Page 1

TABLE OF CONTENTS

In Chapter 1

Contents

Features at a Glance

Chapter 1 Introduction & Installation

Features and Configurations

DATAshuttle Model Variations

Installing Your DATAshuttle

Physical Installation

DATAshuttle Operator’s Manual

iii

1 – 4

1 – 6

1 – 8

1 – 9

i

Page 2

DATA

shuttle

In Chapter 2

OPERATOR’S MANUAL

Table of Contents

ii

Contents

Chapter 2 Technical Notes

Using EDITCAL

Auxiliary Analog and Digital Components

Counter/Timer

Use With the AC Development System

Troubleshooting: Installation

Troubleshooting: Operation

Product Specifications

2 – 3

2 – 4

2 – 12

2 – 13

2 – 14

2 – 15

2 – 18

Page 3

DATA

shuttle

OPERATOR’S MANUAL

Table of Contents

iii

Page 4

TABLE OF CONTENTS

Features At A Glance

Highlights of the DATAshuttle

Maximum Resolution

DATAshuttle-16:

DATAshuttle-12:

16 Bits (.0015%)

12 Bits (.024%)

Maximum Speed

DATAshuttle-16:

DATAshuttle-12:

All DATA

8 Differential analog input channels · Dynamic resolution ·

8 Digital I/O lines, user configurable, with provision for

digital isolation modules · Six voltage input ranges, and

Autoranging · Wide acceptance of sensor devices · High

noise rejection integrating converter · Software

linearization for RTDs and Thermocouples · Input protection

to 50 Volts continuous · On-unit counter/timer · Two

optional analog output channels · Parallel passthrough port

for multiple DATAshuttles or printer on same port · Factory

guaranteed accuracy for two years from date of purchase

shuttle

2 kHz

5 kHz

s Feature

DATAshuttle Operator’s Manual

iv

Page 5

DATA

shuttle

OPERATOR’S MANUAL

Table of Contents

v

Page 6

TABLE OF CONTENTS

DATAshuttle Operator’s Manual

vi

Page 7

INTRODUCTION & INSTALLATION

Chapter 1: Introduction &

Installation of the DATAshuttle

General Information

Thank you for selecting the DATA

Our primary objective is to provide you with data acquisition systems that are

easy to install, operate, and maintain. We also strive to furnish the performance you need at the lowest overall cost. The benefits for you are increased

productivity, data you can count on, and, of course, meeting your budget.

We manufacture the DATA

plugs into the parallel port of an IBM, or compatible, desktop or portable computer.

The product’s high noise rejection, input protection to withstand as much as

50 Volts, and guaranteed long term stability make it ideal both for the laboratory and for harsh industrial environments. With its parallel port interface,

built-in terminal panel, and compact, light size, the DATA

pletely portable, providing for a quick and easy set-up in both in-house labs

and remote test sites.

Using the DATA

ware (such as WorkBench PC™ for Windows or DOS, or QuickLog™ PC),

you can easily and very quickly implement a broad spectrum of research and

commercial tasks, in a wide variety of settings. You can, for example,

· Display, and log data

· Measure temperature, pressure, flow

· Capture maximums, minimums, averages, or differences

shuttle

shuttle

together with our graphical interface application soft-

shuttle

for your project!

as an enhancement product that readily

shuttle

is also com-

to disk for later analysis,

and most other analog inputs

from sensors and instruments,

surements,

of mea-

· Monitor and control processes

· Set alarm limits

· Control devices at preset levels

· Control devices from digital input

· Gather data unattended

Y ou can use the system interactively, operating controls or modifying your setup while the system is running.

on any input,

,

(fans, pumps, heaters, etc.),

(from switches or TTL signals), and

.

DATAshuttle Operator’s Manual

1 – 1

Page 8

DATA

DEVELOPMENT

EXPANDABILITY

RANGES/

DATA

shuttle

OPERATOR’S MANUAL

General Information

SYSTEM

People who decide, on the other hand, to write their own software

(rather than using an off-the-shelf application) can employ the

Analog Connection Development System™ hardware driver to

address all features of the unit from within a program they design

and code for their specific purpose.

UNITS OF MEASURE

PRESENTATION

All DA T A

8 digital input/output lines; and you can add one DA T A

shuttle

s have eight differential analog input channels and

shuttle

at a

time to your computer, for as many as 15 units with a total of 120

analog input channels and 120 digital I/Os!

The six input ranges of the DATA

shuttle

span from 50 milliVolts

through 10 Volts DC, making it capable of accepting data from almost any sensor. You can, as well, install a resistor, making the

DATA

shuttle

capable of DC current measurements.

Its high accuracy makes the DATA

shuttle

ideal for precise evalua-

tions in the laboratory or field.

The DA T A

shuttle

together with our software – such as W orkBench

PC for Windows or DOS and QuickLog PC – make it easy to specify engineering units (degrees, volts, milliAmperes, etc.) for measurements, as well as which ranges to use.

(You can measure temperature, for example, by selecting from

among 11 different thermocouple types, or from a wide variety of

resistance temperature devices – RTDs. With the application software, the process simply consists of selecting the type of sensing

device from a menu – the driver itself automatically handles cold

junction compensation and linearization.)

The combination of OMEGA hardware and application software

(WorkBench PC for Windows or DOS or QuickLog PC) enables

both the display of data on the screen, and the logging of data to

disk for later analysis.

Chapter 1 Introduction

1 – 2

The system is capable of showing data on the monitor in a variety

of formats. On-screen meters can provide accurate readings of any

parameter on any channel. Chart displays can indicate trends for

comparison of actual measurements on several channels, or for

setting data points or alarms.

Page 9

INTRODUCTION & INSTALLATION

DYNAMIC

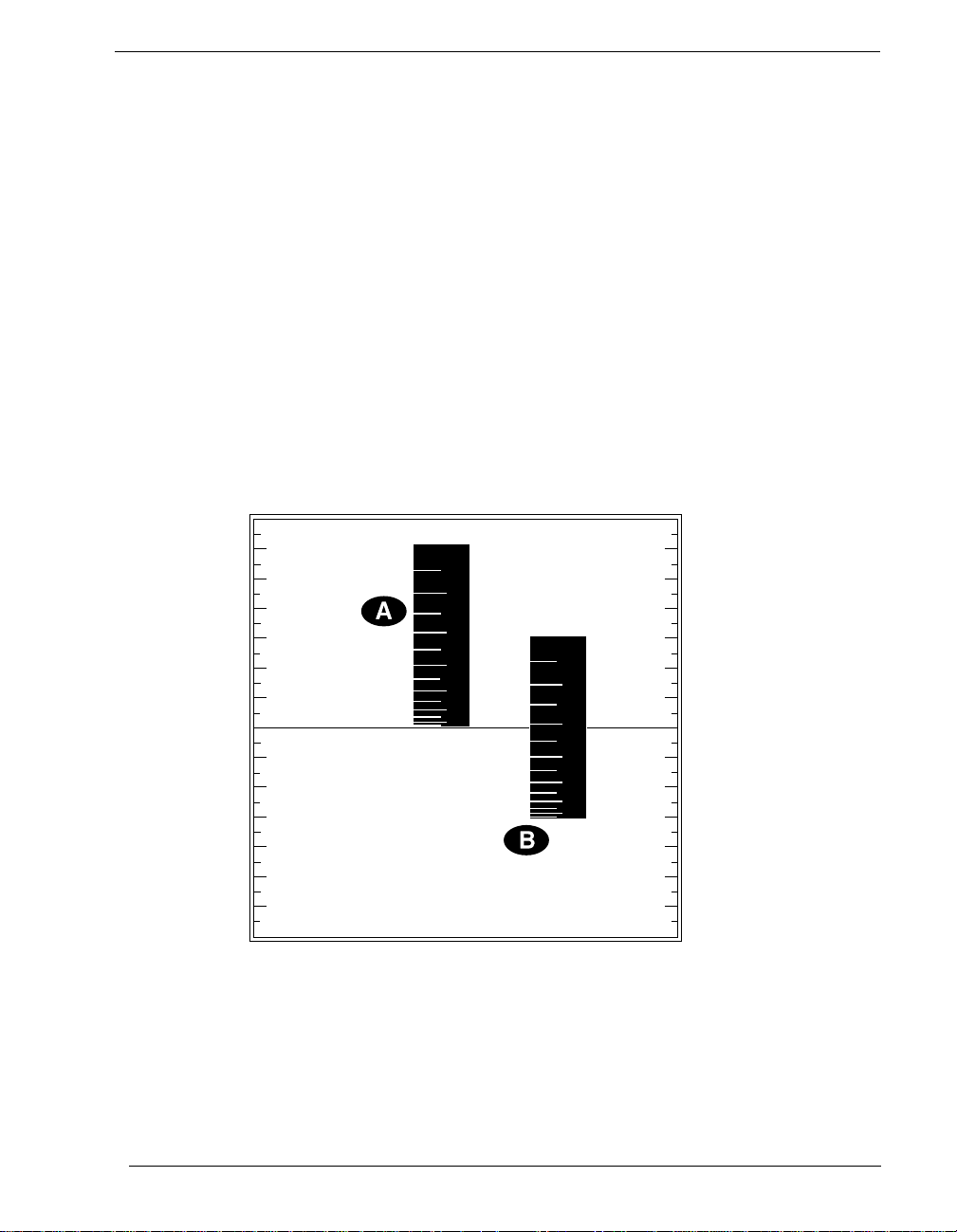

Dynamic Resolution

RESOLUTION

All DATA

shuttle

s incorporate “Dynamic Resolution,” which

improves the unit’s accuracy.

