the

entire range. Each piston and cylinder assembly has a

minimum and maximum operating range. First, determine

what pressure points need to be measured and select the

appropriate assembly. The pressure range of the assemblies is shown in Table 2-1. When priming the pump the

high pressure piston and cylinder assembly should be used.

3.3.2 Priming the Pump

The offset pipe (64 or 66 Figure 2-1) should already be

secured in place and the reservoir should contain the

operating fluid (refer to Installation Section 3.2).

Close the release valve (37) by turning it clockwise and

open the air vent by loosening the filler plug (35) a few

turns. The shuttle valve (51) should be pulled outward

from the pump body, the end of the knob approximately

even with the edge of drip pan. In this position the high

volume displacement mode is selected and the pump is

self-priming. Operate the pump handle several times using

full strokes, until you see fluid appear in the outer pump

body outlet.

The cone seat (82) is located in the base of the outerpump body outlet and serves as the sealing surface

between the bottom of the piston and cylinder assembly

and the pump body. Confirm the coned end of the seat is

facing up and the cylindrical end of it is facing down.

Thread the high pressure piston and cylinder assembly

(79) or (67) into the outer body outlet as shown, using the

wrenches provided.

Operate the pump handle a few more times until fluid is

observed at the end of the offset pipe. Connect the gauge

or other device to be tested to the offset pipe. For purposes of priming, the device must be designed to withstand

the full operating pressure of 10,000 psi (70,000kPa). If a

lower range device must be used, extreme care must be

exercised to avoid overpressuring its pressure element.

Seal the connection to the device by tightening nut adapter

(62) and adapter (60) until the coned end of the pipe is

forced into its inlet. If necessary, rotate the device for viewing by loosening nut adapter (62), set it to the proper position and retighten nut adapter.

Again, operate the pump handle a few more times. After a

few strokes positive pressure will develop and the pump

handle will begin to resist pumping action. Raise the pump

handle to its uppermost travel position. Loosen the bleed

screw (30) a half turn counter clockwise and slowly operate the pump handle through a downward stroke until fluid

flows steadily from the bleed vent. Close the bleed screw

just prior to completing the downward handle motion.

Repeat this action until no air bubbles are observed in the

fluid flow. (Note – the bleed screw must be closed when

the handle is being raised). Push the shuttle valve in

towards the pump body and continue pumping to the

desired test pressure. Open the release valve (37) to vent

the pressure. To check operation pull the shuttle valve outward, close the release valve and operate the pump handle several times. When handle resistance is felt, push the

shuttle valve inward and continue pumping within the

range of the test device.

Entrapped air will prevent the pump from operating in the

high pressure valve position or cause it to achieve only

partial pressure. Repeat the above bleed procedure as

necessary to assure all air is removed. Once air is

removed the pump will continue to operate without further

attention providing the reservoir level is maintained.

3.3.3 Weights

The weight set consists of a selection of various masses

that will produce desired pressure increments when operated with the appropriate piston and cylinder assembly.

Each weight is stamped with two pressure values. When

applied to the high pressure piston and cylinder assembly

the equivalent pressure value is indicated next to the letter

“H”. Conversely, when applied to the low pressure piston

and cylinder assembly the equivalent pressure value is

indicated next to the letter “L”. The piston and piston platform also contribute to the total mass. Their equivalent

pressure value is stamped on the top of the platform.

During normal operation, selected weights are added to

the plate and piston assembly to equal the desired pressure value.

3.3.4 Levelness

The deadweight tester must be level to function properly.

The unit may be leveled by placing a bubble type level on

top of the piston plate and revolving it slowly. Shims may

be used between drip pan and bench to level the piston

plate. The unit is level when the position of the bubble

does not change within the glass as it is rotated on top of

the piston assembly.

3.3.5 Making the Test

Add weight (99 Figure 1-1) to the piston plate to give

desired calibrating pressure.

Pull the shuttle valve (51) outward from the body and close

the pressure release valve (37). Operate the pump handle

until the fluid pressure forces the piston to raise the

weights. When pumping, the weights should be rotated

slowly to decrease cylinder wall friction. If pump handle

resistance is difficult and the weights have not risen, push

the shuttle valve inward and continue pumping. With the

shuttle valve pushed in, the fluid displacement of each

stroke is reduced, thereby requiring less effort to continue

pumping.

The piston assembly has a maximum lift of

3

⁄

4 inch (1.9

cm). It is recommended that readings be taken at midpoint, or

3

⁄

8 inch (1 cm) lift. Small adjustments to the piston

lift can be made with the pump handle or the displacement

valve (41).

Improper readings will result if the piston plate is so low

that it rests on the bushing, or so high that the internal

stop on the piston assembly is touching the underside of

the bushing.

