Page 1

(1*,1((5,1*,1&

DAQP-12/12H/16

PCMCIA

Data Acquisition System

For Machines with Standard PCMCIA Interface

Users Manual

INTERFACE CARDS FOR PERSONAL COMPUTERS

OMEGA ENGINEERING, INC. Tel: (203) 359-1660

One Omega Drive Fax: (203) 359-7700

P.O. Box 4047 Toll free: 1-800-826-6342

Stamford, CT 06907-4047 E-mail: das@omega.com

http://www.dasieee.com

Page 2

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC., warrants this unit to be free of defects in materials and workmanship fo r a period of 13

DAQP-12/12H/16 Users Manual 2

months from the date of purchase. OMEGA warranty adds an additional one (1) month grace period to the normal one (1)

year product warranty

coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number im mediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. OMEGA’s

warranty does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation o utside design limits, impr oper repair or unauthorized modif ication. This WARRANTY is

VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Com ponents which wear are not warranted, including but not limited to contact

points, fuses and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products

in accordance with information provided from OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND

ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PU RPOSE ARE HEREBY D ISCLAIMED . LIMITA TION O F LIABILITY: The remedi es of purc haser set

forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITION S: Equipment so ld by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Comp onent”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity, medical application or used on humans.

Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans or

misused in any way, OMEGA assum es no respo nsibility as set forth in o ur basic WA RRAN TY/DISCLAI MER language, and

additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

to cover shipping and handling time. This ensures that OMEGA’s customers receive maximum

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). THE ASSIGNED

NUMBER SHOULD THEN BE MARKED ON THE OUTSIDE OF THE RETURN PACKAGE AND ON ANY

CORRESPONDEN CE. THE PURCHASER IS RESPONSIBLE FOR SHIPPING C HARGES, FREIGHT, IN SURANCE AND

PROPER PACKAGING TO PREVENT BREAKAGE IN TRANSIT.

FOR WARRANTY

(1) P.O. Number under which the product was purchased,

(2) Model and serial number of the product under warranty, and

(3) Repair instructions and/or specific problems relative to the product.

FOR NON-WARRANTY

BEFORE contacting OMEGA:

(1) P.O. Number to cover the cost of the repair,

(2) Model and serial number of the product, and

(3) Repair instructions relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvem ent is possible. This af fords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC. © Copyright 1999 OMEGA ENGIN EERING, IN C. A ll

rights reserved. This document may not be copied, photocopied, reproduced, translated or reduced to any electronic

medium or machine readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA fo r current repair charges. Have the fo llowing information available

Page 3

Declaration of Conformity

Manufacturer's Name:

Manufacturer’s Address:

Application of Council Directive:

Standards to which

Conformity is Declared:

(EN55022, EN60555-2, EN60555-3)

Type of Equipment:

Equipment Class:

Information Technology Equipment

Commercial, Residential and Light Industrial

89/336/EEC

Omega Engineering, Inc.

One Omega Drive

P.O. Box 4047

Stamford, CT 06907-0047

* EN50081-1

* EN50082-1

(IEC 801-2, IEC 801-3, & IEC 801-4)

Product Name:

Model Number :

DAQP-12/12H/16 Users Manual 3

PCMCIA Card

DAQP-12/12H/16

Page 4

OMEGAnet On-line Service: Internet e-mail:

DAQP-12/12H/16 Users Manual 4

http://www.omega.com

Servicing North America

: One Omega Drive, Box 4047 E-mail: info@omega.com

USA

ISO 9001 Certified

Canada

: 976 Bergar E-mail: info@omega.com

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

info@omega.com

:

For immediate technical or application assistance

USA and Canada

Mexico and Latin America

: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

: Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espanol: (001) 203-359-7803 E-mail: espanol@omega.com

SM

:

SM

SM

Benelux

Czech Republic

France:

Germany/Austria

: Postbus 8034, 1180 LA Amstelveen, The Netherlands

: ul.Rude armady 1868, 733 01 Karvina-Hraniee

Servicing Europe

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

E-mail: nl@omega.com

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

Toll Free: 0800-1-66342 E-mail: czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

E-mail: france@omega.com

: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

E-mail: germany@omega.com

:

Page 5

United Kingdom: One Omega Drive, River Bend Technology Drive

DAQP-12/12H/16 Users Manual 5

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that app ly.

OMEGA is constantly pursuing certification of it’s products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc.

accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, p atient

connected applications.

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

E-mail: info@omega.co.uk

Page 6

Table of Contents

5.9 A/D State Machine

5.8 Digital I/O

5.7 Interrupt and Status

5.6 A/D Converter and Data FIFO

5.5 Trigger Circuit

5.4 Scan List Register

5.3 Programmable Gain Control Amplifier

5.2 Analog Input Multiplexer

5.1 DC/DC Power Supply

5. Theory of Operation

4.4 After Completing Configuration

20

4.3.3 Card and Socket Services Software

20

4.3.2 Socket Numbers

20

4.3.1 Memory Range Exclusion

4.3 Common Problems

4.2 Enabler Examples

4.1 Enabler Command Line Options

4. Using the Enabler

3.5 After Completing Configuration

16

3.4.3 Older Versions of Card and Socket Services

16

3.4.2 Multiple Configuration Attempts

16

3.4.1 Available Resources

15

3.4.1 Generic Client Drivers

3.4 Common Problems

3.3 Client Driver Installation Examples

3.2 Client Driver Command Line Options

3.1 Installing the Client Driver

2.3 Software Setup (Windows 3.xx and MS-DOS®)

11

2.2.3 Changing the Configuration of the DAQP Card

10

2.2.2 Viewing the DAQP Series Card Status

10

2.2.1 Installing the DAQP Series Card

2.2 Software Setup (Windows 95/98®)

2.1 Hardware Setup

1. Introduction

.........................................................

DAQP-12/12H/16 Users Manual 6

9

2. Installation

..........................................................

..................................................

3. Using the Client Driver

...............................................

..............................................

...............................................

................................

.....................................

................................

........................

....................

.........................................

.......................................

.............................

...............................

....................................

...........................

..................................

10

10

10

12

13

13

14

14

15

16

................................................

..................................

................................................

...............................................

...........................................

...................................................

...................................

..................................

............................................

............................................

.........................................

............................

.................................................

...................................................

....................................

..............................................

.......................................................

...............................................

17

18

19

20

20

21

22

22

23

23

24

24

25

25

26

Page 7

10. Specifications

9.2 CP-DAQP Cable Assembly

9.1 UIO-37 Screw Terminal Block

8. I/O Connections

40

7.7.6 Scan Rate Selection

39

7.7.5 Data FIFO Program/Access Control

39

7.7.4 A/D Stop Command

38

7.7.3 Flush Data FIFO Command

38

7.7.2 Flush Scan List Queue Command

38

7.7.1 Trigger/Arm Command

7.7 Auxiliary Control Register (base + 7)

7.6 Pacer Clock (base + 4, + 5, + 6)

36

7.5.2 Digital Input

36

7.5.1 Digital Output

7.5 Digital I/O Register

7.4 Status Register (base + 2, read)

35

7.3.5 Trigger Edge

35

7.3.4 Trigger Mode/Source

34

7.3.3 Interrupt Enable

34

7.3.2 Expansion Mode

34

7.3.1 Clock Source

7.3 Control Register (base + 2, write)

33

7.2.3 Analog Input Offset Correction

33

7.2.2 Channel Configuration

32

7.2.1 Scan List Queue Programming

7.2 Scan List Queue Register (base + 1)

31

7.1.3 FIFO Flags

31

7.1.2 Mode Setting

30

7.1.1 Data FIFO Operation Modes

7.1 Data FIFO Register (base + 0)

7. I/O Registers

6.2 Card Configuration and Status Register (CCSR)

6.1 Configuration and Option Register (COR)

6. PCMCIA Interface

DAQP-12/12H/16 Users Manual 7

................................................

.........................

...................

27

28

28

........................................................

.....................................

........................................

.....................................................

.......................................................

...............................

.......................................

.............................................

......................................

..................................

......................................................

..................................................

...................................................

..............................................