With this feature, resolution is greater at the lower (negative) end

of any range than at the higher end. As your readings approach

the low end of any given range, the resolution becomes finer (that

is, the increments of the signal you can distinguish become

smaller).

Dynamic resolution improvement is most noticeable when the

signal remains below a 10% of full scale threshold (approximately). Our products, consequently, are the best available for

taking accurate measurements of low-level signals, as you would

using a thermocouple sensor.

Dynamic resolution is always best toward the negative end of any

range:

Figure 1. Dynamic Resolution for Dissimilar Ranges –

+

10

10

range

5

+

5

–

-5

–

-5

range

-10

Two vertical black “rulers” (range A and range B) portray the impact of

Dynamic Resolution. Their graduations – representing their ability to

resolve – are always finer at the lower (more negative) ends of their

ranges, regardless of the spectrum of values the ranges are measuring.

-10

DATAshuttle Operator’s Manual

1 – 3

Page 10

DATA

ANALOG

RESOLUTION

DATA ACQUISITION

RANGES

NOISE

SENSORS

ACCURACY

INPUT

DIGITAL I/O

COUNTER/TIMER

ANALOG OUTPUT

shuttle

OPERATOR’S MANUAL

Features and Configurations

Features and Configurations

INPUT CHANNELS

SELECTIONS

SPEED

REJECTION

The DA TA

is, .024% of signal), while the DATA

resolution (.0015% of signal). The units possess these features:

Both the DA T A

ential analog input channels.

The resolution of the DATA

the DATA

With the DATA

(These products also feature advanced “dynamic resolution.” See

page 1 – 3 for further explanation.)

The data acquisition rate for the DA TA

5 kHz at 9 bits, in burst mode, while the maximum rate for the

DATA

DATA

ranges, all selectable individually for each analog input channel.

All DATA

noise rejection integrating converter (in “low noise mode” it helps

reject 50/60 Hz AC power line interference).

The DATA

and linearization for thermocouple devices, and signal conditioning for resistance temperature devices (RTDs).

shuttle

-12 is capable of attaining 12 bit resolution (that

shuttle

-12 and the DA T A

shuttle

shuttle

-12, resolution ranges from 9 through 12 bits.

shuttle

-16, it extends from 12 through 16 bits.

shuttle

-16 is 2.0 kHz at 12 bit resolution.

shuttle

-12 and DATA

shuttle

-12 and DATA

shuttle

supports accurate cold junction compensation

shuttle

-16 products have six voltage

shuttle

shuttle

-16 can achieve 16 bit

shuttle

-16 have eight differ -

s is selectable in software. For

shuttle

-12 reaches as high as

-16 models feature a high

PROTECTION

CHANNELS

Chapter 1 Introduction

1 – 4

We guarantee the factory calibration of the DATA

period of two years from the date of purchase. Calibration constants are stored in non-volatile memory on each DATA

Built-in circuitry assures protection of analog input channels for

±50 Volts continuous.

All DATA

the user can configure individually to be input or output.

Every DATA

(for counting pulses or other events) which you can also use as a

pulse output.

All DATA

output channels with one current (4-20mA) and six voltage

ranges, software selectable.

shuttle

s feature eight digital input/output channels that

shuttle

includes a counter/timer for precise timing

shuttle

-AO models feature two optional 12-bit analog

shuttle

for a

shuttle

.

Page 11

INTRODUCTION & INSTALLATION

FOR MORE

SYSTEM

PACKAGE CONTENTS

Features and Configurations

INFORMATION

REQUIREMENTS

For more information about the capabilities of your DATA

shuttle

please see the “Product Specifications” in Chapter 2.

For instructions on controlling the unit with our interface soft-

ware (such as WorkBench PC for DOS or Windows or QuickLog

PC), refer to that particular software manual.

To learn more about data acquisition and process control in general, and how to use the Analog Connection systems together to

accomplish everyday tasks, consult our

Applications

manual.

And, last but not least, if you’re creating your own program to

address the unit for a custom purpose, please see the

nection Development System

Before installing the DA T A

manual

shuttle

.

, make sure the computer system

Analog Con-

fulfills these minimum requirements:

Hardware –

· IBM PC AT (or higher) or -compatible

, with at least 640k

system RAM,

· Floppy disk drive

Software Environment –

· DOS 3.0

(or higher, depending on the application software),

· Application software

and a hard drive.

(WorkBench PC for DOS or Windows,

QuickLog PC, the Analog Connection Development System, or other compatible proprietary software; please see

your software manual for directions for using it with the

DATAshuttle).

,

Your DATA

·

One DATAshuttle

·

One 6V 1A AC Adapter (for U.S. market; may differ for inter-

·

One parallel cable (DB-25 M-F)

·

This manual, including DATAshuttle, QuickLog PC, Applica-

·

One QuickLog PC Disk

·

One AC Development Disk

shuttle

package should include:

national markets)

tions, and AC Development System

DATAshuttle Operator’s Manual

1 – 5

Page 12

DATA

DATA

GP

DATA

RTD

shuttle

OPERATOR’S MANUAL

DATAshuttle-GP and DATAshuttle-RTD

DATAshuttle Model Variations

Parallel Input

Connector

Serial Number

& Model Type

5-9V DC In

shuttle

shuttle

The DATA

shuttle

family line offers 3 basic model variations, each

available with either 12- or 16-bit resolution and 2 optional analog outputs, for a total of 12 model types.

The DS-12-8-GP and DS-16-8-GP are general purpose units

-

designed for all types of inputs. The DATA

shuttle

-GP features terminals for 8 differential analog inputs and 8 digital I/O lines, with

room for up to 8 high-power optically isolated modules.

The DS-12-8-RTD and DS-16-8-R TD are specifically designed for

-

high accuracy RTD measurements. The DATA

shuttle

-RTD has signal conditioning set resistors pre-installed at the factory for use

with two or three wire RTDs. This model also features terminals

for 8 digital I/O lines, with room for up to 8 optically isolated

modules.

The DATA

shuttle

-RTD can also measure non-RTD inputs. For

channels that are required to measure other signals, remove the

pre-installed resistors at R3 and R4. See example in the Analog

Auxiliary Components section of Chapter 2 for a more detailed

illustration.

