Omega Products DFG 71 Installation Manual

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

DFG 71 Series

Digital Force Gauge

M-4175/0305

DIGITAL FORCE GAUGE

00.0

NG

peak

Lb

OK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

Shop online at

page 2

INTRODUCTION

Model DFG 71 is a state-of-the-art high performance, digital force

gauge which offers a giant, easy-to-read LCD display and high/low

setpoints with color-coded LED indicators for go/no go testing.

These force gauges store up to 1000 data values in memory, which

can be transmitted using RS-232 or Digimatic output formats.

The real time measuring mode is used to display force transients.

Peak measuring mode captures the peak force achieved during a

test. Select measuring units from lbf(ozf), kgf(gf), and N.

IMPORTANT

1. WARNING!! Test samples and fixtures can break or shatter,

wear eye and body protection to avoid injury.

2. WARNING!! REGARDLESS of whether the unit is ON or OFF,

DO NOT exceed the capacity of the gauge. At 110% of the

rated capacity, the overload LED indicator flashes to warn.

NEVER exceed 200% of the rated capacity, or the load cell will

be damaged. Avoid shock load.

3. When mounting DFG-71, use M4 mounting screws with a

maximum insertion depth of 5 mm into the gauge.

4. Measure in line tension and compression forces only. DO NOT attempt to

measure forces perpendicular to the

measuring shaft – damage to load cell

and/or shaft may result.

5. Hand tighten attachments only.

DO NOT use tools.

6. Make sure this gauge and all peripherals are powered down

before attaching any cables.