.....................................................

....................................

..............................................

....................................................

......................................................

....................................

..............................

............................................

....................................

.........................................

...............................................

..................................

................................................

29

29

32

34

35

36

37

38

9. Optional Accessories

...................................................

.............................................

.....................................

.......................................

.....................................................

41

42

42

43

46

Page 8

List of Figures and Tables

45

Table 9-1. DAQP Series Card Cable Mapping

39

Table 7-14. Data FIFO Threshold Setting

38

Table 7-13. Auxiliary Control Register Bit Definition

36

Table 7-12. Digital Input Register Bit Definition

36

Table 7-11. Digital Output Register Bit Definition

35

Table 7-10. Status Register Bit Definition

34

Table 7-9. Control Register Bit Definition

33

Table 7-8. Scan List Queue Programming Example 2

33

Table 7-7. Scan List Queue Programming Example 1

32

Table 7-6. Scan List Queue Entry Bit Definition

31

Table 7-5. Data FIFO Flag Status

30

Table 7-4. Data FIFO Threshold Setting

30

Table 7-3. Data FIFO Operation Mode

30

Table 7-2. Data FIFO Register Bit Allocation

29

Table 7-1. DAQP Series Card Address Map

28

Table 6-3. CCSR Bit Definition

28

Table 6-2. COR Bit Definition

27

Table 6-1. PCMCIA Configuration Registers

12

Table 2-1. Comparison Between Client Driver and Enabler

44

Figure 9-3. CP-DAQP/UIO-37 D-37 Pin Diagram

43

Figure 9-1. DAQP Series Card Accessory Connection

41

Figure 8-1. DAQP Series Card Hirose-32 Output Connector

37

Figure 7-1. Pacer Clock Block Diagram

26

Figure 5-3. Transition Diagram of A/D Conversion Process

21

Figure 5-1. DAQP Data Acquisition System Block Diagram

..........................

DAQP-12/12H/16 Users Manual 8

............................................

................................

...................................

......................................

...................................................

..................................................

.......................................

......................................

...........................................

..........................................

................................................

....................................

...............................

...............................

.........................................

..........................................

...................................

....................................

................................

..........................................

.....................................

..........................

..........................

..........................

Page 9

1. Introduction

DAQP-12/12H/16 Users Manual 9

DAQP CARD FEATURES:

Sampling rate up to 100 kHz with 12 or 16 bit resolution

8 differential or 16 single-ended analog input channels, expandable to 256 channels

Bipolar input range up to ±10 volts

Software programmable gain selection: 1, 2, 4 or 8 for the DAQP-12/16 and

1, 10, 100 or 1000 for the DAQP-12H

2048 sample Data and Scan FIFOs

24-bit pacer clock with variable pre-scalers and internal or external clock source

Digital input/output channels

Flexible trigger mode (internal/external, one-shot/continuous, rising/falling edge)

Omega’s “DaqSuite” data acquisition software included in addition to drivers for

MS-DOS®, Windows 3.xx and Windows 95/98®

The DAQP series card is a PCMCIA type II data acquisition system with 8 differential or 16

single-ended analog input channels. The number of input channels can be expanded to 256

with an i nput e x pansi on card. DAQP series pr od ucts include the DAQP-12, the DAQP-16 and

the high gain DAQP-12H. The programmable gain settings of the DAQP-12 and DAQP-16

span bipolar input ranges of ±1.25 V (gain = 8), ±2. 5 V (gain = 4), ±5 V (gain = 2) and ± 10V

(gain = 1), w hile the DAQP-12H offers a bipol ar input range of ±0.01 V (gain = 1000), ±0.1 V

(gain = 100), ±1 V (gain = 10) and ± 10V (gain = 1).

The DAQP card supports sampling rates up to 100 kHz with either 12 or 16-bit resolution.

Equipped with a data FIFO of 2048 samples, the DAQP card can achieve high speed data

acquisition under various operating platforms including MS-DOS®, Windows 3.xx and

Windows 95®. Also equipped with a scan FIFO of the same size, the DAQP supports full

speed, random order channel scanning and gain selection for all input channels including

expansion channels. The DAQP card uses a 24-bit pacer clock and a programmable

divide-by-2, by-10 or by-100 pre-scaler. The pacer clock can also be used with either an

internal or external cl ock source. With the 10 MH z internal clock source, the pacer clock can

generate accurate sampling rates from 0.006 Hz to 100 kHz. The DAQP card has 4 digital

input and output channels, all TTL compatible, which may be used for process control or

monitoring in addition to analog data acquisition.

Software drivers are provided that support various programming languages like Microsoft

C/C++, Borland C/C++, Delphi, QuickBasic, Visual Basic for DOS and Turbo Pascal. Also

included is a Dynamic Link Library (DLL) that supports programming languages under

Microsoft Windows as well as the Visual Basic Controls (VBX). Omega includes it’s user

friendly data acquisition software: DaqEZ®, as well as turnkey software support for LabTech

NoteBook®, SnapMaster®, LabVIEW® and TestPoint®.

Page 10

2. Installation

DAQP-12/12H/16 Users Manual 10

2.1 Hardware Setup

Insert the DAQP card into any type II PCMCIA socket. All other configuration options are

determined by the operating system.

2.2 Software Setup (Windows 95/98®)

An “.INF” file (DAQPCARD.INF) is provided on the root directory of the DAQSUITE

CD-ROM for easy installati on of the DAQP series car d under Wind ows 95/98. The operating

system uses the “.INF” file to determine what system resources are required by the card,

searches for available resources to fill the requirements, configures the DAQP card hardware

and then updates the hardware registry with an entry that allocates these resources.

2.2.1 Installing the DAQP Series Card

1. Insert the DAQP card in any available PCMCIA socket.

2. The first time a new PCMCIA type card is installed the “New Hardware Found”

window opens. Windows 95/98 will automatically detect and configure the card. If

the “New Hardware Found” window does not open, skip to the next section:

“Viewing the PCMCIA Card Status”.

3. Windows will ask for the CD-ROM that came with the device. Insert the CD, click

“Next” to continue and then click “Finish”.

4. W indows automatically b rowses the root dir ectory on the CD for the IN F file that

defines configurations for the new hardware type found. The file name is not

required. After searching the root directory, Windows will choose the correct file.

5. Your new PCMCIA card should now be configured. In the future, Windows will

automatically recognize and configure this specific PCMCIA card type.

2.2.2 Viewing the DAQP Series Card Status

1. Double click the “My Computer” icon located on the Windows 95/98 desktop. This

opens a folder showing the various drives, printers, etc. (This can also be done by

clicking “Start”, “Settings” and then “Control Panel”).

2. Doub le click the “Control Pane l” icon. This opens another fol der with dif ferent system

configuration utilities.

3. Double click the “PC card (PCMCIA)” icon. This opens the “PC Card (PCMCIA)

Properties” window.

4. The “PC Card (PCMCIA) Properties” window shows the status of your computers

PCMCIA sockets. The DAQP card should be listed in one of these sockets. To change

the DAQP card configuration see the next section.

Page 11

IMPORTANT:

DAQP-12/12H/16 Users Manual 11

If you are using Wi ndows 95/98 to configure the DAQP card then ignore section 2.3 of

this chapter. The Windows 95/98 operating system completely installs and configures the

DAQP series ca rd. Do NOT attempt to use the D AQP series Client Dri ver or Enabler to

configure any DAQP series card under Windows 95/98.

2.2.3 Changing the Configuration of the DAQP Card

1.

Double cli ck the “My Computer” i con located on the Wind ows 95 desktop. Inside the

“My Computer” folder, double click the “Control Panel” icon. This can also be done by

clicking “Start”, “Settings” and then “Control Panel”.

2.

Inside the “Control Panel” fold er, double cli ck the “System” icon so that the “System

Properties” window opens. Select the “Device Manager” tab. Find the entry titled

“Data_Acquisition” on the device list. Expand the entry by clicking the leading “+”

sign or by double clicking the name.

3.

From the expa nded sub-list, choose the DAQP card to reconfigure (ther e may be only

one entry) by double clicking it.

4.

