Page 1

(1*,1((5,1* ,1&

DAQ-801/802

Data Acquisition System

For 16 bit ISA compatible machines

Users Manual

INTERFACE CARDS FOR PERSONAL COMPUTERS

OMEGA ENGINEERING, INC. Tel: (203) 359-1660

One Omega Drive Fax: (203) 359-7700

P.O. Box 4047 Toll free: 1-800-826-6342

Stamford, CT 06907-4047 E-mail: das@omega.com

http://www.dasieee.com

Page 2

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC., warrants this unit to be free of defects in materials and workmanship fo r a period of 13

DAQ-800 Users Manual 2

months from the date of purchase. OMEGA warranty adds an additional one (1) month grace period to the normal one (1)

year product warranty

coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number im mediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. OMEGA’s

warranty does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation o utside design limits, impr oper repair or unauthorized modif ication. This WARRANTY is

VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Com ponents which wear are not warranted, including but not limited to contact

points, fuses and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products

in accordance with information provided from OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND

ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PU RPOSE ARE HEREBY D ISCLAIMED . LIMITA TION O F LIABILITY: The remedi es of purc haser set

forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITION S: Equipment so ld by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Comp onent”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity, medical application or used on humans.

Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans or

misused in any way, OMEGA assum es no respo nsibility as set forth in o ur basic WA RRAN TY/DISCLAI MER language, and

additionally, the purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

to cover shipping and handling time. This ensures that OMEGA’s customers receive maximum

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, THE PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). THE ASSIGNED

NUMBER SHOULD THEN BE MARKED ON THE OUTSIDE OF THE RETURN PACKAGE AND ON ANY

CORRESPONDEN CE. THE PURCHASER IS RESPONSIBLE FOR SHIPPING C HARGES, FREIGHT, IN SURANCE AND

PROPER PACKAGING TO PREVENT BREAKAGE IN TRANSIT.

FOR WARRANTY

(1) P.O. Number under which the product was purchased,

(2) Model and serial number of the product under warranty, and

(3) Repair instructions and/or specific problems relative to the product.

FOR NON-WARRANTY

BEFORE contacting OMEGA:

(1) P.O. Number to cover the cost of the repair,

(2) Model and serial number of the product, and

(3) Repair instructions relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvem ent is possible. This af fords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC. © Copyright 1999 OMEGA ENGIN EERING, IN C. A ll

rights reserved. This document may not be copied, photocopied, reproduced, translated or reduced to any electronic

medium or machine readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA fo r current repair charges. Have the fo llowing information available

Page 3

OMEGAnet On-line Service: Internet e-mail:

http://www.omega.com

Servicing North America

: One Omega Drive, Box 4047 E-mail: info@omega.com

USA

ISO 9001 Certified

Canada

: 976 Bergar E-mail: info@omega.com

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

info@omega.com

:

For immediate technical or application assistance

USA and Canada

Mexico and Latin America

: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

:Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espanol: (001) 203-359-7803

E-mail: espanol@omega.com

SM

:

SM

SM

Benelux

Czech Republic

France:

Germany/Austria

: Postbus 8034, 1180 LA Amstelveen, The Netherlands

: ul.Rude armady 1868, 733 01 Karvina-Hraniee

9, rue Denis Papin, 78190 Trappes

Servicing Europe

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

E-mail: nl@omega.com

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

Toll Free: 0800-1-66342 E-mail: czech@omega.com

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

E-mail: france@omega.com

: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

E-mail: germany@omega.com

:

DAQ-800 Users Manual 3

Page 4

United Kingdom: One Omega Drive, River Bend Technology Drive

ISO 9002 Certified Northbank, Irlam, Manchester

DAQ-800 Users Manual 4

M44 5EX, England

Tel: 44 (161) 777-6611

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that app ly.

OMEGA is constantly pursuing certification of it’s products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc.

accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, p atient

connected applications.

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

E-mail: info@omega.co.uk

Page 5

Table of Contents

4 Theory of Operation

31

3.3.2 Differential Input

30

3.3.1 Single Ended Input

3 Field Wiring

2.5 After Completing Configuration

25

2.4.2 Changing Resources with Device Manager

24

2.4.1 Using the "Add New Hardware Wizard"

2.4 Installation under Windows95/98®

23

2.3.4 Timer0 Internal/External Clock Selection

21

2.3.3 Bipolar/Unipolar Output Range Selection

20

2.3.2 D/A Voltage Reference

18

2.3.1 I/O Base Address Selection

2.3 Configuring the DAQ-801/802

2.2 Auxiliary Connector Cable

2.1 Unpacking

2 Hardware Configuration and Initial Setup

1 Introduction

DAQ-800 Users Manual 5

......................................................

1.1 Analog Input Features

1.2 Analog Output Features

1.3 Digital I/O

1.4 Counter/Timer

1.5 Interrupts

1.6 Software Support

......................................................

..................................................

........................................................

................................................

1.7 Power Requirements

1.8 Applications

.....................................................

............................................

..........................................

.............................................

1.9 DAQ-801/802 Specifications

.....................................

8

9

91.1.1 Gain Selection Ranges ..............................................

101.1.2 Source and Trigger Mode for Analog-to-Digital Conversions .............

101.1.3 Scan List ........................................................

111.1.4 Sampling Rate ....................................................

111.1.5 Data FIFO .......................................................

12

12

12

13

14

14

14

15

.......................................................

.........................................

............................................

.....................................................

3.1 I/O Terminal Connection

........................................

3.2 D37 Connector Pin Diagrams

3.3 Analog Input Field Wiring

................................................

.................................................

3.4 Analog Output Field Wiring

3.5 Timer/Counter Field Wiring

..............

.......................................

...................................

............................

.............................

..............................

.............................

............................

..................................

.....................................

.......................................

.....................................

.....................................

17

17

17

18

24

26

27

27

29

30

32

33

...........................................

34

Page 6

6.5 Programming Examples

6.4 Accessing the Timer/Counter

47

6.3.2 Mode 1 ( Timing Applications)

47

6.3.1 Mode 0 (Event Counting)

6.3 Mode Definition

46

6.2.2 Read Operation

46

6.2.1 Write Operation

6.2 Functional Description

6.1 Introduction

6 8254 Timer/Counter

5.9 Analog Trigger Example

44

5.8.4 Base + 8000, Board Enable/Disable

44

5.8.3 Base + C..F, 82C55 Programmable Peripheral Interface chip

44

5.8.2 Base +A / B, DA1

44

5.8.1 Base + 8 / 9, DA0

5.8 Remaining Base Addresses

5.7 Base + 7, Scan Channel Register

5.6 Base + 6, 4-Bit Digital I/O

5.5 Base + 5 , Interrupt Status Register

5.4 Base + 4, Status Register

5.3 Base + 3, Index Registers

5.2 Base + 2, Index Register

5.1 Base + 0 / 1, Data FIFO

5 Address Map

4.5 Timer/Counter

4.4 Digital I/O

4.3 Analog Output

4.2 Analog Input

4.1 Signal Flow

.....................................................

DAQ-800 Users Manual 6

....................................................

...................................................

......................................................

..................................................

34

35

36

37

37

....................................................

..........................................

.........................................