7. DO NOT disassemble the gauge. Disassembly voids warranty.

8. Recommended recalibration cycle is one year.

DIGITAL FORCE GAUGE

00.0

NGLbOK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

D

IG

I

T

A

L

F

O

R

C

E

G

A

U

G

E

00.0

N

G

Lb

O

K

+

N

G

OVERLOAD

Z

E

R

O

S

E

N

D

P

E

A

K

O

N

O

F

F

page 3

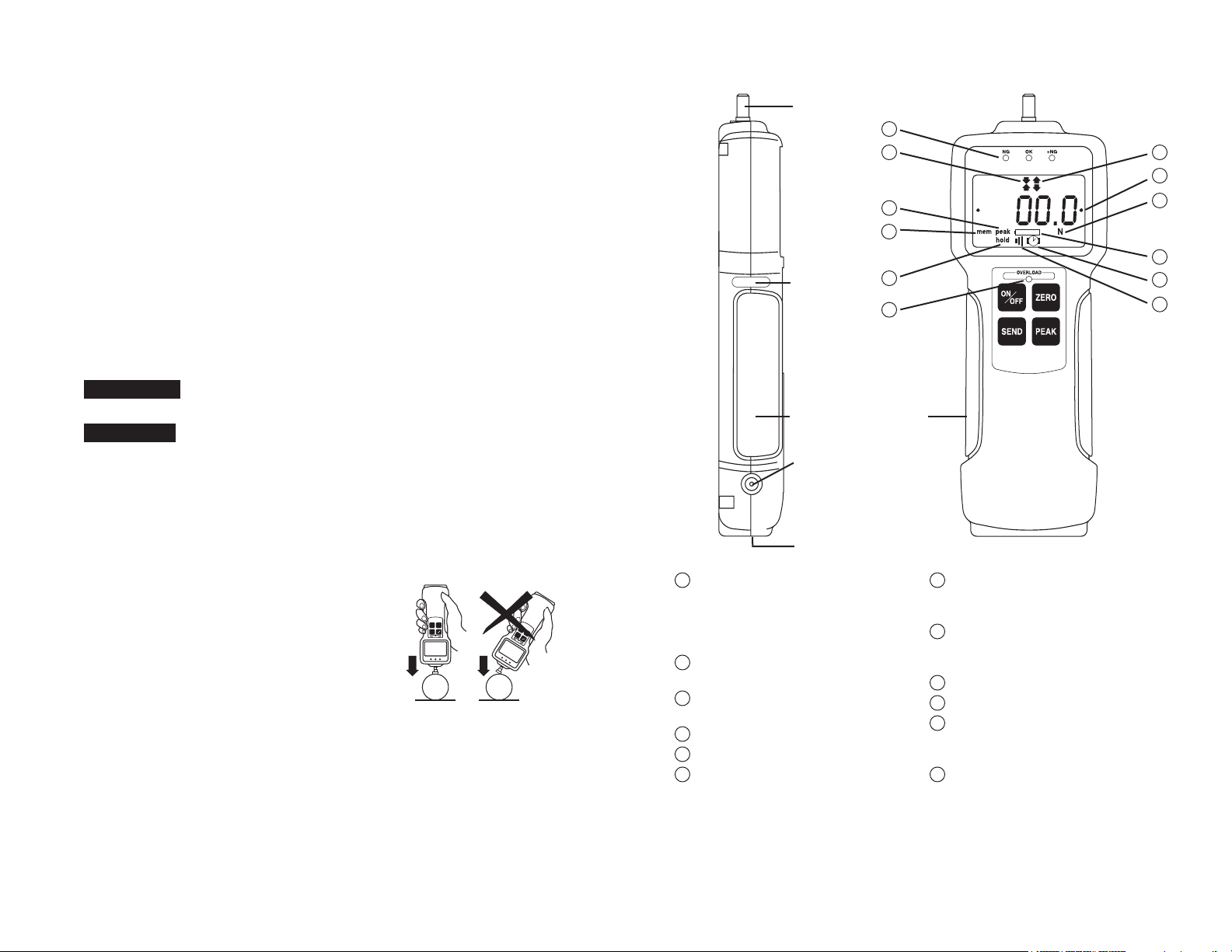

Programmable Setpoint LED’s

When high-low setpoints are set,

LED indicates below (-NG), within

(OK), or above set point value

(+NG).

Compression icon

Indicates compression measurement.

Tension icon

Indicates tension measurement.

Reverse +/– values

Auto Memory - Peak Reset icon

Battery icon

Flashes when Ni-MH cells need

charging.

PEAK icon

Displays continuously when peak

function is active.

HOLD icon

Displays when external hold signal

is active or SEND button is pressed.

Alarm Icon

Auto Power Off icon

Units icon

Displays selected measuring units.

(ozf, Lbf, gf, kgf, or N)

Overload Indicator

Flashes at 110% of rated capacity.