Spin the weights by hand and take readings only when the

weights are spinning. Speed of rotation is unimportant,

although a slow speed is more convenient and

recommended.

To release pressure, turn valve (37) counterclockwise

slowly.

3.3.6 To Dismantle (See Figure 1-1)

To replace the tester in its case, remove the gauge offset

pipe assembly (64 or 66) and the piston and cylinder

assembly (67 or 79). Install shipping plugs (57) in body

outlet holes. Screw in the displacement valve (41) until it

stops. Close the vent plug (35). Open the release valve

(37) approximately _ turn. Replace the tester in its case,

reservoir last. Engage the spring clip catch.

Page 12

3.3.7 General Precautions

It is important that the deadweight tester be connected to

a leak tight system.

The deadweight tester should be set-up so that the axis of

the located piston is vertical, the weights carefully centered on that axis, and the piston rotated during use. The

purpose of the rotation is to spread the lubricant over the

entire surface between piston and cylinder, so that there

will be no metal-to-metal contact. If rotation is not maintained, the lubricant film will not cover the surface properly,

and readings will be in error.

The high and low pressure piston assemblies have an

internal overload stop, which prevents the piston and cylinder from being forced apart if weights are accidentally

removed.

3.3.8 Operating Fluids

Standard Tester:

Any medium weight oil may be used (including automotive

oils S.A.E. 10, 20 or 30) S.A.E. 20-W recommended.

Hydraulic Tester:

Any hydraulic fluid (silicate or phosphate base). Skydrol or

Pydraul is suitable.

For normal operation, it is not necessary to change the

weight of oil for various pressures. A lighter oil may be

used where low pressures are being checked, and a heavier oil where higher pressures are being tested.

The reservoir can be refilled while the tester is operating

under pressure.

3.3.9 Caution

Standard testers designed for oil service may not be used

with water for oxygen service.

3.3.10

Hydraulic service testers should not be filled with water or

any oil other than hydraulic fluid. Serious pump failure may

occur due to O-ring damage.

3.4. Installation Type DWT1327

3.4.1 Set up Procedure (See Figures 1-2 and 2-2)

To remove the test pump from the case, release the spring

clip (93), depressing the clip by hand, grasp the pump

reservoir, and lift up the back end of the pump assembly.

Remove the two plastic shipping plugs (57) from the outlet

connections. Remove the threaded filler plug (35) from

reservoir filling hole. Remove the offset pipe (64) or (66)

from the carrying case and connect to the inner pump

body outlet as shown in Figure 2-2. Remove the straight

pipe extension (58), and assemble to outer vertical pump

body outlet as shown in Figure 2-2.

3.4.2 Connecting The Gauge (See Figure 2-2)

Select a test gauge that is adequate for the pressure

range desired. Assemble the test gauge to the straight

pipe extension, using adapter nut (62), collar (61), adapter

(60) and reducer bushing (59).

Seal the connection by tightening nut adapter (62) and

adapter (60) until the coned end of the pipe is forced into

the gauge socket. Rotate the gauge for viewing by loosening nut adapter (62), setting the gauge to the desired position, and re-tightening nut adapter.

Repeat the above procedure to connect the gauge being

tested to the offset pipe assembly (64) or (66).

3.4.3 Bench Space Required

Allow a space:

10 inch (2.5 cm) width

23 inch (5.8 cm) depth

22 inch (5.6 cm) height allows for testing gauges up to 8_

inch (250 mm) size

3.4.4 Storage Space Required

101⁄

2 inch (27 cm) depth

25 inch (63.5 cm) width

10 inch (25 cm) height

Storage space dimensions are larger than actual size of

test pump carrying case by approximately _ inch (1.3 cm),

in order to facilitate ease of handling in storage.

Page 13

Figure 2-2 Omega Portable Test Pump – Type DWT1327D

Page 14

3.5 Operation DWT1327D

3.5.1 Test Gauge Selection

The portable test pump is used for calibrating instruments

such as pressure gauges, pressure switches or other

pressure devices rated up to 10,000 psi (70,000kPa).

First, select the proper test gauge, depending upon the

pressure range desired. When priming the pump a test

gauge rated to 10,000 psi (70,000kPa) should be used.

3.5.2 Priming The Pump

The offset pipe (64 or 66 Figure 2-2) and straight pipe

extension (58) should already be secured in place and the

reservoir should contain the operating fluid (refer to installation Section 3.4).

