Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

User’s Guide

DAQBOARD-100/200 SERIES

DaqBoard-100, 112, 200, and 216

12 and 16 Bit Resolution, ISA Data Acquisition Boards

OMB-457-0907 rev 1.0

Page 2

OMEGAnetSM On-Line Service

http://www.omega.com

6HUYLFLQJ1RUWK$PHULFD

Internet e-mail

info@omega.com

USA:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada:

976 Berger

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: canada@omega.com

)RULPPHGLDWHWHFKQLFDORUDSSOLFDWLRQDVVLVWDQFH

USA and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

En Espanol: (95) 203-359-7803

SM

FAX: (95) 203-359-7807

e-mail: espanol@omega.com

SM

SM

SM

6HUYLFLQJ(XURSH

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING:

These products are not designed for use in, and should not be used for, patient-connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

ul. Rude armady 1868

733 01 Karvina-Hranice

Tel: 420 (69) 6311899

FAX: 420 (69) 6311114

e-mail:czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

25 Swannington Road,

Broughton Astley, Leicestershire,

LE9 6TU, England

Tel: 44 (1455) 285520

FAX: 44 (1455) 283912

P.O. Box 7, Omega Drive,

Irlam, Manchester,

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

Page 3

&$87,21

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Before setting up and using your

equipment, you should read all documentation that covers your system.

Pay special attention to Warnings and Cautions.

Note:

PDF

OMB-

457-0907

PDF

OMB-

457-0909

PDF

During software installation, Adobe

install onto your hard drive as a part of product support. The default location is in the

Programs directory, which can be accessed from the Windows Desktop. Refer to the

PDF documentation for details regarding both hardware and software.

A copy of the Adobe Acrobat Reader® is included on your CD. The Reader provides

a means of reading and printing the PDF documents. Note that hardcopy versions of the

manuals can be ordered from the factory.

®

PDF versions of user manuals will automatically

DaqBoard-ISA User’s Manual

Contains an overview of Daq systems, setup and startup instructions for ISA-type

DaqBoards, and details regarding the on-board DIP-switch and jumpers. The

following PDFs are companion documents.

DaqView and DaqViewXL

Discusses how to install and use these “out-of-the-box” data acquisition programs.

Post Acquisition Data Analysis User’s Guide(s)

Contains at least one user’s guide that pertains to a post acquisition-data analysis

program. PostView, DIAdem, and eZ-View are examples of post data analysis

programs.

DBK Option Cards and Modules User’s Manual

The DBK Option Cards and Modules Manual discusses each of the DBK products

PDF

OMB-

457-0905

available at the time of print.

Programmer’s Manual

The programmer’s manual pertains to developing custom programs using Applications

PDF

OMB-

1008-0901

Your order was carefully inspected prior to shipment. When you receive your system, carefully

unpack all items from the shipping carton and check for physical signs of damage that may have

occurred during shipment. Promptly report any damage to the shipping agent and your sales

representative. Retain all shipping materials in case the unit needs returned to the factory.

Program Interface (API) commands.

Programmers should check the readme.file on the install CD-ROM for the location of

program examples included on the CD.

Page 4

Page 5

Manual Layout

Chapter 1 – Daq Systems, a Brief Overview discusses the “modular concept” associated with

Chapter 2 – Setup and Startup provides instructions for configuring and installing ISA-type DaqBoards,

Chapter 3 – A Closer Look at DaqBoard-ISA Hardware discusses the differences between

DBK Basics – discusses option cards and modules (DBKs) that can be used to enhance and expand data

Appendix A – Specifications, ISA-Type DaqBoards

DaqBooks, DaqBoards, and DBK options.

product support software, and electronic versions of documentation..

DaqBoard-ISA models, performance factors, jumpers, and connections.

acquisition systems. Note that DBK Basics is not a chapter, but an independent document module

that is applicable to this user’s manual, as well as others.

Reference Notes:

During software installation, Adobe

®

PDF versions of user manuals are automatically

installed onto your hard drive as a part of product support. The default location is in the

Programs directory, which can be accessed from the Windows Desktop.

A copy of the Adobe Acrobat Reader

®

is included on your CD. The Reader provides

a means of reading and printing the PDF documents. Note that hardcopy versions of manuals

can be ordered from the factory.

➣

DaqView and DaqViewXL – explains the use and features of the included out-of-the-box

data acquisition software.

➣

Post Acquisition Data Analysis User’s Guide– contains one or more document modules

pertaining to a post-acquisition analysis program. Examples of such programs are

PostView, DIAdem and eZ-View.

➣

For detailed information regarding specific DBKs, refer to the DBK Option Cards and

Modules User’s Manual, p/n OMB-457-0905. Each DBK section includes device-specific

hardware and software information. The document includes a chapter on power

management.

➣

For programming-related information refer to the separate Programmer’s Manual,

p/n OMB-1008-0901.

OMB-DaqBooard-ISA User’s Manual

02-14-02

iii

Page 6

iv

02-14-02

OMB-DaqBoard-ISA User’s Manual

Page 7

Table of Contents

1 - Daq Systems, a Brief Overview

Daq Systems, the Modular Concept ……1-1

DaqBooks & DaqBoards ….1-2

Using DBK Cards & Modules for Signal

Conditioning …1-3

Daq Software …… 1-3

2 – Setup and Startup

Configure the ISA-DaqBoard ……2-2

Make ISA-DaqBoard Connections…... 2-4

Install Software and Product Support Documentation …… 2-4

Test Hardware…… 2-5

3 – A Closer Look at DaqBoard-ISA Hardware

Overview …… 3-1

Performance Factors …… 3- 1

Switches and Jumpers …… 3- 3

Base Address (SW1) …… 3- 3

External Analog Expansion Power (JP1) …… 3- 4

DAC Reference Selection (JP2) …… 3- 4

DMA and Interrupt Selection (JP8) …… 3- 5

Connections …… 3- 5

P1, DB37 Pinout, Analog I/O …… 3-7

P2, DB37 Pinout, Digital I/O …… 3-8

P3, DB37 Pinout, Pulse/Frequency/High-Speed Digital I/O …… 3-9

DBK Basics

(Document Module)

Introduction…… 1

How Do DBKs Connect to the Data Acquisition Device? …… 2

DBK Identification Tables ….. 3

Analog Output DBKs …… 3

Digital I/O Control DBKs …… 3

Analog Signal Conditioning DBKs …… 3

Expansion and Terminal Panel Connection DBKs …… 4

Power Supply DBKs …… 4

Tips on Setting up a Data Acquisition System …… 4

Power Supplies and Power Connectors ……6

An Introduction to Power-Related DBKs ….. 7

Calculating Your System’s Power Needs …… 9

Additional Reading ….. 11

Appendix A - Specifications, ISA-Type DaqBoards

OMB-DaqBooard-ISA User’s Manual

02-14-02

v

Page 8

vi

Page 9

Daq Systems, a Brief Overview 1

Daq Systems, the Modular Concept …… 1-1

DaqBooks and DaqBoards …… 1-2

Using DBK Cards and Modules for Signal Conditioning ….. 1-2

Daq Software ……1-3

Daq Systems, the Modular Concept

Daq equipment and software form a modular, interrelated family of products that provide great flexibility in

data acquisition system design. This flexibility allows for the development of custom systems that are

unique to the user, and which can be optimized for his or her specific application needs. With the Daq

product line, system expansion or redesign can typically be accomplished with relative ease.

•

Primary Acquisition Device. This is the main data acquisition device, e.g., a DaqBook or DaqBoard.

These devices provide a vital data conversion and communications link between the data source of

transducers and signal conditioners and the data processor of the host computer. Note the DaqBoards

can be one of three types: (1) ISA, (2) PCI, or (3) compact PCI (cPCI). The DaqBoards covered in

this document are of the ISA type.

•

DBK Option Cards and Modules. Over 35 DBK cards and modules (the number is constantly

growing) provide various types of signal conditioning and system expansion. Note that certain DBK

modules exist for the purpose of supplying power to other members of the acquisition system. The

DBK options are discussed in a DBK Basics document module and in the detailed DBK Option Cards

and User’s Manual (p/n OMB-457-0905).

Reference Note:

DBK options are discussed in the DBK Option Cards and Modules User’s Manual

(p/n OMB-457-0905). As a part of product support, this manual is automatically loaded

onto your hard drive during software installation. The default location is the Programs

directory, which can be accessed through the Windows Desktop.

•

Software. DaqView out-of-the-box software provides a graphical user interface with easy to read

spreadsheet formats for viewing channel data, as well as a choice of analog, digital, and bar-graph

meters. Waveform analysis can be performed, when applicable. A product support option, included

on the data acquisition CD, provides a means of performing post data analysis. More information is

included in the software-specific PDF documents that are installed on your hard-drive as a part of

product support.

In addition to the included out-of-the-box software, Daq products can be controlled via user-written

custom programs through Applications Program Interface (API). Several languages are supported,

e.g., C/C++, VisualBASIC, Delphi.

Reference Note:

Programming topics are covered in the Programmer’s User Manual

(p/n OMB-1008-0901). As a part of product support, this manual is automatically

loaded onto your hard drive during software installation. The default location is the

Programs directory, which can be accessed through the Windows Desktop.

OMB-Daq Systems

02-13-02

Overview 1-1

Page 10

DaqBooks and DaqBoards

Daq products connect to one or more DBKs on their signal input side and a computer on their output side.

Each type of Daq device connects to the computer in a different way:

•

The DaqBook is an external module that connects to a computer’s enhanced parallel port (EPP)

interface or PC-Card link.

•

The DaqBoard [ISA type] board is an internal card that plugs into an ISA-bus slot within a

computer.

Features common to the Daq products include:

•

100-kHz channel-to-channel scan and gain switching (10 µs);

200-kHz for DaqBoard/2000 Series and DaqBoard/2000c Series Boards.

•

512-location sequence memory that can be loaded with any combination of channels and gains.