.........................................

..........................................

...............................

.......................................

..................................

.......................................

.................................................

.................................................

..............

..................................

.........................................

............................................

.....................................................

...........................................

..................................................

...................................................

.................................................

...........................................

.....................................

....................................

..........................................

38

39

39

40

42

43

43

43

44

44

45

45

45

47

47

49

Page 7

List of Figures and Tables

46

Table 6-2. Control Word Modes of Operation

45

Table 6-1. Control Word Read/Write Actions

39

Table 5-2. Data FIFO Gain Values

38

Table 5-1. DAQ-800 Series Address Map

21

Table 2-2. DA1 Output Voltage Ranges

21

Table 2-1. DA0 Output Voltage Ranges

9

Table 1-2. Bipolar Analog Input Voltage Ranges

9

Table 1-1. Unipolar Analog Input Voltage Ranges

34

Figure 4-1. DAQ-801/802 Signal Flow Block Diagram

33

Figure 3-7. Timer/Counter Field Wiring

32

Figure 3-6. Analog Output Field Wiring

31

Figure 3-5. Differential Analog Input Field Wiring

30

Figure 3-4. Single-Ended Analog Input Field Wiring

29

Figure 3-3. D37 Pin Diagrams

28

Figure 3-2. Connection of UIO-37 Terminal Blocks to DAQ-800 Series Connectors

27

Figure 3-1. UIO-37 Screw Terminal Block

23

Figure 2-6. Internal/External Clock Selection Jumper

22

Figure 2-5. Bipolar/Unipolar Output Range Selection Jumper

20

Figure 2-4. D/A Voltage Reference Jumper

19

Figure 2-3. I/O Base Address Selection

18

Figure 2-2. I/O Base Address Selection Switches

17

Figure 2-1. Auxiliary Connector Cable

8

Figure 1-1. Component Layout Diagram

...........................................

DAQ-800 Users Manual 7

...................................................

............................................

...................................

...........................................

........................................

........................

...............................

.........................................

................................

..................................

...........................................

..........................................

...............................

..................................

....................................

..........................................

..........................................

.........................................

...............................................

.....................................

.....................................

........

Page 8

1 Introduction

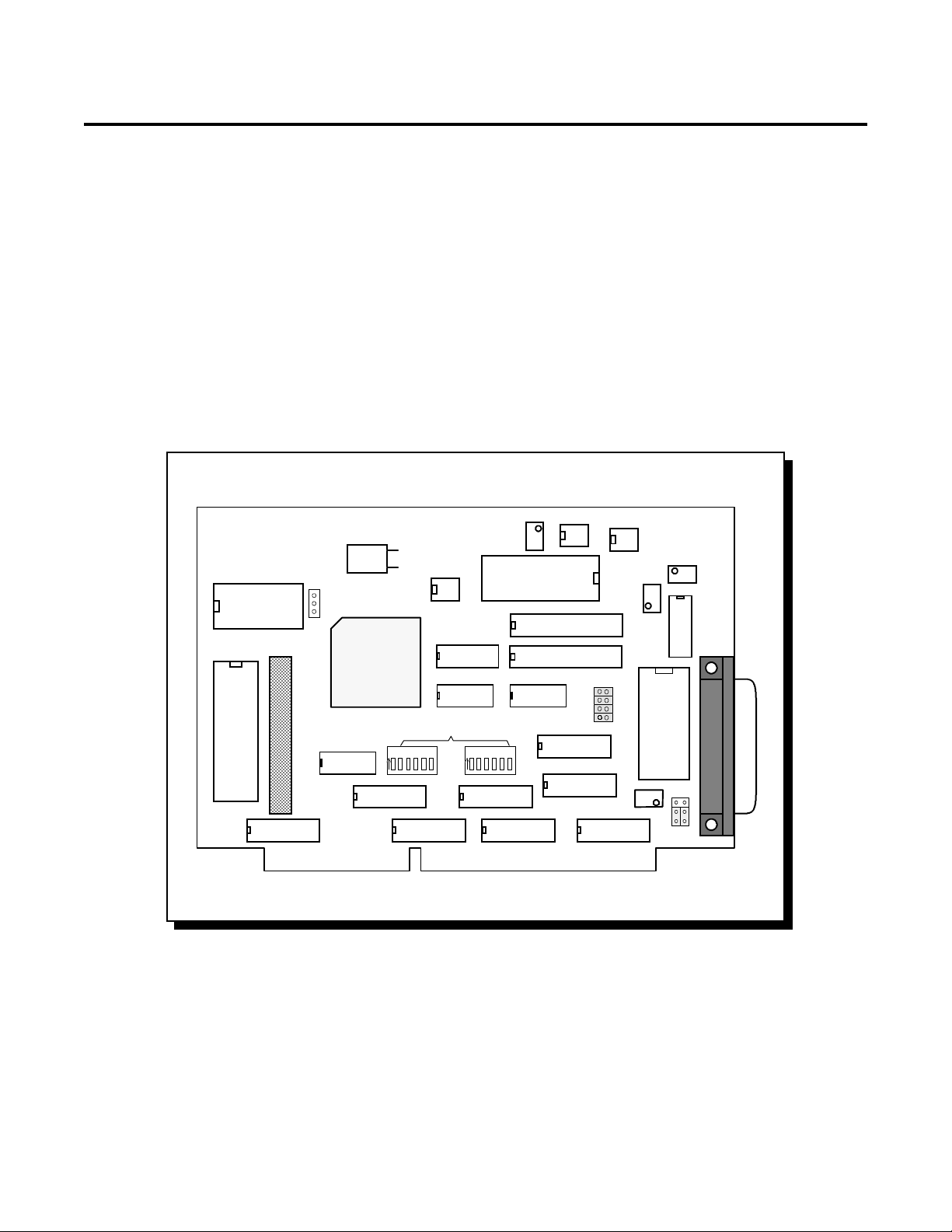

The DAQ-801 and DAQ-802 are cost effective high speed data acquisition boards that plug

DAQ-800 Users Manual 8

into ISA expansi on slots in IBMTM compatible personal computers. The DAQ-800 series circuit

board provides 12-bit analog input, 32-bit digital input/output (I/O) and three 16-bit

programmable timer/counters. Each version of the DAQ-800 series board has it's own

selectable gain range. The DAQ-801 is software programmable for gains of 1, 10, 100 or 1000.

The DAQ-802 is software programmable for gains of 1, 2, 4 or 8.

The maximum sampling r ate of the DAQ- 801/802 is 40KHz. The anal og and d igital I/Os and

the external trigger, clock and reference si gnals are connected via a 37-pi n "D" type connector

which is compatible with the Keithley MetraByteTM DAS-1600. An auxiliary D37 connector is

employed to support an additional 24-bits of digital I/O. The component layout diagram for

the DAQ-800 series circuit board is depicted in Figure 1-1.