Close the release valve (37) by turning it clockwise and

open the air vent by loosening the filler plug (35) a few

turns. The shuttle valve (30) should be pulled outward

from the pump body, the end of the knob approximately

even with the edge of the drip pan. In this position the high

volume displacement mode is selected and the pump is

self-priming. Operate the pump handle several times using

full strokes, until you see fluid appear at the top of the

straight pipe extension. Connect the test gauge to it (refer

to Installation Section 3.4 for proper gauge connection).

Operate the pump handle a few more times until fluid is

observed at the end of the offset pipe. Connect the gauge

or other device to be tested to the offset pipe. For purposes of priming, the device must be designed to withstand

the full operating pressure of 10,000 psi (70,000kPa). If a

lower range device must be used, extreme care must be

exercised to avoid overpressuring its pressure element.

Seal the connection to the device by tightening nut adapter

(62) and adapter (60) until the coned end of the pipe is

forced into its inlet. If necessary, rotate the device for viewing by loosening nut adapter (62), set it to the proper position and retighten nut adapter.

Again, operate the pump handle a few more times. After a

few strokes positive pressure will develop and the pump

handle will begin to resist pumping action. Raise the pump

handle to its uppermost travel position. Loosen the bleed

screw (51) a half turn counter clockwise and slowly operate the pump handle through a downward stroke until fluid

flows steadily from the bleed vent. Close the bleed screw

just prior to completing the downward handle motion.

Repeat this action until no air bubbles are observed in the

fluid flow. (Note – the bleed screw must be closed when

the handle is being raised). Push the shuttle valve in

towards the pump body and continue pumping to the

desired test pressure. Open the release valve (37) to vent

the pressure. To check operation pull the shuttle valve outward, close the release valve and operate the pump handle several times. When handle resistance is felt, push the

shuttle valve inward and continue pumping within the

range of the test device.

Entrapped air will prevent the pump from operating in the

high pressure valve position or cause it to achieve only

partial pressure. Repeat the above bleeding procedure as

necessary to assure all air is removed. Once air is

removed the pump will continue to operate without further

attention providing the reservoir level is maintained.

3.5.3 Making The Test

Tu rn displacement piston handle (41) to mid-position, so

that it may be used for setting an exact pressure on the

gauge. The displacement piston has internal stops which

prevent unscrewing or accidental loss of pressure.

Clockwise rotation of displacement piston will produce an

increase in pressure; counterclockwise will decrease

pressure.

Prior to taking readings, both gauges should be fingertapped lightly at the center of the gauge face, to eliminate

any movement friction. Note the pressure readings on the

test gauge and the gauge under test. If the pressure indicated on the gauge under test is not equal (within the tolerance of the gauge) to the pressures of the master test

gauge, the gauge being tested requires calibration.

CAUTION:

Do not pump handle to pressures greater than the pressure range of the gauges connected to the test pump, as

this may damage the gauges.

3.5.4 To Release Pressure

Open release valve slowly (37), until pressure returns to

zero. Do not loosen any connections until pressure in the

gauge tester has reached zero, as indicated on the test

gauge.

If additional gauges are to be tested, close the release

valve when the pressure reaches zero. This will prevent

complete drainage of oil in the tester back to the reservoir.

Unseal the gauge that has been tested by unscrewing

adapter nut (62) from connector (60) several turns.

Unscrew the gauge from bushing (59) if used, or connector (60), and remove.

Remove the test gauge in the same manner as the gauge

under test.

3.5.5 To Dismantle

To replace test pump in case, remove gauges and both

tube assemblies. Put shipping plugs (57) into pump and

tighten. Close filler plug (35).

3.5.6 Operating Fluids

Standard Test Pump:

Any medium weight oil may be used (including automotive

oils S.A.E 10, 20 or 30) S.A.E. 20-W recommended.

Hydraulic Test Pump:

Any hydraulic fluid (silicate or phosphate base). Skydrol or

Pydraul is suitable.

Oxygen Test Pump:

Distilled or demineralized water with a compatible corrosion inhibitor added. A .1% solution of sodium dichromate

is a suitable inhibitor.

For normal operation it is not necessary to change the

weight of oil for various pressures. A lighter oil may be

used where low pressures are being checked, a heavier oil

where higher pressures are being tested.

The reservoir can be refilled while the test pump is operating under pressure.

3.5.7 Caution

Standard testers designed for oil service may not be used

with water for oxygen service.

3.5.8

Hydraulic service testers should not be filled with water or

any oil other than hydraulic fluid. Serious pump failure may

occur due to O-ring damage.

4.0 FACTORS AFFECTING OPERATION OF

DEADWEIGHT TESTERS

4.1 Deadweight Tester Accuracy

Excellent accuracy is possible using the deadweight tester

through analysis and control of certain factors. If the

tester’s rated accuracy of 1/10th of 1% is adequate, then

Page 15

the nominal pressure (sum of the denominations of the

weights loading the piston) may be assumed to be correct.