Select the “Resources” tab from the pop-up window. Click the resource type (either

“Input/Output range” or “Interrupt Request”) from the “Resource Setting” table and

then click the “Change Settings ...” button. This opens the “Edit Input/Output Range”

or “ Edit Interrupt Request” window.

5.

Change the value by clicking on the slider controls by the “value” list and then click

OK to confirm the change, or CANCEL to discard it. Watch for possible conflicts

shown in the “Conflict Information” box.

The only conf iguration parameters that can be changed for the DAQP car d under Windows

95/98 are “Input/Output Ranges” and “Interrupt Request”.

Page 12

2.3 Software Setup (Windows 3.xx and MS-DOS®)

Does not require PCMCIA Card and

Requires PCMCIA Card and Socket

Does not support automatic

Allows automatic configuration of

Interfaces directly to Intel 82365SL and

Interfaces to PCMCIA Card and

DAQP_EN.EXE

DAQP_CL.SYS

DAQP-12/12H/16 Users Manual 12

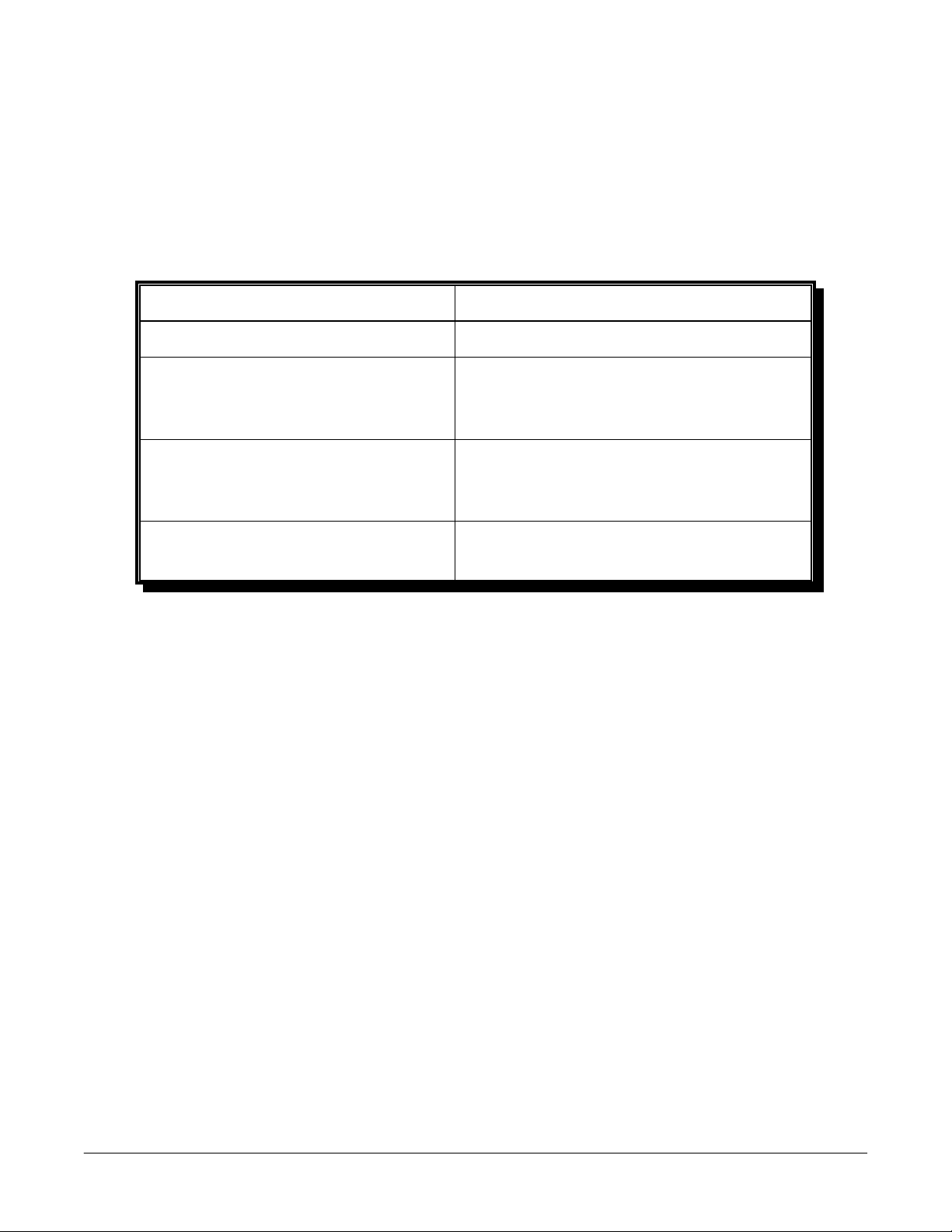

Two software configuration programs are provided with the DAQP card: a Client Driver

named DAQP_CL.SYS and a card Enabler named DAQP_EN.EXE. Either one of these

programs may be used to configure the card

below highlights the differences between the Client Driver and the Enabler programs.

(Detailed instructions for using the Client Driver and Enabler are discussed in Chapters 3 and

4 respectively).

but only one may be used at a time

EnablerClient Driver

. The table

Socket Services software (PCMCIA

host adapter independent)

DAQP card upon insertion (Hot

Swapping)

Services software

Table 2-1. Comparison Between Client Driver and Enabler

On systems with Card and Socket Services installed, the Client Driver is the preferred method

of installation. To determine if Card and Socket Services software is installed, install the

DAQP series Client Driver as discussed in Chapter 3. When loaded, the Client Driver will

display an error message if Card and Socket Services software is not detected.

other PCIC compatible PCMCIA host

adapters

configuration of DAQP card upon

insertion (Hot Swapping)

Socket Services software

Page 13

3. Using the Client Driver

DAQP-12/12H/16 Users Manual 13

3.1

For systems using MS-DOS and PCMCIA Card and Socket Services software, a Client Driver

named “DAQP_CL.SYS” i s provided to confi gure the DAQP series card s. PCMCIA Card and

Socket Services software is not provided and must be purchased independently.

Some versions of Card and Socket Services dated b efore 1993 do not support general purpose

I/O cards. After careful installation of the Client Driver, if the DAQP card still does not

configure or operate properly, an updated version of Card and Socket Services software may

be required. The following procedures are used to install the DAQP series Client Driver:

Installing the Client Driver

1. Copy the file DAQP_CL.SYS located in the PCMCIA\DOS\CLIENTS directory of the

“DAQSUITE” CD-ROM onto the root directory of the system hard drive.

2. Using an ASCII text editor, open the system CONFIG.SYS file located in the root

directory of the boot drive.

3. Locate the line in the CONFIG.SYS file where the Card and Socket Services software is

installed.

4. AFTER the line installing the Card and Socket Services software, add the following line

to the CONFIG.SYS file:

DEVICE = drive:\path\DAQP_CL.SYS options

where options ar e the DAQP series Cl ient Driver command line options discussed on

the following pages. (Path is only required if the user copies the Client Driver into a

directory other than the root directory).

5. Save the CONFIG.SYS file and exit the text editor.

6. Insert the DAQP card into one of the system PCMCIA slots.

NOTE: Since the DAQP series Client Driver supports "Hot Swapping", it is not

necessary to have the DAQP card installed when booting the system. However, by

inserting the card before booting, the Client Driver will report the card configuration

during the boot process and thereby verify changes made to the CONFIG.SYS file.

7. Reb oot the system and note the message d isplay ed when the Cli ent Dri ver is loade d. If

the Client Driver reports an “invalid command line option”, correct the entry in the

CONFIG.SYS f ile and reb oot the system. If the Client D river r eports “Card and Sock et

Services not found”, then either Card and Socket Services software must be installed on

the system or the DAQP series Enabler program must be used to configure the card,

(see Chapter 4 ). If the Client Driver reports the desired card configuration, the

installation process is complete and the DAQP card may be removed and inserted from

the system as desir ed. On each insertion into the PCMCIA socket, the DAQP card wil l

automatically be reconfigured to the specified settings.

