Page 1

(1*,1((5,1* ,1&

DAQDRIVE

Data Acquisition Software

Users Manual

INTERFACE CARDS FOR PERSONAL COMPUTERS

OMEGA ENGINEERING, INC. Tel: (203) 359-1660

One Omega Drive Fax: (203) 359-7700

P.O. Box 4047 Toll free: 1-800-826-6342

Stamford, CT 06907-4047 E-mail: das@omega.com

http://www.dasieee.com

Page 2

WARRANTY/DISCLAIMER

DAQDRIVE Users Manual 2

OMEGA ENGINEERING, INC., warrants this unit to be free of defects in materials and workmanship for a period of

the date of purchase. OMEGA warranty adds an additional one (1) month grace period to the normal

cover shipping and handling time. This ensur es that OMEGA’s customers receive maximum coverage on each product. If the unit should

malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return

(AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective it will be

repaired or replaced at no charge. OMEGA’s warranty does not apply to defects resulting from any action of the purchaser, including but

not limited to mishandling, improper interfacing, operation outside design limits, improper repair or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of

excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components which wear are not warranted, including but not limited to contact points, fuses and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for

any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with

information provided from OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIO NS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusi ve and the

total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict

liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment s old by OMEGA is not int end ed to be u sed, nor shall it be used: (1) as a “Basic Component” under 10 CFR

21 (NRC), used in or with any nuclear installation or activity, medical application or used on humans. Should any Product(s) be used in

or with any nuclear installation or activity, medical application, used on humans or misused in any way, OMEGA assumes no

responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

one (1) year product warranty

13 months

from

to

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY

PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S

CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). THE ASSIGNED NUMBER SHOULD

THEN BE MARKED ON THE OUTSIDE OF THE RETURN PACKAGE AND ON ANY CORRESPONDENCE. THE PURCHASER

IS RESPONSIBLE FOR SHIPPING CHARGES, FREIGHT, INSURANCE AND PROPER PACKAGING TO PREVENT BREAKAGE

IN TRANSIT.

WARRANTY

FOR

(1) P.O. Number under which the product was purchased,

(2) Model and serial number of the product under warranty, and

(3) Repair instructions and/or specific problems relative to the product.

NON-WARRANTY

FOR

contacting OMEGA:

(1) P.O. Number to cover the cost of the repair,

(2) Model and serial number of the product, and

(3) Repair instructions relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC. © Copyright 1999 OMEGA ENGINEERING, INC. All

rights reserved. This document may not be copied, photocopied, reproduced, translated or reduced to any electronic

medium or machine readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE

Page 3

OMEGAnet On-line Service: Internet e-mail:

http://www.omega.com

Servicing North America

: One Omega Drive, Box 4047 E-mail: info@omega.com

USA

ISO 9001 Certified

Canada

: 976 Bergar E-mail: info@omega.com

For immediate technical or application assistance

USA and Canada

Mexico and Latin America

: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

:Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espanol: (001) 203-359-7803 E-mail: espanol@omega.com

info@omega.com

:

:

SM

SM

SM

Benelux

Czech Republic

France:

Germany/Austria

: Postbus 8034, 1180 LA Amstelveen, The Netherlands

: ul.Rude armady 1868, 733 01 Karvina-Hraniee

9, rue Denis Papin, 78190 Trappes

Servicing Europe

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

E-mail: nl@omega.com

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

Toll Free: 0800-1-66342 E-mail: czech@omega.com

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

E-mail: france@omega.com

: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

E-mail: germany@omega.com

:

DAQDRIVE Users Manual 3

Page 4

United Kingdom: One Omega Drive, River Bend Technology Drive

ISO 9002 Certified

It is th e policy of OM EG A to comply wit h all worldwide safe ty and EM C / E M I regulations that

apply. OMEGA is constantly pursuing certification of it’s products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon

certification.

The information contained in this document is believed to be correct but OMEGA Engineering,

Inc. accep ts no liability for a ny errors it contains , and reserves the right to alt er specifications

without notice. WARNING: These products are not designed for use in, and should not be

used for, patient connected applications.

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

E-mail: info@omega.co.uk

DAQDRIVE Users Manual 4

Page 5

Table of Contents

45

2.4.6 Visual Basic for DOS

44

2.4.5.6 Dynamic memory allocation

44

2.4.5.5 Storing a variable's address in a data structure

43

2.4.5.4 The DaqOpenDevice Command

42

2.4.5.3 Adjusting the size of Quick Basic's stack and heap

42

2.4.5.2 Quick Basic and the under-score character

42

2.4.5.1 Quick Basic's on-line help

42

2.4.5 Quick Basic

41

2.4.4.2 Program optimization

41

2.4.4.1 Creating byte-aligned data structures

41

2.4.4 Borland C/C++ and Turbo C

40

2.4.3.1 Creating byte-aligned data structures

40

2.4.3 Microsoft C/C++

39

2.4.2 Removing The TSRs From Memory

38

2.4.1 Loading The TSRs Into Memory

38

2.4 Creating DOS Applications Using The TSR Drivers

37

2.3.2.3 Program optimization

36

2.3.2.2 Creating byte-aligned data structures

36

2.3.2.1 The hardware dependent include file

36

2.3.2 Borland C/C++

35

2.3.1.2 Creating byte-aligned data structures

35

2.3.1.1 The hardware dependent include file

35

2.3.1 Microsoft Visual C/C++

35

2.3 Creating DOS Applications Using The C Libraries

32

2.2.4 Signal Conditioner Database Utility

30

2.2.3 A/D Expansion Board Database Utility

29

2.2.2.10 Viewing the Report File

29

2.2.2.9 Saving The New Configuration

29

2.2.2.8 Configuration Help

28

2.2.2.7 Timer Configuration

27

2.2.2.6 Digital I/O Configuration

27

2.2.2.5 D/A Converter Configuration

26

2.2.2.4 A/D Signal Conditioners

25

2.2.2.3 A/D Converter Expansion Configuration

24

2.2.2.2 A/D Converter Configuration

23

2.2.2.1 General Configuration

23

2.2.2 Generating A DAQDRIVE Configuration File

22

2.2.1 Installation

22

2.2 DAQDRIVE Configuration Utilities

21

2.1 Software Installation

21

2 Before Beginning

18

1 Introduction

.........................................................

DAQDRIVE Users Manual 5

..................................................

........

..............................

.......................................................

.........................

...........................................

....................................

...........................

.........................................

....................................

........................................

............................................

.............................................

...................................

.........................................

...............................

..................................

................

...........................................

..............................

..............................

...................................................

..............................

..............................

...........................................

...............

.....................................

..................................

.................................................

..............................

.......................................

..............................

...........................................

......................................................

........................................

..........................

....................

...................................

.......................

......................................

..............................................

Page 6

79

4 Performing An Acquisition

77

3.4.2 DaqSingleDigitalOutputScan

75

3.4.1 DaqSingleDigitalOutput

75

3.4 Digital Output

73

3.3.2 DaqSingleDigitalInputScan

71

3.3.1 DaqSingleDigitalInput

71

3.3 Digital Input

69

3.2.2 DaqSingleAnalogOutputScan

67

3.2.1 DaqSingleAnalogOutput

67

3.2 Analog Output

65

3.1.2 DaqSingleAnalogInputScan

63

3.1.1 DaqSingleAnalogInput

63

3.1 Analog Input

62

3 Quick Start Procedures

60

2.6.3.4 DaqWriteBufferFlagVB

59

2.6.3.3 DaqWriteBufferVB

57

2.6.3.2 DaqReadBufferFlagVB

57

2.6.3.1 DaqReadBufferVB

56

2.6.3 32-bit Visual Basic

55

2.6.2.2 Program optimization

55

2.6.2.1 Creating dword-aligned data structures

55

2.6.2 Borland C/C++

54

2.6.1.1 Creating dword-aligned data structures

54

2.6.1 Microsoft Visual C/C++

53

2.6 Creating 32-bit Windows 95/98 Applications

52

2.5.4.2 Turbo Pascal for Windows and floating-point math

52

2.5.4.1 Using other Turbo Pascal for Windows / Delphi versions

52

2.5.4 Turbo Pascal for Windows / Borland Delphi

52

2.5.3 Visual Basic for Windows

51

2.5.2.2 Program optimization

51

2.5.2.1 Creating byte-aligned data structures

51

2.5.2 Borland C/C++

50

2.5.1.1 Creating byte-aligned data structures

50

2.5.1 Microsoft Visual C/C++

49

2.5 Creating 16-bit Windows 3.x/95/98 Applications

48

2.4.7.3 Using other Turbo Pascal versions

48

2.4.7.2 Adjusting the size of the Turbo Pascal heap

48

2.4.7.1 Turbo Pascal and floating-point math

48

2.4.7 Turbo Pascal

47

2.4.6.5 Dynamic memory allocation

47

2.4.6.4 Storing a variable's address in a data structure

46

2.4.6.3 The DaqOpenDevice Command

45

2.4.6.2 Adjusting the size of the Visual Basic's stack and heap

................