The pressure normally developed is determined by this

formula: Deadweight Tester Pressure =

Mass of weights plus piston mass

Effective area of piston and cylinder

P = (M-ph) g

A gs

P=pressure

M=mass of the load on the piston

A=effective area of the piston in sq. inches, or sq. cm

g/gs = ratio of the value (g) of gravity at the point of use to

the standard value of gravity (gs)

P=density of liquid used in test

h=difference in level between gauge being tested, and

the bottom of the piston

The deadweight tester is capable of measuring pressures

to proper corrections after analyzing these factors.

4.2 Gravity, Calibrated Weights

Weights furnished are calibrated at standard gravity of

980.665 gals. If precise accuracy is required, the error

introduced by change of weight due to change in gravity at

the locality should be calculated and included in results.

The mechanism of an Omega Pressure Gauge includes a

Bourdon tube and geared movement, which is unaffected

by variations in gravity. Conversely, the pressure developed by a deadweight tester is proportional to the value of

gravity. Readings of this type pressure gauge will correspond to those of a deadweight tester when the tester is

subjected to standard gravity (gs = 980.665 gals. in the

International System). In southern sections of the United

States, the value of gravity may be several thousandths

less than the standard value, if the latitude (Ø) and the elevation above sea level (a) for an area are known, the

approximate value of (g) in gals. may be calculated from

this formula:

g = 980.632-2.586 COS 2Ø

+.003 COS 4Ø - .000094a

Ø=Latitude (Degrees)

a=Elevation above sea level (ft)

4.3 Effective Measured Area: Chamber

The effective area of the deadweight tester may be determined by the average of the cross sectional area of the

piston and the area of the cylinder bore. This effective area

is affected somewhat by temperature, and by the elastic

distortion of the piston and cylinder when pressure is

being applied. The effective area of a stainless steel piston

and cylinder increases approximately .068% with a 50

degree F (28 degree C) change in temperature. The

pressure will, therefore be less than indicated at high

temperatures.

4.4 Mass, Height, and Buoyancy

The density of air at room temperature and sea level pressure is about 0.0012 grams/c.c., and the mass of the piston assembly and weights under these conditions will be

reduced by about one part in 7,000 or .014%. When the

submerged part of the piston has a uniform cross section,

as with the DWT1305D Deadweight Tester, a buoyancy

correction is not necessary. In other designs, the piston is

sometimes enlarged to provide a stop for its upward motion or for increased strength. If these enlargements are

submerged in liquid, a buoyancy correction is necessary.

4.5 Absence of Friction

By rotating the weights and piston, friction effects are

greatly reduced.

4.6 Head of Transmitting Fluid

Oftentimes, the gauge being tested, or the point at which

pressure is being measured, is not at the same level as

the lower end of the piston. A correction, therefore, should

be made for the pressure distance between these points;

the height is considered positive when the gauge is above

the piston. When oil is used in the gauge tester, the correction will be approximately 0.03 psi (.2 kPa) for each

inch (2.54 cm) difference in level.

4.7 Method of Operation

It is important that the piston be kept floating in mid-position, either spinning or oscillating.

4.8 Levelness

The piston assembly should be vertical to within ±1

degree. A 3 degree tilt to piston axis may cause a .13% of

1% error. The deadweight tester is manufactured and tested to 1/10th of 1% accuracy, to this degree of levelness. A

tilt piston/cylinder axis causes excessive friction, due to

side loading of the piston against the cylinder.

4.9 Cleanliness

The weights have been manufactured and tested to a precision of 0.05%. A buildup of dirt and grease may cause

the weight value to exceed its original tolerance and

produce erroneous pressure readings.

Periodically clean the weights to assure proper

performance.

5.0 MAINTENANCE INSTRUCTION

5.1 General Maintenance

The Deadweight tester and test pump are designed to

serve as precise pressure measuring standards. They are

precision built units and should be cared for in the same

manner as other sensitive laboratory equipment. General

maintenance is limited to cleaning and replacement of Oring packings, which can be done with tools supplied with

the equipment and requires only limited disassembly of

the gauge tester.

The piston supporting the weight platform has been manufactured to very close tolerances. It has an area accuracy

of 1/20th of 1% and a weight accuracy of 1/20th of 1%.

The deadweights have been certified traceable to National

Institute of Standards and Technology with the accuracy of

the finished weights better than 1/20th of 1%. To maintain

deadweight tester accuracy, handle the weights with care

and keep the piston and cylinder in clean condition.

The tester should be flushed with a solvent occasionally,

preferably every six months, so that operating fluid is

always clean. This will prolong component life, and provide

protection against possible sticky action between the piston and cylinder. After cleaning, always lubricate parts

before assembly.

