Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

User’s Guide

DaqIO LabVIEW

TM

Support VIs

OMB-471-0903 rev 1.0

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Contents

1. Initial Setup …… 5

2. Using the “How to” Examples …… 6

3. Connector Layout and Naming Convention ……7

4. How to Modify a VI …… 9

5. How to Start a VI from Scratch …… 11

6. How to Run Multiple Acquisitions …… 12

7. DaqIO LabVIEW Palette Layout …… 12

The DaqIO LabVIEW support VIs require LabVIEW 7.0 or greater.

DaqIO LabVIEW Support VIs User’s Guide 877894 3

Page 4

This page is intentionally blank.

4 877894 DaqIO LabVIEW Support VIs User’s Guide

Page 5

Initial Setup

Install Software

Place the Data Acquisition CD into the CD-ROM drive. Wait for PC to auto-run the CD. This

may take a few moments, depending on your PC. If the CD does not auto-run, use the Desktop’s

Start/Run/Browse feature and run the Setup.exe file. After the intro-screen appears, follow the

screen prompts.

After selecting the hardware type, select Enhanced LabVIEW Support from the list of available

software. The Default location is C:\Program Files\DaqIO LabView Support

Setup Hardware

Consult the manual for your specific device for hardware setup and configuration information.

Note: Remember the name you assign to your device as it will be needed in a later step.

Add a DaqIO Pallet to an Existing Palette

1) Open a new blank LabView.vi

2) From the Tools menu item select: Advanced >> Edit palette views

3) In the “Edit Controls and Functions Palettes” dialog box select: “New Setup…”

This is selected from the Palette view list box.

4) Enter a name for the New Palette View

5) Right mouse-click in an open space in the function palette; then select: insert >> submenu.

6) From the “Insert Submenu” dialog select: “Link to a directory”

7) Browse to and open the “C:\Program Files\DaqIO LabView Support” directory.

8) Click the “Select Curr Dir” button. The DaqIO submenu should appear in the function palette.

9) In the “Edit Controls and Functions Palettes” dialog box, click “Save Changes.”

Setting the Paths

In order to use the DaqIO LabVIEW support VI’s from any directory on your machine, the path to

the DaqIO VI’s must be set. This is done as follows:

1) From the Tools menu Item select “Options”

2) In the Options Dialog box select “Paths.”

3) In the second dropdown select “VI Search Path.” Note that the Library Directory is the typical

default displayed.

4) In the test box above the “Insert After” Button, enter:

C:\Program Files\DaqIO LabVIEW Support\*

5) Finish by clicking the “OK” button.

DaqIO LabVIEW Support VIs User’s Guide 877894 5

Page 6

Using the “How to” Examples

Examples for specific devices are located, by default, at:

C:\Program Files\DaqIO LabView Support\Howto and Example VI's

The directory has 4 sub-directories:

Daq Device Examples - For use with Daq Series Devices

DBK Examples - For use with DBK Expansion Cards

Wave Device Examples - For use with WaveBook Series Devices

WBK Examples - For use with WBK expansion modules

The directory also includes a How To with two sub-directories: Daq Devices and Wave

Devices. These sub-directories contain examples of how to perform specific operations

using the DaqIO VI's. Information is provided regarding digital and analog triggering,

waveform output, and asynchronous digital IO along with other operations [that are

included within the directory].

The Howto VI’s contain documented diagrams that explain functions and VI connections

specific to each VI. Howto number 1 and number 2 show the basic steps and most

common wiring connections needed for most VI’s. You should become familiar with

these two VI’s before proceeding with the creation of your own programs.

The Howto VI’s contain generic device configuration VI’s. If you use a Howto VI as a

basis for your own VI, then the generic Howto channel configuration VI’s should be

replaced with channel configuration VI’s that are specific to your device type. This is

necessary to access the full functionality of your device (see following figure).

Replacing a Generic “DAQ Howto” Analog Input VI with a Device Specific VI

6 877894 DaqIO LabVIEW Support VIs User’s Guide

Page 7

Connector Layout and Naming Conventions

Standard Connections

Certain connections are common to the majority of VIs. These “standard connections”

include:

Acquisition Number

Device Name

Error In and Out

Standard Connections

Acquisition Number: This connection exists as an input and output on nearly all VIs. It

is used to keep all the parts of an individual acquisition grouped together. Multip le

acquisitions are, in general, only used when you have multiple main devices running at

different acquisition rates triggered to scan at the same time. See Howto #11 for an

example of multiple acquisitions.

Device Name: This connection is used to tie different sections of a device to its

functions. There are certain VIs that have the Device Name and Device Name Out

connections available, although they are not utilized within the VI itself. The purpose of

these ‘pass through’ connections is to make wiring easier and keep the VI diagram clean

looking.

