Page 1

ANGULAR PNEUMATIC

GRIPPERS 180° SERIES

DIRECTCONNECT™

No

DCT Series

l Highly Configurable Modular Construction,

Exclusive DIRECTCONNECTTM Technology

l Full Jaw Opening (180°) Allows Part to be

Direct Fed into Gripper, Eliminating One

Additional Motion

l Compact Design for Use in Confined Spaces

l Shielding to Repel Chips for Use in

Harsh Environments

l Repeatability ±0.05 mm (0.002") and

Accuracy of ±0.07 mm (0.0028")

l Up to 5 Million Cycles in Typical

Applications and 10 Million with

Maintenance

l Temperature Rating from -35 to 80°C

(-30 to 180°F)

l System Requires 3 to 7 bar (40 to 100 psi)

Dry Filtered (40 microns or better)

Air Supply

l Accessory Equipment Required—

4-Way 2-Position Pneumatic Control Valve

Apadaptor

Plates

Required

DLT-10M-L-C-100

linear thruster

slide visit

omega.com

EXTT-3CU-26S

thermistor and

RTD extension wire,

visit omega.com

Note: Gripper fingers shown

for reference only, tooling is

customers responsibility.

DCT-16M

Shown smaller

than actual size.

PNEUMATIC SPECIFICATIONS

IMPERIAL METRIC

Pressure Operating Range: 3 to 7 bar

(40 to 100 psi)

Cylinder Type: Double acting

Dynamic Seals: Internally lubricated Buna-N

Valve Required to Operate: 4-way, 2-position

AIR QUALITY REQUIREMENTS

Air Filtration: 40 Micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

TEMPERATURE OPERATING RANGE

Buna-N Seals (Standard): -35 to 80°C

(-30 to 180°F)

FKM Seals (Optional): -30 to 150°C

(-20 to 300°F)

MAINTENANCE SPECIFICATIONS

Expected Life Normal Application:

5 million cycles w/preventative maintenance

10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

* Addition of lubrication will greatly increase service life.

MOUNTING INfORMATION

Grippers Can be Mounted and Operated in Any Orientation

Gripper is located from the

top with 2 dowel pins and

assembled with 2 screws.

Fingers are centered over the

jaws, located with 1 dowel pin

and assembled with 2 screws.

C-25

DIRECTCONNECT mounting pattern:

Gripper is located with 2 dowel

pins and assembled with 4 screws.

Alternative pattern: Gripper is

located with 2 dowel pins and

assembled with 2 screws.

The gripper

is protected

from falling

debris when

it is mounted

and operated

upside down.

Gripper can be

operated utilizing top

manifold air ports.