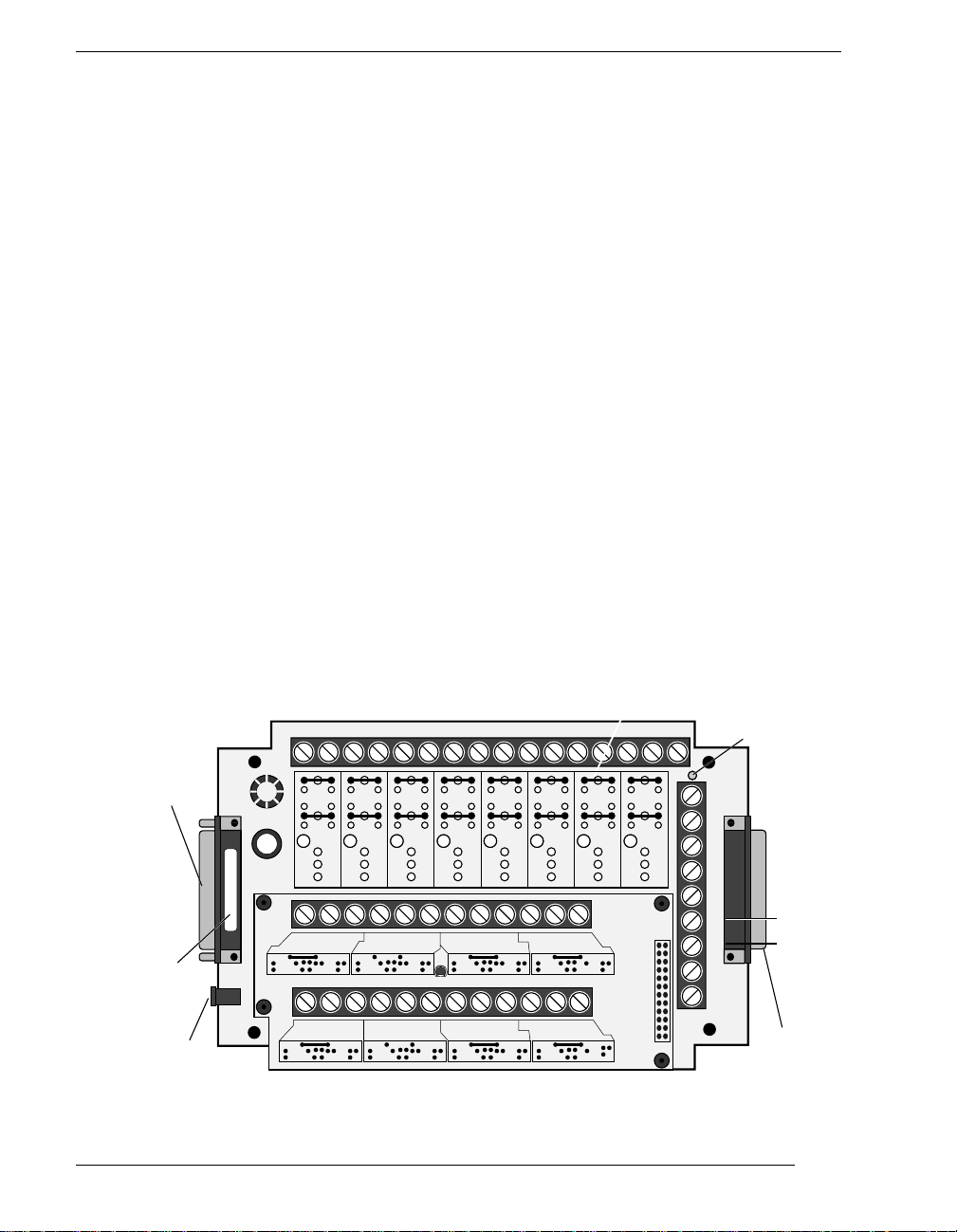

Figure 2. Illustration of the DATAshuttle-GP and DATAshuttle-RTD –

Digital Auxiliary Components &

Dgital Isolation Modules

Out 1 In 1 Out 2 In 2 Out 3 In 3 Out 4 In 4 Out 5 In 5 Out 6 In 6 Out 7 In 7 Out 8 In 8

DIGITAL I/O

R7

R7

R7

R7

R7

R7

R6

R6

R6

R8

R8

+–

CHAN 8 CHAN 7 CHAN 6 CHAN 5

R2

R3/C1 R1

+–

CHAN 1 CHAN 2 CHAN 3 CHAN 4

R2

R3/C1 R1

+–

COM

R

R2

4

R3/C1 R1

+–

COM

R

R2

4

R3/C1 R1

R6

R8

R8

+–

R2

R3/C1 R1

+–

R2

R3/C1 R1

COM

COM

R

U1

4

COM

R

4

R6

R8

COM

R

4

R

4

+–

+–

R6

R8

COM

R2

R3/C1 R1

COM

R2

R3/C1 R1

R7

R6

R8

Analog

Inputs

R

4

Analog

Inputs

R

4

ANALOG

AUXIL

COMPS

ANALOG

AUXIL

COMPS

R7

R6

R8

J1

1 2

23 24

Power Indicator

+5V

CTG

CT

Trig

CT

Out

CT

In

GND

GND

GND

Vref

Light

AO1

(on -AO models)

AO2

Parallel

Passthrough

Chapter 1 Introduction

1 – 6

Page 13

INTRODUCTION & INSTALLATION

DATA

TC

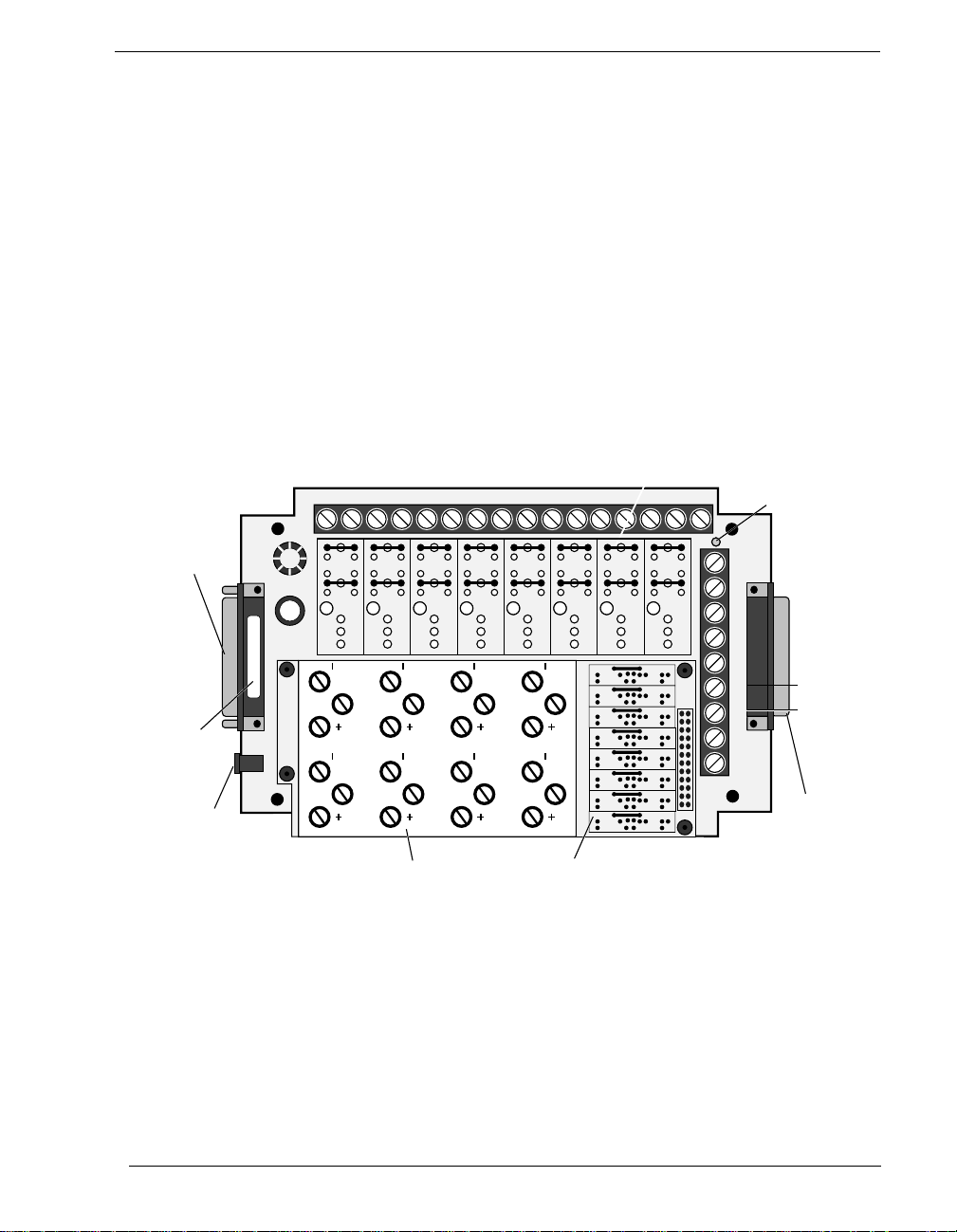

DATAshuttle-TC

shuttle

Parallel Input

Connector

Serial Number

& Model Type

5-9V DC In

The DS-12-8-TC and DS-16-8-TC are the best models for ther-

-

mocouple measurement. The DATA

shuttle

-TC has a large aluminum isothermal plate with screw terminals for 8 analog inputs.

This isothermal plate improves accuracy by attenuating temperature differences at the cold junction connector. Without this

plate, the connectors can vary in temperature by 5˚C or more,

causing a similar error in the reading reported by the DATA

tle

.

The plate, however, does not prevent measurement of other signals, such as voltage or current. In addition, the DATAshuttle-TC

features 8 digital I/O lines, with room for up to 8 optically isolated modules.

Figure 3. Illustration of the DATAshuttle-TC –

Digital Auxiliary Components &

Digital Isolation Modules

Out 1 In 1 Out 2 In 2 Out 3 In 3 Out 4 In 4 Out 5 In 5 Out 6 In 6 Out 7 In 7 Out 8 In 8

DIGITAL I/O

R7

R7

R7

R7

R7

R7

R7

R6

R8

54

ANALOG INPUT

COM COM

R6

R6

R6

R6

R8

R8

R8

6

COM COM

3

COM

7

COM

2

R6

R8

R8

CH

1

R3/C1 R1

CH

2

COM COM

CH

3

CH

4

CH

5

CH

6

CH

7

CH

8

R3/C1 R1

R3/C1 R1

R3/C1 R1

R3/C1 R1

R3/C1 R1

R3/C1 R1

R3/C1 R1

8

1

R7

R6

R6

R8

R8

R

R2

4

AUX

R

R2

R2

R2

R2

R2

R2

R2

COM

4

1 2

R

4

R

4

R

4

R

4

R

4

24

R

4

shut-

Power Indicator

+5V

CTG

CT

Trig

CT

Out

CT

In

GND

GND

GND

Vref

Light

AO1

(on -AO models)

AO2

Parallel

Passthrough

Isothermal Plate

Analog Auxiliary

Components

DATAshuttle Operator’s Manual

1 – 7

Page 14

DATA

shuttle

OPERATOR’S MANUAL

Installation Overview

Installing Your DATAshuttle

Getting your DA TAshuttle up and running is a straightfoward process; you only need to:

· Connect the DATAshuttle to the parallel port of a

computer, and

· Connect power to the DATAshuttle.

Guidelines for loading the software, and for starting up, depend

on the application program you are going to use (such as our

WorkBench PC for DOS or Windows, or QuickLog PC, or a

package by a third party developer who has our authorization).

The program you are going to use with the DATAshuttle might

even be unique and proprietary, a product of your organization.

(The Analog Connection Development System is a powerful set

of utilities making it possible for software engineers to design and

develop their own programs to exploit the DATAshuttle’s many

features).