•

Ability to access up to 256 different channels of DBK signals while maintaining the channel-tochannel scan rate. The DBK expansion options can accommodate mixed-signal inputs from

thermocouples and RTDs to isolated high-voltage inputs and strain gages.

•

Ability to handle 8 differential or 16 single-ended signal inputs without DBK expansion units.

•

Ability to handle fixed digital I/O up to 4 TTL lines in and 4 TTL lines out (accessible only if no

analog expansion cards are in use).

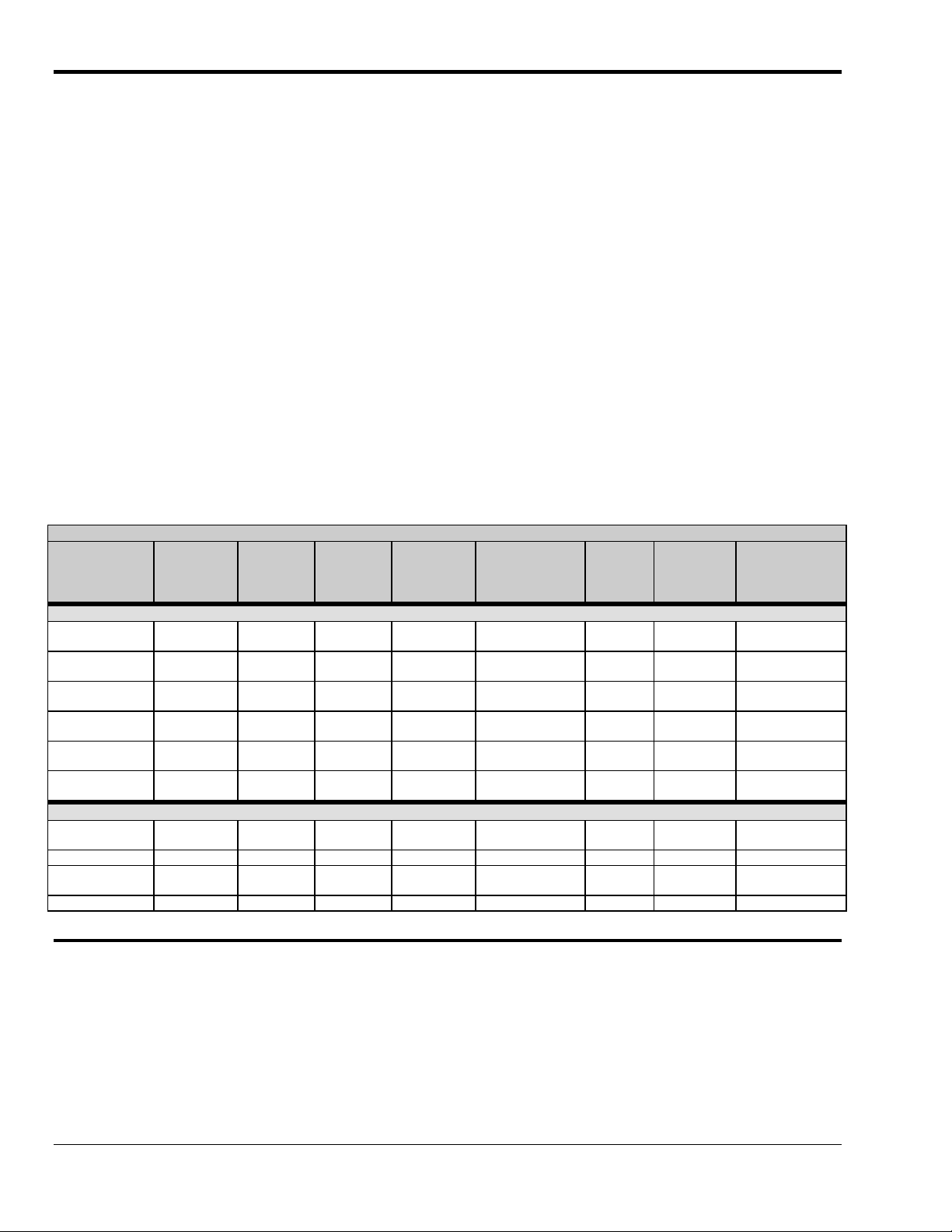

The following table lists various features of DaqBooks and ISA-DaqBoards.

Daq Products, Models and Features

Models

DaqBooks

DaqBook/100 12 bit 2 Jumper Jumper 16 high speed

DaqBook/112 12 bit 2 Jumper Jumper N/A N/A 8.5×11

DaqBook/120 12 bit 2 Jumper Jumper 16 high speed

DaqBook/200 16 bit 2 Software Software 16 high speed

DaqBook/216 16 bit 2 Software Software N/A N/A 8.5×11

DaqBook/260 16 bit 2 Software Software 16 high speed

ISA-DaqBoards

DaqBoard/100A 12 bit 2 Sequencer Software 16 high speed

DaqBoard/112A 12 bit 2 Sequencer Software N/A N/A 4.5×13.125 970 mA @ 5V

DaqBoard/200A 16 bit 2 Sequencer Software 16 high speed

DaqBoard/216A 16 bit 2 Sequencer Software N/A N/A 4.5×13.125 1340 mA @ 5V

*

Does not include power consumption of internal DBK options.

A/D

Resolution

Analog

Output

Channels

Unipolar/

Bipolar

Selection

Single-

ended/

Differential

Selection

Programmable

Digital I/O

Lines

24 gen purpose

24 gen purpose

24 gen purpose

24 gen purpose

24 gen purpose

24 gen purpose

Program

mable

Counter/

Timers

5 ch

7 MHz

5 ch

7 MHz

5 ch

7 MHz

5 ch

7 MHz

5 ch

7 MHz

5 ch

7 MHz

Size

(inches)

8.5×11

×1.375

×1.375

8.5×11

×1.375

8.5×11

×1.375

×1.375

11×13

×3.5

4.5×13.125 1330 mA @ 5V

4.5×13.125 1700 mA @ 5V

Power

Consumption

510 mA @ 12V

360 mA @ 12V

510 mA @ 12V

620 mA @ 12V

600 mA @ 12V

*

mA @ 12V

620

Using DBK Cards and Modules for Signal Conditioning

The DBK signal-conditioning cards and module are designed for use with DaqBooks, LogBooks, and

various types of data acquisition boards, i.e., ISA, PCI, and compact PCI (cPCI) types. The DBKs perform

best when used with an acquisition device that can dynamically select channel, gain, and range. DBK cards

and modules with dynamic channel and gain/range selection allow for high channel-to-channel scan rates

with a variety of transducers.

1-2 Overview

02-13-02

OMB-Daq Systems

Page 11

DBK output signals can be bipolar, e.g., -5 to +5 V, or unipolar, e.g., 0 to 10 V. The user can select a range

of relevant values to correspond to the lowest signal (e.g., -5 or 0 V) and the highest signal (e.g., 5 or 10 V)

signal. This type of range selection guarantees the highest resolution in 12-bit or 16-bit conversion.

DBK modules share the same footprint as the DaqBook and a typical notebook PCs; allowing for

convenient stacking. The majority of these modules have their own power supply; however, several options

exist for packaging and powering the DBKs.

Daq Software

The Daq devices have software options capable of handling most applications. Three types of software are

available:

Reference Note:

DBK options are detailed in the DBK Option Cards and Modules User’s Manual

(p/n OMB-457-0905). As a part of product support, this manual is automatically loaded onto

your hard drive during software installation. The default location is the Programs directory,

which can be accessed through the Windows Desktop.

•

ready-to-use graphical programs, e.g., DaqView, DaqViewXL, and post acquisition data analysis

programs such as PostView, DIAdem, and eZ-View

•

drivers for third-party, icon-driven software such as DASYLab and LabView

•

various language drivers to aid custom programming using API

Ready-to-use programs are convenient for fill-in-the-blank applications that do not require programming for

basic data acquisition and display:

•

DaqView is a Windows-based program for basic set-up and data acquisition. DaqView lets you

select desired channels, gains, transducer types (including thermocouples), and a host of other

parameters with a click of a PC’s mouse. DaqView lets you stream data to disk and display data

in numerical or graphical formats. PostView is a post-acquisition waveform-display program

within DaqView.

•

DaqViewXL allows you to interface directly with Microsoft Excel to enhance data handling and

display. Within Excel you have a full-featured Daq control panel and all the data display

capabilities of Excel.

•

Post acquisition data analysis programs, e.g., PostView, DIAdem, and eZ-View, typically allow

you to view and edit post-acquisition data.

•

The Daq Configuration control panel allows for interface configuration, testing, and

troubleshooting.

Each Daq system comes with an Application Programming Interface (API). API-language drivers include:

C/C++, Delphi, and Visual Basic. The latest software is a 32-bit version API.

Reference Notes:

➣

The software document modules, DaqView, DaqViewXL, and Post Acquisition Data

Analysis User’s Guide, are not included as part of the hardcopy manual, but are

available in PDF version. See the PDF Note, below.

➣

Programming topics are covered in the Programmer’s User Manual

(p/n OMB-1008-0901). As a part of product support, this manual is automatically

loaded onto your hard drive during software installation. The default location is the

Programs directory, which can be accessed through the Windows Desktop.

OMB-Daq Systems

02-13-02

Overview 1-3

Page 12

PDF

Note:

During software installation, Adobe

®

PDF versions of user manuals will automatically install

onto your hard drive as a part of product support. The default location is in the Programs

directory, which can be accessed from the Windows Desktop. Refer to the PDF

documentation for details regarding both hardware and software.

®

A copy of the Adobe Acrobat Reader

is included on your CD. The Reader provides

a means of reading and printing the PDF documents. Note that hardcopy versions of the

manuals can be ordered from the factory.