DAQ-800

20MHz

1234

ADC1241

FIFO

FIFO

sw2

56

D/A

D/A

PGA

J2

5

1

8

4

MUX

J3

3

1

8254

8255

J4

Axiliary I/O

1

3

FPGA3042

sw1

1234

Base I/O Address

56

Figure 1-1. Component Layout Diagram

Page 9

1.1 Analog Input Features

DAQ-800 Users Manual 9

The DAQ-801/802 uses one 12 bit analog-to-digital converter (ADC) to support 8 differential

(positive and negative connections) or 8 single ended analog input signals. Selection of either

single ended or differential analog inputs is software programmable. The DAQ-800 series

ADC can be configured to receive analog input voltages within the ranges of 0 to +5V or ±5V.

1.1.1 Gain Selection Ranges

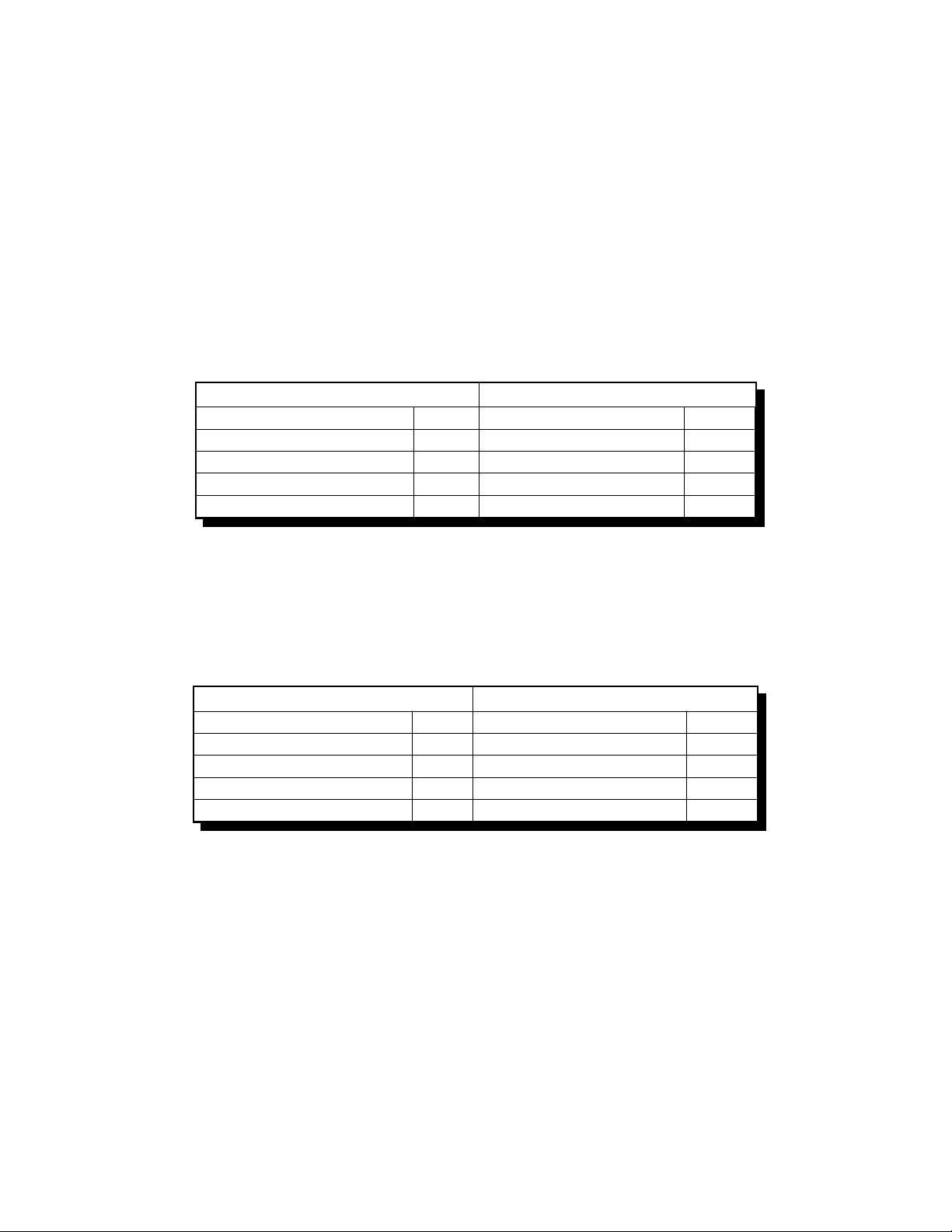

The DAQ-801 provides gains of 1, 10, 100 and 1000 versus the DAQ-802, w hich provides gains

of 1, 2, 4 and 8. Tabl es 1-1 and 1- 2 show the analog input unipolar and bi polar voltage ranges

for the respective gain range.

DAQ-802 DAQ-801

GainInput RangeGainInput Range

10 to +5V10 to +5V

20 to +2.5V100 to +500mV

40 to + 1.25V1000 to +50mV

80 to +0.625V1,0000 to +5mV

Table 1-1. Unipolar Analog Input Voltage Ranges

For a gain setting of 1, the 12-bi t resolution (4096 count) provides a least signif icant bit (LSB)

value of ±1.22 mV in the 0 to +5V range.

DAQ-802 DAQ-801

GainInput RangeGainInput Range

1-5 V to +5 V1-5V to +5V

2-2.5 V to +2.5V10-500mV to +500mV

4-1.25 V to +1.25V100-50mV to +50mV

8-0.625V to +0.625V1,000-5mV to +5mV

Table 1-2. Bipolar Analog Input Voltage Ranges

For a gain setting of 1, the 12-bit resolution (±4096 count) provides a least signif icant bi t (LSB)

value of ±1.22mV in the ±5V range.

Page 10

1.1.2 Source and Trigger Mode for Analog-to-Digital Conversions

Upon initial power up, the DAQ-801/802 is in idle mode and no conversions are performed.

DAQ-800 Users Manual 10

Conversions begin upon receiving a trigger. Two types of triggers are available: internal

trigger and external trigger. The internal trigger is initiated by a software program, whereas

the external trigger is connected through hardware. The external trigger type can be either

TTL or analog. The TTL trigger input comes from pi n 25 on the main connector. The analog

trigger channel is the start channel in the scan list and it's trigger voltage is set by D/A

channel 1. When a trigger is initiated, the ADC immediately converts the analog signal into

12-bit digital data which is stored in the data FIFO (First In First Out) register. In addition to

varied triggering sources, a triggering mode is available to select whether conversions and

channel scans are completed only once or multiple times. Trigger source and trigger mode

types are software selectable.

Triggering functions are summarized as follows:

(a) Trigger sources (internal/external) :

Internal software trigger

External TTL trigger on falling or rising edge

External analog trigger with low to high or high to low transition

For the external TTL trigger, the default trigger pin on the main D37 connector is pin 25.

(b) Trigger mode:

Single -- one scan/conversion for each trigger

Continuous -- continuous scanning/conversions for one trigger

1.1.3 Scan List

The DAQ-801/802 scan list function performs high speed A/D conversions from channel to

channel enabling the user to digitize and collect data from several analog input channels

almost simultaneousl y. The scan FIF O must be programmed w ith the start and stop channel s

and also according to the scan sequence desired. When the scan list function is initiated, A/D

conversion begins from the start channel. After the conversion is completed, digitized data is

entered into the data FIFO an d the b oard sel ects the next locati on to repe at the same task. T his

process continues until the stop channel is reached. Before the scan list function is called, the

FPGA registers must be written with the start and stop channels and their corresponding

gains. If the user specifies the start and stop channels to be the same, then single channel

acquisition mode occurs. Otherwise, the scan is sequential and incremental by one. For single

trigger mod e, i t scans once and then stops. In continuous mode, scanning continues at a speed

set by the sampling rate until the desired number of scan times is reached.