Page 2

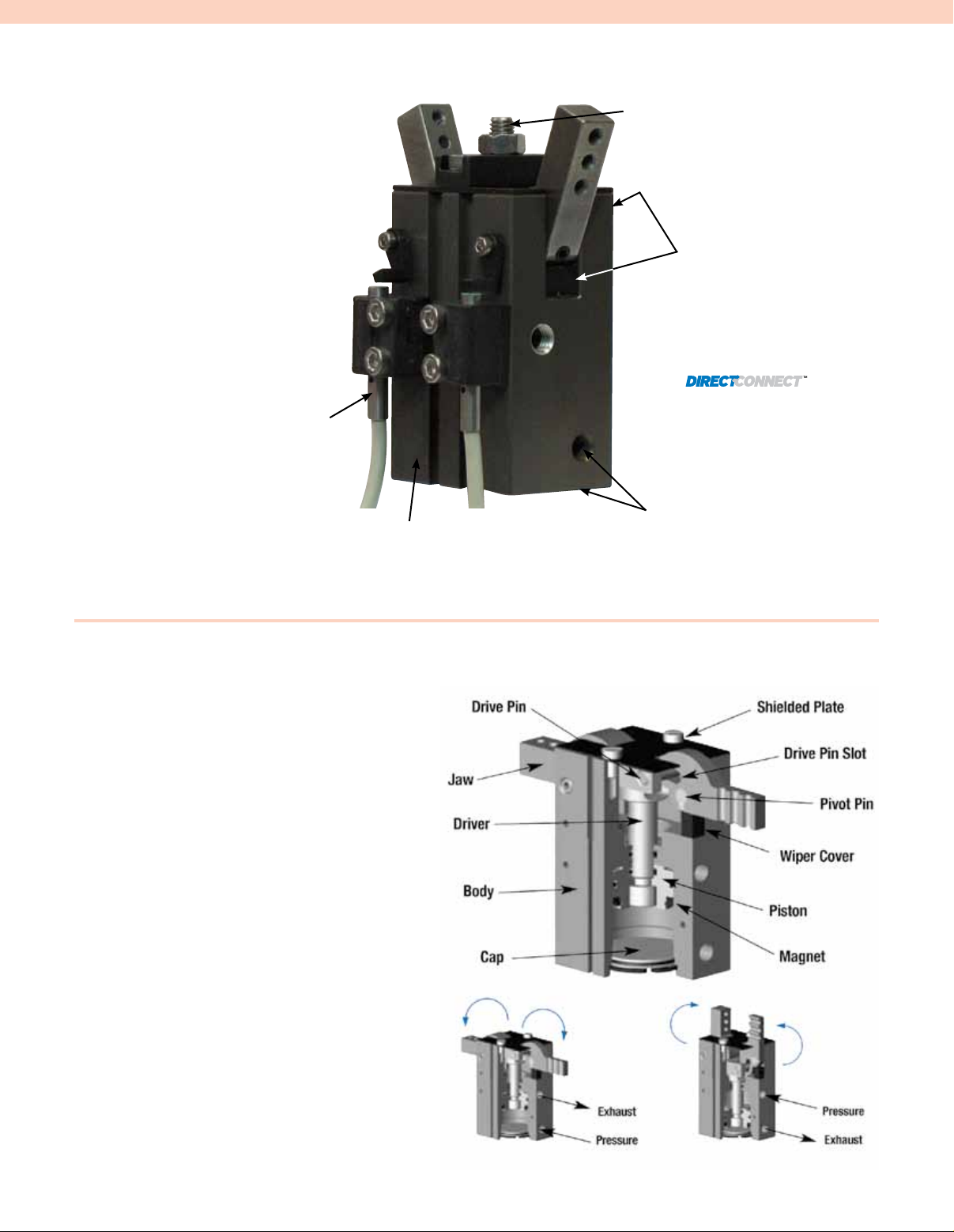

PRODUCT fEATURES

Gripper Attachment

Gripper mounting from

side or bottom

FKM Seals

FKM seals for high temperatures

-30 to 150°C (-20 to 300°F) are optional

Quality Components

Made from aluminum

alloy anodized with

PTFE impregnation.

The gripper’s main

components are made

of heat treated steel.

Inductive Sensor

Accessory (SD) in order to

sense jaw position. Comes

with 2 holders for tubular

sensors and 2 adjustable

flags (except size -12).

Mounting Kit

Magneto Resistive

Sensor Mounting Kit

Standard mounting slots

for magneto resistive sensors.

(sensors sold separately)

Adjustable Stop

Accessory (BR) in order to

adjust the opening of jaws,

between 0° to 180°

Shielded Plate and

Wiper Covers

Gripper body is shielded

to repel chips and other

particulate from internal

drive mechanism

Mounting Patterns

DIRECTCONNECT™

mounting surface on back

of body (sizes 12 to 20)

Multiple

Air Ports

Side or top air

ports (top ports

require O-ring)

OPERATING PRINCIPLE

l A Double Acting Piston, with a Ring

Magnet for Magneto Resistive Sensing,

is Connected to a Fork Driver on which

2 Drive Pins are Fixed

l Jaw Rotation is Synchronized with the

Drive Pin-Jaw Assembly

l Sliding in These Slots, Drive Pins Convert

Vertical Motion of the Piston into Rotating

Opposite Synchronous Motion of Both Jaws

l Each Jaw Has a Useful Rotation Stroke of

90°, Between the 90° Open Position and

the 0° Gripping Position, Plus a Gripping

Over-Stroke of Approximately 1.5° Before

Reaching the Fully Gripped Position; Jaws

Have to be Designed for a 0° Gripping

Position (Parallel Jaws)

C-26

Page 3

90°

36.5

(1.437)

90°

9

(0.35)

C

L

C

L

g6]

[

2.5E7]THRU

[6.00

56.00

(2.2047)

8

(0.31)