1-4 Overview

02-13-02

OMB-Daq Systems

Page 13

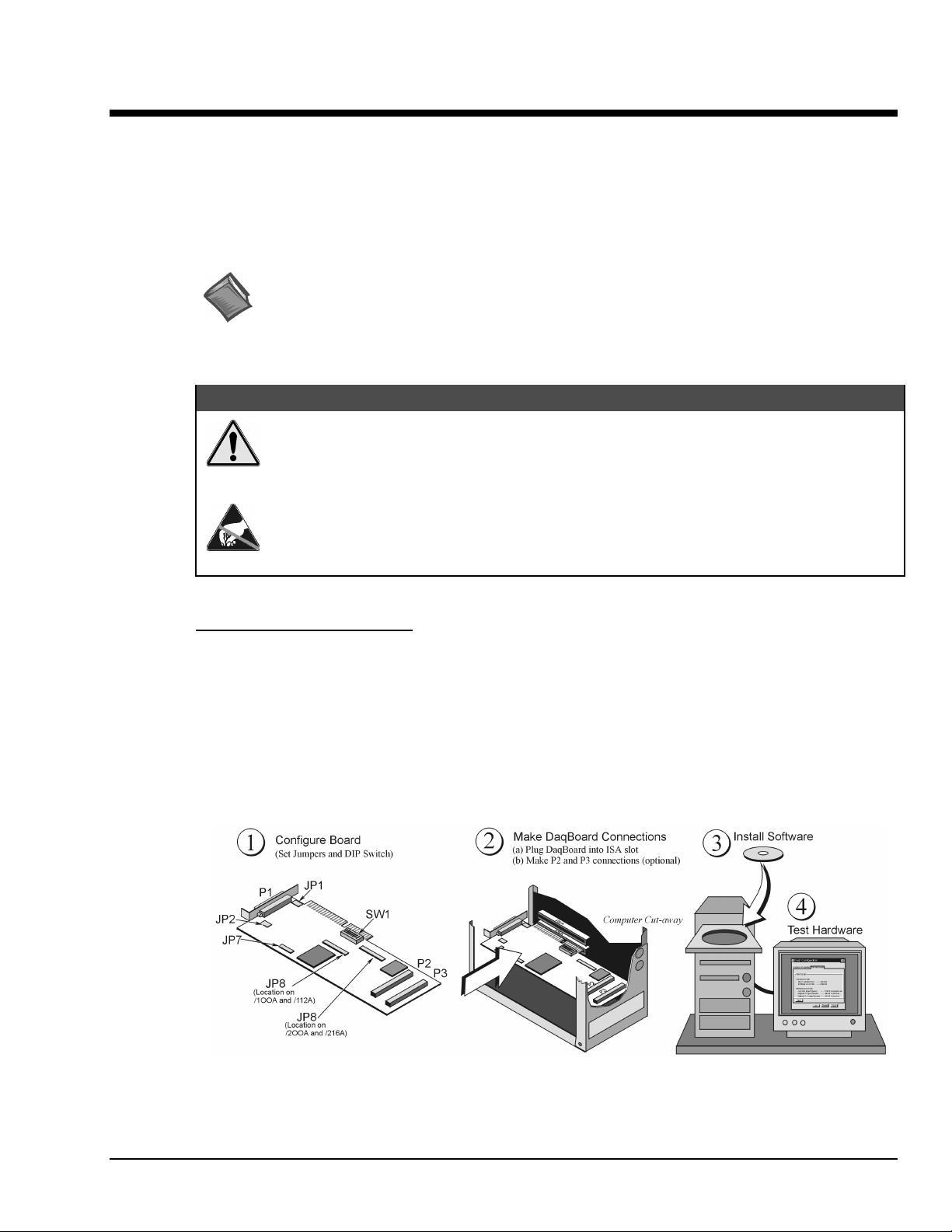

Setup and Startup 2

For DaqBoard/100A, /112A, /200A and /216A

This chapter provides instructions for getting an ISA-type DaqBoard configured, installed into a PC’s

ISA-slot, making board connections, and installing the appropriate software. The figure, provided near the

bottom of this page, provides an overview of the steps necessary for a successful setup.

Reference Note:

The DBK Option Cards and Modules User’s Manual (p/n OMB-457-0905) contains detailed DBK

and power-related information. As a part of product support, the DBK manual is automatically

loaded onto your hard drive during software installation. The default location is the Programs

directory, which can be accessed through the Windows Desktop.

&$87,21

Turn off power to the host PC and externally connected equipment prior to removing the

PC’s cover and installing a DaqBoard. Electric shock or damage to equipment can result

even under low-voltage conditions.

Take ESD precautions (packaging, proper handling, grounded wrist strap, etc.) Use care to

avoid touching board surfaces and onboard components. Only handle boards by their edges

(or ORBs, if applicable). Ensure boards do not come into contact with foreign elements such

as oils, water, and industrial particulate.

Minimum System Requirements

PC system with Pentium® Processor

Windows Operating System

RAM, as follows:

16 Mbytes of RAM for Windows 3.x

32 Mbytes of RAM for Windows 95/98/NT

64 Mbytes of RAM for Windows Me

64 Mbytes of RAM for Windows 2000

64 Mbytes of RAM for Windows XP

DaqBoard-ISA Installation Steps, Pictorial Overview

OMB-DaqBoard-ISA User’s Manual

02-10-02

Setup and Startup 2-1

Page 14

(1) Configure the ISA-DaqBoard

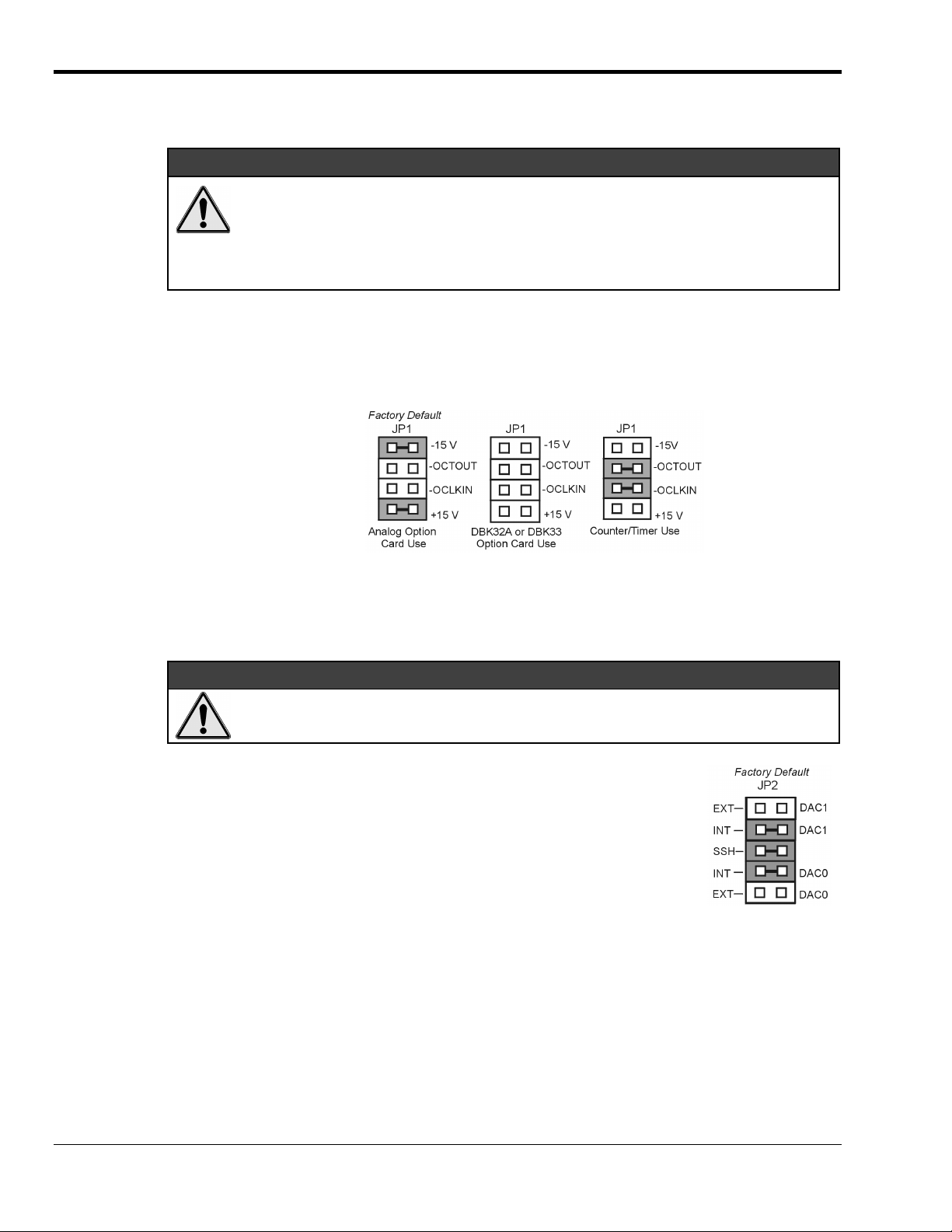

JP1 - External Analog Expansion Power

Placing the jumpers on JP1’s OCTOUT and –OCLKIN could damage the 8254 timer

chip! If either a DBK32A Auxiliary Power Supply or a DBK33 Triple-Output Power

Supply Card is used, the JP1 shunt jumpers must be removed, otherwise timer chip

damage will occur. Refer to the DBK32A, DBK33, and Power Management sections of

the user documentation for more information.

If analog option cards (DBKs) are used, JP1 jumpers are set to provide +15 and -15 VDC to the cards.

If using a DBK32A or DBK33 Power Supply Card, remove all jumpers from JP1.

If no cards are being used, the counter/timer CTR0 is available, and JP1 must be set as shown in the figure.

(Set Jumpers and Configure the DIP-Switch)

&$87,21

JP1 Configurations

JP2 - DAC Reference Voltage and SSH (Simultaneous Sample and Hold)

&$87,21

In regard to JP2, the SSH jumper must be removed if you are using EXT DAC0 or EXT

DAC1. See the user’s manual for details.

JP2 selects an Internal (default) or External reference voltage for the two separate

analog outputs.

JP2 also selects SSH (default) for applications using one or more of the following:

DBK2, DBK4, DBK5, DBK7, DBK17, DBK50, or DBK51.