Page 11

1.1.4 Sampling Rate

DAQ-800 Users Manual 11

When digitizing the analog signal, one user selectable parameter is the sampling rate which

determines how fast the analog signal is digitized. The minimum sampling rate must be at

least two times the input signal frequency to accurately recover digitized data from the

original analog input signal. The maximum sampling rate of the DAQ-801/802 is 65KHz

without auto zero ca l i bration and 3 9KHz with auto ze r o calibrati on an d i s d e r i ve d f r om the on

board 8254 chip which has three 16-bi t timer/counters. The clock input to timer1 is 2.5MHz.

Timer1 and timer2 are cascaded to generate the sampling rate pulse which in turn triggers

A/D conversion.

1.1.5 Data FIFO

DAQ-801/802 uses a data FIFO register between the output of the ADC and the ISA bus to

buffer data from the ADC output. Unlike conventional A/D boards where the di gitized data

output is fetched directly to the PC memory, the output data from the ADC is fed into the

FIFO first for temporary storage. The length of the FIFO register is 1024 sampling points and

the register circuit provides hardware flags for half full, full and empty signals. Utilizing these

signals, the b oard ca n genera te an inter rupt to the PC when the FIFO i s ha lf f ull . Once the PC

interrupt is complete, the interrupt service routine program uses the "MOVE STRING"

instruction to move the FIFO da ta directly in to PC memory at a very high speed. In this case,

it only interrupts the PC every 512 samples and thereby improves the speed of operation. In

Windows appl ications, the latency of the inte rrupt d oes not effect the i ntegr ity of the di gi tized

data as it continues into the FIFO. The status register (see Chapter 5, Table 5-1: Address map)

provides information about FIFO empty, half full and full conditions.

Page 12

1.2 Analog Output Features

In addition to the analog input channels, the DAQ-801/802 contains two analog output

DAQ-800 Users Manual 12

channels. Each channel has its own 12-bit di gital-to-analog converter (DA0 and DA1 at pins 9

and 27 on the main I /O D37 connector ). T he analog outputs a re buf fer ed and capab le of 1 mA

of output current. The output voltage range for each channel is jumper selectable as unipolar

or bipolar. The 12-bit resolution provides a LSB value of 4.88mV on the ±10V range and

2.44mV in the 0 to +10V range. Both channels use multipl yi ng D ACs which requi r e a ref erence

voltage input in addition to the 12-bit digital values. The DAQ801/802 provides an internal

reference voltage while an external reference voltage can also be supplied via jumper

configuration.

1.3 Digital I/O

The DAQ-801/802 has 32 digi tal I/O lines. Of the 32 li nes, 8 of them can be accessed through

the main D3 7 conne ctor . There are 4 inputs: I P0 throug h I P3, and 4 outputs: OP0 through OP3,

(refer to Chap ter 3, Figure 3 -3 for pin l ocations). The remain ing 24 I/O lines ar e generated by

an 8255 programmable peripheral interface chip and are accessed through the auxiliary D37

connector. The 8255 has three ports (A, B and C) and one control register. Any port can be

programmed as in put or output. Ports A and B ar e 8 bit I /O por ts whil e port C can be f urther

divided into two 4-bi t I/O ports. T he 8255 has three modes of operation whi ch are d etermi ned

by values wr itten into the control regi ster. Mode 0 i s for basic input/output config uration in

which the output port is l atched and the input por t is not. Mode 1 employs Port A or B a s the

data port while using Port C for handshake, interrupt, and digital I/O lines. Mode 2 uses Port

A as the bi-directional data port with Port B and C as control and digital I/O lines. For a

detailed functional description, the user is referred to the Intel® 8255 data manual.

1.4 Counter / Timer

The 8254 timer/counter chip on the DAQ-801/802 provides three 16-bit timer/counter

channels for time-related applications. Timer1 and timer2 are cascaded together with an input

clock of 2.5MHz and the output of timer2 is used as the sampling rate clock for the A/D

converter. T hr e e terminal s for timer 0 ar e availab l e to the user vi a the main I/O D 37 connector .

The three terminals are Pin 2 (Timer0 Out), Pin 21 (Timer0 Clk) and Pin 24 (Timer0 Gate). The

gate termina l should b e log ic high i n order for the counter to function. If gate is hel d at logi c

low, the counter is disabled.

Page 13

1.5 Interrupts

DAQ-800 Users Manual 13

The DAQ-801/802 supports AT style ISA bus interrupts which includes IRQ 2-7, 10-12 and

14-15. The selection of inter rupts is softwa re programmabl e through the reg ister setting of the

FPGA. Any interrupt conflict can be conveniently resolved by moving the selection to another

available line without opening the computer case. There are four interrupt sources from

DAQ-801/802:

End of scan

Data FIFO Half Full

Data FIFO Full

Timer0

The end of scan interrupt is normally used in conjunction with single trigger mode or in

continuous mode when the scan rate is less than 1KHz. After the scan list is completed, the

end of scan generates an interrupt to inform the computer to fetch the data.

The data FIFO half full interrupt is used during continuous trigger mode. When the FIFO is

half full, i t interrupts the PC to fetch at least 512 sample points. This interrupt works well in

the Windows environment because of interrupt latency problems inherent in the Windows

operating system.

The data FIFO full interrupt is not recommended for applications unless the interrupt routine

is executed promptly before the next data points are accepted. Otherwise an overflow can

occur and data may be lost.

Timer0 in terrupt is used in conjunction with the external ti mer at the main D37 connector. The

external cl ock pulses are connected to the time r0 clk input (pin 21) and the output of timer0

can be used as an interrupt source. When the user must interrupt the PC at a certain time

interval, timer0 can be programmed to meet the requirement.

Page 14

1.6 Software Support

Software drivers are provided to support various programming languages like Microsoft

DAQ-800 Users Manual 14

C/C++, Borla nd C/C++, Qui ckB asic, Vi sual Basi c f or MS-D OS a nd T urbo Pascal . A D ynami c

Link Library (DLL) is provided for numerous programming languages under Windows as

well as Visual Basic Controls. Software support is available on the Omega "DaqSuite" compact

disk in the following categories:

1. DAQDRIVE® Software driver

2. DaqEZ™ Data Acquisition Package

3. VISUALDAQ® Data Acquisition Package

DAQDRIVE is a low level generic driver consisting of a set of user commands that act as a

library routine for all d ata acquisition boards. Programs written for the DAQ-801/802 can be

ported to other boards in the event the user decides to change boards in the future.

DAQDRIVE is available for Window DLLs and the MS-DOS environment. In the case of

Visual Basic applications, Omega provides VISUALDAQ®. Because of it's user friendly

nature, this software is very practical for interaction with data acquisition boards and for

creating graphic presentations.

Omega also provides driver support for third party data acquisition packages such as

TestPoint® (Capital Equipment Corporation) and LabVIEW® (National Instruments). These

packages allow the user to create custom test, measurement and data acquisition applications.