45

2.4.6.1 Visual Basic for DOS and the under-score character

..................

DAQDRIVE Users Manual 6

...................................

.......................

......................................

.....................................................

.................................

...........................................

...................................................

...........................................

..........................................

...........................................

...................................................

...........................................

.................................................

..............................................

...........................................

..............................................

..........................................

..............................

.........................

.................

..............................

..............................

..........................

.............

..................

.....................

............................

............................

....................................................

...................................................

.....................................................

...................................................

...........................................

............................................

.........................................

...........................................

.......................................

.............................................

.........................................

...........................................

.......................................

.....................................

Page 7

91

6.2.9 Scan Events

91

6.2.8 Number Of Scans

91

6.2.7 Sampling Rate

91

6.2.6.2 External Clock

91

6.2.6.1 Internal Clock

91

6.2.6 Clock Sources

91

6.2.5.4 Background DMA mode

91

6.2.5.3 Foreground DMA mode

90

6.2.5.2 Background IRQ mode

90

6.2.5.1 Foreground CPU mode

90

6.2.5 Data Transfer Modes

90

6.2.4 Trigger Selections

90

6.2.3 Data Buffers

90

6.2.2 Channel Selections

90

6.2.1 Reserved Fields

89

6.2 The Analog Output Request Structure

88

6.1 DaqAnalogOutput

88

6 Analog Output Requests

87

5.3.2 Example 2 - Multiple Channel Input

86

5.3.1 Example 1 - Single Channel Input

86

5.3 Analog Input Examples

85

5.2.12 Request Status

85

5.2.11 Time-out

85

5.2.10.2 Auto-zero

85

5.2.10.1 Auto-calibration

85

5.2.10 Calibration Selections

84

5.2.9 Scan Events

84

5.2.8 Number Of Scans

84

5.2.7 Sampling Rate

84

5.2.6.2 External Clock

84

5.2.6.1 Internal Clock

84

5.2.6 Clock Sources

84

5.2.5.4 Background DMA mode

84

5.2.5.3 Foreground DMA mode

83

5.2.5.2 Background IRQ mode

83

5.2.5.1 Foreground CPU mode

83

5.2.5 Data Transfer Modes

83

5.2.4 Trigger Selections

83

5.2.3 Data Buffers

83

5.2.2 Channel Selections / Gain Settings

83

5.2.1 Reserved Fields

82

5.2 The Analog Input Request Structure

81

5.1 DaqAnalogInput

81

5 Analog Input Requests

...........................................

DAQDRIVE Users Manual 7

.................................................

..............................

...................................................

...................................

......................................................

.................................................

..............................................

..........................................

..........................................

.........................................

.........................................

....................................................

..................................................

..................................................

....................................................

.................................................

......................................................

.............................................

...............................................

....................................................

........................................................

...................................................

..........................................

...................................

.................................

.........................................

...............................................

............................

...................................................

................................................

......................................................

.................................................

..............................................

..........................................

..........................................

.........................................

.........................................

....................................................

..................................................

..................................................

....................................................

.................................................

......................................................

Page 8

105

8.2.6 Clock Sources

105

8.2.5.4 Background DMA mode

105

8.2.5.3 Foreground DMA mode

104

8.2.5.2 Background IRQ mode

104

8.2.5.1 Foreground CPU mode

104

8.2.5 Data Transfer Modes

104

8.2.4 Trigger Selections

104

8.2.3 Data Buffers

104

8.2.2 Channel Selections

104

8.2.1 Reserved Fields

103

8.2 The Digital Output Request Structure

102

8.1 DaqDigitalOutput

102

8 Digital Output Requests

101

7.3.2 Example 2 - Multiple Value Input

100

7.3.1 Example 1 - Single Value Input

100

7.3 Digital Input Examples

99

7.2.11 Request Status

99

7.2.10 Time-out

98

7.2.9 Scan Events

98

7.2.8 Number Of Scans

98

7.2.7 Sampling Rate

98

7.2.6.2 External Clock

98

7.2.6.1 Internal Clock

98

7.2.6 Clock Sources

98

7.2.5.4 Background DMA mode

98

7.2.5.3 Foreground DMA mode

97

7.2.5.2 Background IRQ mode

97

7.2.5.1 Foreground CPU mode

97

7.2.5 Data Transfer Modes

97

7.2.4 Trigger Selections

97

7.2.3 Data Buffers

97

7.2.2 Channel Selections

97

7.2.1 Reserved Fields

96

7.2 The Digital Input Request Structure

95

7.1 DaqDigitalInput

95

7 Digital Input Requests

94

6.3.2 Example 2 - Simple Waveform Generation

93

6.3.1 Example 1 - DC Voltage Level Output

93

6.3 Analog Output Examples

92

6.2.12 Request Status

92

6.2.11 Time-out

92

6.2.10.2 Auto-zero

92

6.2.10.1 Auto-calibration

...............................................

92

6.2.10 Calibration Selections

.............................................

DAQDRIVE Users Manual 8

....................................................

.......................................................

...................................................

........................................

................................

............................

...........................................

.................................................

..............................

...................................................

................................................

......................................................

.................................................

..............................................

..........................................

..........................................

.........................................

.........................................

....................................................

..................................................

..................................................

...................................................

.................................................

......................................................

........................................................

...................................................

..........................................

.....................................

...................................

.....................................................

........................................

...............................................

...........................

..................................................

...............................................

................................................

.............................................

.........................................

.........................................

........................................

........................................

...................................................

Page 9

130

11.1.8 Run-time Error Event

130

11.1.7 Time-out Event

130

11.1.6 User Break Event

129

11.1.5 Scan Event

129

11.1.4 Buffer Full Event

129

11.1.3 Buffer Empty Event

129

11.1.2 Complete Event

129

11.1.1 Trigger Event

129

11.1 Event Descriptions

129

11 DAQDRIVE Events

128

10.2.2 Continuous Trigger Mode

128

10.2.1 One-shot Trigger Mode

128

10.2 Trigger Modes

128

10.1.4 Digital Trigger

127

10.1.3 Analog Trigger

127

10.1.2 TTL Trigger

127

10.1.1 Internal Trigger

127

10.1 Trigger Sources

127

10 Trigger Selections

125

9.3.6 Example 6: Outputting Large Amounts Of Data

123

9.3.5 Example 5: Creating Complex Output Patterns

122

9.3.4 Example 4: Using Multiple Data Buffers

121

9.3.3 Example 3: Multi-Channel Analog Output

120

9.3.2 Example 2: Creating Repetitive Signals

119

9.3.1 Example 1: Single Channel Analog Output

119

9.3 Output Operation Examples

117

9.2.4 Example 4: Acquiring Large Amounts Of Data

116

9.2.3 Example 3: Using Multiple Data Buffers

115

9.2.2 Example 2: Multi-Channel Analog Input

114

9.2.1 Example 1: Single Channel Analog Input

114

9.2 Input Operation Examples

111

9.1 Multiple Channel Operations

109

9 Defining Data Buffers

108

8.3.2 Example 2 - Simple Pattern Generation

107

8.3.1 Example 1 - Single Value Output

107

8.3 Digital Output Examples

106

8.2.11 Request Status

106

8.2.10 Time-out

105

8.2.9 Scan Events

105

8.2.8 Number Of Scans

105

8.2.7 Sampling Rate

105

8.2.6.2 External Clock

.................................................

105

8.2.6.1 Internal Clock

.................................................

DAQDRIVE Users Manual 9

...................................................

................................................

.....................................................

.......................................................

..................................................

........................................

...................................

..............................

...........................................

...................................

......................................

............................

............................

.............................

.......................

....................................

..........................

..............................

...........................

.............................

.......................

......................