In any event, please refer to the software provider’s installation

manual, or user guide, for specific information on how to load

and run the particular program.

Troubleshooting –

work, refer to the “Troubleshooting” section in Chapter 2.

If you have any difficulty getting your unit to

Chapter 1 Introduction

1 – 8

Page 15

INTRODUCTION & INSTALLATION

Physical Installation

Installation very simply consists of plugging the DATAshuttle’s

DB-25 cable into the parallel port outside your computer. The

DATAshuttle may be used in combination with any of our data

acquisition products.

Physical Installation

SINGLE UNIT

INSTALLATION

MULTIPLE UNIT

INSTALLATION

To Install a DATAshuttle–

1. TURN THE COMPUTER OFF!

puter’s parallel port without first turning its power switch to

the “off” position.

2. Connect the parallel input connector

DATAshuttle to the parallel port on your computer with the

provided DB-25 cable. The parallel port on the PC has 25

pins and is often labelled “Printer” or “LPT.” Computers may

have up to four parallel ports; the DATAshuttle may be connected to any one of these.

3. Connect the provided AC Adapter

the side of the parallel port of the DATAshuttle. Plug the AC

Adapter into an AC power line.

4. Connect the sensors needed for your application:

cover of the DATAshuttle by removing the four screws in the

corners of the unit. Connect the sensors needed for your

application to the DATAshuttle screw terminals. Replace the

cover. You may wish to refer to the Applications Reference

Manual for examples of particular applications.

To install more than one DATAshuttle–

install the first DATAshuttle. Then for every additional DATAshuttle you wish to install, simply connect the parallel input port of

that DATAshuttle to the passthrough port of the previously

installed DATAshuttle. You may use the additional DB-25 cables

to do this, or you can plug the next DATAshuttle directly into the

previous one. If you prefer to keep the units separate, you may

also connect additional DATAshuttles directly to any or all of the

other parallel ports on your computer.

Never plug anything into the com-

on the left side of the

to the 6-9V DC input just to

Remove the top

Follow the steps above to

In any of these ways, you may connect up to 15 DATAshuttles to

one computer.

DATAshuttle Operator’s Manual

1 – 9

Page 16

DATA

NEXT STEPS

shuttle

OPERATOR’S MANUAL

Physical Installation

Please note, however, that only three DATAshuttles, or only two

DATAshuttle-AO models, may be powered of f the same 6V, 1 amp

AC Adapter. Ther efor e, you must connect a new AC Adapter (see

Step 3 above) to every fourth (or third) DATAshuttle in a series.

Figure 4. Installation with multiple DATAshuttles and printer–

PRINTER

INSTALLATION

KEYBOARD ADAPTER

INSTALLATION

A Note on Board Numbers–

When you are using multiple units in

your installation, each unit needs to have an identity, or “board

number,” for the software to recognize it as “individual.”

When the software is loaded, it will conduct a search for all

installed hardware, scanning first for in-system boards and then

for any DA TAshuttles connected to the parallel ports. Any plug-in

boards that you have installed will be assigned a board number

first. Then the DATAshuttle connected at LPT1 nearest to the

computer will be assigned the next available board number.

Additional DATAshuttles on LPT1 will be assigned sequentially

higher board numbers. This process will be repeated on LPT2,

LPT3, and LPT4 until all units have received a board number.

If you wish to use a printer on the same parallel port as a DATAshuttle–

Connect the printer cable to the passthrough port of the last

DATAshuttle in the series.

For field applications where no AC power line is available–

The Keyboard Adapter power cable (available optionally) may be used

instead of the AC Adapter. To install, simply connect one end of

the cable to the keyboard port on the computer. (This connector

must be the six pin mini DIN style found on IBM PS-2s and most

portable computers.) Plug the other end of the cable into the

DATAshuttle’s DC input jack. Up to three DATAshuttles may be

powered off of one keyboard adapter. (See the “Multiple Unit

Installation” section on page 1 – 9 for instructions on installing

multiple DATAshuttles.)

Chapter 1 Introduction

1 – 10

Installing the Software –

For information on loading and configuring WorkBench PC for DOS or Windows, QuickLog PC, or other

software please refer to the user guide for that software package.

Page 17

DATA

shuttle

OPERATOR’S MANUAL

Chapter 1 Introduction

1 – 11

Page 18

TECHNICAL NOTES

Chapter 2: Technical Notes

Although operations in this chapter are seldom necessary during everyday

data acquisition, you might want to refer to them at certain times during

operation of the DATAshuttle. They are:

· Block diagram (of the DATAshuttle showing on-unit processing);

· Editing calibration numbers to accommodate changes to your installa-

tion, or to restore missing files;

· Auxiliary analog and digital components

· Counter/Timer

· Use with AC Development System software

Overview

· Troubleshooting: some possible problems and solutions after installing,

and during operation of your unit.

· Specifications of the different DATAshuttle models.

DATAshuttle Operator’s Manual

2 – 1

Page 19

DATA

shuttle

Block Diagram

OPERATOR’S MANUAL

Figure 5. Block Diagram of DATAshuttle-12 and DATAshuttle-16 –

Reference

8 Differential

Analog Inputs

Optional Analog

Isolation Modules

on -5B models

User Terminals

8 Digital I/O Lines

Optically Isolated

Modules

4 Counter/Timer Lines

2 Analog Outputs (optional)

Optional Analog

Isolation Modules

on -5B models

Pass Through Parallel

Port to Printer or

Other DATA

shuttles

Voltage

MUX

+5V

Amplifier

Counter/

Gain Control

I/O

Latches

Timer

+15V

-12V

V/F

Converter

Gain

Control

2 12-Bit D/A

Converter

Power

Supply

5-9V

DC IN

**

Digital

*

Processing

Parallel Port

Interface

Parallel

Input

Chapter 2 Technical Notes

2 – 2

*V/F Converter: 12 bits for DATAshuttle-12; 16 bits for DATAshuttle-16

Page 20

CAUTION

STARTING

EDITCAL

EDITCAL

TECHNICAL NOTES

Using EDITCAL

EDITCAL.EXE (or EDITCAL, for short) is our utility program

that allows the modification of calibration numbers.

Changing these numbers will affect the accuracy of the analog

measurements.

Make sure the EDITCAL.EXE program file is in the same subdirectory as the application programs.

Load the EDITCAL.EXE program from the keyboard:

To Start Up EDITCAL.EXE –

1.

At the DOS prompt, enter EDITCAL, then press the [ENTER]

key. (This invokes the utility.)

Using EDITCAL

SELECTIONS

To Select a Function –

1.

Use the arrow keys to navigate back and forth among these

menu selections:

Data Files To merge calibration files supplied from the factory

AC EEPROM To view or modify calibration data on Analog Con-

HS EEPROM To view or modify calibration data on high speed

DS EEPROM T o view/modify calibration DATAshuttle EEPROMs

QUIT Ends this EDITCAL session.

2.

Move the arrow keys until DS EEPROM is flashing.

3.

Press [ENTER].

Continue –

appear after making your selection.

Help –

key to display help about a field that is highlighted.

Proceed according to the on-screen instructions that

At any time during your use of EDITCAL, press the [F1]

into a single file for systems that have multiple units, or

to update existing calibration files.

nection units that have non-volatile on-unit EEPROMS.

units EEPROM, such as WB-WORKMATE or WBFLASH12.

or perform analog recalibration

DATAshuttle Operator’s Manual

2 – 3

Page 21

DATA

AUXILIARY

shuttle

OPERATOR’S MANUAL

Auxiliary Components

COMPONENTS

Auxiliary Analog and Digital

Components

Auxiliary Components are required by some sensors, are used to

protect digital signals, or are used to pull digital outputs to a set

level. There are two areas (one digital and one analog) on the

DATAshuttle for installing auxiliary components. Schematics of

both Analog and Digital auxiliary components are shown in

detail in Figures 6(a) and 6(b) below.

Figure 6. Schematic for Analog & Digital Auxiliary Components –

COM

Screw

Terminal

Screw

Terminal

IN

OUT

+

–

a. Analog Auxiliary Components, each channel

b. Digital Auxiliary Components, each channel

R1

R5

R6

R7

GND (A)

R2

R8

+5V

R4

R3/C1

7404

Board +

Connector

(to main board)

Board –

GND (A)

Vref

+15V

–12V

I/O

GND

Chapter 2 Technical Notes

2 – 4

Each channel on the DATAshuttle has room for its own separate

set of auxiliary components. Examples of their use can be found

in the following pages and in the Applications Reference Manual.

Page 22

ANALOG

AUXILIARY

POWER SUPPLIES

COMPONENTS

TECHNICAL NOTES

Analog Auxiliary Components

Instructions for installing components–

Most common sensors can be connected without the use of auxiliary components. Some of the sensor installations (bridges, RTD

circuits, voltage dividers and current sensors), however, require

auxiliary components. These components can be installed on the

DA TAshuttle for convenience. This requires soldering and some

familiarity with electronics. In the examples in the Applications

Reference Manual, and the following, the component locations are

shown but not the component values; you must calculate the values if they are not supplied with the sensor.

The first step is to remove the daughterboard from the unit, as

you will need full access to it for soldering on the auxiliary components. To do this, simply remove the four screws in the corners

of the daughterboard and lift it off of the DATAshuttle.