10

(0.39)

2x[M3] THRU

16.5

(0.650)

9

(0.35)

Side airport

CLOSE

x6DP]

[5M

Side air port

OPEN

x6DP]

1.6

(0.063)

48

(1.89)

0.2362

-0.0005

-0.0002

2 Slotstomount

magnetic sensors

35.5

(1.398)

C

L

C

L

[3Mx5.5DP]

20

(0.79)

24.50

(0.9646)

(suppliedplugged)

CLOSE

Topair port

OPEN

(suppliedplugged)

Topair port

9

(0.35)

30

(1.18)

8.6

(0.339)

x7DP]32x[M

14.50

(0.5709)

[M3x5.5 DP]

2x[

2.5H9x4.5DP]

Shielded plate

C

L

Jaws in

gripping

position

at 0°

C

L

18

(0.71)

6.0

(0.236)

25

(0.98)

2x[M3x7DP]

64

(2.52)

24.50

(0.9646)

14.50

(0.5709)

2x[

2.5H9x4.5DP]

20.00

(0.7874)

12.50

(0.4921)

O-Ring

[1 x 3]

Gripper's

top air port

Our grippers are supplied

with open side air ports and

top air ports plugged.

When operating top air

ports, produce manifold

sealing as shown.

4x[M3x7DP]

3H7 x6DP]

9.5

(0.375)

2x[

19.05

(0.7500)

[5M

ø3

(0.12)

ø5

(0.2)

0.8

(0.03)

DCT-12M DIRECTCONNECTTM

4

3

2

1

0

16

12

8

4

0

lbs.

N

EFFECTIVE FINGER LENGTH FROM ROTATION AXIS - L

- ECROF REGNIF 2/F

GRIP FORCE PER FINGER @ 0°

1

25

1.5

35

2.5 in.

65mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

2.0

50

ISP 001 ]rab 7[

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

ISP 04 ]rab 7.2[

SPECIFICATIONS DCT-12M

Total Rated Grip Force, F @ 7 bar (100 psi)

L = 25 mm (1") @ 0°: 32 N (7.2 lb)

Stroke: 90° of stroke for each finger

Weight: 0.09 Kg (0.20 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Cylinder Bore Ø: 12 mm (0.472")

Displacement: 1.92 cm3 (0.117 in3)

TEMPERATURE RANGE

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 150°C (-20 to 300°F)

Actuation: 0.06 sec

Accuracy: ±0.07 mm (±0.0028")

Repeatability: ±0.05 mm (±0.002")

Valve Required to Actuate: 4-way, 2-position

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

LOADING INfORMATION

- ECROF REGNIF 2/F

lbs.

N

4

16

3

12

2

8

1

4

0

0

1

25

EFFECTIVE FINGER LENGTH FROM ROTATION AXIS - L

Third Angle

Projection

GRIP FORCE PER FINGER @ 0°

Metric Threads

Course Pitch

ISP 001 ]rab 7[

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

1.5

35

ISP 04 ]rab 7.2[

2.0

50

MAXIMUM EFFECTIVE

Imperial inch

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.0005 0.00 = ±0.013

WARNING!

DO NOT EXCEED

FINGER LENGTHS

2.5 in.

65mm

0.00 = ±0.0 0.0 = ±0.25

Dimensions: mm (inch)

Notes: DirectconnectTM dimensions are shown in blue.

Metric mm

LOADING CAPACITY† STATIC DYNAMIC

DCT-12M

Maximum Tensile T 47 N (11 lb) 9.4 N (2 lb)

Maximum Compressive C 47 N (11 lb) 9.4 N (2 lb)

Maximum Moment Mx 1.1 Nm (10 in-lb) 0.3 Nm (3 in-lb)

Maximum Moment My 1.1 Nm (10 in-lb) 0.3 Nm (3 in-lb)

Maximum Moment Mz 1.1 Nm (10 in-lb) 0.3 Nm (3 in-lb)

†

Capacities are per set of jaws and are not simultaneous.

C-27

Jaws have to be designed for a 0° gripping position

(parallel jaws).

Jaws will close 1.5° past parallel. To limit shocks at

the end of an opening or closing stroke, it is highly

recommended to design jaws with minimal inertia

(as light and short as possible).

Flow Controls make it possible to reduce the rotation

speed and are highly recommended.