Page 14

3.2

DAQP-12/12H/16 Users Manual 14

The DAQP series Client Dri ver accepts up to eight command l ine arguments from the user to

determine the configuration of the DAQP card. If any arguments are provided, the Client

Driver will attempt to configure any DAQP card with the options specified in the order they

are entered on the command line. Each argument must be enclosed i n parenthesi s and must be

separated from other arguments by a space in the command line. Inside an argument, a

comma (no space) should b e used to separate the para meters f rom each other if there are two

or more parameters. Within each argument, any or all of the following parameters may be

specified:

(b address) Specifies the base I/O address of the DAQP card in hexadecimal.

(i irq) Specifies the interrupt level (IRQ) of the DAQP card in hexadecimal.

Client Driver Command Line Options

“Address” must be in the range 100H - 3F8H and must reside on an even 8-byte

boundary (“address” must end in 0 or 8). If this option is omitted, a base address

will be assigned by Card and Socket Services software.

“Irq” must be one of the following values: 3, 4, 5, 7, 9, 10, 11, 12, 14, 15 or 0 if no

IRQ is desired. If this option is omitted, an interrupt level will be assigned by

Card and Socket Services software.

(s socket) Specifies the PCMCIA socket number to configure.

“Socket” must be in the range 0 - 15. If this option is omitted, the configuration

argument will be applied to any DAQP card inserted into any socket(s) in the

system.

3.3 Client Driver Installation Examples

With the Client Driver, the user may specify a list of selections (in the form of command line

arguments) for the configuration of the DAQP series cards. The Client Driver scans this list

from left to right until it finds a selection that is currently available in the system. If none of

the preferred selections are available, the Client Driver requests a configuration from Card

and Socket Services software.

Example 1: DEVICE = C:\DAQP_CL.SYS

In example 1, no command line arguments are specified. The Client Driver will configure the

DAQP card into ANY socket with a base ad dress and IRQ level assigned by Card and Socket

Services.

Example 2: DEVICE = C:\DAQP_CL.SYS (b300)

In this example, a single command line argument is provided. The Client Driver will attempt

to configure a DAQP card inserted into ANY socket with a base address of 300H and an IRQ

level assigned by Card and Socket Services. If the base address 300H is not available, the

DAQP card will NOT be configured.

Page 15

Example 3: DEVICE = C:\DAQP_CL.SYS (s0,b300,i5)

Example 3 is also a single command line argument. The Client Driver will attempt to

DAQP-12/12H/16 Users Manual 15

configure the DAQP card inserted in socket 0 at base address 300H and IRQ level 5. If either

address 300H or IRQ 5 are unavailable, the card will NOT be configured. In addition, the

Client Driver will NOT configure any DAQP card unless inserted into socket 0.

Example 4: DEVICE = C:\DAQP_CL.SYS (b300,i5) (i10) ( )

Three command line arguments are provided in this example. The Client Driver will first

attempt to configure a DAQP card inserted into any socket wi th a base address 300H and IRQ

level 5. If either address 300H or IRQ 5 are unavailable, the Client Driver will proceed to the

second command line argument and attempt to configure the card with a base address

assigned by the Card and Socket Services and IRQ level 10. If IRQ 10 is also unavailable, the

Client Driver will then go to the third command line argument and attempt to configure it

with a base address and an IRQ level assigned by Card and Socket Services.

Example 5: DEVICE = C:\DAQP_CL.SYS (b300,i5) ( ) (i10)

The difference between examples 5 and 4 is the order of the second and third command line

arguments. The Client Driver will first attempt to configure a DAQP card inserted into any

socket with a base address 300H and IRQ level 5. If either address 300H or IRQ 5 are

unavailable, the Client Driver will proceed to the second command line argument and attempt

to configure the card with a base address and IRQ level assigned by Card and Socket Services.

Since the second command line argument includes all available address and IRQ resources,

the third command line argument will never be reached. The user must ensure the command

line arguments are placed in a logical order.

Example 6: DEVICE = C:\DAQP_CL.SYS (s0,b300,i5) (s1,b310,i10)

There are two command line arguments in example 6, which is desirable in systems where

two or more DAQP cards are to be installed. The Client Driver will attempt to configure the

DAQP card in socket 0 with base addr ess 300H and IRQ level 5. If there is a DAQP card i n

socket 1, it will be configured with base address 310H and IRQ 10. This allows the user to

force the card addresses and I RQ settings to be socket speci f i c as required by software or cable

connections. If the requested resources are not available, the DAQP cards will not be

configured.

3.4 Common Problems

3.4.1 Generic Client Drivers

Many Card and Socket Services packages include a generic client driver (or SuperClient)

which configures standard I/O devices. If one of these generic client drivers is installed, it

may configure the DAQP card and cause the DAQP series Client Driver to fail installation. If

this is the case, the operation of the generic client driver can be modified so that it will not

configure the DAQP card. Place the DAQP series Client Driver command line before the

generic client driver command line in the CONFIG.SYS file. Consult the Card and Socket

Services documentation for availability and details of this feature.

Page 16

3.4.1 Available Resources

DAQP-12/12H/16 Users Manual 16

One function of Card and Socket Services software is to track which system resources

(memory addresses, I/O addresses, IRQ levels, etc.) are available for assignment to inserted

PCMCIA cards. Sometimes, however, the Card and Socket Services assumes or incorrectly

determines that a particular resource is unavailable when it actually is available. Most Card

and Socket Services generate a resource table, typically in the form of an “.INI” file, which the

user can modify to ad j ust the avai l a b l e system resources. Consul t the Card and Socket Services

documentation for the availability and details of this feature.

3.4.2 Multiple Configuration Attempts

Some Card an d Socket Services have a setting whi ch aborts the confi guration process after a

single configuration failure (such as a configuration request for an unavailable resource). The

user should change this setting to allow f or mul ti ple configurati on attempts. Consult the Car d

and Socket Services documentation for the availability and details of this feature.

3.4.3 Older Versions of Card and Socket Services

Some versions of Card and Socket Services dated b efore 1993 do not support general purpose

I/O cards like the DAQP series card s. If after careful installati on of the DAQP Client Dri ver,

the DAQP card still can not be configured or operated properly, an updated version of Card

and Socket Services may be required.

3.5 After Completing Configuration

The DAQP card is now configured and ready for use. Depending on the type of application

software to be used, the user may wish to review one or more of the following:

1. Chapter 5 of this document provides basic theory of operation for users that wish to

learn technical details about the operation of the DAQP card.

2. For users that want to program direct I/O transfers to the DAQP card’s register set,

Chapter 7 provides an address map and a detailed description of each register.

3. User s that wish to write custom application software w ithout programming the DAQP

card di rectl y should consult the D AQDRI VE® softwar e ref ere nce manual . DA QDRIVE

provides a library of data acquisition subroutines for various data acquisition cards and

is included free of charge with the DAQP card.

4. For turnkey data acquisition software such as LabTech NoteBook®, SnapMaster®,

LabVIEW® and TestPoint®, consult the documentation provided by the software

manufacturer.

Page 17

4. Using the Enabler

For systems that are not operating PCMCIA Card and Socket Services software, the DAQP

DAQP-12/12H/16 Users Manual 17

series card includes an Enabler program to enable and configure the DAQP series card. This

Enabler, DAQP_EN.EXE, will operate in any DOS system using an Intel 82365SL or PCIC

compatible PCMCIA host adapter including the Cirrus Logic CL-PD6710/6720, the VLSI

VL82C146 and the Vadem VG-365.

In order to use the DAQP seri es Enabler for DOS, the system must NOT be confi gured with

Card and Socket Services software. If Card and Socket Services software is installed, the

Enabler may interfere with its operation and the devices it controls. Therefore use either the

DAQP series Client Driver or Enabler exclusively.

The DAQP se ries Enabler d oes not support automatic configurati on of PCMCIA cards upon

insertion, more commonly referred to as “Hot Swapping”. This means the card must be

installed in one of the system's PCMCIA sockets before executing DAQP_EN.EXE. If more

than one adapter is installed in a system, the Enabler must be executed separately for each

card. Furthermore, DAQP_EN.EXE should be executed to release the resources used by the

card bef ore it is removed from the PCMCIA socket. Si nce PCMCIA cards do not retain their

configurati on af ter r e moval , any card r e moved from the syste m must b e reconfigur ed with the

Enabler after being reinserted into it’s PCMCIA socket.