Error In and Out: Error In and Out connections are utilized to keep certain code from

executing, or to force the execution of code under certain circumstances. To avoid hard

failures and un-initialized configuration problems, it is highly recommended that the

Error In and Error Out ALWAYS be connected between applicable VIs.

DaqIO LabVIEW Support VIs User’s Guide 877894 7

Page 8

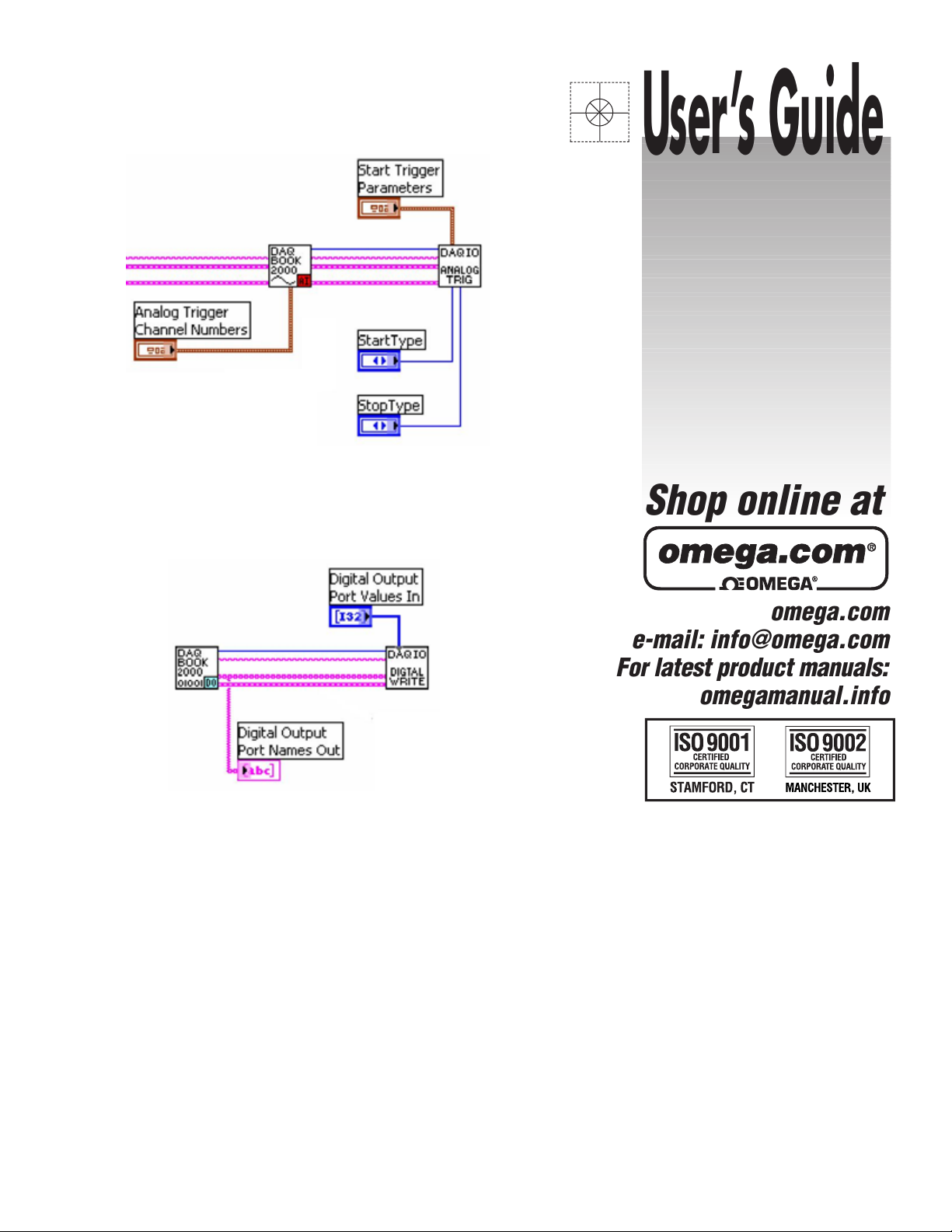

Using Channel Names and Trigger Channel Names

Once configured, device channels are referred to by name. All device-configuration VIs

contain string controls that allow you to enter a name for any given channel. If you choose

not to enter a name a default name will be generated. The channel names are used by various

VIs for functions, e.g., Digital Output, and Triggering.

Where applicable, you can select channel numbers to be used as trigger channels. When you

select channels for triggering, the names of the associated channels are then available from

the ‘Trigger Channel Names’ output connection. This connection can be wired directly into

one of the triggering VIs.