...............................................

................................................

.................................................

....................................................

.................................................

.................................................

.................................................

..........................................

........................................

.............................................

.............................................

..................................................

.................................................

.............................................

................................................

.....................................................

...............................................

.................................................

............................................

Page 10

208

13.19 DaqGetADGainInfo

207

13.18 DaqGetAddressOf

204

13.17 DaqGetADCfgInfo

202

13.16 DaqFreeRequest

200

13.15 DaqFreeMemory32 (32-bit DAQDRIVE only)

198

13.14 DaqFreeMemory (16-bit DAQDRIVE only)

193

13.13 DaqDigitalOutput

188

13.12 DaqDigitalInput

186

13.11 DaqConvertScan

184

13.10 DaqConvertPoint

182

13.9 DaqConvertBuffer

181

13.8 DaqCloseDevice

179

13.7 DaqBytesToWords

178

13.6 DaqArmRequest

173

13.5 DaqAnalogOutput

168

13.4 DaqAnalogInput

165

13.3 DaqAllocateRequest

163

13.2 DaqAllocateMemory32 (32-bit DAQDRIVE only)

161

13.1 DaqAllocateMemory (16-bit DAQDRIVE only)

160

13 Command Reference

158

12.4.2 Example 2

157

12.4.1 Example 1

157

12.4 Output Examples

155

12.3.2 Example 2

154

12.3.1 Example 1

154

12.3 Digital Input Examples

152

12.2.4 Example 4

150

12.2.3 Example 3

148

12.2.2 Example 2

147

12.2.1 Example 1

147

12.2 Analog Output (D/A) Examples

144

12.1.5 Example 5

142

12.1.4 Example 4

140

12.1.3 Example 3

138

12.1.2 Example 2

137

12.1.1 Example 1

137

12.1 Analog Input (A/D) Examples

136

12 Common Application Examples

135

11.4 Monitoring Events Using Messages In Windows

132

11.3 Monitoring Events Using Event Notification

130

11.2 Monitoring Events Using The Request Status

...................

DAQDRIVE Users Manual 10

....................

................

.............................

.................................

.....................................................

.....................................................

.....................................................

.....................................................

.....................................................

...............................

.....................................................

.....................................................

.....................................................

.....................................................

........................................

.....................................................

.....................................................

..............................................

.....................................................

.....................................................

............................................

.................

...............

...........................................

...............................................

.............................................

...............................................

.............................................

...............................................

.............................................

..............................................

..............................................

...............................................

.............................................

.....................

...................

...............................................

............................................

.............................................

...........................................

Page 11

282

A.1.2 Creating DOS Applications Using The TSR Drivers

282

A.1.1 Creating DOS Applications Using the C Libraries

282

A.1 Distribution Software

282

Appendix A: PXB-241

274

14 Error Messages

272

13.49 DaqWordsToBytes

270

13.48 DaqVersionNumber

268

13.47 DaqUserBreak

266

13.46 DaqTriggerRequest

264

13.45 DaqStopRequest

262

13.44 DaqSingleSigConInputScan

260

13.43 DaqSingleSigConInput

258

13.42 DaqSingleDigitalOutputScan

256

13.41 DaqSingleDigitalOutput

254

13.40 DaqSingleDigitalInputScan

252

13.39 DaqSingleDigitalInput

250

13.38 DaqSingleAnalogOutputScan

248

13.37 DaqSingleAnalogOutput

246

13.36 DaqSingleAnalogInputScan

244

13.35 DaqSingleAnalogInput

243

13.34 DaqResetDevice

242

13.33 DaqReleaseRequest

241

13.32.1 The Event Message

241

13.32 DaqPostMessageEvent (Windows Versions Only)

239

13.31.3 DaqOpenDevice - TSR Version

237

13.31.2 DaqOpenDevice - Windows Version

235

13.31.1 DaqOpenDevice - C Library Version

235

13.31 DaqOpenDevice

233

13.30.1 The user-defined event procedure

232

13.30 DaqNotifyEvent

230

13.29 DaqGetTimerCfgInfo

228

13.28 DaqGetSigConParamInfo

225

13.27 DaqGetSigConCfgInfo

223

13.26 DaqGetRuntimeError

221

13.25 DaqGetExpGainInfo

219

13.24 DaqGetExpCfgInfo

217

13.23 DaqGetDigioCfgInfo

215

13.22 DaqGetDeviceCfgInfo

213

13.21 DaqGetDAGainInfo

210

13.20 DaqGetDACfgInfo

............................................

DAQDRIVE Users Manual 11

...........................................

.........................................

..........................................

............................................

...........................................

..........................................

.........................................

......................................

..........................................

...............................................

................................

...............................................

..............................

..............................

...................................

..............

.............................................

............................................

...............................................

........................................

...................................

......................................

..................................

.........................................

....................................

.......................................

..................................

........................................

....................................

...............................................

............................................

.................................................

...........................................

............................................

...................................................

..............................................

...........................................

.....................

...................

Page 12

303

D.1.1 Creating DOS Applications Using the C Libraries

303

D.1 Distribution Software

303

Appendix D: IOP-241

302

C.5 Digital Output

302

C.4 Digital Input

301

C.3.3 Using the PIO-241 with Windows

300

C.3.2 Using the PIO-241 with the TSR drivers

299

C.3.1 Using the PIO-241 with the C libraries

299

C.3 Opening The PIO-241

298

C.2.2 Digital I/O Configuration

298

C.2.1 General Configuration

298

C.2 Configuring The PIO-241

297

C.1.3 Creating Windows Applications

296

C.1.2 Creating DOS Applications Using The TSR Drivers

296

C.1.1 Creating DOS Applications Using the C Libraries

296

C.1 Distribution Software

296

Appendix C: PIO-241

295

B.5 Digital Output

295

B.4 Digital Input

294

B.3.3 Using the PXB-721 with Windows

293

B.3.2 Using the PXB-721 with the TSR drivers

292

B.3.1 Using the PXB-721 with the C libraries

292

B.3 Opening The PXB-721

291

B.2.2 Digital I/O Configuration

291

B.2.1 General Configuration

291

B.2 Configuring The PXB-721

290

B.1.3 Creating Windows Applications

289

B.1.2 Creating DOS Applications Using The TSR Drivers

289

B.1.1 Creating DOS Applications Using the C Libraries

289

B.1 Distribution Software

289

Appendix B: PXB-721

288

A.5 Digital Output

288

A.4 Digital Input

287

A.3.3 Using the PXB-241 with Windows

286

A.3.2 Using the PXB-241 with the TSR drivers

285

A.3.1 Using the PXB-241 with the C libraries

285

A.3 Opening The PXB-241

284

A.2.2 Digital I/O Configuration

284

A.2.1 General Configuration

284

A.2 Configuring The PXB-241

.......................................

283

A.1.3 Creating Windows Applications

...................................

DAQDRIVE Users Manual 12

...........................................

........................................

..........................................

...................................................

.................................................

...............................................

...........................................

...................................

.......................................

............................................

.........................................

...........................................

....................................................

..................................................

..............................

.............................

..................................

.....................

...................

..............................

.............................

..................................

...............................................

...........................................

.....................

...................

...................................

.......................................

............................................

.........................................

...........................................

..............................

.............................

..................................

...................................................

..................................................

..............................................

...........................................

.....................

Page 13

321

F.3 Opening The DAQ-16

320

F.2.5 Timer Configuration

320

F.2.4 Digital I/O Configuration

320

F.2.3 D/A Converter Configuration

320

F.2.2 A/D Converter Configuration

320

F.2.1 General Configuration

320

F.2 Configuring The DAQ-16

319

F.1.3 Creating Windows Applications

318

F.1.2 Creating DOS Applications Using The TSR Drivers

318

F.1.1 Creating DOS Applications Using the C Libraries

318

F.1 Distribution Software

318

Appendix F: DAQ-16

317

E.7 Digital Output

317

E.6 Digital Input

316

E.5 Analog Output

316

E.4 Analog Input

315

E.3.3 Using the DAQ-12 with Windows

314

E.3.2 Using the DAQ-12 with the TSR drivers

313

E.3.1 Using the DAQ-12 with the C libraries

313

E.3 Opening The DAQ-12

312

E.2.5 Timer Configuration

312

E.2.4 Digital I/O Configuration

312

E.2.3 D/A Converter Configuration

312

E.2.2 A/D Converter Configuration

312

E.2.1 General Configuration

312

E.2 Configuring The DAQ-12

311

E.1.3 Creating Windows Applications

310

E.1.2 Creating DOS Applications Using The TSR Drivers

310

E.1.1 Creating DOS Applications Using the C Libraries

310

E.1 Distribution Software

310

Appendix E: DAQ-12

309

D.5 Digital Output

309

D.4 Digital Input

308

D.3.3 Using the IOP-241 with Windows

307

D.3.2 Using the IOP-241 with the TSR drivers

306

D.3.1 Using the IOP-241 with the C libraries

306

D.3 Opening The IOP-241

305

D.2.2 Digital I/O Configuration

305

D.2.1 General Configuration

305

D.2 Configuring The IOP-241

304

D.1.3 Creating Windows Applications

...................................