1.7 Power Requirements

The DAQ-801/802 is powered directly by the +5V and +12V power source provided by the

computer bus.

1.8 Applications

The DAQ-801/802 performs the following functions: analog input (A/D), analog output

(D/A), digital I/O and timer/counter functions. Typical applications for each function are

listed as follows:

A/D conversion converts analog voltage into digital information, which enables the computer

to process or to store the signals. Typical appl ications are sensor or transd ucer measurement,

wave form acquisition/analysis and data storage. (Most sensor/transducer measurements

require signal conditioning prior to measurement by an A/D converter).

D/A conversion is the opposite of A/D conversion. This operation converts digital

information to analog voltage. Typical applications are process control and function/pulse

train genera tion. The dig ital input f unction is useful in appl ications such as contact closure or

switch status monitoring. The digital output function is useful for relay control and industrial

on/off control. A timer/counter is typi cally used for eve nt counting and pulse g eneration. It

can also be used for frequency, period or pulse measurement.

Page 15

1.9 DAQ-801/802 Specifications

Adjustable to 0

Gain Error

Adjustable to 0

Zero Error

8 Samples

Size of Scan List

without auto zeroing: 15.2µs

with auto zeroing: 25.6µs

Scan Time (channel to channel)

Twos complement

Output Data Code

-5V to +5V

Input Ranges

8 differential, 8 single ended

Channels

39 Khz (with auto-zero calibration)

65 Khz (without auto-zero calibration)

Maximum Sampling Rate

Analog Input

Analog Output

4

Input Bits

82C54

Type

3, down

Number of Counters

Timer/Counter

24 bits

I/O

(24 bits on Auxiliary Connector)

Digital I/O

DAQ-800 Users Manual 15

Gain Ranges:

Model 801

Model 802

1, 10, 100, 1000

1, 2, 4, 8

1 M ohmInput Impedance

50pAInput Bias Current

Surge Protection up to

±20 V

12-bit + signResolution

Successive ApproximationConversion type

2Channels

0 - 5V, 0 - 10V, ±5V, ±10VOutput Ranges

Straight BinaryOutput Data Coding

12-bitResolution

(8 bits on main D37 Connector)Digital I/O

4Output Bits

82C55AType

Page 16

60 mA typ, 80 mA max

-12vdc

120 mA typ, 160 mA max

+12vdc

15 mA typ, 20 mA max

-5vdc

750 mA typ, 900 mA max

+5vdc

Power Requirements

0 - 70° COperating Temperature

Environments

DAQ-800 Users Manual 16

3-7, 9-12, 14, 15Interrupt Level

0-95%Humidity

7 in x 4.8 inDimensions

Page 17

2 Hardware Configuration and Initial Setup

This section describes how to unpack and configure the DAQ-800 series circuit board.

DAQ-800 Users Manual 17

2.1 Unpacking

The DAQ-801/802 is packed in an antistatic bag to avoid possib le damage to the electrostatic

discharge se nsi ti ve components on the board . Before r emoving the product f r om i t's pr otecti ve

bag, touch both the bag and the computer chassis to establish grounding. If available, utilize a

static free work station to unpack the DAQ-801/802. Once grounding has been established,

remove the board from it's packaging and inspect it for signs of damage.

2.2 Auxiliary Connector Cable

The DAQ-801/802 auxiliary I/O connector can be accessed via a PC expansion slot by

attaching the cable assembly included with the product.

40 pin

Male

Connector

Connector

Auxiliary I/O

Main I /O

40 pin

DAQ-801/802

Female

Cable Assembly: P/N 920-0048-01A

Figure 2-1. Auxiliary Connector Cable

D37 Male

Connector

Page 18

2.3 Configuring the DAQ-801/802

DAQ-800 Users Manual 18

The user must decide the appropriate configuration for the DAQ-801/802 board d epend i ng on

the application. The D IP switch settings for SW1 and SW2 and the jumper settings f or J2, J3

and J4 must be selected before installing the board in the computer. While software

programmable configurations can be done later, the following items are jumper or switch

selectable and must be decided before installation into the PC:

1. I/O base address selection

2. D/A voltage reference, bipolar/unipolar output range.

3. Internal/external clock source for Timer 0

2.3.1 I/O Base Address Selection

Each board in the PC must have a uni que input/output a ddr ess. No tw o b oard s can shar e the

same address. Similar to a mail box, the PC processor sends data to or fetches data from this

address. Some of the I /O locations are pre-assigned standard d efault locati ons such as COM1

(3F8H) and COM2 (2F8H). Printer port locations such as LTP1 are also fixed. The I/O base

address for most other hardware is flexible and can be any value as long as that space is not

occupied. Figure 2-2 shows the location of SW1 and SW2, the base address selection switches.

DAQ-800

8254

Auxiliary I/O

8255

J4

Don't Care

1

3

20MHz

FPGA3042

SW1

1234

456

231

A A A A A

14 13 12 11 10

Base I/O Address

56

1234

2

1

A A A A A A

9 8 7 6 5 4

ADC1241

SW2

56

SW2SW1

3456

FIFO

FIFO

D/A

D/A

ON

J2

PGA

MUX

J3

Figure 2-2. I/O Base Address Selection Switches

Page 19

The I/O base address of the DAQ-801/802 is set using two DIP switches SW1 and SW2.

DAQ-800 Users Manual 19

When a switch bit is in the "ON" position, then the corresponding address line is logic 0.

When a switch bit is in the "OFF" position, then the corresponding address line is logic 1. The

I/O base address can be selected from 0000H to 7FF0H with a 0010H interval. The upper limit

of 7FF0H implies that the address has only 15 lines and the most significant bit A15 is always

0. Switches SW1 and SW2 select address lines A14 through A4. Since the board encompasses

16 register locations which require 4 address lines, (A3, A2, A1 and A0), only A14 through A4

address lines are used for base address decoding. Figure 2-3 shows several switch

configurati ons and the I/O base addresses they repr esent. The factory defa ult address setting

is 300H.

Do n't ca re

xxxxx

123456

O

N

A A A A A

14 13 12 11 10

SW1

xxxxxx

123456

O

N

SW2

A A A A A A

9 8 7 6 5 4

03 10

00000 11 1000

123456

O

N

Example1: Base I/O Address = 0310H

123456

O

N

6A D0

11010 10 1110

123456

O

N

123456

O

N

Example 2: Base I/O Address = 6AD0H

0000

Bit=0 Bit=1

xxxx Hex

0000 : 0

0001 : 1

0010 : 2

0011 : 3

0100 : 4

0101 : 5

0110 : 6

0111 : 7

1000 : 8

1001 : 9

1010 : A

1011 : B

1100 : C

1101 : D

1110 : E

1111 : F

Figure 2-3. I/O Base Address Selection

Page 20

2.3.2 D/A Voltage Reference

The digital to analog converter in the DAQ-801/802 uses a multiplying D /A converter which

DAQ-800 Users Manual 20

requires a reference voltage connection. There are two reference voltages selections available:

one is the interna l power supply +5 vdc refer ence voltage and the other is an ex ternal input.