L

C

Z

Y

T

F/2

Mx

Z

Mz

My

F/2

X

Page 4

O-Ring

[1 x 3]

Gripper's

top air port

Our grippers are supplied

with open side air ports and

top air ports plugged.

When operating top air

ports, produce manifold

sealing as shown.

(0.453)

11.5

9 °0

40.5

(1.594)

(0.67)

17

°09

C

L

C

L

CLOSE

(suppliedplugged)

x5.5 DP]

Top airport

10

(0.39)

(1.1417)

29.00

9

x9DP]42x[M

[M3x5.5DP]

OPEN

(supplied plugged)

(0.98)

[M3

25

Top airport

(1.42)

36

(0.35)

(0.7087)

18.00

2x[

3H9x6DP]

C

L

C

L

C

L

5x6DP]

56

Sideair port

(0.807)

[M

(0.39)

0.0002

]THRU32x[M

-

0.0006

-

0.3150

(0.31)

(2.5197)

10

(0.39)

(2.20)

g6]

10

8

64.00

Side air port

CLOSE

x6DP]

OPEN

20.5

(0.08)

2

[8

[

2.5E7] THRU

2Slots to mount

magnetic sensors

41.5

(1.634)

23.5

(0.925)

(0.35)

9

4x[M3x5.5DP]

C

L

Shielded plate

Jaws in

gripping

position

at 0°

C

L

x7DP]

(0.7500)

19.05

4x[M3

(0.375)

2x[3H7 x6DP]

9.5

29.00

3

(1.1417)

(1.043)

26.5

(2.83)

2x[

20.00

(0.315)

20

(0.79)

72

8.0

(0.7087)

18.00

H9 x5.5 DP]

(0.7874)

(0.5512)

14.00

2x[M4x9DP]

[M5

ø3

(0.12)

ø5

(0.2)

0.8

(0.03)

9

7

4

2

0

40

30

20

10

0

lbs.

N

EFFECTIVE FINGER LENGTH FROM ROTATION AXIS - L

- ECROF REGNIF 2/F

GRIP FORCE PER FINGER @ 0°

1

25

1.25

32

1.75

44

2.25

57

2.5

64

1.5

38

2.75 in.

70mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

2.0

51

ISP 001 ]rab 7[

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

ISP 04 ]rab 7.2[

DCT-16M DIRECTCONNECTTM

SPECIFICATIONS DCT-16M

Total Rated Grip Force, F @ 7 bar (100 psi)

L = 25 mm (1") @ 0°: 70 N (16 lb)

Stroke: 90° of stroke for each finger

Weight: 0.16 Kg (0.35 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Cylinder Bore Ø: 16 mm (0.630")

Displacement: 4.12 cm3 (0.251 in3)

TEMPERATURE RANGE

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 150°C (-20 to 300°F)

Actuation: 0.13 sec

Accuracy: ±0.07 mm (±0.0028")

Repeatability: ±0.05 mm (±0.002")

Valve Required to Actuate: 4-way, 2-position

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

LOADING INfORMATION

N

40

30

- ECROF REGNIF 2/F

20

10

0

Third Angle

Projection

lbs.

9

7

GRIP FORCE PER FINGER @ 0°

4

2

Metric Threads

Course Pitch

ISP 001 ]rab 7[

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

ISP 04 ]rab 7.2[

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

0

1

1.25

25

32

EFFECTIVE FINGER LENGTH FROM ROTATION AXIS - L

1.5

38

1.75

44

2.0

51

2.25

57

2.5

64

Imperial inch

0.00 = ±0.0 0.0 = ±0.25

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.0005 0.00 = ±0.013

2.75 in.

70mm

Dimensions: mm (inch)

Notes: DirectconnectTM dimensions are shown in blue.

Metric mm

Jaws have to be designed for a 0° gripping position

(parallel jaws).

Jaws will close 1.5° past parallel. To limit shocks at

the end of an opening or closing stroke, it is highly

recommended to design jaws with minimal inertia

(as light and short as possible).

Flow Controls make it possible to reduce the rotation

speed and are highly recommended.