If a deadweight tester is not used for long periods of time,

or if a piston and cylinder assembly is being replaced, the

piston should be removed from the cylinder and coated

with the hydraulic fluid, so that it never operates in a dry

state. When removing or replacing the piston, it should be

rotated back and forth.

Should a piston or cylinder wear excessively, the tester

will leak oil at a high rate, and will not be operable. A new

piston and cylinder assembly should be installed.

Page 16

Piston wear will result from improper or contaminated

lubrication, excessive dirt, or from several years of

continuous use.

5.2 Cleaning

Both the Tester and Test Pump should be cleaned thoroughly whenever the operating fluid is seriously contaminated with dirt, grit, or chemicals. A good practice is to

clean the test unit prior to anticipated periods when the

unit will not be in use.

5.3 To Disassemble for Cleaning

(See Figure 2-1, Figure 2-2 and Figure 5-1)

It is necessary to disassemble only those components

which come in contact with the operating fluid. Complete

disassembly is rarely necessary.

a. Remove pipe extension assembly (58) or piston and

cylinder assembly(67) and (79).

b. Then remove lower or back connection pipe assembly

(64, 66).

5.4 Removing Pump Handle and Piston

a. Remove four retaining rings (8).

b. Slide out two clevis pins (9).

c. Remove clevis (10).

d. Lift hand assembly (4) with piston pin (7) piston (20)

O-ring packing (12, 19) and back-up ring (11)

attached to it, out of piston sleeve (6).

e. Remove back-up washers (18, 11) and O-ring packing

(12, 19).

f. Unscrew piston (20)

g. Remove piston sleeve (6) and O-ring packing (45, 16)

and back-up washers (46, 17)

5.5 Removing Reservoir and Fill Tube

a. Unscrew filler plug (35) from reservoir.

b. Remove gasket (36).

c. Remove reservoir (5) by removing three screws (24).

d. Twist reservoir to free O-ring packing (21) seat.

e. Remove O-ring packing (21) from body (2).

f. Remove fill tube assembly (23) and O-ring packing (27).

g. Remove plug (22).

5.6 Removing Shuttle Valve, Shuttle Valve Plug

and Check Valve

a. Remove set screw (33) and spring (32).

b. Slide shuttle valve piston (31) out of body (2). Operate

back and forth as necessary to dislodge pin (31)

engagement.

c. Remove shuttle pin (31) by pushing it into the shuttle

valve piston cavity using a plastic shaft less than

1

⁄

8

inch (3mm) in diameter.

d. Unscrew shuttle valve plug (43) and remove O-ring

packing (27).

e. Remove check valve spring (14) and check valve (44).

f. Remove O-ring packing (15) from check valve (44).

5.7 Removing Bleeder Valve and Check Valve Assembly

a. Unscrew bleeder valve (51)

b. Unscrew bleed plug (50) and remove O-ring packing

(27).

c. Remove valve spacer (29) check valve spring (14)

and check valve (44).

d. Remove O-ring (15) from check valve (44).

5.8 Removing High Pressure Check Valve

a. Unscrew plug (28) and remove O-ring packing (27).

b. Unscrew adjusting screw (26).

c. Remove guide rod (13), check valve spring (14), and

check valve (44).

d. Remove O-ring packing (15) from check valve (44).

5.9 Removing Release Valve

a. Remove release valve assembly (37) and O-ring

packing (27)

b. Disassemble valve assembly by rotating handle

counter-clockwise until valve stem is free from valve

body.

c. Remove O-ring packing from valve stem.

d. Remove screw (38) and seal (39) by turning counter-

clockwise.

e. Remove O-ring packing (40).

5.10 Removing Displacement Valve

a. Remove displacement valve assembly (41).

b. Remove O-ring packing (27).

c. Remove handle from stem by rotating handle counter-

clockwise. This is not required for normal cleaning.

d. Rotate the stem clockwise (using screwdriver in the

slot at the top of the stem) until it is free from body.

e. Remove nut back-up washers and ring packing from

stem.

5.11 Stem Body from Drip Pan

a. Take out three bolts (25). This is not required for

normal cleaning.

b. Remove body assembly (2) from drip pan (3). This is

not required for normal cleaning.

5.12 Inspection

Visually inspect these parts for wear, damage, chips,

cracks and stripped threads:

Body Assembly Threads

Piston

Piston Sleeve (6)

Displacement Stem and Mating Surface in Body

Back-up Washers

Moving O-ring Packings

Dead Weights

Piston and Cylinder Assembly – DWT1305D

Test Gauges – DWT1327D

Back-up washers must fit snugly into piston sleeve and

into displacement valve body. Then check static (non-moving) packing for pinch marks, tearing or extrusion. Check

all valve seats for scratches and roughness.