303

D.1.2 Creating DOS Applications Using The TSR Drivers

...................

DAQDRIVE Users Manual 13

.......................................

...........................................

........................................

..........................................

..................................

...................................................

.................................................

...............................................

...........................................

...................................

.......................................

............................................

.....................................

.....................................

.........................................

.............................................

...........................................

..................................

...................................................

.................................................

....................................................

..................................................

..............................

.............................

.....................

...................

..............................

.............................

...............................................

...........................................

.....................

....................

....................................

.......................................

............................................

.....................................

.....................................

.........................................

.............................................

...........................................

Page 14

340

H.4 Analog Input

339

H.3.3 Using the DAQ-1201/1202 with Windows

338

H.3.2 Using the DAQ-1201/1202 with the TSR drivers

337

H.3.1 Using the DAQ-1201/1202 with the C libraries

337

H.3 Opening The DAQ-1201/1202

336

H.2.5 Timer Configuration

336

H.2.4 Digital I/O Configuration

336

H.2.3 D/A Converter Configuration

336

H.2.2 A/D Converter Configuration

336

H.2.1 General Configuration

336

H.2 Configuring The DAQ-1201/1202

335

H.1.3 Creating Windows Applications

334

H.1.2 Creating DOS Applications Using The TSR Drivers

334

H.1.1 Creating DOS Applications Using the C Libraries

334

H.1 Distribution Software

334

Appendix H: DAQ-1201/1202

333

G.7 Digital Output

333

G.6 Digital Input

332

G.5 Analog Output

332

G.4 Analog Input

331

G.3.3 Using the DAQ-801/802 with Windows

330

G.3.2 Using the DAQ-801/802 with the TSR drivers

329

G.3.1 Using the DAQ-801/802 with the C libraries

329

G.3 Opening The DAQ-801/802

328

G.2.5 Timer Configuration

328

G.2.4 Digital I/O Configuration

328

G.2.3 D/A Converter Configuration

328

G.2.2 A/D Converter Configuration

328

G.2.1 General Configuration

328

G.2 Configuring The DAQ-801/802

327

G.1.3 Creating Windows Applications

326

G.1.2 Creating DOS Applications Using The TSR Drivers

326

G.1.1 Creating DOS Applications Using The C Libraries

326

G.1 Distribution Software

326

Appendix G: DAQ-801/802

325

F.7 Digital Output

325

F.6 Digital Input

324

F.5 Analog Output

324

F.4 Analog Input

323

F.3.3 Using the DAQ-16 with Windows

322

F.3.2 Using the DAQ-16 with the TSR drivers

.............................

321

F.3.1 Using the DAQ-16 with the C libraries

..............................

DAQDRIVE Users Manual 14

..................................

...................................................

.................................................

....................................................

..................................................

.............................................

...................................................

.................................................

...................................................

.................................................

.......................................

...........................................

....................

...................

...................................

.................................

...........................................

.....................................

.....................................

........................................

....................................

.........................

........................

.............................

...................................................

.....................................

..........................................

.....................

...................

...................................

...............................

...........................................

.....................................

.....................................

........................................

.............................................

..................................

.......................

......................

...........................

Page 15

358

J.7 Digital Output

358

J.6 Digital Input

357

J.5 Analog Output

356

J.4 Analog Input

355

J.3.3 Using the DAQP-208 / DAQP-208H / DAQP-308 with Windows

354

J.3.2 Using the DAQP-208 / DAQP-308 with the DOS TSR Driver

353

J.3.1 Using the DAQP-208 / DAQP-308 with the C libraries

353

J.3 Opening The DAQP-208 / DAQP-308

352

J.2.5 Timer Configuration

352

J.2.4 Digital I/O Configuration

352

J.2.3 D/A Converter Configuration

352

J.2.2 A/D Converter Configuration

352

J.2.1 General Configuration

352

J.2 Configuring The DAQP-208 / DAQP-308 / DAQP-308

351

J.1.3 Creating Windows Applications

350

J.1.2 Creating DOS Applications Using the TSR Driver

350

J.1.1 Creating DOS Applications Using the C Libraries

350

J.1 Distribution Software

350

Appendix J: DAQP-208 / DAQP-208H / DAQP-308

349

I.7 Digital Output

349

I.6 Digital Input

349

I.5 Analog Output

348

I.4 Analog Input

347

I.3.3 Using the DAQP-12 / DAQP-12H / DAQP-16 with Windows

346

I.3.2 Using the DAQP-12 / DAQP-12H / DAQP-16 with the DOS TSR

345

I.3.1 Using the DAQP-12 / DAQP-12H / DAQP-16 with the C libraries

345

I.3 Opening The DAQP-12 / DAQP-12H / DAQP-16

344

I.2.4 Timer Configuration

344

I.2.3 Digital I/O Configuration

344

I.2.2 A/D Converter Configuration

344

I.2.1 General Configuration

344

I.2 Configuring The DAQP-12 / DAQP-12H / DAQP-16

343

I.1.3 Creating Windows Applications

342

I.1.2 Creating DOS Applications Using the TSR Driver

342

I.1.1 Creating DOS Applications Using the C Libraries

342

I.1 Distribution Software

342

Appendix I: DAQP-12 / DAQP-12H / DAQP-16

341

H.7 Digital Output

341

H.6 Digital Input

340

H.5 Analog Output

.................................................

DAQDRIVE Users Manual 15

...................................................

.................................................

.............

............................................

.....................

.....................

....................................

............

............................................

......................................

.........................................

..............................................

................

.......

Driver ...............................................................

...........

....................................................

..................................................

....................................................

..................................................

.........

............................................

.....................

.....................

....................................

...........

............................................

......................................

......................................

.........................................

..............................................

............................

.................

............

........

....................................................

..................................................

....................................................

..................................................

Page 16

366

K.7 Digital Output

366

K.6 Digital Input

365

K.5 Analog Output

365

K.4 Analog Input

364

K.3.3 Using the DA8P-12 with Windows

363

K.3.2 Using the DA8P-12 with the TSR drivers

362

K.3.1 Using the DA8P-12 with the C libraries

362

K.3 Opening The DA8P-12

361

K.2.4 Timer Configuration

361

K.2.3 Digital I/O Configuration

361

K.2.2 D/A Converter Configuration

361

K.2.1 General Configuration

361

K.2 Configuring The DA8P-12

360

K.1.3 Creating Windows Applications

359

K.1.2 Creating DOS Applications Using The TSR Drivers

359

K.1.1 Creating DOS Applications Using The C Libraries

359

K.1 Distribution Software

359

Appendix K: DA8P-12

.............................................

DAQDRIVE Users Manual 16

...........................................

....................

...................

...................................

......................................

............................................

.....................................

.........................................

.............................................

..........................................

.............................

............................

.................................

...................................................

.................................................

...................................................

..................................................

Page 17

List of Figures

250

Figure 27. output_array data types as a function of analog output channel type.

246

Figure 26. input_array data types as a function of analog input channel type.

230

Figure 25. Counter/timer configuration structure definition.

Figure 24. Analog input signal conditioner board configuration structure

220

Figure 23. Analog input expansion board configuration structure definition.

217

Figure 22. Digital I/O configuration structure definition.

215

Figure 21. Device configuration structure definition.

211

Figure 20. D/A converter configuration structure definition.

205

Figure 19. A/D converter configuration structure definition.

195

Figure 18. Digital output request structure definition.

194

Figure 17. Digital output request structure.

190

Figure 16. Digital input request structure definition.

189

Figure 15. Digital input request structure.

175

Figure 14. Analog output request structure definition.