12

11

10

9

8

7

6

5

4

3

2

1

AC ADAPTER/CHARGER

RECEPTACLE

MEASURING SHAFT

WARRANTY

SEAL

NON-SLIP RUBBER GRIP

COMMUNICATION PORT

RS-232, DIGIMATIC & ±2VDC

ANALOG

1

2

3

4

5

6

7

8

9

10

11

12

page 4

OPERATION

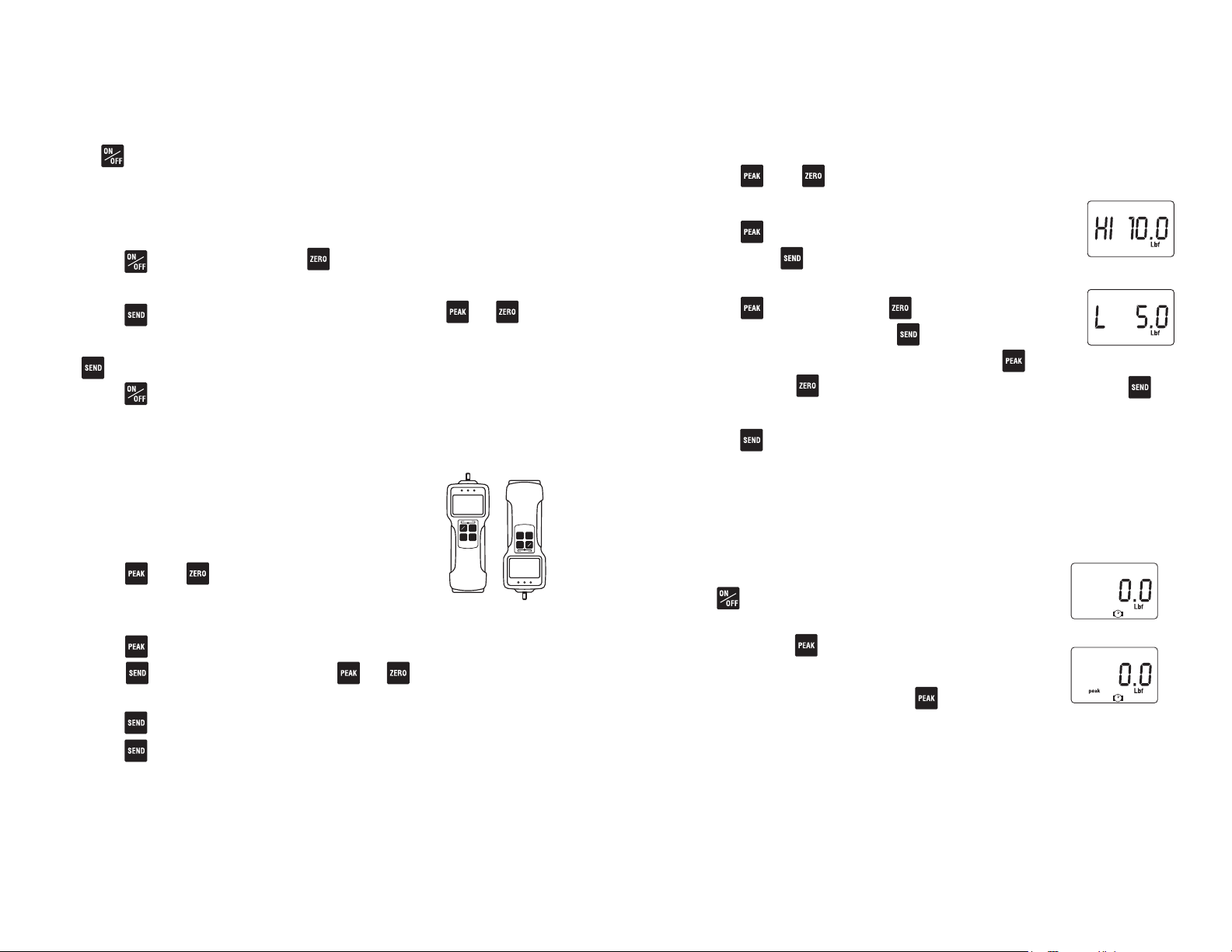

Selecting Units

Press to turn on the gauge. The LCD display briefly shows the

capacity of the gauge and then zero with a measuring unit (factory

setup is lbf). If you want to change to other units:

1. Turn off the gauge.

2. Press again while holding to enter Power-Off program-

ming mode (CF9 flashes with solid nn0).

3. Press to display U-03 with a unit, then press or

to cycle desired units (ozf or lbf, gf or kgf, and N), and press

to select (CF9 flashes with solid End).

4. Press to exit 1st. programming mode.

Once units are selected, the gauge retains them as a default.

page 5

Programming Setpoints (optional)

Program High and Low setpoints for easy GO/NO GO testing.

1. Turn on the gauge

2. Press and for 3 seconds to enter Power-On program-

ming mode (CF9 flashes with solid F0).

3. Press to display flashing CF9 with solid F1,

then press to display –HI– and then the

high set value (i.e. H 10.0).

4. Press to increase and to decrease the

High set value, then press to display –LO–

and then low set value (i.e. L 5.0). Press to

increase and to decrease the Low set value and press to

display flashing CF9 with solid End.

5. Press again to exit Power-On programming mode.

Hand Tighten the selected attachment (No tools!) to the measuring shaft.

HIGH SETPOINT

LOW SETPOINT

Reversing the Display

The factory default is standard display.

To reverse the display:

1. Turn on the gauge

2. Press and for 3 seconds to enter

Power-On programming mode (CF9 flashes

with solid F0).

3. Press 5 times to display flashing CF9 with solid F5, then

press to display -12345. Press or , to cycle between

standard and reverse .

4. Press to select, the display flashes CF9 with solid End.

5 Press again to exit Power-On programming mode.

Once desired display is selected, the gauge retains it as a default.

-12345

DIGITAL FORCE GAUGE

00.0

NGLbOK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

DIGITAL FORCE GAUGE

00.0

NGLbOK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

STANDARD

DISPLAY

REVERSE

DISPLAY

Peak or Real time Measuring Mode

Press to turn on and the gauge automatically

enters real time measuring mode. For peak mea-

surement press . The “Peak icon” appears on

the display. Peak readings will not change until a

higher value is measured. Press again to

return to real time mode.

“Or PEAK“ is the factory default which measures peak compression or peak tension. “And PEAK“ measures both peak compression and peak tension during a test. Refer to the F2 function of

the Power-On programming table for the “And PEAK” function.

REAL TIME MODE DISPLAY

PEAK MODE DISPLAY

Loading...

Loading...