Figure 2-4 illustrates internal/external reference voltage selection for D/A channels DA0 and

DA1. Configure jumper J3 for the desired reference as follows:

DA0 DA1

External reference Pins 2 & 3 Pins 5 & 6

Internal reference Pins 1 & 2 Pins 4 & 5

DAQ-800

20MHz

8254

Auxiliary I/O

J4

1

3

FPGA3042

ADC1241

FIFO

FIFO

PGA

8255

J2

Base I/O Address

SW1

1234

56

DA0

DA1

1234

56

SW2

D/A

D/A

J3

6

3

5

2

41

External Reference

Internal Referenc e

Figure 2-4. D/A Voltage Reference Jumper

MUX

J3

Page 21

2.3.3 Bipolar/Unipolar Output Range Selection

Each D/A output has an option of either Unipolar or Bipolar connections. In addition, the

DAQ-800 Users Manual 21

output voltage range can also be selected. Unipolar or bipolar output selection is made by

either connecting or not connecting jumper J2 as applicable for the desired output result.

Tables 2-1 and 2-2 list the combinations of jumper confi gurations for available voltage range

selections. The location and configuration options for jumper J2 are shown in Figure 2-5.

D/A0 output voltage Pins 2 & 6Pins 1 & 5

-5V to +5V, bipolarConnectConnect

-10V to +10V, bipolarOpenConnect

0 to +5V, unipolarConnectOpen

0 to +10V, unipolarOpenOpen

Table 2-1. DA0 Output Voltage Ranges

D/A1 output voltage Pins 4 & 8Pins 3 & 7

-5V to +5V, bipolarConnectConnect

-10V to +10V, bipolarOpenConnect

0 to +5V, unipolarConnectOpen

0 to +10V, unipolarOpenOpen

Table 2-2. DA1 Output Voltage Ranges

Page 22

DAQ-800

DAQ-800 Users Manual 22

8254

Auxiliary I/O

J4

1

3

20MHz

FPGA3042

ADC1241

FIFO

FIFO

PGA

D/A

D/A

J2

1

MUX

8

8255

SW1

1234

Base I/O Address

56

1234

SW2

56

J3

DA0 DA1

J2

Connect: 5v range

Open: 10v ra nge

Connect: bipolar

Open: unipolar

Connect: bipolar

Open: unipolar

Connect: 5v range

Open: 10v ra nge

5678

1234

Figure 2-5. Bipolar/Unipolar Output Range Selection Jumper

Page 23

2.3.4 Timer0 Internal/External Clock Selection

The timer0 connection is used f or timing or counting applicati ons. Jumper block J4, shown in

DAQ-800 Users Manual 23

Figure 2- 6, is used to sele ct the internal or external clock w hich connects to the clock input of

timer0 at pin 21 on the main I/O D37 conne ctor. When configured for an external input, the

timer/counter can be used for pulse counting an external event. Configure jumper J4 as

necessary for the desired clock input:

Internal 2.5MHz clock Jumper pins 1 & 2 on J4 (timer operation)

External clock Jumper pins 2 & 3 on J4 (counter operation)

DAQ-800

8254

Auxiliary I/O

8255

20MHz

J4

1

3

FPGA3042

SW1

1234

Timer 0 clock source

Base I/O Address

56

1234

J4

1

2

3

ADC1241

FIFO

FIFO

J2

SW2

56

Internal 2.5MHz

External clock

D/A

D/A

PGA

MUX

J3

Figure 2-6. Internal/External Clock Selection Jumper

Page 24

2.4 Installation under Windows95/98®

Windows95/98 maintains a registry of all known hardware installed in a computer. Inside

DAQ-800 Users Manual 24

this hardware r e gistry Windows k eeps track of all system resour ces such as I/O locations, IRQ

levels and DMA channels. The "Add New Hardware Wizard" utility in Windows95/98 was

designed to add new hardware and update this registry.

An "INF" fi le is included wi th the DAQ-801/802 to allow easy configuration in the Wind ows

environment . Windows95/98 uses the "INF" file to determine the system resources required

by the DAQ-801/802, searches for available resources to fill the boards requirements and then

updates the hardware registry with an entry that allocates these resources.

Windows will not automatically configure the DAQ-801/802. The user is required to

manually confi gure the hardware to match the resources that Windows95/98 allocate s to the

DAQ-801/802. Another option is to use the "Devi ce Manager" to change the system resources

allocated to match the configuration of the hardware.

2.4.1 Using the "Add New Hardware Wizard"

The following instructions provide step-by-step instructions for installing the DAQ-801/802

with Windows by using the "Add New Hardware Wizard". Select Start/Help from the

Windows95/98 start bar for additional information on this utility.

1. Start the Add New Hardware Wizard utility. The icon for this utility is located in

the Windows95/98 control panel.

2. A dialog box will appear which initiates the "Add New Hardware Wizard" utility.

Select the "Next" button to continue.

3. An option box appe ars al lowi ng the choi ce of havi ng Wind ows automa ticall y d etect

the new hardware. Select the "No" option. The dialog in the box recommends

selecting the "Yes" option, but unless the hardware is installed with standard I/O

and IRQ levels, this option will fail. Select the "Next" button to continue.

4. A hardwar e type l ist box shoul d appear . Select the "Other D evices" ty pe on the li st

and then select the "Next" button to continue.

5. A list box opens wi th manufacturers on the left a nd the associated boa rd models on

the right. Select the "Have Disk" button.

6. An "Install From Disk" dialog box should pop open. Insert the customer CD-ROM

with the DAQ-801/802 INF files on it, select the correct drive letter and then select

the "OK" button. Windows95/98 automatically browses the root directory for an

INF file that defines configurations for the circuit board. If no INF files are found,

click the " Browse" button and sea rch the Wi n95/98 sub d irectory on the install ation

CD for the file “DAQPCARD.inf” . (The file name is not required. After finding the

directory containing the INF files, Windows will choose the correct file).

7. Your computer should read the INF file and display a list of data acquisition board

models supported by Windows95/98. Select the DAQ-801 or DAQ-802 model name

from the list and select the "Next" button to continue.

Page 25

8. A dialog box will appear with an unused I/O range and IRQ resources that

Windows has f ound avai l ab l e i n the registry. Wi nd ow s has assi g ned these resources

DAQ-800 Users Manual 25

to the DAQ-801/DAQ-802. Review these settings carefully before proceeding.

2.4.2 Changing Resources with Device Manager

The following instructions provide step-by-step instructions on viewing and changing

resources of the DAQ-801/802 in Windows95/98 using the "Device Manager" utility. Select

Start|Help from within Windows for additional information on this utility.

Either take notes of the resources being allocated to the new hardware or have

Windows95/98 print a copy. The D AQ-801/802 must then be manually configured

to match these resources. Windows will not automatically configure the

DAQ-801/802 board.

9. Another dialog box will open when the installation is complete. Select the "Finish"

button to end the software installation.

10. Windows will then instruct the user to shut down the computer and install the

hardware. Select the "Yes" button to shut down the computer. When

Windows95/98 sends the "safe" message, power down the computer.

11. Either manually configure the DAQ-801/802 to match the resources allocated by

Windows, or use the "Device Manager" i n Windows95/98 to change the previ ously

allocated system resources to match your preferences.