We recommend that you leave the JP2 jumpers at their factory default setting

(see figure at right). Refer to the JP2 material in chapter 3 prior to making

changes.

JP7 – Calibration

Leave JP7 in the default position. Only use JP7 during calibration.

2-2 Setup and Startup

02-10-02

OMB-DaqBoard-ISA User’s Manual

Page 15

JP8 – DMA and Interrupt

Interrupt Selection. ISA-type DaqBoards may be set to interrupt the PC when certain

hardware conditions occur. The interrupt may be set to IRQ level 10, 11, 12, 14 or 15.

DaqBoard’s IRQ level cannot be shared with another device. To disable interrupt assistance

and background transfers you can configure JP8 to “Open Interrupt.” See the “Open

Interrupt” setting in the following figure.

DMA Selection. Direct Memory Access (DMA) configuration provides for:

Note: Only DMA channels 5-7 (of an ISA AT machine’s seven channels) are

Set DRQ and DACK jumpers to the desired DMA channels. Note that DaqBoard does not

share DMA channels.

Set the DMA jumpers to OPEN when other devices will be using DMA channels 5, 6 and 7.

(a) high-speed data transfer from the ADC FIFO, or

(b) high-speed data transfer to the DAC FIFO.

available to DaqBoard.

SW1 - Base Address

SW1’s factory default is 300 Hex. If 300 Hex presents an address conflict, set a new SW1 address within

the range of 1FF to 3FF (256 to 1023 Decimal). Note that the address must be on a 4-byte boundary.

Industry Standard I/O Addresses

Hex Range Device Hex Range Device

000-1FF Internal system 368-36B PC network (high address)

200-207 Game I/O 36C-36F Reserved

20C-20D Reserved 378-37F Parallel printer port 1

21F Reserved 380-38F SDLC, bisynchronous 2

278-27F Parallel printer port 2 390-393 Reserved

2B0-2DF Alternate enhanced graphics adapter 3A0-3AF Bisynchronous 1

2E1 GPIB (Adapter 0) 3B0-3BF Monochrome display and printer adapter

2E2 & 2E3 Data acquisition (Adapter 0) 3C0-3CF Enhanced graphics adapter

2F8-2FF Serial port 2 3D0-3DF Color/Graphics monitor adapter

300-31F Prototype card 3F0-3F7 Diskette Controller

360-363 PC network (low address) 3F8-3FF Serial port 1

364-367 Reserved

Notes:

(1) SW1’s address must be unique, i.e., not used by another device.

(2) I/O addresses, hex 000 to 0FF, are reserved for system board I/O.

(3) Hex 100 to 3FF are available on the I/O channel.

(4) Although the above table represents industry standards, some systems may vary.

OMB-DaqBoard-ISA User’s Manual

02-10-02

Setup and Startup 2-3

Page 16

(2) Make ISA-DaqBoard Connections

Before connecting your ISA-type DaqBoard, you should review the following connector descriptions.

P1 Analog I/O. Provides 16 analog input channels, 2 analog output channels, a 16-bit counter/timer,

four TTL inputs and outputs, and various signals for driving expansion cards.

P2 Digital I/O. Provides three 8-bit TTL programmable I/O ports and external interrupt input. To ensure

reliable operation, for P2 expansion cables do not exceed 14 inches per attached DBK card.

P3 Frequency I/O. Provides five 16-bit counters and 16 high-speed digital inputs and external interrupt

input.

(a) Turn power OFF to the PC and all attached equipment.

(b) Remove the PC’s cover. Refer to your PC Owner’s

Manual as needed.

(c) Choose an empty 16-bit ISA slot. Loosen and remove the

screw at the top of the slot’s blank adapter plate. Then

slide the plate up and out to remove. Refer to your PC

Owner’s Manual as needed.

(d) Align DaqBoard’s edge-connector with the desired ISA

slot, and with the PC’s corresponding rear-panel slot.

Gently press the board into the ISA slot.

(e) Secure the board by inserting the rear-panel adapter-plate

screw.

(f) If using P2, P3, or both, connect CA-60 cables to the

appropriate on-board P2 and/or P3 headers (see figure).

Secure the P2 and P3 panel connectors to the computer’s

back panel, as applicable.

(g) Replace the computer’s cover. Plug in all cords and

cables; then apply power to the PC.

DaqBoard’s I/O Connectors

If used, P2 and P3 require cable CA-60.

(3) Install Software and Product Support Documentation

Data Acquisition Software, Master Setup Screen

(a) Remove previous version Daq device drivers, if present. You can do this through Microsoft’s

Add/Remove Programs feature by navigating from your desktop as follows:

Start ⇒ Settings ⇒ Control Panel ⇒ Add/Remove Programs

(b) Place the Data Acquisition CD into the CD-ROM drive. Wait for PC to auto-start the CD. This may

take a few moments, depending on your PC. If the CD does not auto-start, use the Desktop’s Start,

Run, Browse feature.

(c) If a Licensing Agreement appears, read over the agreement, then click “Agree.” The Data Acquisition

Software Master Setup Screen appears (see previous figure).

2-4 Setup and Startup

02-10-02

OMB-DaqBoard-ISA User’s Manual

Page 17

(d) Select DaqBook/DaqBoard Support. For Windows95/98/Me/NT/2000/XP, select 32-bit.

If using Windows3.1, or DOS, select 16-bit instead of 32-bit.

(e) If you do not have Acrobat Reader version 4.0 or greater installed on your PC, select Acrobat

Reader. This will enable you to read and print documentation that is included on the install CD-ROM.

Note that PDF versions of the documents are automatically installed onto your hard drive. The default

location is the Programs directory. It can be accessed from the Windows Desktop via the Start button.

(f) Select Post Acquisition Data Analysis Program. Refer to the Post Acquisition Data Analysis

Program document module (e.g. DIAdem, PostView, eZ-View) for information. A copy of the

applicable document module is included in this manual.

(g) Click “Start Install” and follow the screen prompts.

(4) Test Hardware

Use the following steps to test your ISA-type DaqBoard.

(a) Run the Daq Configuration control panel applet.

(b) Click “Add Device.”

(c) Select your DaqBoard model from the “Device Type” scroll box

and click OK.

(d) Select your DaqBoard from the “Device Inventory” window and

click “Properties.”

(e) Ensure settings are correct, and make changes if needed.

(f) Select the “Test Hardware” tab.

(g) Click the “Resource Test” button.

(h) Click the “Test” button.

Test results should be displayed within a few seconds. Note that test

results have two components: Resource Tests and Performance

Tests.

Note: Testing the DaqBoard device may, in some cases, cause the

system to hang. If test results are not displayed in 30 seconds

or the system does not seem to be responding, reboot the

system. Upon power-up, re-enter the Daq Configuration and

change DaqBoard configuration settings to those that work

properly.

Resource Tests

The resource tests are intended to test system capability for the current

device configuration. These tests are pass/fail.

Resource test failure may indicate a lack of availability of the resource

or a possible resource conflict.

•

Base Address Test - Tests the base address for the selected

ISA bus. Failure of this test may indicate that the bus is not

properly configured within the system. See relevant operating

system and computer manufacturer’s documentation to correct

the problem.

•

Interrupt Level Test - Tests the ability of the ISA bus to

generate interrupts. Failure of this test may indicate that the

ISA bus may be currently unable to generate the necessary

hardware interrupt.

Device Inventory and

Device Type Windows

DaqBoard Properties Tab

OMB-DaqBoard-ISA User’s Manual

02-10-02

Setup and Startup 2-5

Page 18

Performance Tests

Performance tests check various DaqBoard functions with the current

device configuration. These tests give quantitative results for each

supported functional group. The results represent maximum rates at

which the various operations can be performed. Note that the rates

depend on selected ISA protocol and will vary according to bus

hardware capabilities.

•

ADC FIFO Input Speed - Tests the maximum rate at which

data can be transferred from the DaqBoard’s internal ADC

FIFO to computer memory, through the PC’s ISA bus.

Results are given in samples/second, where a sample (2 bytes

in length) represents a single A/D value.

•

Digital I/O Input Speed - Tests the maximum rate at which

DIO input data can be transferred from DaqBoard’s Digital

I/O ports to computer memory, through the PC’s ISA bus

slot. Results are given in bytes/second.

•

Digital I/O Output Speed – Tests the maximum rate at which

DIO output data can be transferred from the computer’s

memory to DaqBoard’s Digital I/O ports, through the PC’s

ISA bus slot. Results are given in bytes/second.

Test Hardware Tab

Test Results

Reference Note:

If you experience difficulties, please consult other sections of this manual and to the additional user

documentation before calling technical support. User documentation is included on your data acquisition CD, and is

installed automatically as a part of product support, when your software is installed. The default location is in the

Programs

directory.

Note that hardcopy versions of the manuals can be ordered from the factory.

2-6 Setup and Startup

02-10-02

OMB-DaqBoard-ISA User’s Manual

Page 19

A Closer Look at DaqBoard-ISA Hardware 3

Applies to DaqBoard/100A, /112A, /200A, and /216A

Overview …… 3-1

Performance Factors …… 3- 1

Switches and Jumpers …… 3- 3

Base Address (SW1) …… 3- 3

…… 3-

4

…… 3-

7

8

4

5

…… 3-

9

Overview

External Analog Expansion Power (JP1)

DAC Reference Selection (JP2)

DMA and Interrupt Selection (JP8)

…… 3-

Connections …… 3- 5

P1, DB37 Pinout, Analog I/O

P2, DB37 Pinout, Digital I/O

P3, DB37 Pinout, Pulse/Frequency/High-Speed Digital I/O

…… 3-

…… 3-

The DaqBoard/100A, /112A, /200A, and /216A are 100 kHz ISA-bus plug-in boards that provide analogto-digital conversion with a wide selection of signal-conditioning, signal expansion, and software support.

ISA-DaqBoards feature an on-board 512-location sequencer that lets you select any channel and gain

combination and configure each channel for unipolar or bipolar operation.