Using Trigger Channel Names

Channel Names for Asynchronous and Other Operations

In the case of digital VIs the list of configured channel names is available at the “Channel

Names Out” connection of the digital VIs. This string array can be wired to the “Digital

Output Port Names” connection on the DaqIO Digital Asynchronous Write VI to facilitate

writing data to the configured channels.

Using a Channel Name as an Input to the Digital Write VI

Channel Names can be used to start and stop timers, counters and analog outputs.

8 877894 DaqIO LabVIEW Support VIs User’s Guide

Page 9

How to Modify a VI

All Channel configuration VI’s are similar in connector layout with inputs and outputs for Acquisition#,

Device Name, and Errors. Inserting expansion VI’s is simply a matter of cutting the existing common

connections, making room for the new sub VI, inserting the sub VI, and making new connections and

controls for the sub VI.

Adding a Device

In this illustrated example we will be adding a DBK80 to the Howto #1

diagram (right-hand figure).

1) Delete existing connections (see figure).

2) Make space. After deleting the wires (connections):

(a) Place the mouse cursor between the DaqBook VI (DAQBOOK2000) and the basic trigger VI

(DAQIO BASIC TRIG).

(b) Press and hold the “Control Key,” and at the same time click and hold down the left mouse

button. Next move the mouse an inch or so to the left.

Releasing the mouse button and control key will cause all items in the diagram to shift to the left

the same distance you moved the mouse.

3) Add a DBK Channel Configuration VI to the Diagram.

(a) Select the DaqIO Data Acquisition sub-menu from the Functions palette.

(b) Navigate through the sub-menus as follows:

>> DaqDevice and DBK Configuration >> DBK Expansion >> Analog Input >> DBK80

(c) Select the DBK80 Channel Configuration VI and place it on the diagram.

4) Make Connections to the VI.

For Acquisition Number, Device Name and Error In and Out, make connections on

both sides of the DBK80 Configuration VI.

5) Create the Control.

To complete adding the expansion (DBK80), right-click on the DBK80

Channels connection and select “Create Control.”

DaqIO LabVIEW Support VIs User’s Guide 877894 9

Page 10

Adding Device Sections

Adding Digital channels to the VI diagram follows the preceding steps with the exception

of where the Digital IO channel configuration VI is located. For Example if you wished

to add Digital Inputs to the preceding diagram you would:

(a) Delete the existing wires either to the left or right of

the DBK80.

(b) Make space available to insert the Digital IO

configuration VI.

(c) Browse to the Digital Input Configuration VI

[specific to your device].

(d) Insert the new VI into the diagram.

(e) Connect the wires.

(f) Create the Digital Control.

Adding a Second Device

Adding a second device to a VI is very similar

to adding a device section or DBK expansion.

However, note that device names must be

unique.

Using Device Names on Subsequent VI’s with Multiple Devices

When multiple devices exist, the device name parameter is passed to DBK expansion and

device section VI’s to determine how the connections inter-relate and which main device

is to be utilized in the case of more advanced triggering.

10 877894 DaqIO LabVIEW Support VIs User’s Guide

Page 11

How to Start a VI from Scratch

With the exception of channel and device configuration VI’s, mandatory VI’s can be found under

Acquisition Setup and Control >> Acquisition Control Palette. The Howto #1 Simple Acquisition,

shows the minimum requirements for an acquisition [using DaqIO LabVIEW support VI’s].

Required VI’s for all VI’s for initialization and closure:

COMM INIT: Initializes the DaqIO LabVIEW support (Must be first)

COMM CLOSE: Closes the DaqIO LabVIEW support and releases any resources utilized

(Must be last)

Required VI’s for synchronous operation:

SCAN CONFIG: Sets Scan rate and other scan specific parameters

ACQ ARM: Depending on the trigger method can either immediately start a scan or wait

for a specific trigger condition to occur.

READ SCAN: Once the acquisition has commenced this will retrieve specified amount of

data from the acquisition buffer.

VI’s for Asynchronous operations:

With the exception of Digital IO, asynchronous operations will have

and associated start and stop VI’s. The start, stop and update VI’s

are universal for all configured voltage output channels. This is true,

regardless of device type.

Digital IO VI’s will have only read and write VI’s.

Each of these VI’s has a “Channel Names” connection that must be

wired to determine what channels the operation will be performed

on.

Trigger VI’s:

A method of triggering the acquisition must be provided within your VI. The VI’s are

separated into three groups simple, analog, and digital.

SIMPLE: Generally immediate trigger or TTL trigger starts with manual or scan count

based stops.

ANALOG: Uses individual analog channel voltages or values to start or stop and

acquisition.