The Enabler requires a region of high DOS memory when configuring the DAQP card. This

region is 1000H (4096) bytes long and by default begins at address D0000H (this may be

changed by the “W” option as will be described later). If a memory manager such EMM386,

QEMM or 386MAX is installed on the system, this region of DOS memory must be excluded

from the memory manager’s control (normally by using the “x” switch). Consult the

documentation provided with the memory manager software for instructions on how to

exclude this memory region.

The following procedures are used to install the DAQP series Enabler:

1. Copy the file DAQP_EN.EXE located in the PCMCIA\DOS\ENABLERS directory of

the “DAQSUITE” CD-ROM onto the root directory of the system hard drive.

2. Using an ASCII text editor, open the system's CONFIG.SYS file located in the root

directory of the boot drive.

3. Add the following line to the CONFIG.SYS file:

DEVICE = drive:\DAQP_EN.EXE (options)

where (options) are the DAQPA series Ena bler command line opti ons discussed on the

following pages.

4. Save the CONFIG.SYS file and exit the text editor.

Page 18

5. Insert the DAQP card into one of the system PCMCIA slots.

DAQP-12/12H/16 Users Manual 18

NOTE: Since the DAQP series Enabler does not support "Hot Swapping",

it is necessary to have the DAQP card installed when booting the system.

6. Reboot the system and note the message displayed when the Enabler is loaded.

If the Enabler reports the desired card configuration, the installation process

is complete.

4.1 Enabler Command Line Options

To configure a DAQP series card in the system, the Enabler requires one command line

argument from the user to determine the configuration. This argument must be enclosed in

parenthesis. Within the argument, a comma (no space) must be used to separate the

parameters from each other if there are two or more parameters. The following parameters

may be specified in the command line argument:

(s socket) Specifies the PCMCIA socket number to configure.

“Socket” must be in the range 0 - 15. This option is always required.

(b address) Specifies the base I/O address of the DAQP card in hexadecimal.

“Address” must reside on an even 8-byte boundary (“address” must end in 0 or 8).

This option is required if the “r” option is not used.

(i irq) Specifies the interrupt level (IRQ) of the DAQP card in hexadecimal.

“Irq” must be one of the following values: 3, 4, 5, 7, 9, 10, 11, 12, 14, 15, or 0 i f no

IRQ is desired. This option is required if the “r” option is not used.

(w address) Specifies the base address of the memory window required to configure the

DAQP card. Set “address” = D0 for a memory window at D0000, = D8 for a

memory window at D8000, etc. Valid settings for address are C8, CC, D0, D4,

D8, and DC. If omitted, “address” = D0 is assumed.

(r) Instructs the Enabl er to release the resources previousl y allocated to the DAQP

card. When this option is used, (b address) and (i irq) options will be ignored.

Therefore, do NOT use this option when initially configuring the DAQP card.

Page 19

4.2 Enabler Examples

DAQP-12/12H/16 Users Manual 19

Example 1

No command line argument is specified. The Enabler will report an error and display the

proper usage of the Enabler.

Example 2: DEVICE=C:\DAQP_EN.EXE (s0,b300,i5)

In this example, the Enabler will configure the DAQP card in socket 0 with a base address

300H and IRQ level 5 using a configuration memory window at D0000H.

Example 3: DEVICE=C:\DAQP_EN.EXE (i10,b310,s1)

In example 3, the Enabler will configure the DAQP card in socket 1 with a base address at

310H and IRQ level 10 using a configuration memory window at D0000H. Note the parameter

order is not significant.

Example 4: DEVICE=C:\DAQP_EN.EXE (s0,b300,i5,wCC)

Here the Enabler will configure the DAQP card in socket 0 with a base address at 300H and

IRQ level 5 using a configuration memory window at CC000H.

:

DEVICE=C:\DAQP_EN.EXE

Example 5: DEVICE=C:\DAQP_EN.EXE (s0,r)

DEVICE=C:\DAQP_EN.EXE (s0,r,b300,i5)

These two command line arguments are equivalent because of the “r” option. The Enabler

will release the configuration used by the DAQP card in socket 0 using a configuration

memory window at D0000H.

Example 6: DEVICE=C:\DAQP_EN.EXE (s0,r,wC8)

Here the Enabler will release the configuration used by the DAQP card in socket 1, using a

configuration memory window at C8000H.

Page 20

4.3 Common Problems

4.3.1 Memory Range Exclusion

DAQP-12/12H/16 Users Manual 20

The Enabler requires a region of high DOS memory when configuring a DAQP card. This

region is 1000H (4096) bytes long and by default begins at address D0000H (this default

address can be changed by usi ng the “W” option). If a memory manager such as EMM386,

QEMM or 386MAX is installed on the system, this region of DOS memory must be excluded

from the memory manager’s control (normally by using the “x” switch). Consult the

documentation provided with the memory manager software for instructions on how to

exclude this memory r egion. Furthermor e, some systems use the high memory area for ROM

shadowing to i mprove overall system per formance. For the E nabler to properl y operate, any

ROM shadowing must be disabled in the address range specified for the configuration

window. This can usually be completed by using the system’s CMOS setup utility.

4.3.2 Socket Numbers

The Enabler requi res that the socket number be specifi ed for the DAQP card to be configured .

The DAQP card must be inserted into the socket before executing the Enabler. For the DAQP

series Enabler, the lowest socket number is always designated as socket 0 and the highest

socket number as N-1, (assuming there are N sockets avail able). Some vendors number their

sockets from 1 to N. In that case, the vendor socket number minus 1 should be used in the “s”

option for the DAQP series Enabler.

4.3.3 Card and Socket Services Software

In order to use DAQP seri es Enab ler for DOS, the system must NOT be configure d with Card

and Socket Services software. If Card and Socket Services software is installed, the Enabler

may interfere with its operation and the devices it controls.

4.4 After Completing Configuration

The DAQP card is now configured and ready for use. Depending on the type of application

software to be used, the user may wish to review one or more of the following:

1. Chapter 5 of this document provides basic theory of operation for users that wish to

learn technical details about the operation of the DAQP series card.

2. For users that want to program direct I/O transfers to the DAQP card’s register set,

Chapter 7 provides an address map and a detailed description of each register.

3. User s that wish to write custom application software w ithout programming the DAQP

card di rectl y should consult the D AQDRI VE® softwar e ref ere nce manual . DA QDRIVE

provides a library of data acquisition subroutines for various data acquisition cards and

is included free of charge with the DAQP card.

4. For turnkey data acquisition software such as LabTech NoteBook®, SnapMaster®,

LabVIEW® and TestPoint®, consult the documentation provided by the software

manufacturer.

Page 21

5. Theory of Operation

The DAQP card consists of 8 differential or 16 single-ended analog input channels. The A/D

DAQP-12/12H/16 Users Manual 21

converter, either 12 -bit or 16-bit, can be operated at a top speed of 100,000 samples per

second, (10 ms per sample). The A/D converter uses l eft-j ustifi ed 2's complement cod ing. For

the 16-bit version, the output ranges f rom -32768 to 32767. The 12-bit version i s structured so

that it’s contents occupy the most significant 12 bits, padding the least significant 4 bits with

all zeros to make a 16-bit output word for each converted input sample.

8 Differential

or

16 Single Ended

Analog Input

Multiplexer

Programmable

24-bit

Pacer Cl o c k

Programmable

Gain Amp

x1, 2, 4, 8

512 or 2048

step

Scan List

A/D

Converter

512 or 2048

word

Data FIFO

Clock

Selection

Trigger

Control

Digital I/O

Sampling

Control

PCMCIA

BUS

Interface

Card Info

Memory

Figure 5-1. DAQP Data Acquisition System Block Diagram

The DAQP card can be operated as an I/O de vice, occupying eight consecutive bytes in the

I/O address space . It can also be config ured to operate via memory mapped I/O. The DAQP

fully compli es with PCMCIA standard 2.10 as a type II card. The card has no jumpers or DIP

switches. All the configurable features are software programmable.