L

LOADING CAPACITY† STATIC DYNAMIC

DCT-16M

Maximum Tensile T 90 N (20 lb) 18 N (4 lb)

Maximum Compressive C 90 N (20 lb) 18 N (4 lb)

Maximum Moment Mx 2.9 Nm (26 in-lb) 0.7 Nm (6 in-lb)

C

Z

Y

T

F/2

Mx

Z

Maximum Moment My 2.9 Nm (26 in-lb) 0.7 Nm (6 in-lb)

Maximum Moment Mz 2.9 Nm (26 in-lb) 0.7 Nm (6 in-lb)

†

Capacities are per set of jaws and are not simultaneous.

C-28

Mz

My

F/2

X

Page 5

O-Ring

[1 x 3]

Gripper's

top air port

Our grippers are supplied

with open side air ports and

top air ports plugged.

When operating top air

ports, produce manifold

sealing as shown.

(0.531)

13.5

90°

(0.87)

22

°09

(1.949)

49.5

C

L

C

L

C

L

[10g6]

5

11

(0.43)

x6DP]

Sideair port

Side air port

CLOSE

0.3937

68

(3.1102)

x6DP][M

(2.68)

79.00

24.5

5

(0.31)

0.0002-

[M

-0.0006

(0.965)

OPEN

4] THRU2x[M

8

12

(0.47)

(0.102)

2.6

[

3E7] THRU

C

L

C

L

Top air port

x5.5 DP]

(1.3189)

Top air port

[M

OPEN

(supplied plugged)

30

x5.5 DP]3[M

(1.18)

3

33.50

CLOSE

(supplied plugged)

(0.43)

42

11

10

x11 DP]52x[M

(0.39)

(1.65)

(0.8465)

21.50

2x[

4H9 x8DP]

2Slots to mount

magnetic sensors

51.5

(2.028)

29

(1.14)

(0.35)

9

4x[M3x5.5DP]

C

L

Shielded plate

Jaws in

gripping

position

at 0°

C

L

4x[M

22.00

33

(0.87)

22

5

(1.3189)

21.50

10.0

(1.30)

4

89

33.50

(3.50)

H9 x8DP]

(0.8465)

2x[

x6DP]

(0.394)

(0.8661)

(0.7087)

18.00

(0.7500)

(0.375)

2x[

x6DP]

3H7x6DP]

4x[M3

19.05

9.

5

ø3

(0.12)

ø5

(0.2)

0.8

(0.03)

DCT-20M DIRECTCONNECTTM

13

11

9

7

4

2

0

60

50

40

30

20

10

0

lbs.

N

EFFECTIVE FINGER LENGTH FROM ROTATION AXIS - L

- ECROF REGNIF 2/F

GRIP FORCE PER FINGER @ 0°

1.25

32

1.75

44

2.25

57

2.75

70

3.25 in.

83mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

ISP 001 ]rab 7[

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

ISP 04 ]rab 7.2[

SPECIFICATIONS DCT-20M

TOTAL RATED GRIP FORCE, F @ 7 bar (100 psi)

L = 25 mm (1") @ 0°: 112 N (25 lb)

Stroke: 90° of stroke for each finger

Weight: 0.28 Kg (0.62 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Cylinder Bore Ø: 20 mm (0.787")

Displacement: 7.92 cm3 (0.483 in3)

TEMPERATURE RANGE

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 150°C (-20 to 300°F)

Actuation: 0.16 sec

Accuracy: ±0.08 mm (±0.003")

Repeatability: ±0.05 mm (±0.002")

Valve Required to Actuate: 4-way, 2-position

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Third Angle

Projection

Metric Threads

Course Pitch

Imperial inch

0.00 = ±0.0 0.0 = ±0.25

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.0005 0.00 = ±0.013

Metric mm

Dimensions: mm (inch)

Notes: DirectconnectTM dimensions are shown in blue.

Jaws have to be designed for a 0° gripping position

(parallel jaws).

Jaws will close 1.5° past parallel. To limit shocks at

the end of an opening or closing stroke, it is highly

recommended to design jaws with minimal inertia

(as light and short as possible).

Flow Controls make it possible to reduce the rotation

speed and are highly recommended.

LOADING INfORMATION

- ECROF REGNIF 2/F

lbs.

N

13

60

11

50

9

40

7

30

4

20

2

10

0

0

GRIP FORCE PER FINGER @ 0°

ISP 001 ]rab 7[

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

1.25

32

EFFECTIVE FINGER LENGTH FROM ROTATION AXIS - L

1.75

44

ISP 04 ]rab 7.2[

2.25

57

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

2.75

70

WARNING!