Replace all worn or damaged parts. Replace all O-ring

packings at each overhaul. Coat O-ring packings with suitable lubricant before replacing, to prevent sticking and

tearing during assembly and tightening of connections.

5.13 Reassembly

When reassembling, use where possible the wrenches

supplied with the equipment. These wrenches permit

enough leverage to seal all connections. Excessive tightening of parts with tools other than those supplied may

cause distortion and eventual failure of threaded portions

of the tester body assembly casting. When replacing Oring packings, coat them with suitable lubricant to prevent

sticking and tearing during assembly and tightening of

connection.

5.14 To Reassemble

Body assembly on drip pans.

Replace body assembly (2) on drip pan (3) using bolts (25).

5.15 Replacing Displacement Valve

a. Place O-ring packing between back-up washers.

b. Attach back-up washers and O-ring packing to dis

placement valve stem with nut.

c. Thread stem into body from the bottom – use screw

driver in the slot at top of stem.

Page 17

d. Screw stem through body until the back-up washers,

and O-ring packing are fully enclosed in the body.

CAUTION: Do not damage O-ring packing when

threading stem through body.

e. Screw handle onto stem.

f. Replace displacement valve assembly (41) with

O-ring packing (27) in body assembly (2).

5.16 Replacing Release Valve

a. Place O-ring packing (40) in body casting (2) hole.

b. Insert seat (39) into body casting hole.

c. Thread & tighten screw (38) into body casting hole.

CAUTION: Be sure that stem of seat (39) fits into

screw hole.

d. Place O-ring packing on valve stem.

e. Screw handle onto valve stem.

f. Screw valve stem into body until end of stem does not

extend beyond valve body.

CAUTION: Do not damage O-ring packing when

threading valve stem through valve body.

g. Replace O-ring packing (27).

h. Replace release valve assembly (37) in body

assembly (2).

5.17 Replacing High Pressure Check Valve

a. Place O-ring packing (15) on check valve (44).

b. Slide check valve (44), check valve spring (14), and

guide rod (13) into body assembly (2).

c. Replace adjusting screw (26) and screw it in until it

stops.

d. Then turn (26) back two complete revolutions.

e. Replace plug (28) with O-ring packing (27) in body

assembly (2).

5.18 Replacing Bleeder Valve and Check

Valve Assembly

a. Replace O-ring packing (15) on check valve (44).

b. Slide check valve (44), check valve spring (14) and

valve space (29) into body assembly (2).

c. Replace bleed plug (50) with O-ring packing (27) into

body assembly (2).

5.19 Replacing Shuttle Valve, Shuttle Valve Plug and

Check Valve

a. Insert shuttle valve piston (3) into body (2).

b. Slide shuttle pin (31) into 1/8 inch (3mm) diameter

opening adjacent to fill tube (23) port. Apply slight

inserting pressure to shuttle pin (31) with plastic shaft

and operating shuttle valve (30) to insure proper

pin engagement.

c. Replace spring (32) directly behind shuttle pin (31)

and secure with set screw (33). Set screw must be

recessed by .050 inch (12mm) minimum.

d. Replace O-ring packing (15) on check valve (44).

e. Slide check valve (44) and check valve spring (14)

into body assembly (2).

5.20 Replacing Reservoir and Fill Tube

a. Replace plug (22).

b. Replace fill tube assembly (21) and O-ring packing (27).

c. Replace O-ring packing (21) on body assembly (2).

d. Replace reservoir (5) using three screws (24).

e. Replace filler plug (35) and gasket (36) on body.

5.21 Replacing Pump Handle and Piston

a. Replace piston sleeve (6) and O-ring packing (45, 16)

and back-up washers (46, 17) in body assembly (2).

b. Place O-ring packing (12, 19) between back-up

washers (18, 11)

c. Attach back-up washers (18,11) and O-ring packing

(12, 19) to piston (20).

d. Lubricate piston and sleeve.

e. Attach assembled piston to handle assembly (4).

CAUTION: Do not damage O-ring packing (12, 19)

when sliding assembled piston into piston sleeve (6).

f. Attach clevis (10) to handle assembly and to body

assembly (2), using clevis pins (9) and retaining

rings (8).

5.22 Replacing Piston/Cylinder Assemblies

The piston/cylinder assembly for a deadweight tester

should be replaced when excessive wear is detected on

any component part. Worn piston assemblies are usually

noted by:

1. Excessive leakage of operating fluid through piston

assembly when under pressure.