Page 22

Functionally, the DAQP card consists of the following components: the DC/DC power

DAQP-12/12H/16 Users Manual 22

supply, analog input multiplexer, programmable gain control amplifier, A/D converter, data

FIFO, scan list FIFO, trigger control circuit, pacer clock, interrupt & status registers, digital

I/O register and associated control circuits.

5.1 DC/DC Power Supply

The DAQP card uses a standard +5 volt digital input power supply from the PCMCIA

connector to generate the ±15 volt power supplies for the analog front end and the +5 volt

power supply for the A/D converter. The DC/DC converter uses 140 mA, 78% of the 180 mA

total load current, from the digital input power supply to generate the necessary voltages.

According to the PCMCIA standard, any card that draws more than 100 mA must not be

automatically turned on upon insertion until it is intentionally accessed by writing to the card

configuration and option register (or its allocated I/O space). The DAQP card supports this

specification by providing a unique power down mode control. When the card is first

powered up or af te r a r e se t, the D C/D C conver te r is turned of f, so that only the d igital portion

of the DAQP card is up and running. This requires only 40 mA from the digital input +5 volt

power supply. The user has the option of reading the card information memory, where the

maximum power consumption is listed for reference, and then decide whether or not to

“wake up” the card. If required, the card can be set to full power mode immediately when it’s

PCMCIA configuration and option register (COR) is written by the software.

After the card is set for full power mode for the first time by writing the PCMCIA

configuration and option register, it can then be set to power down mode by writing a ‘1’ into

bit 2 (the power down bit) of the PCMCIA auxiliary control register. Refer to Chapter 6 for

more information about the COR.

5.2 Analog Input Multiplexer

Differential or single-ended configuration is determined by bit 6 of the high byte in the scan

list register. ‘1’ selects differential input, while a ‘0’ selects single-ended input. Expansion

cards will only support single-ended channels. It is strongly recommended that single-ended

or differential selection be uniform for all internal channels (e.g., all 8 channels as differential

or all 16 channels as single-ended). Although it is possible to have some channels configured

as single-ended and others as differential, doing so may cause confusion and unexpected

signal errors.

With differential configuration, there are 8 channels. However, if the user specifies channels 8

to 15 in a differential configuration, it will short the inputs to ground for system offset

measurement. The readings taken under such a circumstance can be used for offset

correction.

The input multiple xers have built-i n protection against over-vol tage when the board i s at full

power AND when it is powered down. The protection mechanism will isolate the input from

the rest of the board, as long as the input voltage is within the protection range of ± 30 volts.

Page 23

5.3 Programmable Gain Control Amplifier

DAQP-12/12H/16 Users Manual 23

The DAQP-12 and DAQP-16 cards have an internal gain of 1, 2, 4 or 8; and the DAQP-12H has

an internal gain of 1, 10, 100 or 1000. The gai n can be changed “on the fly” when scanning

from channel to channel by changing the configuration of the programmable gain

instrumentation amplifiers. The internal gain selection is specified by the scan list entry, bits 4

and 5 of the high byte. The contents of these two bits will determine the gain of the analog

front end.

The settling time of the analog front end meets speed re quirements, however, if the amplifi er

is saturated i t may need more time to recover. T his can cause di stortion at the input sig nal to

the A/D converter. It is recommended that amplifier saturation be avoided by using a low

gain and attenuating the input signal whenever possible.

5.4 Scan List Register

One entry to the scan list register contains a 16-bit word or two 8-bit bytes. It specifies the

internal channel and gain selection in the high byte or MSB, and the external channel and gain

selection in the low byte or LSB, in addition to other control and configuration settings. The

external selections are used for expansion card channels (up to 256), while the internal

selections are for channels on board the DAQP card. Expansion cards are not included as part

of the DAQP seri es data acquisiti on system, however, they can be purchased se parately from

your vendor.

The number of entries in the scan list ranges from 1 to 2048. There are no dependencies

implied among the entries of the scan list. The user may choose any valid gain combination

for any channel, internal or external. Channels can be scanned in any order required, repeated

or not, with the same or different gain for each entry.

The scan list has to be f lushed before programming to g uarantee the integrity of each entry .

There must be an even number of bytes programmed into the scan list, with the low byte

sitting at an even offset followed by the high byte, otherwise the channel scan result will be

unpredictable.

It is strongly recommended that the differential/single-ended control bit (bit 14, MSB) be

programmed the same for all the entries in the scan list. Single-ended configuration should be

selected if there are expansion cards connected to the DAQP card. The synchronous sample

hold bit (bit 6, LSB) is reserved for expansion cards.

The fir st channel flag ( bit 7, LSB ) has to be set for the first (and ONLY the first) entry of the

scan list. Th e DAQP card hard ware relies on thi s bit to tell the end (or the start) of the scan.

During normal operations, the DA QP card starts one scan when tri ggered, (software or TTL

trigger i n one- shot mode or sampling pulse tr i g g er s f r om the pace r clock in conti nuous mod e ) .

During the scan, each entry in the scan list will be processed until it finds the entry that has

the first channel flag set to ‘1’. The hardware then stops scanning and waits for the next

trigger. The scan will continue indefinitely if none of the list entries has the flag set to ‘1’. On

the other hand, if more than one entry has the flag set to ‘1’, the scan list will then be chopped

Page 24

into pieces. Each piece will require a trigger to be scanned. Should the flag be set to ‘1’ on an

entry other than the first, a “starting offset” will be introduced to the scan list. Channel

DAQP-12/12H/16 Users Manual 24

scanning will start from the entry with the flag set to ‘1’, run through the list, turn around and

end at the one before it. Although this may be useful for diagnosis or special applications, it is

the abnormal way of setting the first channel flag and should be avoided unless absolutely

necessary.

5.5 Trigger Circuit

The DAQP card can be trigger ed by software, an external T TL signal or the pacer clock. F or

the external TTL trigger, an active trigger edge can be selected for either the low-to-high or

high-to-low transition.

In one-shot trigger mode, one trigger, either internal or external, will start one and only one

scan of all channels specified in the scan list. (The pacer clock has no effect in this mode

although it is good practice to program the pacer clock with a divisor greater than 2).

Multiple scans can be initiated by issuing multiple triggers.

In continuous trigger mode, the software or TTL trigger initiates a series of scans. The first

scan begins immediately on receiving a trigger, while the rest are carried out each time the

pacer clock fires. The process will continue until an A/D stop command is received.

If the internal trigger (or software trigger) is selected, the trig/arm command will serve as a

trigger w hen received by the DAQP card . For the external tri gger source, the same command

will be taken as an arm command, which arms the DAQP card so that the first proper trigger

edge following the arm command will serve as the trigger. Unexpected edge transitions

during the trigger source configuration are totally ignored if the DAQP card is not armed.

5.6 A/D Converter and Data FIFO

The DAQP ca rd alw ays assumes a bipol ar input range of ±10V if the gain i s one. The output

data format will always be in 2's complement (and left justified for 12-bit versions). The data

acquisition time of the A/D converter is 2µs while it’s conversion time is no more than 8µs.

The output of the A/D converter is fed into a data FIFO providing data buffering of up to

2048 samples. The A/D converter, once triggered, will complete conversion for every analog

input channel in the scan list at the specified scan speed and then feed the results into the data

FIFO. In between scans, the DAQP card waits until another trigger is received (one-shot

mode) or the pacer clock fires (continuous mode).

The data FIFO has two progr ammable thr esholds, one for almost full and the other for almost

empty. The DAQP card uses the almost full threshold and ignores the other one. The data

FIFO should always be flushed prior to using the arm/trig command to start data acquisition.

When the FIFO is flushed or emptied by the host reading its content, the FIFO empty flag will

be set. As long as there are samples left in the data FIFO, the empty flag will be cleared.

When the number of data sa mples in the FIFO b ecomes greater than the progr ammed almost

full threshold, the almost full flag is set. When the number becomes less than or equal to the

specified almost full threshold, the flag will be cleared. On power up or reset, the threshold is

Page 25

defaulted at 7 bytes to full (3.5 samples). Correct setting of the threshold will help achieve

optimal performance of the card.