1. Double click the "System" icon inside the Control Panel folder. This opens up the

System Properties box.

2. Select the "Device Manager" tab located at the top of the System Properties box.

This lists all hardware devices listed inside the Windows95/98 registry. Additional

information is available on any of these devices by clicking on the device name and

then selecting the "Properties" button.

3. Double click the devi ce group "Data_Acquisiti on". The DAQ-801/802 model name

should appear on the list of hardware.

4. Double click the DAQ-801/802 model name and a properties box should open.

Page 26

5. Click the "Resources" tab located along the top of the properties box. Confirm

Windows95/98 has allocated resources for the DAQ-801/802 that match the board's

DAQ-800 Users Manual 26

hardware confi guration. To modify any of the resource settings select the resource

name and click the "Change Setting" button. Sele ct "Cancel" to exi t without maki ng

changes.

6. When the "Change Settings" button is selected, an "Edit Resource" window will

open. Insid e thi s wi ndow, cli ck on the up/dow n arrow s to the rig ht of the resour ce

value. This scrolls through all of the allowable resources for your hardware. Note

the Conflict Inf ormation at the bottom of the window . Do not sele ct a resource that

causes a conflict with any other installed hardware. Select "OK" to save your

changes or "Cancel" to abort changes.

7. You are required to manually configure the DAQ-801/802 to match the resources

allocated by Windows95/98.

2.5 After Completing Configuration

The DAQ-801/802 is now configured and ready f or use. Depending on the type of application

software to be used, the user may want to review one or more of the following:

1. Chapter 4 of this d ocument provi des ba sic theory of operati on for user s tha t wish to

learn technical details about the operation of the DAQ-801/802.

2. For users that want to program the DAQ-801/802 with direct transfers to the

register set, Chapter 5 provides an address map and a detailed description of each

I/O register.

3. Users that wish to write custom application software without programming the

DAQ-801/802 directly should consult the DAQDRIVE software reference manual.

DAQDRIVE provides a library of data acquisition subroutines for all Omega data

acquisition cards and is included free of charge with the DAQ-801/802.

4. For third party data acquisition software such as LabTech Notebook®, LabVIEW®,

TestPoint® or SnapMaster®, consult the documentation provided by the software

manufacturer.

Page 27

3 Field Wiring

Before completing any installation or connection, ensure power is not applied to the computer

DAQ-800 Users Manual 27

or external circuits. Install the DAQ-801/802 as directed by the procedures in Chapter 2:

Hardware Configuration and Initial Setup. The main I/O D37 connector on back of the PC

contains all the analog input and output signal pins. The auxiliary connector is used for

digital I/O connection. Both connectors and Omega cables are Keithley MetroByte

DAS-1600 compatible.

3.1 I/O Terminal Connection

The user can connect either one or both I/O connectors on the DAQ-801/802 to the external

UIO-37 screw terminal block shown in Figure 3-1. The UIO-37 has 37 numbered screw

terminals that correspond one to one to the pins on both the main I/O and auxiliary D37

connectors on the DAQ-801/802. The UIO-37 provides a convenient connection for external

wiring and is avai l abl e w i th either a male or female D37 connector. Wire gage 16 through 28 is

recommended for screw terminal connections.

D37 Connector (Male or Female available)

TM

Screw Terminal Connections

Ground

Figure 3-1. UIO-37 Screw Terminal Block

Page 28

The UIO-37 is connected to the PC using the Omeg a CP-DAQ D37 f emale to mal e 3 foot cable

DAQ-800 Users Manual 28

as shown in Figure 3-2. The CP-DAQ cable male end connects to the UIO-37 female D37

connector and the female end connects to the main I/O and auxiliary connectors on the

DAQ-801/802.

Computer

Main

CP-DAQ

Auxiliary

19

18

19

18

3

2

1

3

2

1

UIO-37

19

CP-DAQ

D37 female to male

3 foot cable

1

18

19

18

3

2

3

2

1

UIO-37

Figure 3-2. Connection of UIO-37 Terminal Blocks to DAQ-800 Series Connectors

Page 29

3.2 D37 Connector Pin Diagrams

DAQ-800 Users Manual 29

Analog I/O connections are made through D37 connectors as shown in Figure 3-3.

Analog GND

-CH0

-CH1

-CH2

-CH3

-CH4

-CH5

-CH6

-CH7

DA0 Ref

DA0 Out

Vref (-5V)

Power GND

IP1

IP3

OP1

OP3

Timer0 Out/-15V

+5V

Main I/O Connector

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

+CH0

+CH1

+CH2

+CH3

+CH4

+CH5

+CH6

+CH7

Analog GND

Analog GND

DA1 Out

DA1 Ref

IP0/Ext TTL T r i g / Tim er 1 C l k

IP2/Ti mer0 Gate

OP0

OP2

Timer0 Clk/+ 15V

Timer2 Out

Auxiliary Connector

DIG COM

+5V

DIG COM

DIG COM

DIG COM

DIG COM

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

OP=Digital Output (4 bit port) PA=Port A (bit 0-7)

DA=Digital to Analog Channe l

IP=Digital Input

PC=Port C (bit 0-7)

PB=Port B (bit 0-7)

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

DIG COM

+5V

Figure 3-3. D37 Pin Diagrams

Pins 11 through 18 and pins 30 through 37 are the available analog input channels. For

differential input, the eight available channels are numbered 0 through 7 and each channel

consists of one positive input (+CHx) and one negative input (-CHx). For single-ended

operation, the available channels are numbered 0 through 7 with the - CHx i nputs connected to

ground.

Page 30

3.3 Analog Input Field Wiring

(

)

Q

DAQ-800 Users Manual 30

3.3.1 Single Ended Input

The analog input signals can have either single ended or differential inputs. Figure 3-4

illustrates field wiring for single ended inputs. There are 8 single ended channels available,

each with a positive (+CHx) and negative (-CHx) connection. Connect the (+) wire to the

desired input channel terminal and the (-) wire to the UIO-37 analog ground at terminals 19

and 29.

If a high electrical noise environment exists, individual shielded wiring is recommended.

Keep the signal lines as far from the power line as possib l e and never bund l e si gnal cabl es and

high current or voltage cables in the same harness. High electric field intensity may

deteriorate or interfere with the signal being measured.

Vin0

+

Vin1

+

.

.

Vin7

.

+

External Trigger

+CH0

-CH0

+CH1

-CH1

+CH7

-CH7

IPO/EXT

GROUND

37

18

CP-DA

36

17

30

11

25

19

29

DAQ-801/802

ADC1241

FIFO

PGA

FIFO

145

J2

8

Gain,UI/BI

MUX

Base I/O Ad dre ss

D/A

sw1

sw2

D/A

J3

3

14

Referenc e

UIO-37

Terminal Block

Figure 3-4. Single-Ended Analog Input Field Wiring

FPGA3042

20MHz

DAQ-800

J4

1

8254

3

8255

Interrupt

Mode

123456123456

Axiliary I/O

Page 31

3.3.2 Differential Input

Differential input signals normally have three wire connections: (+) signal input, (-) signal

(

)

gg

Q

DAQ-800 Users Manual 31

input and a ground connection. Figure 3-5 illustrates differential input field wiring. Connect

the (+) input to +CHx and the (-) input to the corresponding -CHx terminal on the UIO-37.