174

Figure 13. Analog output request structure.

170

Figure 12. Analog input request structure definition.

169

Figure 11. Analog input request structure.

166

Figure 10. Analog input request structure.

133

Figure 9. event_mask bit definitions.

132

Figure 8. event_type definition.

130

Figure 7. request_status bit definitions.

127

Figure 6. Summary of DAQDRIVE trigger sources and parameters.

Figure 5. buffer_status definition for output operations (D/A and digital

111

Figure 4. buffer_status definition for input operations (A/D and digital input).

Figure 3. DAQDRIVE interface between an application program and multiple

Figure 2. DAQDRIVE interface between an application program and multiple

Figure 1. DAQDRIVE interface between an application program and one

hardware device. .............................................................

DAQDRIVE Users Manual 17

19

devices of the same family. .....................................................

devices of different families. ....................................................

........

output). .....................................................................

..................

..........................................

................................................

............................................

.......................................

.......................................

..............................

......................................

.............................

........................................

...............................

......................................

..............................

........................

........................

...............................

...........................

..........

19

20

111

definition. ...................................................................

........................

226

..........

........

Page 18

1 Introduction

DAQDRIVE is Omega's universal data acquisition interface for the "DAQ" series of ISA bus

DAQDRIVE Users Manual 18

and PCMCIA data acquisition adapters. DAQDRIVE goes beyond the drivers normally

distributed with data acquisition adapters by isolating the application programmer from the

hardware.

DAQDRIVE provides support for application programs written in the following languages:

y

Microsoft C/C++

y

Borland C/C++

y

Visual Basic for DOS

y

Quick Basic version 4.5

y

Turbo Pascal for DOS version 7.0 and newer

y

Most Windows languages supporting Dynamic Link Libraries (DLLs) including Visual

C/C++, Borland C/C++, Turbo Pascal for Windows, and Borland Delphi

DAQDRIVE uses a "data defined" rather than a "function defined" interface. What this means

is that each data acquisition operation is defined by a series of configuration parameters and

requires very few function calls to implement. Because of this approach, DAQDRIVE may

seem a little unusual; even intimidating at times. However, after writing a few example

programs, we feel the user will discover the power behind this type of interface.

DAQDRIVE supports high speed data I/O by providing support for foreground (CPU

software polled) and background (DMA and interrupt driven) operation. For increased

flexibility, DAQDRIVE also supports software (internal) and hardware (external) clock and

trigger sources.

DAQDRIVE supports multiple data acquisition adapters in a single system. In fact, the

number of ad apters is l imited onl y by the amount of availabl e system memory . DAQDRIVE

also supports multiple tasks from one or more applications operating on one or more

hardware devices. This multi-tasking support is accomplished by tracking all system and

data acquisition resources and rejecting any request for which all of the necessary resources

are not available.

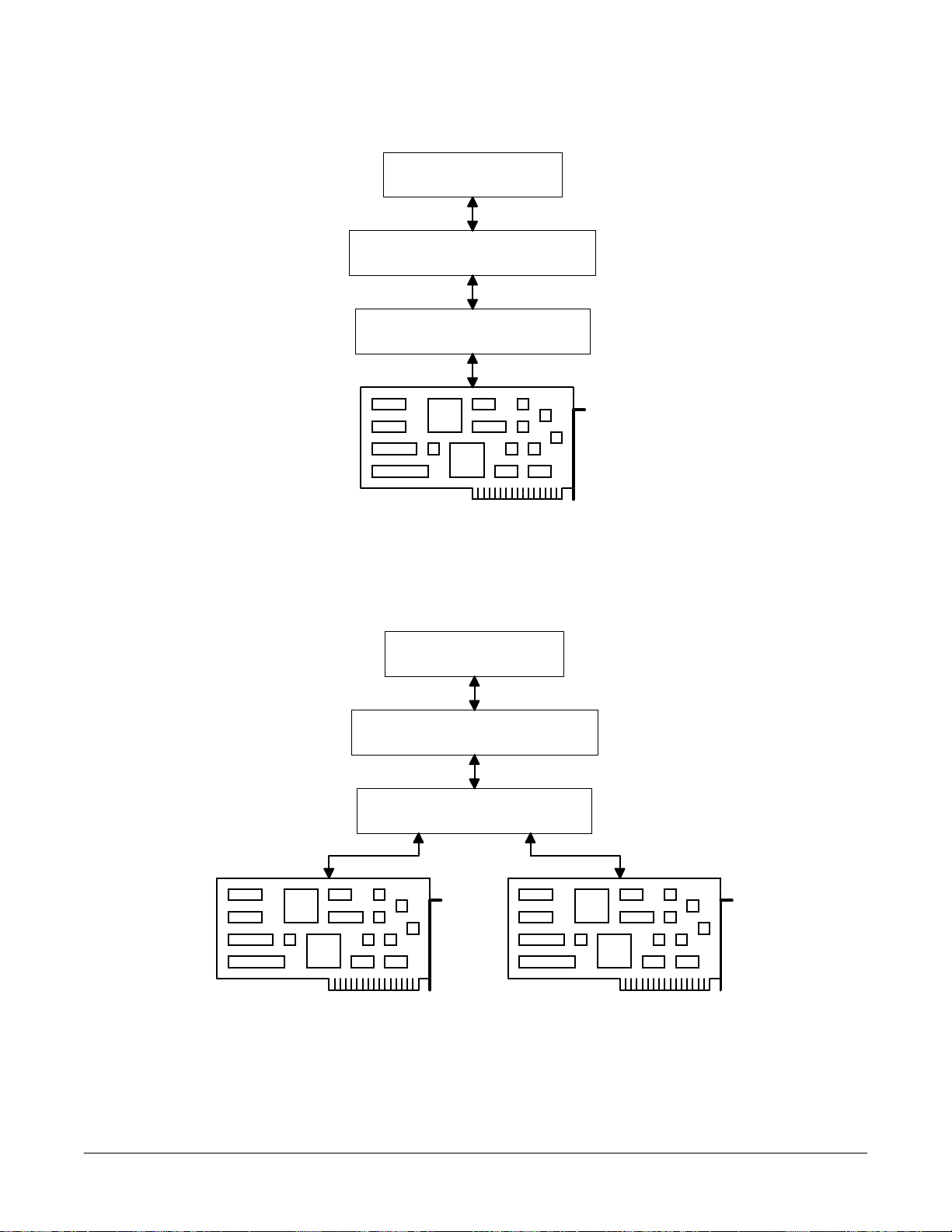

In orde r to minimize the code size of the application progr a ms, DAQDRIVE i s distribute d a s a

two-part driver. The first part contains the application program interface (API) and is also

responsible for memory management, file I/O, and other hardware independent functions.

Regardless of the number of hardware devices installed, only one copy of the hardware

independent driver is required.

The second part of the driver is hardware dependent and is responsible for implementing the

requested operations on the target hardware device. These dri vers are supplied wi th the data

Page 19

acquisition adapter and generally support only one family of hardware devices. Only one

hardware dependent driver is required for each family of hardware installed in the system.