DAQP-12/12H/16 Users Manual 25

When the FIFO is full, the full flag will be set, and no more samples can be written into the

FIFO. At the end of each scan, the DAQP card will set the data lost flag if the data FIFO is

already full. Thi s flag is not set b efore or duri ng the scan, but a t the end of it. Once the data

lost flag is set, it will not clear until the status register is read.

5.7 Interrupt and Status

The DAQP card has two interrupt sources, the end-of-scan (EOS) interrupt and the FIFO

threshold interrupt. The control register (base + 2, write only) has two bits to enable or

disable either one of the interrupts independently. However, it is strongly recommended that

the two interrupts be used exclusively.

When the EOS interrupt is enab led, an interrupt is sent to the host at the end of each scan of

the channel list. If there is only one channel in the scan list, the EOS interrupt is reduced to an

EOC (end-of-conversion) interrupt. The FIFO threshold interrupt, when enabled, is sent to the

host when the almost ful l fl ag i s set. The host then uses the “str ing input” instr uction to move

a block of samples from the FIFO. The EOS and FIFO threshold event bits in the status

register (base + 2, read only) and will be set whenever the corresponding event happens.

These bits can be used for indica ting the source of the interr upt. Once set, the event bits wil l

not be cleared until the host reads the status register.

5.8 Digital I/O

The DAQP ca rd has one dig ital in put port (ba se + 3, read onl y) of four b its (bi ts 0-3) and one

digital output port (base + 3, write only) of four bits (bits 0-3). The output port is latched,

while the input port is not. Four input lines are connected to the digital input port, each

representi ng one bit in the port. When read ing the di gital i nput port, the CURRENT sta tus of

the digital input lines are returned to the host.

All four input lines are shared with other functions. Bit 0 is shared as the external trigger

input, while bit 2 is shared as the external clock input. Bits 1 and 3 are taken over as the

external gain selection lines if there is an expansion card(s) connected and the expansion bit in

the control regi ster is set to ‘1’. In this case, the digi tal output lin es are drive n by the exte rnal

channel selection bits of the current scan list entry. Otherwise, they will be connected to the

latched bits 0-3 of the digital output port. The current status of the digital input lines will

always be returned when the host reads the digital input port regardless of whether the lines

are shared or not.

Page 26

5.9 A/D State Machine

The DAQP card has an internal state machi ne that controls A/D oper ation. The state machine

DAQP-12/12H/16 Users Manual 26

defaults to S0 afte r power up or rese t. The normal sta te flow w ould be fi rst S0 to S3, ini tiated

by a scan list (queue) flush command (RSTQ). Then the queue must be programmed by

writing into the queue (base + 1). With the queue being programmed, the next step is moving

the state machine from S3 back to S0. This is done by issuing a flush data FIFO command

(RSTF), which sets up the gain and channel selections for the first channel in the scan list and

then waits f or a tri gger to start the sca n. When the trigger (ADCLK) comes, the state machine

moves from S0 to S1 and then A/D conversion is started. The state machine will wait at S2

until the conversion is completed. It then moves to S4, where the A/D conversion result is

written into the data FIFO. The scan ra te is determine d by the time the state machine moves

from S1 to S4, which can be programmed as either 10, 20 or 40 µs. If there are more channels

left in the scan list, the state machine will skip to S1 for another conversion loop. Otherwise it

will return to S0, waiting for another trigger (or a sampling pulse from the pacer clock if in

continuous trigger mode). Any time during data acquisition, an A/D stop command will stop

the data acquisition by moving the state machine back to S0.

ADCLK (trigger)

RSTF

data

FIFO

flush

S0

RSTQ

<

>

scan

list flush

S1

<

S3

Figure 5-3. Transition Diagram of A/D Conversion Process

It is important that the sequence of S0-S3-S0 be followed as described above. The user must

issue two commands to the DAQP card: the flush scan list command (RSTQ) and the flush

data FIFO command (RST F). This guarantees that the scan list and the data FIFO are flushed

properly for the expected data acquisition. Once the flush data FIFO command is issued, the

DAQP card will prepare the first channel in the scan list and then return to state S0 waiting for

the first trigger. Anytime the data FIFO is flushed, the default threshold setting will be

restored (7 bytes to full) by the hardware. The data FIFO threshold should always be

programmed after flushing if the required threshold is different from the default threshold.

Wait (A/D conve r si on)

S2

Channels

remaining

S4

< Scan list comple ted

Page 27

6. PCMCIA Interface

Card Configuration and Status Register

R/W

0x8002

Configuration Option Register

R/W

0x8000

Description

Access

Offset

DAQP-12/12H/16 Users Manual 27

The information in this section is provided for those who need low level PCMCIA interface

details for the DAQP card. The client driver or enabler that comes with the DAQP card will

be sufficient for most applications.

The DAQP card performs data acquisition for all host computers equipped with a version 2.10

compliant PCMCIA i nterface. The D AQP card has a form f actor of type II (5 mm thick). The

card is highly flexible with respect to addressing and interrupt level use. It can be configured

either as a memor y only i nterf ace or a s an I/O inter face a nd can b e power ed up or d own wi th

the help of PCMCIA card and socket services. T he D AQP car d pr ovi des a single inter r upt that

can be routed to any system interrupt via the PCMCIA socket controller.

There are two sets of reg isters on the D AQP card : the prog ram reg ister s and the confi gura tion

registers.

Program regi sters f all under progra m control and bel ong to the DAQP card . T he I/O l ocation

of these regi sters is control led by the PCMCI A socket config uration and b y the contents of the

PCMCIA configuration registers.

The configuration registers are as those defined in the PCMCIA 2.10 specification and are

located in the DAQP card’s confi guration space at offset 8000H. T he configuration space al so

contains the Card Information Structure (CIS) which is located at offset 0000H. The CIS

memory contains information about the DAQP card as defined by the PCMCIA 2.10

specification. It is recommended that configuration and power up/down control of the DAQP

card be car ried out through the standard card and socket servi ces although an enabl er can be

used to complete these tasks.

Two PCMCIA configuration registers are supported by the DAQP card, (see Table 6-1): the

Configuration Option Register and the Card Configuration and Status Register.

Table 6-1. PCMCIA Configuration Registers

Page 28

6.1 Configuration and Option Register (COR)

Bits 7 and 6 of the Configura tion Option Regi ster are d efined by the PCMCIA stand ard as the

000000 = Memory mode

Index Bits

5-0

1 = Level mode interrupt

LevlReq

6

1 = Put the card into reset state

SRESET

7

Description

Name

Bit

Reserved as ‘0’

Reserved

0

1 = Interrupt pending

Intr11 = Power down mode

PwrDwn

2

Reserved, all ‘0’ when writing and reading

Not Used

7--3

Description

Name

Bit

DAQP-12/12H/16 Users Manual 28

SRESET and the LevlREQ Bits. A ‘1’ written into the SRESET bit puts the card in reset state,

while a ‘0’ moves i t out of r eset state. I n reset state, it be haves as i f a har d w ar e r eset is received

from the host. The LevlREQ bi t controls the type of interrupt sign al generated by the DAQP

card. Setting the Configuration Index bits to ‘0’ makes the DAQP card a memory only card

(accessed only by memory read /write operations), while setting it to ‘1’ enable s the card for

standard I/O. Table 6-2 lists the COR bit definition.

0 = Get out of reset state

0 = Edge mode interrupt

000001 = I/O mode

Table 6-2. COR Bit Definition

6.2 Card Configuration and Status Register (CCSR)

The DAQP card uses two bits i n this register. W hen bit 1 is set to ‘ 1’, it indic ates a pending

interrupt. The bit will remain as ‘1’ until the interrupt source is cleared. Bit 2 is used for

power down control. Setting a ‘1’ at this bit will put the card into power down mode, while a

‘0’ brings it back to full power mode. The remaining bits are not used.