When using analog auxiliary components R1, R2, and R5 you

must cut the shorting metal trace that connects the two ends of

the line together before installing any of the components in these

locations. Use a sharp knife to carefully slice through the trace

without cutting additional traces. In the case of R5 this is a plastic

covered metal wire. Diagrams of the auxiliary component area,

hole functions, and connection possibilities are shown on the following page.

A Note on Power Supplies –

The DA TAshuttle supplies the following

voltages to power transducers, strain gauges, etc. The currents

available to the user are limited as follows:

Voltage Tolerance

Maximum Current

(mA)

Output Impedance

(ohms)

Vref(6.9V) ±5% 10 <1

+5V 4.5 to 5.0V 100 <50

+15V ±3% 10 100

-12V ±3% 10 100

Users of the open collector digital outputs and buffer amplifiers

should be careful not to exceed these limits. Any power used

from these supplies will add to the specified supply current used

by the DATAshuttle.

DATAshuttle Operator’s Manual

2 – 5

Page 23

DATA

shuttle

OPERATOR’S MANUAL

Analog Auxiliary Components

Analog Auxiliary Component Area on the DATAshuttle –

– Screw

Board –

Terminal

GND (A)

Ground (A)

Vref

+15V

COM

–12V

– Screw

Terminal

Fig. 7

Fig. 8

Fig. 9

Fig. 10

R5

R2

R3/C1 R1

Board + Board – Board +

R5

R2

R3/C1 R1

R5

R2

R3/C1 R1

R5

R2

R3/C1 R1

R

4

R

4

R

4

R

4

Placement of holes

in auxiliary component

area for a single channel

+ Screw Terminal

Placement of resistors

R1, R2 and R5.

Placement of capacitor

C1 or R3 Resistor for

current measurement.

Placement of R3 may

be to one of five places

on the right side of the

resistor.

Fig. 11

Chapter 2 Technical Notes

2 – 6

R5

R2

R3/C1 R1

R

4

R4 may be in one of

two holes on the right

side to one of 4 holes

on the left.

Page 24

TECHNICAL NOTES

EXAMPLES

Examples: Analog Auxiliary Components

Example 1: Current sense resistor

The DATAshuttle can measure currents up to 50 mA directly. A

24.9 Ohm precision resistor needs to be installed in the auxiliary

component area to do so. This connection for current measurement is shown below. (To see how this connection adds to the

circuit, refer to Figure 6(a).) R3 is used as a shunt resistor across

the positive and negative lines of the channel in use.

To install this resistor, push the resistor ends through the holes

for R3 (from the terminal side) until the resistor lies flat with the

panel surface. On the back side, solder the wires to the holes, and

then clip off the extra wire with pliers. This connection does not

require any additional traces to be cut.

Be sure to select current measurement in the software package

that you are using. This installation allows the measurement of

voltage across the resistor and the conversion of this measurement to current using the equation V=IR. Observe the power rating of the resistor you install at R3. Space is provided for a 1/4

Watt resistor.

Figure 12. Current Measurement Connection –

R5

R2

R1

R

4

DATAshuttle Operator’s Manual

2 – 7

Page 25

DATA

shuttle

OPERATOR’S MANUAL

Examples: Analog Auxiliary Components

Example 2: 3-Wire RTD components

The most popular connection for RTDs is the three wire type.

This sensor requires the installation of resistors R3 and R4. Both

resistors are already installed in the DATAshuttle-RTD model.

Figure 13. 3-Wire RTD Components

RTD

SHIELD

+

COM

–

GND

3-Wire RTD

Vref

R3

R4

+

Analog

Connector

-

However, if you need to install these resistors yourself then do

the following: Figure 10 and Figure 11 show the possible locations of R3 and R4. Figure 7 will show you that R3 and R4 need

to be connected as in Figure 14. R5 is already in place and should

not be removed. To install these resistors push the resistor ends

through the holes for R3 and R4 as shown in Figure 10 (from the

terminal side) until the resistor lies flat with the panel surface. If

two wires cannot fit into the Vref hole then one wire may be soldered to another that is already inserted. On the back side solder

the wires to the holes. Then clip off the extra wire with pliers.

The auxiliary component area in question will now look like Figure 14. This connection does not require any additional traces to

be cut.

Figure 14. 3-Wire RTD Connection –

R5

R

R2

4

R3/C1 R1

Chapter 2 Technical Notes

2 – 8

Page 26

TECHNICAL NOTES

Examples: Analog Auxiliary Components

Example 3: Ground loops

Occasionally there is an installation where the ground connection

is made at the sensor, but it is not reliable. The solution to this

“intermittent” ground is to replace the COM to GND(A) jumper

wire at R5 (Figure 6(a)) with a 10 Megohm, 5%, 1/4 Watt resistor. This provides a ground reference for the analog inputs in

question, but allows very little ground current to flow. In very

noisy environments with intermittent grounds, a smaller resistor

may be used if the readings are erratic.

To install this resistor the wire at R5 must first be removed. After

R5 has been removed push the resistor ends through the holes for

R5 (from the terminal side) until the resistor lies flat with the

panel surface. On the back side, solder the wires to the holes.

Then clip off the extra wire with pliers. The auxiliary component

area in question will now look like Figure 15. This connection

does not require any additional traces to be cut.

Figure 15. Ground Loop Connection

–

R5

R2

R3/C1 R1

R

4

DATAshuttle Operator’s Manual

2 – 9

Page 27

DATA

DIGITAL

CAUTION

shuttle

OPERATOR’S MANUAL

Digital Auxiliary Components

AUXILIARY

COMPONENTS

Installing Digital Modules –

Modules are available to safely connect the digital I/O lines to high

voltage AC and DC sources. There are four basic types:

· AC output: to switch AC power (relay)

· DC output: to switch DC power (relay)

· AC input: to sense AC voltage

· DC input: to sense DC voltage

The output types are used to switch loads on and off. The input

types are used to sense the high/low status of a signal. All of the

modules provide optical isolation between the high voltage and

terminations.

These modules may be installed on any DATAshuttle. You may

have had modules installed at the factory. If not, you may do the

installation yourself. First, remove the jumpers labeled R6 and R7.

This disconnects the digital I/Os from the terminals. The module

will not fit into the panel until these jumpers are removed. Then,

simply insert the module and fasten the retention screw.

Chapter 2 Technical Notes

2 – 10

The terminals for that I/O have now changed their function from

low voltage I/O to high voltage isolated I/O. The two terminals

become one input channel (high and low lines), or one output

channel (like relay contacts), depending on the type of module

you have installed.

When using these terminals as input lines, be sure to connect the

positive line to the old OUT terminal and the negative line to the

old IN terminal. Failure to do this will result in the module not

switching.

Installing Pull-up Resistors –

As noted in the Applications Reference Manual and previously in

this manual, the digital outputs are open collector and must have

a power source connected in order to drive loads. Merely connecting the output terminal through a load (such as a bulb) and then

to digital ground will not work. In this case, a pull-up resistor connecting the output terminal to a power supply will complete the

circuit.

This pull-up resistor is installed in position R8, as shown in Figure

6(b), which connects the output to the unit’ s +5 volt power supply.

Page 28

TECHNICAL NOTES

Digital Auxiliary Components

Figures 2 and 3 in Chapter 1 show the physical location of R8 on

the DATAshuttle. Note that R8 must be installed manually

between the +5 volt supply and the output terminal in question.

To install this resistor, push the resistor ends through the holes

for R8 (from the terminal side) until the resistor lies flat with the

panel surface. On the back side, solder the wires to the holes.

Clip off the extra wire with pliers. This connection does not

require any additional traces to be cut.

Installing Current Limiting Resistors –

To limit the current in the digital input line, install a resistor in

the R6 position (remove the corresponding jumper first).

Install a resistor in the R7 position (after removing the jumper) to

limit the current in the digital output line.

DATAshuttle Operator’s Manual

2 – 11

Page 29

DATA

shuttle

Counter/Timer

OPERATOR’S MANUAL

Counter/Timer

The DATAshuttle features one 16 bit counter/timer that may be

used to count up to 2

16

(65,535) events. The maximum rate of

pulses it can measure is 3MHz. The counter/timer is connected to

an internal 2MHz clock, allowing it 0.5µS resolution.

There are four dedicated terminals for the counter/timer:

Counter/Timers lines available on the DATAshuttle –

Label Name Function

CTG Gate Input/output functions may operate when this

line is high and stop when it is low

CT Trig Trigger Initiate input or output functions on rising

edge

CT Out Output Output pulses or square waves

CT In Input Measure frequency of pulses, count pulses, or

time events

All of these lines are TTL compatible. Please note that they may

not be optically isolated with modules.

For more information and examples about the uses of the

counter/timer please see the Applications Reference or QuickLog

manuals.

Chapter 2 Technical Notes

2 – 12

Page 30

TECHNICAL NOTES

AC Development System

Use With the AC Development System

The DATAshuttle was developed using the framework of our WBAAI/FAI family of plug-in data acquisition boards. As a result, the

DATAshuttle responds to the same commands in our AC Development System software as these boards. Should you wish to use the

AC Development System with the DATAshuttle, you should treat

the DATAshuttle-12 as an WB-FAI and the DATAshuttle-16 as an

WB-AAI. Please note, however, that there are two significant differences between the DATAshuttle and WB-AAI/FAI boards:

1. The DATAshuttle contains its calibration numbers in onboard nonvolatile

RAM

(ACAL, BCAL, DCAL and CCAL) instead of in a calibra-

tion file. CALIB.DAT is not necessary.