DAQDRIVE Users Manual 19

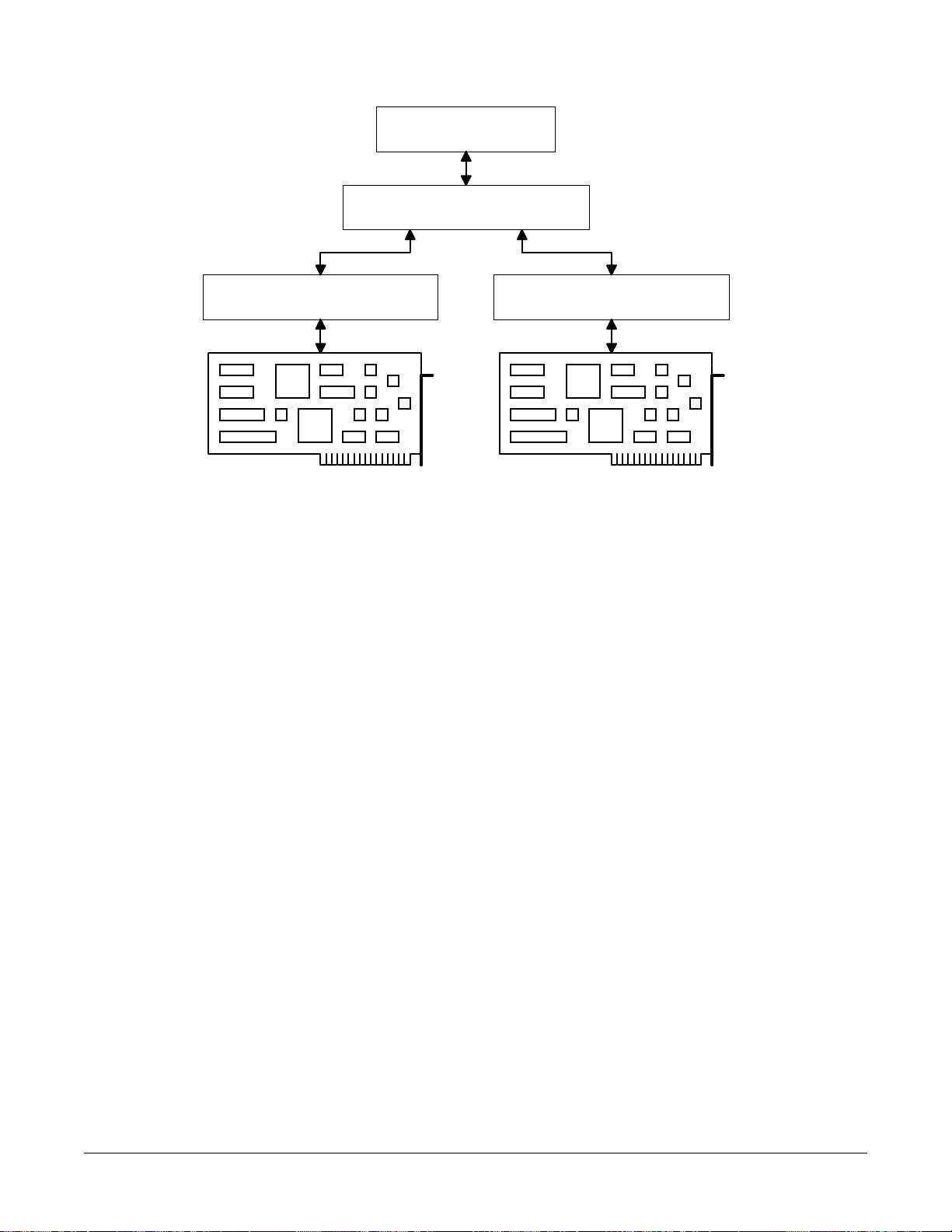

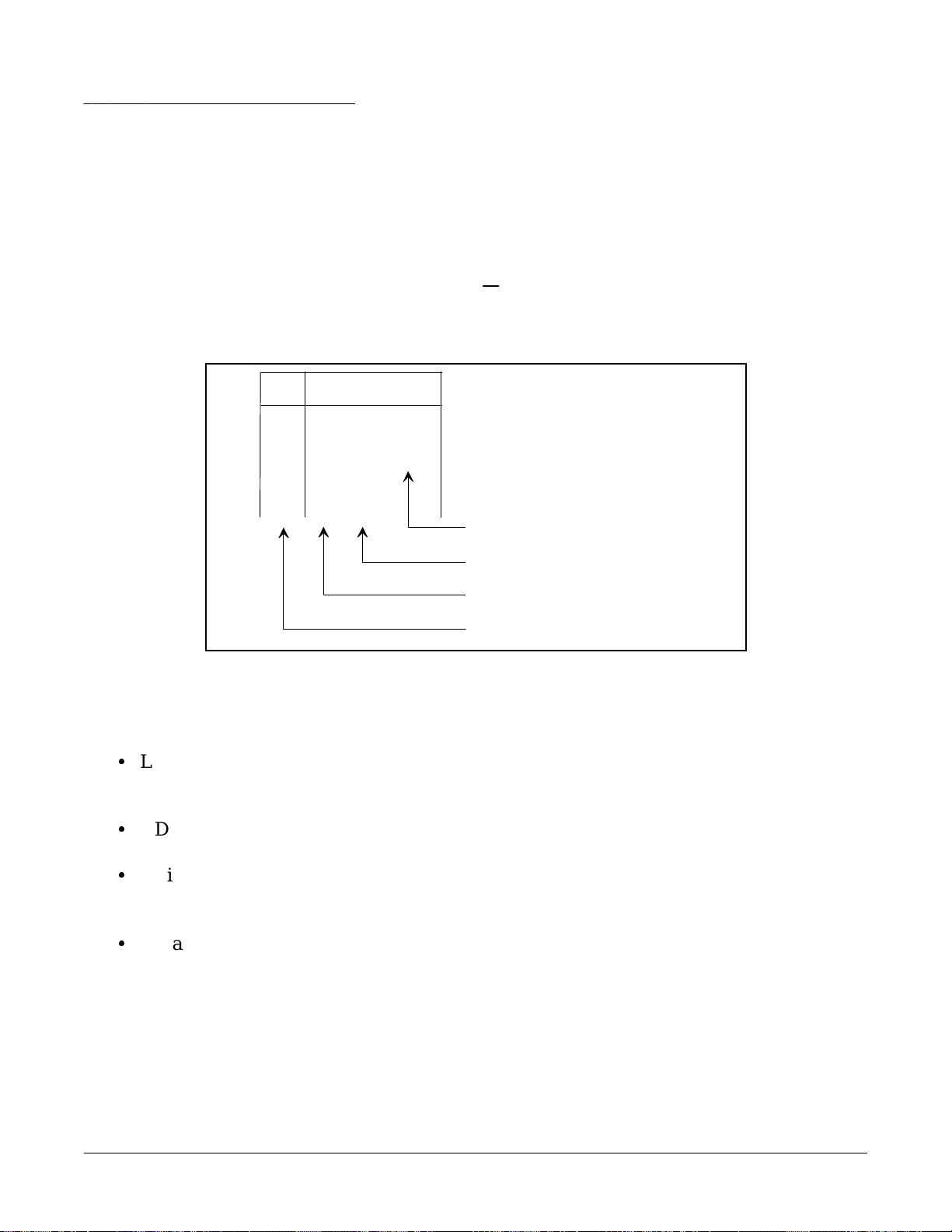

Figure 1. DAQDRIVE interface between an application program and one hardware device.

Application Program

Hardware independent driver

Hardware dependent driver

Application Program

Hardware independent driver

Hardware dependent driver

Figure 2. DAQDRIVE interface between an application program and multiple

devices of the same family.

Page 20

Application Program

DAQDRIVE Users Manual 20

Hardware independent driver

Hardware dependent driver Hardware dependent driver

Figure 3. DAQDRIVE interface between an application program and multiple

devices of different families.

Page 21

2 Before Beginning

2.1 Software Installation

DAQDRIVE Users Manual 21

The DAQDRIVE distrib uti on CD contains a Setup prog r am tha t allows the user to quickly and

easily install the necessary DAQDRIVE components onto the host computer. The Setup

program is compatible with Windows 3.x and Windows 95/98 and all ows the user to install

DAQDRIVE for DOS, Windows 3.x, and/or Windows 95/98.

From Windows 3.x:

1. Insert the compact disk into the computer's CD-ROM drive.

2. From the Windows program manager, select File then Run.

3. Assuming the CD-ROM drive is drive D, enter "D:\SETUP" in the command line

text box and click OK.

From Windows 95, Windows 98, and Windows NT 4.0:

1. Insert the compact disk into the computer's CD-ROM drive.

2. Click the Start button, point to Settings, then click Control Panel.

3. Double-click on Add/Remove Programs.

4. On the Install/Uninstall tab, click Install.

5. Click Next.

6. If the correct Setup program is found, click Finish. If not, click Browse and select

the Setup program in the root directory of the CD.