3.25 in.

83mm

Y

Z

Mz

My

F/2

X

F/2

Z

T

C

Mx

LOADING CAPACITY† STATIC DYNAMIC

DCT-20M

Maximum Tensile T 150 N (34 lb) 30 N (7 lb)

Maximum Compressive C 150 N (34 lb) 30 N (7 lb)

L

Maximum Moment Mx 6 Nm (53 in-lb) 1.5 Nm (13 in-lb)

Maximum Moment My 6 Nm (53 in-lb) 1.5 Nm (13 in-lb)

Maximum Moment Mz 6 Nm (53 in-lb) 1.5 Nm (13 in-lb)

†

Capacities are per set of jaws and are not simultaneous.

C-29

Page 6

20 (0.79)

MAX

6 (0.24)

8 (0.31)

11.7 (0.46)

15 (0.59)

5.5 (0.22)

12.3 (0.48)

20.5 (0.81)

INDUCTIVE SENSORS AND

MOUNTING KIT (SD)

ADJUSTABLE

STOP KIT (BR)

4 (0.16)

45.5 (1.79)

6 (0.24)

Sensors

Ø4 (0.16)

10 (0.39)

M5

ACCESSORIES DIAGRAM

Dimensions: mm (inch)

To Order Visit omega.com/dct_series for Pricing and Details

MODEL NO. DESCRIPTION FORCE N (lb)

DCT-12M 180° Series angular gripper with 18 mm (0.71") jaw opening 32 (7.2)

DCT-16M 180° Series angular gripper with 20 mm (0.79") jaw opening 70 (16)

DCT-20M 180° Series angular gripper with 22 mm (0.87") jaw opening 112 (25)

Note: Sensor and cable sold separately. Inductive sensor not available on DCT-12M.

Ordering Example: DCT-12M, 180° Series pneumatic angular gripper with 18 mm (0.71") jaw opening and gripper force of 32 N (7.2 lb). See

air fittings for M5 threaded flow control valve, highly recommended due to jaw closing 1.5° past parallel. Suggested accessories include two

PNP magneto resistive sensors with short 90° barrel OHSP-011, and BR-CT-16, adjustable stop kit.

Quick disconnect sensors will require cable, CABL-013, with 5 m (16') length. See accessory table below. DCT-16M, 180° Series pneumatic

angular gripper with 20 mm (0.79") jaw opening and gripper force of 70 N (16 lb). See air fittings for M5 threaded flow control valve, highly

recommended due to jaw closing 1.5° past parallel. Suggested accessories include two PNP inductive quick disconnect sensors, OISP-014,

with two mounting kits, SD-CT-16 and BR-CT-16, adjustable stop kit. Quick disconnect sensors will require cable, CABL-013, with 5 m (16')

length. See accessory table below. CAD file available at omega.com.

ACCESSORIES

MODEL NO. QUANTITY DESCRIPTION

OISP-014 1 or 2 4 mm PNP inductive sensor with quick disconnect

OISN-014 1 or 2 4 mm NPN inductive sensor with quick disconnect

OHSP-017 1 or 2 PNP magneto resistive sensor long barrel with quick disconnect

OHSN-017 1 or 2 NPN magneto resistive sensor long barrel with quick disconnect

OHSP-011 1 or 2 PNP magneto resistive sensor short 90° barrel with quick disconnect

OHSN-011 1 or 2 NPN magneto resistive sensor short 90° barrel with quick disconnect

CABL-010 1 or 2 Quick disconnect cable 2 m (6') in length

CABL-013 1 or 2 Quick disconnect cable 5 m (16') in length

BR-CT-12 1 Adjustment stop kit (1 stop and 1 shielded plate) for DCT-12M

BR-CT-16 1 Adjustment stop kit (1 stop and 1 shielded plate) for DCT-16M

BR-CT-20 1 Adjustment stop kit (1 stop and 1 shielded plate) for DCT-20M

SD-CT-16 1 or 2 Inductive sensor mounting kit for DCT-16M

SD-CT-20 1 or 2 Inductive sensor mounting kit for DCT-20M

C-30

Loading...

Loading...