Analog input capabilities are flexible. The A/D maximum sample rate is 100 kHz (divide by number of

channels for scan rate) with a 16-channel multiplexer and a programmable-gain input amplifier. Users can

expand channel capacity to 256 analog inputs via expansion modules for multiplexing RTDs,

thermocouples, strain gages, anti-aliasing filters, and simultaneous sample and hold amplifiers. Expansion

cards and modules attach to the P1 I/O connector. Refer to the Connections section beginning on

page 3-5. The P1 DB37 interface is compatible with multiplexers and signal conditioners from several

manufacturers.

Input power for the DaqBoard comes from the host computer’s bus. Output power from the P1 connector

includes +5 VDC (pin 1) and ±15 VDC (pins 21 and 2). The section beginning on page 3-4 entitled,

External Analog Expansion Power (JP1), explains how to set JP1 based on power use in the system.

Related information is included in the Power Management section of the DBK Option Cards and Modules

User’s Manual (p/n OMB-457-0905).

Each ISA-DaqBoard provides 16 analog inputs (expandable up to 256), 2 analog outputs, and 4 digital

inputs and outputs. DaqBoard/100A and DaqBoard/200A have additional digital I/O and counter/timer

capabilities. The various DaqBoard models have either 12-bit or 16-bit resolution. 12-bit models include

DaqBoard/100A and DaqBoard/112A. 16-bit models include DaqBoard/200A and DaqBoard/216A.

Performance Factors

The DaqBoard performs 100 kHz scan sequences and provides programmable delays from 10 µs to

12 hours. The unit’s 100 kHz conversion rate fixes the time skew between channels at 10 µs. The

512-location scan sequencer allows selection of the input amplifier gain for each channel. The

DaqBoard/100A and DaqBoard/200A can scan 16 digital inputs in the same sequence used for analog

inputs (such inputs are thus time-correlated). Optional simultaneous-sample-and-hold (SSH) cards enable

ISA-DaqBoards to sample up to 256 channels at the same instant. Scanning and timing specifications are

met even with a full complement of expansion modules. All types of transducers are scanned within the

same scan group without PC intervention.

ISA-type DaqBoards offer a wide selection of triggering capabilities. The scan can be triggered by

software, a TTL signal, or an analog input level (including slope). The trigger is hardware-based to

minimize trigger latency to less than 10 µs.

Two data transfer modes are supported:

•

•

Real-time data can be collected at 100 K readings/s.

OMB-DaqBoard-ISA User’s Manual

DMA

Fast I/O to data memory via block move instruction REP INSW.

02-14-02

Hardware 3-1

Page 20

This following block diagram can be applied to DaqBoard-ISA models /100A, /112A, /200A, and /216A.

B

Signal

I/O

P1

ANALOG I/O

(DAS-16

compatible)

P2*

DIGITAL I/O

(PIO-12

compatible)

P3*

PULSE/FREQ.

HIGH-SPEED

DIGITAL I/O

(CT M-05

compatible)

*Models /100A and /200A.

8 DE/16 SE

analog input

multiplexer

4 digital outputs

for high-speed

channel expansion

4 general purpose

digital outputs

4 general purpose

digital inputs

1 auxiliary counter gate

1 TTL trigger input

2 gain select outputs for

expansion boards

Dual-DAC

Dual 12-bit

digital-toanalog

converter

24-bit general purpose

digital I/O lines

An optional adapter cable (CA-60) is

}

required for external access to 40-pin

ports P2 and P3 (located on DaqBoards).

16 high-speed

digital inputs

5 counter/timer

channels

Block Diagram for DaqBoard Models /100A, /112A. /200A, /216A

lock Diagram for DaqBoard Models /100A, 112A, 200A, and 216A

-or-

-or-

External

control

MUX

Analog Trigger-In

Com parator

4K - word FIFO

Data Buffer

PGA

x1, x2

x4, x8

per channel

512-step

random access

channel/gain

sequencer

Trigger

Select

Am plifier

Sample

&

Hold

Sequencer

rese t

Programmable

sequencer

tim eba se .

10 us to 12 hrs

12 or 16-bit,

100 kHz

analog-to-digital

converter

100 kHz

Clock

ADC

4K word

FIFO

data

buffer

PC (ISA)

Bus

Interface

DMA &

Interrup t

Interface

+15

-15

& address bus

DC-DC

converter

P C (ISA ) B u s

16-bit data

PC +5V

Power Supply

3-2 Hardware

02-14-02

OMB-DaqBoard-ISA User’s Manual

Page 21

Switches and Jumpers

y

To ensure that the desired mode of operation is obtained, the ISA-type DaqBoards must be configured.

This is accomplished via on-board jumpers and a DIP-switch. Although the configuration of all four

DaqBoard-ISA models is similar, jumper locations differ, as can be seen in the following figures.

DaqBoard/100A/112A Motherboard

The following DIP-switch and jumpers must be properly set to ensure the desired mode of operation:

•

•

•

•

•

Base Address (SW1)

The computer must know the DaqBoard’s base address. Check the base address setting (3-digit hex) on

SW1, the Base Address switch. The factory default is 300 hex (within the standard range for a prototype

card; see table). If the default value does not work, you must select an address within 200 to 3FF (256 to

1023 decimal). In addition, the address must be on a 4-byte boundary, and it must not conflict with

addresses already in use.

JP7

JP2

JP8

SW1

0

1

Base Address

JP1

Location of DaqBoard Jumpers

SW1 - Base Address

JP1 - External Analog Expansion Power

JP2 - DAC Voltage Reference Header

JP7 –Reserved for factory use.

JP8 - Interrupt & DMA

JP7

SW1

0

JP8

DaqBoard/200A/216A Motherboard

1

Base Address

JP2

JP1

Industry Standard I/O Addresses

: Systems vary. This is only a guide.

Note

Hex Range Device

000-1FF Internal system

200-207 Game I/O

20C-20D Reserved

21F Reserved

278-27F Parallel printer port 2

2B0-2DF Alternate enhanced graphics adapter

2E1 GPIB (Adapter 0)

2E2 & 2E3 Data acquisition (Adapter 0)

2F8-2FF Serial port 2

300-31F Prototype card

360-363 PC network (low address)

364-367 Reserved

368-36B PC network (high address)

36C-36F Reserved

378-37F Parallel printer port 1

380-38F SDLC, bisynchronous 2

390-393 Reserved

3A0-3AF Bisynchronous 1

3B0-3BF Monochrome display and printer adapter

3C0-3CF Enhanced graphics adapter

3D0-3DF Color/Graphics monitor adapter

3F0-3F7 Diskette Controller

3F8-3FF Serial port 1

: I/O addresses, hex 000 to 0FF, are reserved for

Note

the system board I/O. Hex 100 to 3FF are available on

the I/O channel.

A2 A3 A4 A5 A6 A7 A8 A9

300

Factor

Default

OPEN

A2 A3 A4 A5 A6 A7 A8 A9

304

OPEN

A2 A3 A4 A5 A6 A7 A8 A9

2 3 14

308

OPEN

A2 A3 A4 A5 A6 A7 A8 A9

30C

OPEN

A2 A3 A4 A5 A6 A7 A8 A9

2 3 14

310

OPEN

Sample Base Addresses

on SW1

6 7 8 5 2 3 14

0

1

6 7 8 5 2 3 14

0

1

6 7 8 5

0

1

6 7 8 5 2 3 14

0

1

6 7 8 5

0

1

OMB-DaqBoard-ISA User’s Manual

02-14-02

Hardware 3-3

Page 22

External Analog Expansion Power (JP1)

Def

The JP1 4×2 header has 3 possible settings.

If analog option cards (DBKs) are used, the

JP1 pins are set to provide ±15 VDC to the

cards. If such cards are not used, the

counter/timer CTR0 is available, and JP1

must be set accordingly. The default

setting is for use of analog option cards.

If using a DBK32A Auxiliary Power Supply or a DBK33 Triple-Output Power

Supply Card, the JP1 shunt jumpers must be entirely removed. Placing the

jumpers on -OCTOUT and -OCLKIN will damage the 8254 timer chip.

Reference Note:

Refer to the Power Management section of the DBK Option Cards and Modules User’s

Manual (p/n OMB- 457-0905), as needed.

DAC Reference Selection (JP2)

The JP2 5×2 header allows you to select internal or external voltage references for the two separate analog

outputs. If the internal -5 VDC reference is selected, either DAC can output from 0 to +5 VDC as the

register count varies from 0 to 4095 (12-bit). If an external voltage reference is desired (up to 10 VDC in

either polarity), the shunt jumpers must be set accordingly. There is also a provision to allow the outputting

of a simultaneous Sample-Hold command signal on the DAC1-REFIN pin with the DAC1 set up for an

internal reference.

JP1

-15V

-OCTO UT

-OCLKIN

+15 V

Co unter/Tim er Use

(16-bit mode only)

JP1 External Analog Expansion Settings

&$87,21

Factory

ault

JP1

-15 V

-OCTO UT

-OCLKIN

+15 V

Analog Option

Card Use

JP1

-15 V

-OCTO UT

-OCLKIN

+15 V

DBK32A or DBK33

Option Card Use

JP2

EXT

INT

SSH

IN T

EXT

DAC0 External Ref

DAC1 External Ref

Reference Note:

The SSH setting is used with DBKs: 2, 4, 5, 7, 17, 50, and 51. In regard to specific DBK

information, refer to the DBK Option Cards and Modules User’s Manual

(p/n OMB-457-0905), as needed.

DAC1

DAC0

DAC0 External Ref

DAC1 Internal Ref

&$87,21

The SSH setting cannot be used at the same time as a DAC1 external reference due

to a potentially damaging conflict on P1 pin #26. The defaults are both DAC0 and

DAC1 set to Internal Reference.