2. The DATAshuttle has different minimum sample periods

(set by the J or

j commands) than the WB-AAI/FAI boards. They are as follows:

Minimum sample period for DATAshuttle-12† –

Resolution

Sample Period

(Single Channel)

Sample Period

(Multiple Channels)

9 bits 167 µS 250 µS

10 bits 200 µS 294 µS

11 bits 333 µS 357 µS

12 bits 455µS 500 µS

18 bits * *

†

Minimum sample period for DATAshuttle-16

Resolution

Sample Period

(Single Channel)

(Multiple Channels)

–

Sample Period

12 bits 455 µS 455 µS

13 bits 833 µS 909 µS

14 bits 1,250 µS 1,333 µS

15 bits 2,381 µS 2,500 µS

16 bits 4,545 µS 4,545 µS

18 bits * *

* Low noise mode; 16,667 if power line fre-

quency is 60 Hz; 20,000 if 50 Hz

†

Rates describe a 33MHz IBM 386DX. Minimums

are somewhat lower in faster computers.

DATAshuttle Operator’s Manual

2 – 13

Page 31

DATA

shuttle

OPERATOR’S MANUAL

Troubleshooting: Installation

Troubleshooting: Installation

If you experience difficulty in getting your DATAshuttle up and

running, please check to see that the installation is according to

the descriptions in Chapter 1.

If the software reports a unit failure, or that it cannot find a

DATAshuttle, then try these remedies:

1. Make sure the cable is securely connected

input connector to the parallel port on the computer.

from the DATAshuttle

2. Make sure the DATAshuttle is connected to a power source

AC Adapter or Keyboard Adapter . A r ed light on the board will

indicate that power is present.

3. Verify that the software is up to date

the unit you are using). Contact us, or your software provider.

4. Disconnect additional DATAshuttles

(a version compatible with

and printers in your setup.

, either an

5. Connect the DATAshuttle to another parallel port.

6. Remove any additional data acquisition cards

7. If possible, install the DATAshuttle with another computer

its correct operation.

8. Remove other terminate and stay resident (TSR)

your system’s AUTOEXEC.BAT file, temporarily. Also REM out

any AUTOEXEC.BAT and CONFIG.SYS lines that relate to a

PCMCIA port, such as device drivers, as these have been

known to cause conflicts.

from the computer.

to verify

programs from

9. Make sure that you plug the DATAshuttle in and that power is connected

before starting your computer. Many laptops will deactivate

the parallel port at the start-up if nothing is attached to it.

10. Make sure that the Print Manager is not active in the Windows environment

puters automatically load the Print Manager at startup, and it

can interfere with WorkBench PC for Windows’ ability to communicate with the hardware. Printing is possible while using

the DATAshuttle but not during the initial loading of the WorkBench PC for Windows software.

when attempting to start the DATAshuttle. Some com-

(Please call our Technical Support line before returning a DATAshuttle

– we hope to assist you with your problem via telephone.)

Chapter 2 Technical Notes

2 – 14

Page 32

HINTS

OPERATING

Qs AND As

TECHNICAL NOTES

Troubleshooting: Operation

Troubleshooting: Operation

It’s essential to have exactly one ground reference per channel.

This single connection to ground makes sure you don’t exceed

the common mode range of input.

(More than one connection per channel can lead to ground loops,

causing errors or erratic readings. Connecting the – to the Com

terminal provides a single ground. Your sensor might also provide another ground. If you’re not sure that your sensor is

grounded, try connecting the – to Com, and not, and see which

works best.)

Remember that if speed is not critical, selecting the “low noise

mode” in software always provides the best accuracy and resolution with your data acquisition unit.

Here are mini “case studies” of difficulties, along with some easy

solutions:

Problem: My unit reads analog inputs wrong.

Make sure the calibration numbers in the non-volatile

Action:

memory are non-zero (run EDITCAL to check this). If the

figures are correct, try shorting + to – to Com: the unit

should return a reading around 0V.

Problem: My unit reads the thermocouple as a very negative temperature.

Verify the connections are secure. Opens read as negative

Action:

temperature.

Problem: My readings are noisy.

Try using the low noise mode (see your software manual

Action:

for more information).

Problem: I can’t measure any voltage change with my voltmeter on my

digital output.

Action:

With nothing but a voltmeter connected, this is normal.

The digital outputs are termed “open collector.” These

kind of outputs do not supply any voltage; it must be supplied from another source. This allows the flexibility to

use any supply voltage up to 30V. The easiest way to see

the state of any output terminal is to check the state of the

input terminal with a voltmeter.

DATAshuttle Operator’s Manual

2 – 15

Page 33

DATA

BEFORE CALLING

shuttle

OPERATOR’S MANUAL

Troubleshooting: Operation

Problem: My digital inputs are “high” with nothing connected to them.

This is normal. The digital inputs are pulled up to about

Action:

1.5 volts by leakage from the LS7407 chips. This is

enough to read logic high. You can pull them low with a

470 ohm resistor to ground.

Problem: Can I get any output signal from the digital input terminals?

Yes, you can use an input terminal to drive light loads

Action:

such as a TTL input.

Problem: What should I do with the jumpers connecting the analog input

to COM?

In general, it is best to leave them connected as shipped.

Action:

Problem: My 5V terminal reads only 4.6V.

This is normal. Tolerance is 4.5 to 5V.

Action:

Problem: My analog output accuracy is poor.

From the DOS command line, or in GO.BA T, run GFIND -C.

Action:

This calibrates analog outputs. Note, however, that calibration sends full scale outputs, so it may be necessary to

remove any instruments connected to the outputs.

CUSTOMER SUPPORT

Chapter 2 Technical Notes

2 – 16

Check the following key areas to validate whether or not the DATAshuttle

is operational:

1. Make

sure the AC Adapter is not damaged.

To do this, detach the

adapter from the DATAshuttle, while leaving it plugged in to

the wall outlet. Then measure the voltage between the inside

and outside surfaces of the cylindrical connector. In this noload condition, the voltage should measure approximately 9V.

If this is not the case, it is likely that the AC Adapter will need

to be replaced.

2. Check the power section of the DATAshuttle.

After plugging the AC

Adapter back into the DATAshuttle, check to make sure the

LED is functioning. If the LED is not lighting up, then there is

likely a problem with the power section of the unit. Contact

technical support for further assistance.

3. Check the DATAshuttle’s internal power supply.

To do this, it is necessary to measure four voltage terminals on the unit itself: the

+5V and Vref(6.9V) terminals, found at opposite ends of the

terminal strip next to the passthrough connector, and the

Page 34

IF YOU NEED

CUSTOMER SUPPORT

TECHNICAL NOTES

Troubleshooting: Operation

+15V and the -12V terminals, which can be found on the

raised section of the DATAshuttle called the terminal board.

(Please consult the diagrams on pages 1–6 and 1–7 if you are

unable to locate these terminals.)

If you have been installing resistors or capacitors on the analog

input auxiliary section, then it is necessary to remove the terminal board and re-check the +5V and Vref voltages. If, after

removal, these voltages return to normal, it is likely that there

is a short-to-ground on the terminal board. Check the resistor/

capacitor installations for such a short and reinstall the board.

If removal does not fix the +5 and -12 voltages, then there is a

problem with the DA T Ashuttle’s internal power supply. Contact

technical support for further assistance.

T o help us serve you better, please have the following information ready:

Have the part number of your DATAshuttle ready.

1.

2.

Have the type and version number of the software you’re

using.

3.

Have your computer’s type, model, and the version of the

operating system.

DATAshuttle Operator’s Manual

2 – 17

Page 35

DATA

ACCURACY

shuttle

OPERATOR’S MANUAL

Product Specifications: Accuracy & Resolution

Product Specifications

DATAshuttle-12 ACCURACY & RESOLUTION–

Range

-5 to +50 mV 12 µV 0.08% –

-25 to +25mV 12 µV 0.16% –

-50 to +500mV 120 µV 0.05% 0.2%

-250 to +250 mV 120 µV 0.05% 0.2%

VOLTAGE

-1 to +10 V 2.4 mV 0.05% 0.2%

-5 to +5 V 2.4 mV 0.05% 0.3%

T ypical Resolution

at Full Scale

DATAshuttle-16 ACCURACY & RESOLUTION–

Range

-5 to +50 mV 0.8 µV 0.04% –

-25 to +25mV 0.8 µV 0.08% –

-50 to +500mV 8 µV 0.01% 0.05%

-250 to +250 mV 8 µV 0.01% 0.05%

VOLTAGE

-1 to +10 V 150 µV 0.01% 0.05%

-5 to +5 V 150 µV 0.01% 0.10%

General Conditions –

interface unit, source resistance less than 1k Ohms. Includes linearity, drift, offset, resolution, and calibration error. In this table

12 bit (0.024%) resolution in use for the DATAshuttle-12, while

16 bit is in use for the DATAshuttle-16 (0.0015%).