0 = Full powered mode

0 = No interrupt pending

Table 6-3. CCSR Bit Definition

Page 29

7. I/O Registers

Auxiliary Control Register

Write Only

base + 7

111

Pacer Clock, high byte

Write Only

base + 6

110

Pacer Clock, middle byte

Write Only

base + 5

101

Pacer Clock, low byte

Write Only

base + 4

100

Digital Output Register

Write

base + 3

011

Control Register

Write

base + 2

010

Scan List (Queue)

Write Only

base + 1

001

Data FIFO

Read/Write

base + 0

000

Register Description

Port Access

I/O Address

Address Lines

DAQP-12/12H/16 Users Manual 29

The DAQP card uses eight consecutive I/O locations within the system I/O address space.

The base address of the adapter is determined by the Client Driver or Enabler as discussed in

Chapters 3 and 4. The ei ght I/O locations are used by the D AQP card as summarized in the

following table.

(A2A1A0)

Read

Read

Table 7-1. DAQP Series Card Address Map

All registers are 8-bits wide and each is discussed in detail in the following sections.

Status Register

Digital Input Register

7.1 Data FIFO Register (base + 0)

Note:

register be accessed as a 16 bit word to guarantee integrity. The low byte (LSB or the least

significant byte) should always be accessed first, followed by the high byte (MSB or the most

significant byte).

Although the data FIFO register is 8 bits wide, it is strongly recommended that the

The data FIFO register is considered as the access port to the data FIFO, which holds up to

2048 data words of the A/D conversion results. The port is also used for programming the

data FIFO thresholds, as explained later in this section.

Page 30

Two consecutive by tes should be rea d from or written into the port each time it is accessed.

D8D9D10

D11

D12

D13

D14

D15

MSB

D0D1D2D3D4D5D6

D7

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

--

Read data FIFO

Read

Run

1, data FIFO

3

Verify data FIFO threshold

Read

Run

0, threshold

2

Read data FIFO

Read

Idle

1, data FIFO

1

Verify data FIFO threshold

Read

Idle

0, threshold

0

512

1..1023

7

Almost Full

Irrelevant

Irrelevant

7

Almost Empty

Suggested Value

Threshold Range

Default

Threshold

DAQP-12/12H/16 Users Manual 30

The following table illustrates bit allocation.

LSB

Table 7-2. Data FIFO Register Bit Allocation

7.1.1 Data FIFO Operation Modes

Depending on the mode of operation, the 16-bit word read from or written into the register

has different meanings, as described in the following table.

OperationAccessA/DSelection BitMode

Write

Write

Write

Write

Table 7-3. Data FIFO Operation Mode

The “selection bit” is also called the “program/access” control bit, as defined in the auxiliary

control register (base + 7). Mode 0 is the FIFO program mode, under which the two

consecutive words (four bytes) written into the register address will set the almost full and

almost empty threshol ds (in b ytes). The first wor d specif ies the almost empty threshold, (not

used, can be set to anything), while the second word determines the almost full threshold.

The threshold shoul d b e set to a value f rom 1 to FIF O si ze mi nus 1. (D efa ult is set to 7 at re set

or power up). Refer to Table 7-4 for FIFO threshold settings.

Program data FIFO threshold

Write data FIFO (diagnosis)

Not allowed

Not allowed

Table 7-4. Data FIFO Threshold Setting

Page 31

Mode 1 is FIFO test mode, in which data bytes will be written into the data FIFO and read

True

True

False

FIFO size (either 1024 or 4096)

False

True

False

Threshold to (FIFO size - 1)

False

False

False

1 to (Threshold - 1)

False

False

True

0

DAQP-12/12H/16 Users Manual 31

back from it. The FIFO flags (empty, almost full, and full) will change according to the data

bytes available in the data FIFO and the configured threshold.

Mode 2 should be avoid ed. The d ata bytes can not be written into the FIFO under this mode,

while the bytes read from the FIFO will be the same as in mode 0.

Mode 3 is data transfer mode. Data bytes will be written into the FIFO by the A/D converter.

The data byte read from the address is the first available byte in the data FIFO if it is not

empty. If the FIFO is empty then the most recent byte written into the FIFO will be returned.

The data F IF O r eg i ste r is read- onl y under this mode therefore the user cannot w r i te data bytes

into the data FIFO through I/O instructions.

7.1.2 Mode Setting

The FIFO operation mode setting is always initiated by the data FIFO flush command with the

access/program b it set to ‘0’ (bi t 0 at base + 7) befor e data acquisition is started. This will set

mode 0 (threshol d setti ng mode) . A fter the threshold is progra mmed or verif ied , set the bit to

‘1’ so the following read/write operation to the FIFO will be data access operation.

The DAQP card is in idle mode before it is triggered into run mode. For one-shot operation,

the DAQP card will be set to run mode after it receives the trigger signal. It will not return to

idle mode until the specified scan list is completed or an A/D stop command is received. For

continuous trigger operation, the DAQP card will stay in run mode after being triggered until

an A/D stop command is received.

7.1.3 FIFO Flags

When readi ng the registe r under mod e 1 or 3, the fi rst avail able d ata byte f rom the data FIF O

will be returned if it is not empty, otherwise the returned byte is not defined. The FIFO full

flag will be cleared after the data FIFO register is read provided there are no more data bytes

written into the FIFO by the A/D converter under mode 1 or 3. The same will happen to the

FIFO almost full flag if the data bytes available in the FIFO are less than the almost full

threshold. The FIFO empty flag will be set immediately after the last byte is read from the

FIFO. FIFO size is measured in bytes (4096). Table 7-5 lists the FIFO flag status.

EmptyData bytes in FIFO

Full

Table 7-5. Data FIFO Flag Status

FullAlmost

Page 32

7.2 Scan List Queue Register (base + 1)

0000..1111 : channel 0..15

External channel

LSB

3-0

00/01/10/11 : 1/2/4/8 (or

External gain selection

LSB

5-4

for expansion cards (as SSH)

Reserved

LSB

6

Set to ‘1’ for the 1st entry in the list

Starting channel mark

LSB

7

0000..1111 : channel 0..15

Internal channel

MSB

11-8

00/01/10/11 : 1/2/4/8 or

Internal gain selection

MSB

13-12

1/0 : differential/single-ended

Analog input mode

MSB

14

as 0

Reserved

MSB

15

DAQP-12/12H/16 Users Manual 32

The Scan List Queue Register is considered the access port to the scan list queue which can

hold up to 2048 entri e s ( each has two bytes). E ach entry specifies an analog input channel and

it’s associated gain as well as other settings. The bit definition of an entry to the scan list

queue is explained in Table 7-6.

Note: Although the scan list queue register is 8 bits wide, it is required that the register be

accessed as a 16 bit word to guarantee integrity. The low byte (LSB or the least significant

byte) should always be accessed first, followed by the high byte (MSB or the most significant

byte).

ExplanationDefinitionByteBit

00/01/10/11 : 1/10/100/1000

selection

Set to ‘0’ for all the rest entries

1/10/100/1000)

selection

Table 7-6. Scan List Queue Entry Bit Definition

7.2.1 Scan List Queue Programming

The scan list queue must be programmed when the DAQP card is idle. Each queue entry

contains two b ytes as d escri bed above a nd the in tegri ty of the e ntry must be g uarante ed. (T he

scan list queue is write only). The queue should be flushed before writing into it. Refer to

section 7.7: Auxiliary Control Register for information on scan list queue reset. The first entry

of the queue should have bit 7 (LSB) set to ‘1’ as the first channel mark. For the remaining

entries, set the b it to ‘0’ . The synchronous sample hold b it ( LSB ) is not used by D AQP ca rd. It

is reserved for the expansion cards.

Page 33

Example 1.

Table 7-7 lists the required queue entri es to specify a scan list of three single-ended internal

Select channel 7, gain 4

2700

0010 0111 0000 0000

3

Select channel 12, gain 4

2C00

0010 1100 0000 0000

2

Select channel 0, gain 2, 1st

0180

0001 0000 1000 0000

1

Select channel 7, gain 1

4700

0100 0111 0000 0000

4

Select channel 6, gain 1

4600

0100 0110 0000 0000

3

Select channel 1, gain 1

4100

0100 0001 0000 0000

2