JP2 JP2 JP2

DAC0 Internal Ref

DAC1 External Ref

DAC0 Internal Ref

DAC1 Internal Ref

JP2 DAC Reference Settings

Factory Default

JP2

DAC0 Internal Ref

DAC1 Internal Ref

with S S H

JP2

DAC0 External Ref

DAC1 Internal Ref

with S S H

3-4 Hardware

02-14-02

OMB-DaqBoard-ISA User’s Manual

Page 23

DMA and Interrupt Selection (JP8)

The JP8 11×2 header determines both the interrupt IRQ level and the Direct Memory Access (DMA)

channel for control of background data transfers. The preset default is for DMA channel 5 and for

Interrupt 10 (see figure).

•

Interrupt Selection. The DaqBoard may be set to interrupt the PC when certain hardware conditions

occur. The main board interrupt may be set to IRQ level 10, 11, 12, 14 or 15. The DaqBoard’s IRQ

level cannot be shared with any other device. Setting the JP8 interrupt jumper to OPEN can disable

interrupt assistance and background transfers.

•

DMA Selection. Direct Memory Access allows high-speed data transfer either from the ADC FIFO

or to the DAC FIFO. Only DMA channels 5, 6, and 7 (of an ISA AT machine’s seven channels) are

available for the DaqBoard. Set both the DRQ and DACK jumpers to the desired DMA channel (the

DaqBoard does not share DMA channels). Set the DMA jumpers to OPEN when other devices use

DMA channels 5, 6 and 7.

Factory D efault

DRQ7

DRQ6

DRQ5

IRQ15

DACK7

21

22

DM A Channel 5 and Interrupt 10

DRQ7

DACK6

DRQ6

DACK7

DACK6

Open In ter rup t

DRQ5

IRQ14

DACK5

IRQ 15

IRQ 14

DACK5

IRQ12

IRQ11

IRQ10

1

JP8

2

IRQ 12

IRQ 11

IRQ 10

1

DRQ7

DRQ6

DRQ5

DRQ5

IRQ15

DACK5

IRQ15

DACK5

DACK7

21

22

DM A Channel 7 and Interrupt 12

DRQ7

2121

DACK6

DRQ6

DACK7

DACK6

IRQ14

IRQ12

IRQ11IRQ11

IRQ10

1

JP8

2

IRQ14

IRQ12

IRQ10

1

JP8JP8

2222

Open DMA

22

Connections

Expansion cards connect to the ISA-type DaqBoards via one externally accessible P1 DB37 I/O connector,

or by two on-board 40-pin headers [for P2 and P3 connections] on the DaqBoard/100A and the

DaqBoard/200A. The DBK option cards can be used without an enclosure, or can be installed in a multicard enclosure such as the DBK10, DBK41, or DBK60. The multi-card enclosures can be stacked, making

it possible for a system to accommodate a large number of cards.

JP8 DaqBoard DMA and Interrupt Selection

Reference Notes:

➣

This section pertains to connections and pinouts for ISA-type DaqBoard applications.

➣

For installation instructions, refer to chapter 2, Setup and Startup.

DaqBoard [ISA type] Multi-Card Cabling

OMB-DaqBoard-ISA User’s Manual

02-14-02

Hardware 3-5

Page 24

The P1 connector on the DaqBoard and on each DBK is a DB37 male connector. Connecting DBKs to a

DaqBoard is accomplished with a CA-131-x cable, where the x is the number of option cards to be

connected; for example, a CA-131-3 cable would be used to attach three DBK option cards to a DaqBoard.

Such connections are often referred to as a “daisy-chain.” Note that the CA-131-x cables consist of female

DB37 connectors.

&$87,21

Before connecting DBKs to the DaqBoard, power-down all connected units.

Failure to do so could result in damage to the DBK or DaqBoard.

&$87,21

Do not confuse connectors. Ensure that you only connect P1 I/Os to P1,

P2 I/Os to P2, and P3 I/Os to P3. Improper connection may result in equipment

damage.

In addition to P1 ports, DaqBoard/100A and DaqBoard/200A devices have P2 and P3 ports. For these

devices a CA-60 cable is required to connect the DaqBoard 40-pin headers with a DB37 connector outside

the PC, and then to the DBK option card.

A DaqBoard with CA-60 Cables for P2 and P3

•

P1 Analog I/O. Provides sixteen analog input channels, two analog output channels, a 16-bit

counter/timer, four TTL inputs and outputs, and various signals for driving expansion cards.

•

P2 Digital I/O. Provides three 8-bit TTL programmable I/O ports and external interrupt

input.

P2 expansion cables must be kept relatively short to ensure reliable operation. Do not

exceed 14 inches per attached DBK card.

•

P3 Frequency I/O. Provides five16-bit counters and sixteen high-speed digital inputs and

external interrupt input.

To gain access to the DaqBoard port connectors, signals can be connected via CA-131-x cable through a

D-shell 37-pin female connector or a DBK11 screw-terminal option card with component sockets.

Reference Notes: You must set up DaqView for the particular DBKs in your system. If you

are unfamiliar with the method of setting up DBKs in DaqView, or if you need a refresher,

refer to one or more of the following:

➣

the DaqView document module

➣

the DBK Set Up in DaqView chapter of the DBK Option Cards and Modules User’s

Manual.

➣

The DBK document modules, for hardware configuration aspects that require setup in

software.

3-6 Hardware

Note: As new DBKs become available, be sure to use the latest revision of DaqView with the proper

configuration options.

02-14-02

OMB-DaqBoard-ISA User’s Manual

Page 25

DB37 Pinout Analog I/O Connections for ISA-Type DaqBoards

P1,

N

N

N

N

N

I

I

I

I

N

I

C

D

V

5

1

-

/

T

3

1

U

R

S

S

O

H

H

W

0

C

C

P

/

/

R

V

T

5

+

C

1

2

1

0

2

2

2

C

T

S

D

U

V

H

O

5

C

1

/

/

2

+

/

0

2

N

R

I

P

P

T

0

0

K

C

C

C

/

O

2

L

P

C

I

0

R

T

C

G

/

1

3

3

P

P

P

I

O

O

6

5

3

4

2

4

3

2

2

2

0

0

E

S

T

G

A

I

H

E

R

G

C

R

T

/

0

1

0

R

P

A

I

T

/

D

/

H

S

S

D

N

)

T

V

G

5

U

-

0

1

R

(

O

S

S

/

1

P

I

7

5

2

N

I

F

A

/

D

E

F

0

G

W

A

E

/

A

O

/

R

D

P

V

D

0

1

8

9

1

1

9

8

7

6

2

U

O

1

L

3

2

2

2

T

N

D

D

I

N

N

I

H

G

H

G

6

L

7

L

L

H

H

C

C

I

H

H

4

5

1

1

H

N

H

I

C

C

*

*

C

/

/

*

F

/

N

N

I

I

E

N

I

R

O

O

0

L

7

H

C

2

1

0

3

N

I

I

H

5

H

C

O

O

L

L

L

5

4

6

H

H

H

C

C

C

C

3

4

5

1

1

1

3

1

4

2

3

3

3

N

N

N

I

I

I

I

I

I

I

H

H

H

4

3

2

H

H

H

C

C

C

C

I

I

H

3

1

H

C

*

/

N

I

L

3

H

6

1

5

3

N

I

H

1

H

C

N

I

H

2

1

H

C

*

/

N

I

O

O

L

2

H

C

C

7

1

6

3

N

I

I

H

0

H

N

I

I

I

I

I

I

I

H

H

H

H

0

1

1

H

H

C

*

/

N

I

O

L

1

H

H

C

8

1

7

3

N

I

I

D

8

1

9

N

H

H

G

C

C

*

*

/

/

E

N

N

I

I

S

N

O

E

L

S

0

L

L

9

1

Pin Signal Name Description for P1 Pin Use

1+5 PWR

2 CTR 0 OUT/-15 VDC

+5 V supply (Refer to

Counter 0 output (8254 chip)/ -15 V supply (Refer to

Power Management

, in the DBK manual).

Power Management

, in the DBK manual).

3 OP 3/CHS 3 Digital out bit 3/channel select line for expansion cards

4 OP 1/CHS 1 Digital out bit 1/channel select line for expansion cards

5 IP 3/GS 1 Digital in bit 3/gain select line for expansion cards

6 IP 1/GS 0 Digital in bit 1/gain select line for expansion cards

7 POWER GND Digital ground

8 VREF (-5V) -5 V supply @ 10 mA max

9 D/A 0 OUT Digital to analog converter output ch 0

10 D/A 0 REF IN Digital to analog converter reference in ch 0 (must invert)

11 CH 7 LO IN/CH 15 HI IN Ch 7 LO IN (differential mode)/ch 15 HI IN (single-ended mode)

12 CH 6 LO IN/CH 14 HI IN Ch 6 LO IN (differential mode)/ch 14 HI IN (single-ended mode)

13 CH 5 LO IN/CH 13 HI IN Ch 5 LO IN (differential mode)/ch 13 HI IN (single-ended mode)

14 CH 4 LO IN/CH 12 HI IN Ch 4 LO IN (differential mode)/ch 12 HI IN (single-ended mode)

15 CH 3 LO IN/CH 11 HI IN Ch 3 LO IN (differential mode)/ch 11 HI IN (single-ended mode)

16 CH 2 LO IN/CH 10 HI IN Ch 2 LO IN (differential mode)/ch 10 HI IN (single-ended mode)

17 CH 1 LO IN/CH 9 HI IN Ch 1 LO IN (differential mode)/ch 9 HI IN(single-ended mode)

18 CH 0 LO IN/CH 8 HI IN Ch 0 LO IN (differential mode)/ch 8 HI IN (single-ended mode)

19 L.L. GND Low-level ground (analog ground - use with analog inputs and outputs)

20 CTR 2 OUT Counter 2 output (8254 chip)

21 CTR 0 CLOCK IN/+15 VDC

Counter 0 clock in (8254 chip)/+15 V supply (Refer to

Power Management

, in the DBK

manual).