Typical Resolution

at Full Scale

From 15 to 35 degrees C, ambient at the

Absolute Accuracy, the larger of

% of Range: % of Reading:

Absolute Accuracy, the larger of

% of Range: % of Reading:

Chapter 2 Technical Notes

2 – 18

Page 36

TECHNICAL NOTES

Product Specifications: Thermocouple Accuracy

DATAshuttle-12 THERMOCOUPLE ACCURACY –

Type Range (°C.) Resolution (°C.) Accuracy (°C.)

-210 to -100 0.1 – 0.3 ± 2.3

J

-100 to 0 0.05 ± 1.2

0 to 880 0.05 – 0.2 ± 1

-250 to -75 0.15 – 1.0 ± 8

K

-75 to 1260 0.07 – 0.3 ± 1.4

0 to 900 0.06 – 0.2 ± 1.2

-250 to -70 0.1 – 0.5 ± 4

E

-70 to 100 0.04 ± 1

100 to 680 0.04 – 0.15 ± 0.8

-250 to -50 0.15 – 0.8 ± 6

T

-50 to 10 0.02 – 0.8 ± 1.4

10 to 150 0.06 ± 1.2

150 to 400 0.06 – 0.1 ± 1

-50 to 120 0.4 ± 10

S

120 to 380 0.3 ± 5

380 to 1770 0.2 – 0.6 ± 4

-50 to 250 0.2 – 0.4 ± 10

R

250 to 800 0.2 ± 4

800 to 1770 0.2 – 0.4 ± 3

200 to 300 0.7 – 1 ± 20

B

300 to 500 0.4 – 0.7 ± 13

500 to 1000 0.2 – 0.4 ± 8

1000 to 1820 0.2 – 0.4 ± 4

G

25 to 200 0.2 – 1 ± 15

200 to 2315 0.15 – 0.8 ± 4

D

-20 to 2315 0.2 – 1 ± 4

150 to 2000 0.15 – 0.6 ± 3

C

-20 to 2315 0.15 – 1 ± 4

100 to 1500 0.15 – 0.4 ± 3

N

-200 to -100 0.7 – 1.4 ± 5

-100 to 1300 0.4 – 0.7 ± 3

DATAshuttle Operator’s Manual

2 – 19

Page 37

DATA

shuttle

OPERATOR’S MANUAL

Product Specifications: Thermocouple Accuracy

DATAshuttle

-16

THERMOCOUPLE ACCURACY –

Type Range (°C.) Resolution (°C.) Accuracy (°C.)

-210 to -100 0.02 – 0.04 ± 1.2

J

-100 to 100 0.02 ± 0.7

100 to 880 0.01 ± 0.5

-250 to -150 0.03 – 0.15 ± 4

K

-150 to -50 0.03 ± 1

-50 to 1260 0.02 ± 0.7

-250 to -100 0.08 – 0.01 ± 2

E

-100 to 200 0.01 ± 0.6

200 to 680 0.01 ± 0.4

-250 to -120 0.03 – 0.1 ± 3

T

-120 to -25 0.02 – 0.03 ± 0.9

-25 to 200 0.01 – 0.02 ± 0.7

200 to 400 0.01 ± 0.5

-50 to 50 0.1 – 0.2 ± 5

S

50 to 300 0.1 ± 3

300 to 1770 0.08 ± 2

-50 to 25 0.1 – 0.2 ± 5

R

25 to 200 0.1 ± 3

200 to 1770 0.08 ± 2

200 to 300 0.25 – 0.4 ± 10

B

300 to 500 0.15 – 0.25 ± 6

500 to 1000 0.08 – 0.15 ± 4

1000 to 1820 0.08 ± 2

G

25 to 200 0.08 – 0.3 ± 8

200 to 2315 0.08 ± 2

D

-20 to 2315 0.04 – 0.08 ± 2

300 to 1500 0.04 ± 1.3

C

-20 to 2315 0.04 – 0.08 ± 2

100 to 1500 0.05 ± 1.5

N

-200 to -100 0.05 – 0.1 ± 3

-100 to 1300 0.02 – 0.05 ± 1.5

Chapter 2 Technical Notes

2 – 20

Page 38

TECHNICAL NOTES

Product Specifications: Thermocouple Accuracy

Thermocouple Conditions –

Same as General Conditions. Does not

include the accuracy of the thermocouple itself (cold junction

error must be added in; cold junction compensation with

DATAshuttle-TCs only). Resolution assumes 12 bit resolution in

use for DA TAshuttle-12, 16 bit resolution for DAT Ashuttle-16; it is

approximate as resolution varies with temperature measured.

Thermocouples use the 50 mV range. For inputs below -5 mV

(below approximately -100 degrees C), use the +/-25 mV range.

Cold Junction Compensation Error

– For the best resolution while

using the DATAshuttle-TCs, use the 50 mV range above -5 mV.

Cold Junction Compensation Error (degrees C) at terminal temperature of:

Type 25˚C 15˚ & 35˚C 5˚ & 45˚C

J

K

E

T

S

R

B

G

C

D

N

0 < 0.25 < 0.6

0 < 0.3 < 0.7

0 < 0.3 < 0.8

0 < 0.4 < 1.2

0 < 0.6 < 1.3

0 < 0.4 < 1.6

0 < 1.0 < 2.0

0 < 0.7 < 1.7

0 < 0.5 < 1.2

0 < 0.6 < 1.8

0 < 0.6 < 1.2

Cold junction compensation error is in reference to the temperature of the terminals. For types B and G the above error applies

for measured temperatures above 200 degrees C only. The cold

junction sensor can be recalibrated at any temperature from 0 to

50 degrees to improve the accuracy if it will not be used at 25

degrees.

DATAshuttle Operator’s Manual

2 – 21

Page 39

DATA

shuttle

OPERATOR’S MANUAL

Product Specifications: Thermocouple Accuracy

Cold Junction Temperature Differential:

For the DATAshuttle-TC only, the temperature gradient in the air

adjacent to the cold junction plate is attenuated 15 times when

AWG #22 gage or smaller thermocouple wire is used and the

wires are bundled together for at least one foot from the cold

junction terminals. The error is usually less than 0.1 degree C.

For the DATAshuttle-GPs there is no isothermal plate. The cold

junction compensation error consists of the above table plus the

difference between the terminal temperature and the cold junction

sensor. This dif fer ence can be several degrees. The above table applies only after user calibration of the cold junction.

Chapter 2 Technical Notes

2 – 22

Page 40

TECHNICAL NOTES

Product Specifications: RTD Accuracy

DATAshuttle-12 RTD ACCURACY –

Set Resistor

Ω

RTD

Ω

Range

°C.

Resolution

°C.

10 k 50 -200 to 115 0.02 to 0.1 0.9

20 k 50 -200 to 525 0.04 to 0.2 1.2

20 k 100 -200 to 115 0.02 to 0.1 0.9

50 k 50 -200 to >850 0.1 to 0.5 2.1

50 k 100 -200 to 750 0.05 to 0.2 1.4

50 k 200 -200 to 115 0.02 to 0.1 1.0

100 k 100 -200 to >850 0.1 to 0.5 2.1

100 k 200 -200 to 750 0.05 to 0.2 1.4

100 k 500 -200 to 115 0.02 to 0.1 0.9

200 k 200 -200 to >850 0.1 to 0.5 2.1

200 k 500 -200 to 525 0.04 to 0.2 1.2

200 k 1000 -200 to 115 0.02 to 0.1 0.9

500 k 500 -200 to >850 0.1 to 0.5 2.1

500 k 1000 -200 to 750 0.05 to 0.2 1.4

1000 k 1000 -200 to >850 0.1 to 0.5 2.1

Accuracy

°C.

DATAshuttle Operator’s Manual

2 – 23

Page 41

DATA

shuttle

OPERATOR’S MANUAL

Product Specifications: RTD Accuracy

DATAshuttle-16 RTD ACCURACY –

Set Resistor

Ω

RTD

Ω

Range

°C.

Resolution

°C.

Accuracy

10 k 50 -200 to 115 0.005 0.8

20 k 50 -200 to 525 0.01 0.9

20 k 100 -200 to 115 0.005 0.8

50 k 50 -200 to >850 0.03 1.4

50 k 100 -200 to 750 0.01 1.0

50 k 200 -200 to 115 0.005 0.8

100 k 100 -200 to >850 0.03 1.4

100 k 200 -200 to 750 0.01 1.0

100 k 500 -200 to 115 0.005 0.8

200 k 200 -200 to >850 0.03 1.4

200 k 500 -200 to 525 0.01 0.9

200 k 1000 -200 to 115 0.005 0.8

500 k 500 -200 to >850 0.03 1.4

500 k 1000 -200 to 750 0.01 1.0

1000 k 1000 -200 to >850 0.03 1.4

RTD Conditions –

Same as General Conditions. Does not include

the accuracy of the RTD sensor itself. Includes linearization and

signal conditioning errors.

°C.

Assumes 12 bit resolution in use for the DATAshuttle-12; 16 bit

resolution in use for the DATAshuttle-16.

RTD measurements are on the 0-50 mV range.

Chapter 2 Technical Notes

2 – 24

Page 42

TECHNICAL NOTES

INPUT IMPEDANCE

NOISE REJECTION

COMMON MODE

INPUT PROTECTION

RESOLUTION/

Product Specifications

All analog inputs have an impedance rating of >20ΜΩ

Important: All noise measurements are in low noise mode, with

inputs shorted to COM.