DIGITAL: Uses the value of a digital port to start or stop an acquisition.

Advanced triggering can be accomplished by combining the above VI’s. See the various

triggering examples in the “Howto” example section for details.

DaqIO LabVIEW Support VIs User’s Guide 877894 11

Page 12

How to Run Multiple Acquisitions

If you desire to run multiple devices at different rates, or trigger the devices independent of each

other, then you must use a multiple acquisition VI layout. Howto #11 Multiple Acquisition

provides details. In the Howto example, an “Acquisition Stop” VI is used to allow the other

acquisition to continue running in the event that one acquisition stops. When both acquisitions

have completed “Acquisition Close” is called to release all resources.

DaqIO LabVIEW Palette Layout

| -- Acquisition Setup and Control VI's

| -- Acquisition Control

These VI’s perform initialization and control functions for DaqIO LabVIEW

support, Asynchronous operations such as digital port read and write, voltage

output adjustment, and timer adjustment VI’s can be found in this palette

| -- Advanced

Advanced level VI’s should not be altered without an understanding of DaqCOM

| -- Triggering

This palette contains simples and more advanced triggering VI’s

| -- Daq Device and DBK Configuration VI's

| -- Daq Device VI's

This palette contains the base channel configuration VI’s for the Daq series

devices. Select the appropriate sub palette for the device type that you have.

| -- DBK Configuration VI's

This palette contains the channel configuration VI’s for DBK series expansion

devices. It is separated by the type of DBK device.

12 877894 DaqIO LabVIEW Support VIs User’s Guide

Page 13

| -- Howto and Example VI's

| -- Daq Device Examples

This palette contains example VI’s for Daq series devices.

| -- DBK Examples

This palette contains example VI’s for DBK expansion devices.

| -- Howto VI's

The Howto palette contains operation specific example VI’s. Triggering,

reconfiguration, and asynchronous operations and other advanced examples are

located in this palette. Select the appropriate sub palette for the device type that

you have.

| -- PDQ Examples

This palette contains examples describing the utilization of an OMB-PDQ30

for use with an OMB-DAQBOARD-3000 or OMB-DAQ-3000 Series device.

| -- Wave Device Examples

This palette contains the base channel configuration VI’s for the Daq series

devices. Select the appropriate sub palette for the device type that you have.

| -- WBK Examples

This palette contains the channel configuration VI’s for WBK series expansion

devices. It is separated by the type of WBK device.

| -- Utility VI's

This palette contains VI’s used to display channel information, read and write

data files and separate analog and digital data types. See the associated Howto

sections for the utilization of these VI’s.

| -- Wave Device and WBK Configuration VI's

| -- Wave Device VI's

This palette contains the base channel configuration VI’s for the Wave series

devices. Select the appropriate sub-palette for the device type that you have.

| -- WBK Configuration VI's

This palette contains the channel configuration VI’s for DBK series expansion

devices. It is separated by the type of DBK device.

DaqIO LabVIEW Support VIs User’s Guide 986993 13

Page 14

This page is intentionally blank.

14 986993 DaqIO LabVIEW Support VIs User’s Guide

Page 15

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) mont

grace period to the normal one (1) year product warrant

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request

Upon examination by OMEGA, if the unit is found to be defective, it will be

charge. OMEGA’s

including but not limited to

improper repair, or unauthorized modification. This

having been tampered with or shows evidence of having been damaged as a

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operatin

conditions outside of OMEGA’s control. Components in which wear is not warranted,

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that

OMEGA, either verbal or written. OMEGA warrants only that the parts

company

REPRESENT

TITLE, AND ALL IMPLIED

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMIT

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

co mponent upon which liabil ity is base d. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS:

Component” under 10 CFR 21

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no

as set forth in our basic

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of

Product(s) in such a manner

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

ATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

WARRANTY does not apply to defects resulting from any action of the purchaser,

mishandling, improper interfacing, operation outside of design limits,

WARRANTY is VOID if the unit shows evidence of

the use of its various products. However,

result from the use of its products in accordance with information provided by

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

(NRC), used in or with any nuclear installation or activity; or (2) in medical

WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

.

y to cover handling and shipping time. This

repaired or replaced at no

result of excessive corrosion;

include but are not

manufactured by the

ATION OF

warranty, negligence,

responsibility

the use of the

h

g

.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) N U MBER FR O M O MEGA’S CU S TOMER S E RVI C E DEPARTM E NT (IN ORD E R TO

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the retur

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

WARRANTY RETURNS, please have the

FOR

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the produc

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

t

1. Purchase Order number to cover the COST

of the repair

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

,

consult OMEGA

AVOID

n

Page 16

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M4285/0106

Loading...

Loading...