22 OP 2/CHS 2 Digital output bit 2/ channel select line for expansion cards

23 OP 0/CHS 0 Digital output bit 0/channel select line for expansion cards

24 IP 2/CTR 0 GATE Digital input bit 2/counter 0 gate (16-bit support only)

25 IP 0/TRIG 0 Digital input bit 0/trigger 0

26 D/A 1 REF IN/SSH Digital-to-analog converter reference in ch 1 (must invert)/ SSH

27 D/A 1 OUT Digital-to-analog converter output ch 1

28 L.L. GND Low-level ground (analog ground - use with analog inputs and outputs)

29 L.L. GND Low-level ground (analog ground - use with analog inputs and outputs)

30 CH 7 HI IN Ch 7 HI IN (single-ended mode or differential mode)

31 CH 6 HI IN Ch 6 HI IN (single-ended mode or differential mode)

32 CH 5 HI IN Ch 5 HI IN (single-ended mode or differential mode)

33 CH 4 HI IN Ch 4 HI IN (single-ended mode or differential mode)

34 CH 3 HI IN Ch 3 HI IN (single-ended mode or differential mode)

35 CH 2 HI IN Ch 2 HI IN (single-ended mode or differential mode)

36 CH 1 HI IN Ch 1 HI IN (single-ended mode or differential mode)

37 CH 0 HI IN Ch 0 HI IN (single-ended mode or differential mode)

Notes

:

(1) Software configuration commands determine P1 digital I/O pin functions.

(2) Actual shunt-jumper placement is required to provide ±15 VDC to expansion cards or disconnect internal DAC references to

allow externally selected DAC references.

(3) Digital I/O is not available with DBKs due to line use for addressing. “/” indicates the pin can be used for either function but not

both at the same time.

(4) DaqBoard [ISA-Type] P1 is compatible with Metrabyte DAS-16.

(5) The pinout is for ISA-type DaqBoards. It does not apply to PCI or cPCI type DaqBoards.

OMB-DaqBoard-ISA User’s Manual

02-14-02

Hardware 3-7

Page 26

DB37 Pinout Digital I/O Connections for ISA-Type DaqBoards

P2,

E

L

6

7

4

5

T

U

P

N

N

E

I

R

R

I

I

P

1

3

2

B

B

B

A

T

T

R

R

O

O

P

P

4

5

B

B

B

T

T

T

R

R

R

R

O

O

O

O

P

P

P

8

6

7

0

2

1

3

B

B

B

T

T

T

R

D

R

/

O

N

O

N

P

G

P

2

0

1

1

1

9

1

D

D

C

G

3

1

C

C

N

/

N

/

N

G

N

6

5

4

7

1

1

1

1

The DaqBoard [ISA-Type] P2

interface is available on:

DaqBoard/100A

3

1

DaqBoard/200A

3

1

2

0

2

2

2

2

6

7

D

V

5

N

C

C

+

G

T

T

T

R

R

R

O

O

O

P

P

P

DB37 Connector via CA-60 Inte rfa ce Cable

6

4

5

2

2

2

2

3

5

2

4

C

C

C

C

T

T

T

T

R

R

R

R

O

O

O

O

P

P

P

P

P

0

9

8

7

3

2

2

6

7

0

1

A

A

C

C

T

T

T

T

R

R

R

R

O

O

O

O

P

P

P

4

2

3

5

A

R

O

P

5

3

3

3

3

1

3

4

2

A

A

A

A

T

T

T

T

T

R

R

R

R

O

O

O

O

P

P

P

P

Pin Signal Name Description for P2 Pin Use

1 IR INPUT Interrupt line input (no functions to access this)

2 IR ENABLE Interrupt line enable (no functions to access this)

3 PORT B 7 Digital input/output - port B bit 7

4 PORT B 6 Digital input/output - port B bit 6

5 PORT B 5 Digital input/output - port B bit 5

6 PORT B 4 Digital input/output - port B bit 4

7 PORT B 3 Digital input/output - port B bit 3

8 PORT B 2 Digital input/output - port B bit 2

9 PORT B 1 Digital input/output - port B bit 1

10 PORT B 0 Digital input/output - port B bit 0

11 GND Digital ground

12 N/C Pin not connected/not used

13 GND Digital ground

14 N/C Pin not connected/not used

15 GND Digital ground

16 N/C Pin not connected/not used

17 GND Digital ground

18 +5 V

+5 V supply (Refer to

Power Management

, in the DBK manual).

19 GND Digital ground

20 +5 V

+5 V supply (Refer to

Power Management,

in the DBK manual).

21 GND Digital ground

22 PORT C 7 Digital input/output - port C bit 7

23 PORT C 6 Digital input/output - port C bit 6

24 PORT C 5 Digital input/output - port C bit 5

25 PORT C 4 Digital input/output - port C bit 4

26 PORT C 3 Digital input/output - port C bit 3

27 PORT C 2 Digital input/output - port C bit 2

28 PORT C 1 Digital input/output - port C bit 1

29 PORT C 0 Digital input/output - port C bit 0

30 PORT A 7 Digital input/output - port A bit 7

31 PORT A 6 Digital input/output - port A bit 6

32 PORT A 5 Digital input/output - port A bit 5

33 PORT A 4 Digital input/output - port A bit 4

34 PORT A 3 Digital input/output - port A bit 3

35 PORT A 2 Digital input/output - port A bit 2

36 PORT A 1 Digital input/output - port A bit 1

37 PORT A 0 Digital input/output - port A bit 0

40

D

D

N

N

5

G

+

G

9

8

1

1

6

7

3

3

0

A

2

The P2 40 -pin header does not

have a direct pin-to-pin correlation

with the P 2 D B 37 conn ec tor.

39

1

Note: No local lines are available if digital expansion cards are in use.

.

P2 expansion cables must be kept relatively short to ensure reliable operation.

Do not exceed 14 inches per attached DBK card.

Note: The pinout is for ISA-type DaqBoards. It does not apply to PCI or cPCI type DaqBoards.

3-8 Hardware

02-14-02

OMB-DaqBoard-ISA User’s Manual

Page 27

, DB37 Pinout Pulse/Frequency/High-Speed Digital I/O for ISA-Type DaqBoards

P3

E

E

T

E

L

T

B

U

A

P

N

5

7

N

I

I

E

D

D

R

R

I

I

S

1

S

2

3

4

3

6

4

I

I

I

I

D

D

D

S

S

S

5

7

8

6

0

I

D

2

I

D

D

S

S

1

9

R

1

I

T

D

N

S

C

G

0

2

3

1

1

1

1

T

A

I

G

5

5

R

T

T

C

C

5

4

1

1

A

A

N

N

I

G

G

4

3

4

R

R

R

R

T

T

T

C

C

C

C

7

8

6

1

1

1

The DaqBoard P3 interface is

available on:

1

2

3

DaqBoard/100A

DaqBoard/200A

7

1

0

2

2

2

2

4

C

V

5

/

1

1

5

I

I

N

+

D

D

D

S

S

S

DB37 Connector via CA-60 Inte rfa ce Cable

6

3

4

2

2

2

3

2

1

1

I

I

D

D

S

S

8

0

5

1

1

I

D

S

9

2

2

2

2

3

0

9

I

1

I

D

S

O

T

8

T

I

U

U

D

O

O

O

S

5

4

C

S

R

R

R

T

T

T

C

C

C

4

7

6

3

3

T

U

O

3

R

T

C

5

3

3

3

3

3

T

T

U

U

O

2

1

R

T

C

T

E

N

I

T

U

1

A

O

G

R

T

1

C

R

T

C

Pin Signal Name Description for P3 Pin Use

1 IR INPUT Interrupt line input (used with counters)

2 IR ENABLE Interrupt line enable (used with counters)

3 SDI 7 High-speed digital input bit 7 (low byte)

4 SDI 6 High-speed digital input bit 6 (low byte)

5 SDI 5 High-speed digital input bit 5 (low byte)

6 SDI 4 High-speed digital input bit 4 (low byte)

7 SDI 3 High-speed digital input bit 3 (low byte)

8 SDI 2 High-speed digital input bit 2 (low byte)

9 SDI 1 High-speed digital input bit 1 (low byte)

10 SDI 0 High-speed digital input bit 0 (low byte)

11 GND Digital ground

12 CTR 5 GATE Counter 5 gate (9513 chip)

13 CTR 5 IN Counter 5 input (9513 chip)

14 CTR 4 GATE Counter 4 gate (9513 chip)

15 CTR 4 IN Counter 4 input (9513 chip)

16 CTR 3 GATE Counter 3 gate (9513 chip)

17 CTR 3 IN Counter 3 input (9513 chip)

18 CTR 2 GATE Counter 2 gate (9513 chip)

19 CTR 2 IN Counter 2 input (9513 chip)

20 +5 V

+5 V supply (Refer to

Power Management,

in the DBK manual).

21 D IN STROBE NC

22 SDI 15 High-speed digital input bit 15 (high byte)

23 SDI 14 High-speed digital input bit 14 (high byte)

24 SDI 13 High-speed digital input bit 13 (high byte)

25 SDI 12 High-speed digital input bit 12 (high byte)

26 SDI 11 High-speed digital input bit 11 (high byte)

27 SDI 10 High-speed digital input bit 10 (high byte)

28 SDI 9 High-speed digital input bit 9 (high byte)

29 SDI 8 High-speed digital input bit 8 (high byte)

30 OSC. OUT Oscillator output - fout (9513 chip)

31 CTR 5 OUT Counter 5 output (9513 chip)

32 CTR 4 OUT Counter 4 output (9513 chip)

33 CTR 3 OUT Counter 3 output (9513 chip)

34 CTR 2 OUT Counter 2 output (9513 chip)

35 CTR 1 OUT Counter 1 output (9513 chip)

36 CTR 1 IN Counter 1 input (9513 chip)

37 CTR 1 GATE Counter 1 gate (9513 chip)

E

T

N

I

A

3

G

R

R

T

T

C

9

1

40

E

T

N

I

2

2

The P3 40 -pin header does not

have a direct pin-to-pin correlation

with the P 3 D B 37 conn ec tor.

39

1

Note: The pinout is for ISA-type DaqBoards. It does not apply to PCI or cPCI type DaqBoards.