CMRR –

Common Mode Rejection Ratio (CMRR) is >80dB under

these conditions: DC to 100 Hz, common mode input ± 7.0 Volts

channel to ground. This specification applies even when one or

more nonmeasured channels exceeds the operating common

mode range.

RANGE

SCAN RATE

DATAshuttle NOISE REJECTION –

Range Typical Internal Noise (RMS)

50 mV 0.5 µV

± 25 mV 0.5 µV

500 mV 4 µV

± 250 mV 4 µV

10 V 50 µV

± 5 V 50 µV

Operating, channel-to-ground –

Nonoperating –

±50 Volts continuous.

±7 Volts

On analog input channels: 50 Volts continuous; 150 Volts

momentary.

Both resolution and scan rate are selectable in software:

DATAshuttle-12 RESOLUTION AND SCAN RATE* –

Resolution

Scan Rate

(Single Channel)

Scan Rate

†

(Multiple Channels)

low noise mode: 0.024 % 50 / 60 Hz 50 / 60 Hz

12 bits: 0.024 % 2,200 Hz 2,000 Hz

11 bits: 0.05 % 3,000 Hz 2,800 Hz

10 bits: 0.1 % 5,000 Hz 3,400 Hz

9 bits: 0.2 % 6,000 Hz 4,000 Hz

DATAshuttle Operator’s Manual

2 – 25

Page 43

DATA

ANALOG INPUT

DIGITAL

shuttle

OPERATOR’S MANUAL

Product Specifications

DATAshuttle

-16

RESOLUTION AND SCAN RATE* –

Resolution

Scan Rate

(Single Channel)

Scan Rate

†

(Multiple Channels)

low noise mode: 0.0015% 50 / 60 Hz 50 / 60 Hz

16 bits: 0.0015% 220 Hz 220 Hz

15 bits: 0.003 % 420 Hz 400 Hz

14 bits: 0.006 % 800 Hz 750 Hz

13 bits: 0.012 % 1,200 Hz 1,100 Hz

12 bits: 0.024 % 2,200 Hz 1,800 Hz

* Rates describe an IBM PC 386DX running at 33 MHz with a

math coprocessor. Rates are somewhat faster in faster computers. Please also see the discussion of “Dynamic Resolution” on page 1 – 3.

†

Preliminary

Scan Rate –

Scan rate is the rate in Hertz (or, samples per second)

to read data into memory, including the time it takes to switch

channels and ranges.

To calculate the total scan time for all channels, divide the rate by

the number of channels.

(After placing a burst of data into memory, and depending on

your computer and software, the system requires additional processing time before the data are available to you, or before you can

collect more data).

For the analog input terminals on the DATAshuttle –

· Maximum voltage on any terminal: 150 volts.

For the Digital Input/Output termination on the DATAshuttle –

INPUT/OUTPUT

Chapter 2 Technical Notes

2 – 26

· Maximum current on any terminal: 1 Amp.

· Each line is individually selected to be an input or output.

· Inputs are TTL and MOS compatible

· Outputs are high voltage open collector:

Low Level: 50 mA max, < 0.7 volts at 40 mA (sink)

High Level: 30 volts max, <250 µA (source)

· TTL outputs are available at the input terminals when an I/O is

set to an output:

Low Level: < 0.4 volts at 2 mA (sink)

High Level: > 2.4 volts at 100 µA (source)

Page 44

TECHNICAL NOTES

COUNTER/TIMER

ANALOG OUTPUT

GENERAL

Product Specifications

The DATAshuttle has one on-unit 16 bit counter/timer with 2

MHz internal clock. It can count pulses as fast as 3 MHz.

· Low Level: <0.4 volts at 2mA (sink)

· High Level: >2.4 volts at 100 µA (source)

For the analog output terminals on the DATAshuttle-AO –

· Voltage compliance: will drive up to 1K load positive or negative

· Current compliance: 3 to 30V, sinking current only

· Maximum output speed: 2KHz (preliminary)

DATAshuttle-AO RESOLUTION AND ACCURACY –

INFORMATION

Output Range

Nominal

Resolution

Accuracy

0 to 10V 2.4mV ±10mV

0 to 5V 1.2mV ±5mV

0 to 2V 0.48mV ±3mV

±5V 2.4mV ±10mV

±2.5V 1.2mV ±5mV

±1V 0.48mV ±3mV

4 to 20mA 3.9µA ±50µA

General specifications of the DATAshuttle –

· Analog input operating ambient temperature: 0 to 50 degrees

C, 5 to 90% RH, noncondensing

· Input power voltage range: 5.0 to 9.0 VDC

· Maximum input voltage before damage: 10.0VDC

· Supply current consumed with no external loads: <450mA

· Polarity of DC input connector: Outer surface +, inner surface -

DATAshuttle Operator’s Manual

2 – 27

Page 45

DATA

shuttle

OPERATOR’S MANUAL

Chapter 2 Technical Notes

2 – 28

Page 46

TECHNICAL NOTES

DATAshuttle Operator’s Manual

2 – 29

Page 47

INDEX

A – I

A

AC Adapter 1-5, 1-9, 2-14

with multiple DATAshuttles 1-10

Accuracy

in general conditions 2-18

in RTD measurement 2-23 to 2-24

in thermocouple measurement

2-19 to 2-22

Acquisition speed, data iii, 1-4

Analog auxiliary components 2-5 to

2-9

Analog Connection Development

System 1-2, 1-5, 1-8, 2-13

Analog input

maximum current 2-26

maximum voltage 2-26

Analog input channels iii, 1-4, 2-15

Analog output channels iii, 1-4, 2-16,

2-27

Autoranging iii, 1-4

Auxiliary components 2-4 to 2-11

B

Block Diagram of DATAshuttle 2-2

Board Number 1-10

D

Data acquisition speed iii, 1-4

DATAshuttle-GP 1-6

DATAshuttle-TC 1-7, 2-21, 2-22

DATAshuttle-RTD 1-6

DB-25 parallel cable 1-5, 1-9, 2-13

Digital auxiliary components 2-10 to

2-11

Digital input/output channels 1-4, 1-6,

1-7, 2-16, 2-26

Dynamic Resolution iii, 1-3

E

EDITCAL 2-3

EEPROM 2-3

F

G

Ground loops 2-9, 2-15

C

Calibration numbers 2-3, 2-13

Cold junction compensation 1-2, 1-4

error 2-20

Common mode range 2-25

Common Mode Rejection Ratio

(CMRR) 2-24

Counter/timer iii, 1-4, 2-12, 2-27

Current

maximum 2-26

measurement 1-2

sense resistor 2-7

H

Hardware requirements 1-5

Highlights of the DATAshuttle iii

I

Illustration of DATAshuttle-GP/

DATAshuttle-RTD 1-6

Illustration of DATAshuttle-TC 1-7

Input impedance 2-25

Input protection iii, 1-4, 2-25

Installation

of 3-wire RTD 2-8

of a printer with DA TAshuttle 1-10

DATAshuttle Owner’s Manual

Index – 1

Page 48

DATA

I – S

shuttle

OWNER’S MANUAL

of a single DATAshuttle 1-9

of current sense resistor 2-7

of digital module 2-10

of multiple DATAshuttles 1-10

of pull-up resistors 2-10

troubleshooting 2-14

with the keyboard adapter cable

1-10

J

K

Keyboard Adapter power cable 1-10,

2-14

L

Low noise mode 1-4, 2-13, 2-15

M

Maximum

analog input channels (in an

installation) 1-2

current 2-26

DATAshuttles 1-2

digital input channels (in an

installation) 1-2

resolution iii

speed iii

voltage 2-26

Minimum sample periods 2-13

Multiple DATAshuttles

installation of 1-10

N

O

P

Parallel cable (DB-25) 1-5, 1-9, 2-14

Power supplies 2-5

Printer

installation with DATAshuttle(s)

1-10

Pull-up resistors 2-10

Q

QuickLog PC 1-2, 1-5, 1-8

R

Range

input power voltage 1-2, 1-4, 2-26

Resistance Temperature Device (RTD)

iii, 1-2, 1-4, 1-6, 2-5, 2-8

accuracy in measurement of 2-23

to 2-24

Resolution

and scan rate 2-25 to 2-26

dynamic 1-3

maximum iii, 1-4

selection 1-4

S

Sample periods

minimum 2-13

Scan rate 2-25 to 2-26

Software requirements 1-5

System requirements 1-5

Noise rejection 1-4, 2-25

Alphabetical Index of this Volume

Index – 2

Page 49

T

Thermocouple

accuracy of measurements 2-19 to

2-21

cold junction compensation error

2-21

conditions 2-21

innacurate measurement of 2-15

measurement 1-7

types 1-2

Troubleshooting

of installation 2-14

of operation 2-15

U

V

INDEX

T – Z

Voltage 1-4, 2-26

W

WB-AAI/FAI 2-13

WorkBench PC for DOS 1-2, 1-5, 1-8

WorkBench PC for Windows 1-2, 1-5,

1-8, 2-14

X

Y

Z

DATAshuttle Owner’s Manual

Index – 3

Loading...

Loading...