2. Seizure of piston in cylinder.

3. Damaged piston plate, damaged cylinder threads, or

damage to any component part that results in inferior

performance, or malfunctioning of the unit.

The piston/cylinder assembly is available as a unit only.

This assures the user of maximum accuracy in his Omega

Deadweight Tester and maintains certified traceability to

the National Institute of Standards and Technology.

Page 18

Pressure does

not build up when

pumping handle.

Insufficient fluid

level in reservoir.

Piston O-rings

worn or ruptured.

Bleed port check

valve or shuttle

check valve

inoperative.

Fill tube assembly

and filter plugged.

Shuttle valve

pushed in for

small fluid displacement when

large fluid displacement is

required.

Add fluid.

Inspect O-rings

and replace as

necessary. If

O-rings are new,

verify their fluid

compatibility.

Inspect O-rings

and replace as

necessary.

Remove and clean

fill tube assembly.

Refill reservoir

with clean fluid.

Pull shuttle valve

outward from

body.

High pressure

does not increase

when pumping

handle while

shuttle valve is

pushed in.

Air trapped in

pump piston.

Rapid pump handle strokes which

lessen fluid flow

through the pump

piston.

Reprime pump.

Operate pump

handle with

smooth moderate

action.

Pump handle rises

after pumping.

High pressure

check valve O-ring

worn or ruptured.

Inspect O-ring

and replace as

necessary.

Piston plate (with

deadweights)

drops rapidly.*

Unable to hold

constant pressure.

Worn piston and

cylinder assembly.

Use a heavy oil

temporarily.

Replace piston &

cylinder.

Stacked deadweights wobble

when spinning piston plate.*

Damaged deadweights.

Check deadweights for visible

damage (bends,

dents, nicks, etc.)

and alignment.

Piston plate

assembly will not

spin.*

Too heavy an oil

grade being used.

Flush & fill unit

with proper grade

of oil (SAE 20 or

SAE 10).

Replace piston &

cylinder assembly.

Disassemble and

flush complete test

unit with kerosene

or alcohol.

Reassemble unit.

Pressure builds up

when pumping

handle, but

decreases when

pumping is

stopped.

Leakage at outlet

or gauge connections(s).

High pressure

check valve O-ring

worn or ruptured.

Defective pressure

release valve.

Inspect connections and tighten

as necessary.

Inspect O-ring and

replace as necessary.

Hand tighten

release valve.

Inspect release

valve seating surfaces. Replace as

necessary.

Remove release

valve seat and

inspect O-ring

underneath.

Replace as

necessary.

5.4 Troubleshooting Chart

Corrective

Symptom Case Action

Corrective

Symptom Case Action

*These symptoms apply only to the DWT1305D Deadweight

Testers.

Page 19

5.0 RETURN SHIPPING INFORMATION

Company Name

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Phone Number

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

FAX Number – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Person to Contact

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Address

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

email Address

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Model

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Serial Number

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Symptoms

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Page 20

4A

Page 21

REPLACEMENT PARTS

PORTABLE DEADWEIGHT TESTER – TYPE DWT1305D

PORTABLE TEST PUMP – TYPE DWT1327D

Qty.