OMB-DaqBoard-ISA User’s Manual

02-14-02

Hardware 3-9

Page 28

3-10 Hardware

02-14-02

OMB-DaqBoard-ISA User’s Manual

Page 29

DBK Basics

Introduction…… 1

How Do DBKs Connect to the Data Acquisition Device? …… 2

DBK Identification Tables ….. 3

Analog Output DBKs …… 3

Digital I/O Control DBKs …… 3

Analog Signal Conditioning DBKs …… 3

Expansion and Terminal Panel Connection DBKs …… 4

Power Supply DBKs …… 4

Tips on Setting up a Data Acquisition System …… 4

Power Supplies and Power Connectors ……6

An Introduction to Power-Related DBKs ….. 7

Calculating Your System’s Power Needs …… 9

Additional Reading ….. 11

&$87,21

Introduction

The term “DBK” typically refers to a card or module that is used to expand or enhance a primary data

acquisition device, such as a DaqBook, DaqBoard, or LogBook. As will be seen in the upcoming DBK

identification tables, DBKs provide a wide variety of data acquisition functions. Depending on the DBKs

used, one or more of the following can be realized:

Turn off power to all devices connected to the system before connecting cables or

setting configuration jumpers and switches. Electrical shock or damage to

equipment can result even under low-voltage conditions.

&$87,21

The discharge of static electricity can damage some electronic components.

Semiconductor devices are especially susceptible to ESD damage. You should

always handle components carefully, and you should never touch connector pins or

circuit components unless you are following ESD guidelines in an appropriate ESD

controlled area. Such guidelines include the use of properly grounded mats and

wrist straps, ESD bags and cartons, and related procedures.

•

signal conditioning

•

analog output

•

digital I/O

•

channel expansion

•

supplying powering to another acquisition device

•

providing an interface for different connectivity.

Daq Systems

02-19-02

OMB-DBK Basics, pg. 1

Page 30

Reference Notes: During software installation, Adobe

®

PDF versions of user manuals will

automatically install onto your hard drive as a part of product support. The default location

is in the Programs directory, which can be accessed from the Windows Desktop. Refer to

the PDF documentation, especially the DBK Option Cards and Modules User’s Manual

(p/n OMB-457-0905) for details regarding both hardware and software in relevant to DBKs.

A copy of the Adobe Acrobat Reader

®

is included on your CD. The Acrobat Reader

provides a means of reading and printing the PDF documents. Note that hardcopy versions

of the manuals can be ordered from the factory.

How Do DBKs Connect to the Data Acquisition Device?

Each DBK connects to the primary data acquisition device; e.g., a DaqBook, DaqBoard, or LogBook,

through one of three 37-pin ports, which are designated as follows:

•

P1 – Analog I/O

•

P2 – Digital I/O

•

P3 – Pulse/Frequency/High-Speed Digital I/O

Depending on the primary data acquisition device, connectivity issues differ slightly. This will be made

clear by the figures and accompanying text that follow.

For DaqBooks, ISA-Type DaqBoards, and LogBooks, DBK connections are not made directly to the port,

but through a CA-37-x ribbon cable, where “x” indicates the number of expansion devices that can be

connected. For example, in addition to providing a DB37 connector to interface with the primary data

acquisition device, a CA-37-3 cable includes three additional DB37 connectors. These provide a means of

adding three DBKs to one port. Use of a CA-37-16 cable will allow up to 16 DBKs to be added. The

CA-37-x cable system is excellent for DaqBooks, LogBooks, and ISA-type DaqBoards.

The above figure applies to LogBooks, DaqBooks, and ISA-type DaqBoards. As will be seen elsewhere in

the documentation, some models do not include all three connectors (P1, P2, and P3).

pg. 2, OMB-DBK Basics

Connecting DBKs to a DaqBook

02-19-02

Daq Systems

Page 31

DBK Identification Tables

Analog Output DBKs

Analog Output

Product Name/Description I/O

DBK2 Voltage Output Card 4 channels P1

DBK5 Current Output Card 4 channels P1

Digital I/O Control DBKs

Digital I/O / Control

Product Name/Description I/O

DBK20 General-Purpose Digital I/O Card (Screw Terminals) 48 channels P2

DBK21 General-Purpose Digital I/O Card (DB37 Connectors) 48 channels P2

DBK23 Optically Isolated Digital-Input Module 24 channels P2

DBK24 Optically Isolated Digital-Output Module 24 channels P2

DBK25 Relay Output Card 8 channels P2

Analog Signal Conditioning DBKs

The DBKs that are used for analog signal conditioning attach to transducers and condition their outputs into

analog voltages. An A/D converter, located in the primary acquisition device, measures the analog

voltages. There are many signal-conditioning solutions available (and more are in development). Note that

DBK high-capacity modules require more circuitry than can fit on a compact card.

Analog Signal Conditioning

Product Name/Description I/O

DBK4 Dynamic Signal Input Card 2 channels P1

DBK7 Frequency-to-Voltage Input Card 4 channels P1

DBK8 High-Voltage Input Card 8 channels P1

DBK9 RTD Measurement Card 8 channels P1

DBK12 Low-Gain Analog Multiplexing Card 16 channels P1

DBK13 High-Gain Analog Multiplexing Card 16 channels P1

DBK15 Universal Current/Voltage Input Card 16 channels P1

DBK16 Strain-Gage Measurement Card 2 channels P1

DBK17 Simultaneous Sample & Hold Card 4 channels P1

DBK18 Low-Pass Filter Card 4 channels P1

DBK19 Thermocouple Card 14 channels P1

DBK42 5B Isolated Signal-Conditioning Module 16 channels P1

DBK43A Strain-Gage Measurement Module 8 channels P1

DBK44 5B Isolated Signal-Conditioning Card 2 channels P1

DBK45 SSH and Low-Pass Filter Card 4 channels P1

DBK50 Isolated High-Voltage Input Module 8 channels P1

DBK51 Isolated Low-Voltage Input Module 8 channels P1

DBK52 Thermocouple Input Module 14 channels P1

DBK53 Low-Gain Analog Multiplexing Module 16 channels P1

DBK54 High-Gain Analog Multiplexing Module 16 channels P1

DBK80 Differential Voltage Input Card with Excitation Output 16 channels P1

DBK81 Thermocouple Card, High-Accuracy 7 channels P1

DBK82 Thermocouple Card, High-Accuracy 14 channels P1

DBK83 Thermal Couple Card, High-Accuracy; uses Connection Pod 14 channels POD-1

DBK84 Thermocouple Module, High-Accuracy 14 channels P1

Conectivity

Conectivity

Connectivity

Daq Systems

02-19-02

OMB-DBK Basics, pg. 3

Page 32

Expansion and Terminal Panel Connection DBKs

The following DBKs offer provide various expansion and connection options. The stackable 3-slot DBK10

low-profile enclosure can be used for up to three DBKs. If a system has more than 3 DBKs, the 10-slot

DBK41 can be used. Several DBK41s can be daisy-chained to accommodate many DBKs in one system.

Expansion and Connection, General

Product Name/Description I/O

DBK1 16-Connector BNC Adapter Module 16 connectors P1

DBK10 3-Slot Expansion Chassis 3 cards P1, P2, or P3

DBK11A Screw-Terminal Option Card (DB37-Screw Terminal Block) Component

DBK40 BNC Interface 18 connectors P1 or P3

DBK41 Analog Expansion Enclosure 10 cards P1 or P2

DBK60 Expansion Chassis with Termination Panels 3 cards P2

Termination Panels, Connectivity for DaqBoard/260

Product Name/Description I/O

DBK601 Termination Panel - blank rear panel none none

DBK602 Termination Panel - BNC rear panel 16 connectors BNC

DBK603 Termination Panel - Safety Jacks, single ended 16 connectors Safety Jacks

DBK604 Termination Panel - Safety Jacks, differential 8 differential (16) Safety Jacks

DBK605 Termination Panels - Thermal Couple, differential panels;

specify type: B, J, K, R, S, or T

DBK606 Termination Panel – 3 Terminal Blocks; 16 connections per TB 48 connectors Screw Terminal

DBK607 Termination Panel – strain relief clamp none none

DBK608 Termination Panel – 3 female DB37 connectors three DB37 DB37

Connectivity

P1

sockets

Connectivity

16 differential T/C Connectors

Power Supply DBKs

Power supply type DBKs are typically used in laboratory, automotive, and field applications. Input power

can come from any +10 to +20 VDC source, or from an AC source by using an appropriately rated AC-toDC adapter. The DBK30A rechargeable power supply can power DBK modules where AC mains are not

available (the DBK30A outputs 28 V for powering transducers). For a large number of DBK cards, the

DBK32A or DBK33 can be installed into an expansion slot. The DBK33 is used when +5 V is required in

addition to ±15 VDC. The DBK34 provides a steady 12 or 24 VDC while working with vehicle electrical

systems that may be turned on or off during testing.

Power Supply

Product Name/Description Power

DBK30A Rechargeable Battery/Excitation Module +12-14, 24-28 VDC (3.4 A-hr @ 14 VDC)

DBK32A Auxiliary Power Supply Card ±15 V @ 500 mA

DBK33 Triple-Output Power Supply Card ±15 V @ 250 mA; +5 V @ 1 A

DBK34 Vehicle UPS Module 12/24 VDC (5 A-hr @12 VDC)

DBK34A UPS Battery Module 12/24 VDC (5 A-hr @12 VDC)

Tips on Setting up a Data Acquisition System

A successful installation involves setting up equipment and setting software parameters. In addition to this

manual, you may need to consult your Daq device or LogBook user’s manual.

DBKs should be configured before connections are made and power is applied. This sequence can prevent

equipment damage and will help ensure proper operation on startup. Many DBKs have on-board jumpers

and/or DIP switches that are used for setting channels and other variables. You will need to refer to the

individual DBK document modules to ensure that the DBKs are properly configured for you application.

Prior to designing or setting up a custom data acquisition system, you should review the following tips.