Follow the on- screen in structions to sele ct the DAQD RIVE components to be install ed. Whe n

the Setup program is complete, one or more of the following subdirectories will have been

created in the target directory:

...\DAQDRIVE\CONFIG DAQDRIVE Configuration Utility

...\DAQDRIVE\DAQEZ DaqEZ

...\DAQDRIVE\C_LIBS C library support for DOS applications

...\DAQDRIVE\TSR TSR driver support for DOS applications

...\DAQDRIVE\WINDLL Support for Windows 3.x and 16-bit Windows 95 applications

...\DAQDRIVE\VISDAQLT Support for 16-bit Visual Basic applications

...\DAQDRIVE\WIN32 Support for 32-bit Windows 95 applications

Page 22

2.2 DAQDRIVE Configuration Utilities

Before DA QDRIVE can operate an ad apter, a confi guration file must be generated to specif y

CAUTION:

DAQDRIVE Users Manual 22

the hardware configuration. Three separate Windows based utility programs are provided to

generate these configuration files:

1. DAQCFGW.EXE utility to edit DAQDRIVE hardware adapter configuration files

2. EXPBOARD.EXE utility to edit the data base defining available A/D expansion

boards and their parameters

3. SIGCON.EXE utility to edit the data base defining available A/D channel signal

conditioners and their parameters

IMPORTANT:

The DAQDRIVE configuration utilities must be used to edit the

DAQDRIVE hardware configuration files. Under no circumstances

should the user attempt to create and /or edit D AQDRIVE hard ware

configuration files directly.

2.2.1 Installation

The DAQDRIVE configuration utilities are automatically installed into the

..\DAQDRIVE\CONFIG subdirectory whenever the Setup program is executed. In addition,

the Setup program installs sample hardware configuration data files (.DAT), and their

associated report files (.RPT). These sample configuration files must be modified to create the

user’s configuration as DAQCFGW does not allow the creation of new hardware

configuration data files, but instead requires all files to be a modified version of an existing

file.

DAQCFGW does not al low the crea tion of new hardw are config uration data f iles, but instead

requires all files to be a modified version of an existing data file. The DAQDRIVE installation

program installs the necessary sample hardware configuration data files (.DAT), and their

associated report files (.RPT), into the ..\DAQDRIVE\CONFIG directory along with the

configuration utilities.

Older versions of DAQDRIVE may not be compatible with

files generated by the latest configuration utilities.

Page 23

2.2.2 Generating A DAQDRIVE Configuration File

DAQCFGW does not allow the creation of new data files but instead requires all files to be a

DAQDRIVE Users Manual 23

modified version of an existing data file (*.DAT). For this reason, one or more sample data

files are provided on the DAQDRIVE installation diskettes. To view and/or edit a

configuration data file:

1. Execute DAQCFGW by double-clicking on the DAQDRIVE configuration utility

icon located in the DAQDRIVE program group

2. Select File, Open

3. Select the drive and directory in the corresponding list boxes.

4. Type the name of an existing configuration data file (.DAT) in the file name text box

or select the file from the corresponding list box.

5. Choose OK.

Some or all of the following configuration options will appear in the Hardware Setup menu:

y

General

y

A/D Converter

y

A/D Expansion Boards

y

A/D Signal Conditioners

y

D/A converter

y

Timer

y

Digital I/O

y

Configuration Help

To select a subsystem for conf iguration, select it f rom the Hardware Setup menu or cl ick the

associated tool bar icon. If a specif ic subsystem is not availab le on the adapter or if there are

no user-definable options within that subsystem, the option will be disabled. The hardware

specific appendix for the adapter being configured lists the available options.

2.2.2.1 General Configuration

The general confi gurati on wind ow is used to def ine the i nterf ace be tween the ad apter a nd the

host system. All adapters require the general configuration options:

Base Address

The base I/O ad dress of the a dapter must be specif ied using the base add ress text box . If the

adapter i s PCMCIA, or PCI compatibl e, the user may speci fy a base ad dress of 0. Setti ng the

base address to 0 instructs DAQDRIVE to determine the ad apter 's b a se ad d r ess, interrupt, and

DMA settings automatically each time the device is opened.

IRQ Level

The adapter's interrupt level (IRQ) must be selected from the corresponding drop-down list

box. If the adapter does not support interrupts or if the base I/O address is set to 0, the

interrupt list box is not displayed.

Page 24

DMA Channel 1

The adapter 's pri mary DMA channel must be selecte d fr om the cor respond ing d rop-d own li st

DAQDRIVE Users Manual 24

box. If the adapter doe s not support DMA or if the base I/O ad dress is set to 0, the primary

DMA list box is not displayed.

DMA Channel 2

The adapter's secondary DMA channel must be selected from the correspond ing drop-down

list box. If the adapter does not support two DMA channels, or if the base I/O address is set

to 0, the secondary DMA list box is not displayed.

2.2.2.2 A/D Converter Configuration

The A/D converter wi ndow is used to define the configuration of the adapter 's analog i nput

channels. When these parameters define a specific jumper setting on the adapter, it is the

user's responsibility to assure the adapter is configured properly. The Configuration Help

window provides information regarding hardware modification requirements (see page 29).

The number and type of user-definab le options availa ble in this window i s dependent on the

hardware installed and is discussed in the hardware specific appendix for the adapter being

configured.

A/D Converters

Select the a nalog-to-dig ital (ADC) device on the A/D a dapter to be configured fr om this list

box. Most A/D adapters have only one ADC device (ADC 0).

Channels

Dialog b ox shows the number of A/D input channels availab le on the adapter in its current

configuration. A multiplexer (mux) feeds multiple analog inputs back into the actual ADC

device(s). The number of channels may be affected by the Input Mode.

Input Mode

Select the A/D input mode from the list box.

y

Single Ended: A/D converter measures the voltage from one input to ground. All

A/D channels normally share common ground.

y

Differential: A/D converter measures the voltage difference between two inputs that

are isolated from ground.

Signal Type

Select the signal type from the list box.

y

Unipolar: A/D converter measures only positive voltages.

y

Bipolar: A/D converter measures both positive and negative voltages.

Gain

This list box provide s opti onal signal a mpl i f ier settings. Note that this opti on i s only avail ab l e

on devices with hardw are sele ctable g ain setti ngs. D evices wi th software prog rammabl e gai ns

are configured at run-time.

Page 25

2.2.2.3 A/D Converter Expansion Configuration

The A/D converter expansion wi ndow i s used to defi ne the confi guration of any analog i nput

DAQDRIVE Users Manual 25

expansion adapters connected to the analog input channels. To assign an expansion board to

a main A/D channel click in the Expansion Board Names column and a choose from the drop

down list box. The first analog input expansion board must always be connected to A/D

channel 0, and additional expansion boards then connect to the next lowest channel.

Expansion adapters are defined in a data base using the EXPBOARD utility. The expansion

board data base may be viewed from the DataBase menu. However, to add or edit the

expansion board data base this utility must be run independently (see page 22).

The number and type of user-definab le options availa ble in this window i s dependent on the

hardware installed and the configuration of the expansion board as defined by the

EXPBOARD utility. When these parameters define a specific jumper setting on the expansion

board adapter, it is the user's responsibility to assure the adapter is configured properly.

The parameters in this window r e f er only to the expansion boar d adapter and do not ef f e ct the

A/D converter configuration of the main board. In most cases however, these two sets of

parameters must be examined together. For example, a gain of 2 in the A/D converter

configuration combined with a gain of 10 on the analog input expansion board results in an

overall gain of 20.

Channels

Dialog b ox shows the number of a nalog input channel s availabl e on the expansion board in its

current configuration. The values in this box are defined in the EXPBOARD utility. The

number of channels may be effected by the Input Mode.

Input Mode

Select the input mode from the list box.

y

Single Ended: input signals are measured from one input to ground. All inputs

normally share a common ground.

y

Differential: input signals are measured as the difference between two inputs that are

isolated from ground.

Signal Type

Select the signal type from the list box.

y

Unipolar: expansion board accepts only positive voltages.

y

Bipolar: expansion board accepts both positive and negative voltages.

Gain

This list box provide s opti onal signal a mpl i f ier settings. Note that this opti on i s only avail ab l e

on devices with hardware selectable gain settings. Devices with software programmable

gains are configurable at run-time.

Page 26

2.2.2.4 A/D Signal Conditioners

A signal conditioner may be connected to any A/D main channel, and/or to any A/D

DAQDRIVE Users Manual 26

expansion channel marked “Signal Conditioner Connectable” in the EXPBOARD utility (see

page 24). Expansion boards are normally used in conjunction with signal conditioners, but

are not required. To assign a signal conditioner to an A/D channel click in the Signal

Conditioner Name column and a choose from the drop down list box.

Signal conditioners are defined in a data base using the SIGCON utility. The signal

conditioner data base may be viewed from the DataBase menu. H owever, to add or edit the

signal conditioner data base this utility must be run independently (see page 24).