Item Per

No. Asmy. Part No. Description

21603D001-01 Body Only, Pump

31 LB285A Drip Pan

41603X010-01 Handle

4A 1 636X003-01 Grip

51 LF341A Reservoir

61610C001-01 Sleeve, Piston

71 LA810A Pin, Piston

84 BA221L Retaining Ring

92 LB810A Pin, Clevis

10 1 LD278A Clevis

11 1 607A002-02 Backup Ring

12 1 607A001-02 “O” Ring

13 1 LB802 Guide Rod

14 3 LA242 Spring, Valve

15 4 SSSS882 “O” Ring

16 1 607A001-03 “O” Ring

17 1 607A002-03 Backup Ring

18 1 607A002-01 Backup Ring

19 2 607A001-01 “O” Ring

20 1 614C001-01 Piston, Dual Diameter

21 1 BA122R “O” Ring

22 1 604A003-01 Plug

23 1 615B001-01 Fill Tube Assembly

24 3 605A002-06 Screw, Round Head

25 3 SAFH37 Screw, Allen Socket Head

26 1 LK260A Adjusting Screw

27 6 BA122V “O” Ring

28 1 LK696A Plug

29 1 — Spacer, Valve, Use Item 50

30 1 614B002-01 Piston, Shuttle

31 1 609A001-01 Pin, Shuttle

32 1 612B001-01 Spring, Shuttle Pin

33 1 605A001-01 Set Screw

34 2 LP696 Plug, Shipping

35 1 604B002-01 Plug, Fill

36 1 607A003-01 Gasket, Fill Plug

37 1 LAH292C Valve Assembly, Release

37a 1 328A105-01 Knob

37b 1 LD870B Valve Stem

37c 1 LAH292A Body, Release Valve

38 1 LD83A Scew, Seat

39 1 LD911A Seat

40 2 BA122U “O” Ring

41 1 LAG292C Valve Assembly, Displacement

41a 1 328A105-02 Knob

41 b 1 LE83 Nut

41c 2 LB122 Backup Washer

41d 1 LB870A Stem

41e 1 LAG292A Body, Displacement Valve

42 1 LA521A Sleeve

43 1 604B001-01 Plug, Shuttle Valve

44 3 609B003-01 Check Valve

45 1 BA122W “O” Ring

46 1 607A002-04 Backup Ring

50 1 604B004-01 Plug, Bleed

51 1 609B004-01 Bleed Valve

52 1 618B001 Nameplate

58 1 LK227 Pipe Extension Assembly

PA RTS IN THE SECTION BELOW ARE USED IN

HYDRAULIC SERVICE UNITS. THESE UNITS CAN BE

RECOGNIZED BY THE INCLUSION OF THE LETTER “H”

IN THE MODEL DESIGNATION.

PA RTS IN THE SECTION BELOW ARE USED IN OXYGEN

(DISTILLED WATER) SERVICE UNITS WHICH ARE IDENTIFIED BY THE INCLUSION OF THE LETTER “O” IN THE

MODEL DESIGNATION.

Qty.

Item Per

No. Asmy. Part No. Description

59 2 LD227A Bushing

60 2 LN141 Adapter

61 4 LD186 Collar

62 4 LD117 Nut, Adapter

63 1 LH227A Extension Pipe

64 1 LJ227 Lower Connection Pipe Assembly

65 1 LF227A Lower Connection Pipe

66 1 LG227A Back Connection Pipe

67 — Low Pressure Piston Assembly

1LM869 psig

1 LM869D kg/cm

2

1 LM869E bar & Pascal

79 – High Pressure Piston Assembly

1 LN869 psig

1 LN869D kg/cm

2

1 LN869E bar & Pascal

82 1 LF217 Disc Seat

83 1 LM141 Adapter

1 617C002-01 “O” Ring Kit, Oil

1 617A003-01 Overhaul Kit, Oil (see note 1)

1 LH244A Wrench (1 x 11⁄8)

1 LH244 Wrench (7⁄8 x 1)

1 LG244 Wrench (

5

⁄8)

12 1 607A004-02 “O” Ring

15 4 BA122H “O” Ring

16 1 607A004-03 “O” Ring

19 2 607A004-01 “O” Ring

21 1 BA122E “O” Ring

27 6 BA122D “O” Ring

37 1 LAH292D Valve Assembly, Release

40 2 BA122G “O” Ring

41 1 LAG292D Valve Assembly, Displacement

45 1 BA122F “O” Ring

1 LGG236A Nameplate, Hydraulic

1 617C002-02 “O” Ring Kit, Hydraulic

1 617A003-02 Overhaul Kit, Hydraulic (see note 1)

47 1 LKK236 Oxygen Warning Label

58 1 LK227A Pipe Extension Assembly

59 3 LD227B Bushing

60 3 LN141A Adapter

61 6 LD186A Collar

62 6 LD117A Nut, Adapter

64 1 LJ227A Lower Connection, Pipe Assembly

83 1 LM141A Adapter

*Piston and bushing can only be replaced as a complete assembly, the

part number for this assembly is for:

DWT1305DH – part no. 617B001-01

DWT1305DH – part no. 617B001-02

1 Overhaul kit includes all O-rings required to overhaul pump as

well as piston and bushing assembly.

Page 22

Page 23

WARRANTY/DISCLAIMER

OMEGA warrants this unit to be free of defects in materials and workmanship and to give satisfactory

service for a period of

13 months from date of purchase. OMEGA’s Warranty adds an additional one (1)

month grace period to the normal

one (1) year product warranty to cover handling and shipping

time. This ensures that OMEGA’s customers receive maximum coverage on each product. If the unit

should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no

charge. However, this WARRANTY is VOID, if the unit shows evidence of being damaged as a result of

excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse

or other operating conditions outside of OMEGA’s control. Components which wear or which are damaged

by misuse are not warranted. These include contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. Nevertheless, OMEGA

only warrants that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the total

liability of OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or

special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER

TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of

the return package and on any correspondence.

FOR

WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS OR CALIBRATION,

consult OMEGA for current repair charges. Have

the following information available BEFORE contacting OMEGA:

1. P. O. number to cover the COST of the

repair/recalibration,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

MADE IN

Page 24

M0627/0495

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...