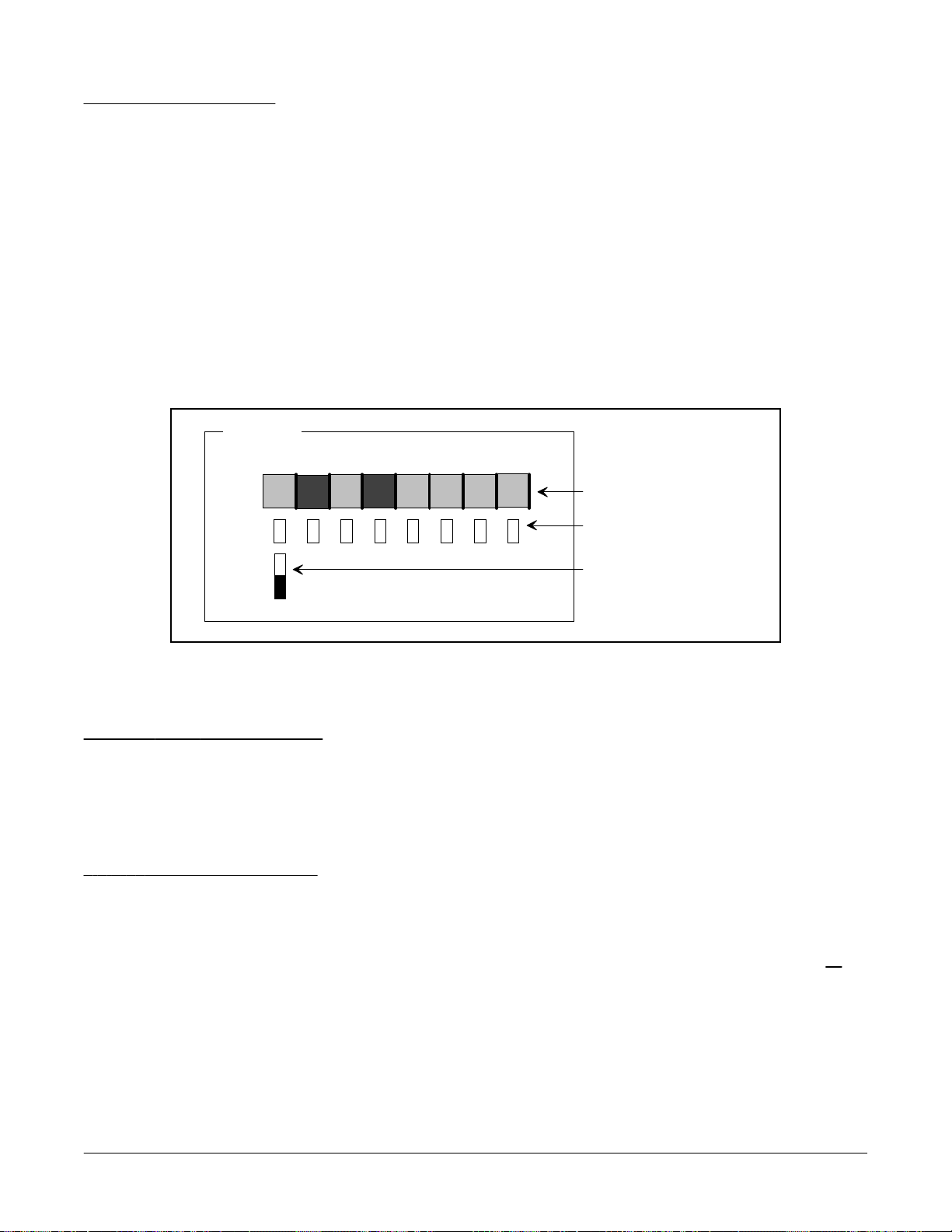

Mux CHCH

0-00-00

0

0-00-01

1

0-01

2

0-02

3

Expansion Channel

Main ADC Channel

ADC Device

Logical Channel

Figure 1. A/D Channel Numbering

To help understand the A/D channel numbering system the following terms are defined:

y

Logical Channel: The CH column designates the logical number that software

should use to access the analog input channel. When using

expansion boards you may have up to 256 logical channels.

y

ADC Device: The ADC device number. Most A/D adapters have only one

ADC device (ADC 0).

y

Main ADC Channel: Analog input channel on the A/D adapter board. A multiplexer

(mux) on the A/D adapter feeds multiple analog inputs back into

the actual ADC device(s).

y

Expansion Channel: Analog input channel provided by an expansion board

connection to a single main analog channel. Expansion boards

use digital I/O to address multiple expansion channels from a

single main channel through a multiplexer.

Page 27

2.2.2.5 D/A Converter Configuration

The D/A converter wi ndow is used to d efine the config uration of the adapte r's analog output

DAQDRIVE Users Manual 27

channels. When these parameters define a specific jumper setting on the adapter, it is the

user's responsibility to assure the adapter is configured properly. The Configuration Help

window provides information regarding hardware modification requirements (see page 20).

The number and type of user-definab le options availa ble in this window i s dependent on the

hardware installed and is discussed in the hardware specific appendix for the adapter being

configured.

D/A Channels

Select the D/A channel to configure from the list. Each D/A channel typically has its own

digital-to-analog converter (DAC).

Signal Type

Select the signal type from the list box.

y

Unipolar: DAC device outputs only positive voltages.

y

Bipolar: DAC device outputs both positive and negative voltages.

Ref. Source

Analog output from DAC is proportional to a reference voltage. Select the voltage source

from the list box.

y

Internal: Reference voltage generated by adapter board.

y

External: Reference voltage supplied by an external source.

Ref. Voltage

The reference voltage is used as scal ing multiplier for DAC output. For example, on a 12-bit

unipolar operation the analog output can be calculated from the equation:

V

OUT

= V

* (Digital_Count / 4096) * Gain

REF

Gain

This list box provide s opti onal signal a mpl i f ier settings. Note that this opti on i s only avail ab l e

on devices with hardware selectable gain settings. Devices with software programmable

gains are configurable at run-time.

2.2.2.6 Digital I/O Configuration

The digital I/O window is used to define the configuration of the adapter's digital input /

output channels. When these parameters def ine a specific jumper setting on the adapter, it is

the user's responsibility to assure the adapter is configured properly. The Configuration Help

window provides information regarding hardware modification requirements (see page 20).

The number and type of user-definab le options availa ble in this window i s dependent on the

hardware installed and is discussed in the hardware specific appendix for the adapter being

configured.

Page 28

Channel Configuration

Each digital I/O bit on an adapter can be individually accessed though the connector for

DAQDRIVE Users Manual 28

control/monitori ng of external dig ital devices. The digital I/O bits on each ad apter must be

configured into logical channels. Digital I/O channels can be set only 1 bit wide to access

single I/O lines at the connector, or logical channels that access multiple I/O bits

simultaneously are configurable.

Assign a logical channel number to the target d igital I/O bit by clicki ng on the current logical

channel number. A drop down channel selection box will appear with the possible channel

configurations for this I/O bit (see Figure 2). The rest of the digital I/O bits will be

automatically upda ted with corr ect channel numbers reflecti ng any changes. Repeat thi s step

for each digital I/O bit.

Port 0

bit

CH

76

3

3

4

54321

InIn

3

In

OutOut

12

0

InIn

In

0

000

Direction Control

Logical Channel

Channel Select

Figure 2. Digital I/O Configuration Display

Input/Output Configuration

After all of the logical channels have been defined, they may be configured for input, output,

or input/output (I/O) b y cli cking on the di rection contr ol b utton for each l ogical channel. Al l

bits defined as a member of that logical channel will toggle between the available settings.

2.2.2.7 Timer Configuration

The timer configuration window is used to define the adapter's onboard counter / timer

circuits. Examples of settings found in this section include counter size and input clock

frequency. When these parameters define a specific jumper setting on the adapter, it is the

user's responsibility to assure the adapter is configured properly. The Configuration Help

window provides information regarding hardware modification requirements (see page 20).

The number and type of user-definab le options availa ble in this window i s dependent on the

hardware installed and is discussed in the hardware specific appendix for the adapter being

configured.

Page 29

2.2.2.8 Configuration Help

The hardware configuration of the adapter is the responsibility of the user. Some of these

DAQDRIVE Users Manual 29

hardware configuration settings may be handled through software, while others may require

switches or jumper blocks to be modified. The configuration help window provides the user

with the jumper block or switch numbers to modify if required.