The ground wires can be tied together and connected to the UIO-37 analog ground at

terminals 19 and 29. T he advantage of differential input wiring is that noise picked up along

the input signal lines will be canceled out at the instrumentation amplifier on the

DAQ-801/802 and only the pure signal will remain at the input to the A/D converter. For

noise levels greater than 1 or 2 LSB, differential configuration will definitely improve the

accuracy of the input signal.

Sensors with only two input wires, (no ground wire), can still be connected for differential

operation. Connect the signal input wires as described above and omit the ground

connection.

DAQ-801/802

PGA

145

J2

8

Gain,UI/BI

MUX

D/A

D/A

J3

3

14

Referenc e

UIO-37

Terminal Block

Ground

Vin0

Vin1

Vin7

+

+

+

-

+CH0

-CH0

+CH1

+CH7

External Tri

-CH1

-CH7

37

18

36

CP-DA

17

30

11

25

er

19

Ground

29

Figure 3-5. Differential Analog Input Field Wiring

20MHz

Base I/O Ad dre ss

sw1

sw2

FPGA3042

DAQ-800

J4

1

8254

3

8255

Interrupt

Mode

123456123456

Axiliary I/O

ADC1241

FIFO

FIFO

Page 32

3.4 Analog Output Field Wiring

DAQ-800 Users Manual 32

Typical analog output field wiring is shown in Figure 3-6. In this case, two shielded conductor

cables are recommended. The positive output is connected to the UIO-37 terminal block at

terminal 9 for DA0 and terminal 27 for DA1. The negative output is connected to analog

ground at terminals 19 and 29. The D/A output requires either an internal or external

reference. For the internal reference configuration, no connection is required at terminals 10

and 26 for DA0/DA1 reference i nputs. If the external reference confi guration is used, then an

external reference voltage must be applied to the UIO-37 terminal block at terminal 10 for

DA0 and terminal 26 for DA1. The external reference voltage can be either fixed or a varying

timing signal. Since the DAQ-801/802 uses a multiplyi ng D/A converter the output voltage is

the result of multiplying the D/A output by the reference voltage input. If the reference

voltage is fixed (non time varying), then the reference voltage only affects the magnitude of

the output voltage. If the reference signal is time varying, then the D/A output signal can

become an amplitude modulated signal.

DAQ-801/802

LOAD 0

LOAD 1

DA0

9

10

Vref DA0

CP-DAQ

DA1

27

UIO-37

Terminal Block

Vref DA1

Ground

26

19

29

()

Figure 3-6. Analog Output Field Wiring

20MHz

Base I/O Ad dre ss

sw2

DAQ-800

J4

1

8254

3

FPGA3042

8255

Interrupt

Mode

123456123456

sw1

Axiliary I/O

ADC1241

FIFO

PGA

FIFO

145

J2

8

Gain,UI/BI

MUX

D/A

D/A

J3

3

14

Referenc e

Page 33

3.5 Timer/Counter Field Wiring

The DAQ-801/802 has three 16-bit timer/counters. Timer1 and timer2 are used to generate the

DAQ-800 Users Manual 33

pacer clock for the A/D function. Timer0 is availa ble for the user and becomes a timer if the

input clock is connected to the i nternal 2. 5MHz clock. ( For config uration informati on refer to

Chapter 2, section 2.3.4: Internal/External Clock Selection). The output of thi s timer is pi n 2 on

the main I/O connector, (UIO-37 terminal 2). The frequency of this output signal will depend

on how the counter is programmed. A gate signal at pin 24 (main I/O D37) controls the

output signal. When the gate is opened , the output at pin 2 b ecomes active. When the gate is

closed or connected to ground, the output becomes 0.

When the DAQ-801/802 is configured for external clock, then the timer0 output changes to a

16-bit counter function. The counter can be used to count pul ses a nd the results can b e read by

the software. The signal to be counted i s connected at pin 21 and the counter can b e enab l ed or

disabled by controlling the gate signal at pin 24. If the switch is open, the counter is enabled

and any pulses present at pin 21 will be counted. If the switch is closed, the counter is

disabled. When the counter overflows, a pulse will be generated at terminal 2 at the output

clock. Figure 3-7 illustrates timer0 field wiring.

DAQ-801/802

20MHz

Base I/O Ad dre ss

sw1

sw2

FPGA3042

DAQ-800

J4

1

8254

3

8255

Interrupt

Mode

123456123456

Axiliary I/O

Signal

Source

Switch

External

Gating

Timer 0 CLK

GND

Gate

21

7

24

CP-DAQ

ADC1241

FIFO

PGA

FIFO

145

J2

8

Gain,UI/BI

MUX

D/A

D/A

J3

3

14

Referenc e

UIO-37

Terminal Block

2

Timer0 output

Figure 3-7. Timer/Counter Field Wiring

Page 34

4 Theory of Operation

4.1 Signal Flow

DAQ-800 Users Manual 34

The DAQ-801/802 signal flow block diagram is shown in Figure 4-1. The heart of the circuit is

the Field Programmable Gate Array (FPGA). This FPGA controls the timing required for A/D

conversion, D/A output and d igital I/O. There is a common b us on the board which car ries

the binary data g enerated by A/D conversion and binar y data sent to the D/A converter. The

data coming in fr om the digital input port or going out to the digi tal output port also passes

through the common bus. The common bus is separated from the ISA bus by a 16-bit data bus

buffer.

Ref

8 CHs

8-CH

MUX

Main D-37 Connector

PGA

Channel

Comp

Gain

FPGA

Scan List

(channel+gain)

12-bit A/D with

Auto-Zeroing &

Self Calibrating

Trigger Source

and MODE

12bit DA1

Auxiliary D-37

Ref

8-bit

8-bit

4-bit

4-bit

12bit DA0

8255A

PA

PB

PC1

PC2

U/B

1,2

Gain

Polar

IRQ 3-7,9-12,14,15

4-bit

Input

4-bit

Output

Interrupt

I/O Base

Select

Control

Select

Status Register

Interna l Bu s

div 4

buffer

Buffers

12-bi t + sign

1K X 16

FIFO

8254

Timer0

Timer1

Timer2

10MHz

ISA BUS

Figure 4-1. DAQ-801/802 Signal Flow Block Diagram

The FPGA sends out the necessary information to select the multiplexer, the gain of each

channel and sampling rate. The CPU sends the appropriate data to the registers residing

inside FPGA. When these settings are complete, the input signal comes through the analog

multiplexer and to the A/D converter via the Programmable Gain Amplifi er (PGA). The A/D

converter initiates conversion upon commands from the FPGA.

Page 35

The output of the A/D converter is 12-bit binary data and is in 2s complement format. The

stream of A/D output is fed into a 1K X 16 FIFO (First in Fir st Out) and the CPU then reads

DAQ-800 Users Manual 35

the data. The CPU can rea d data afte r each A/D conversion, a fter the FIF O is hal f full and all

at once using the "MOVE STRING" operation. Since the end of A/D conversion, FIFO half full

and FIFO full can generate interrupts to the processor, efficient data acquisition can be

achieved without using polling techniques. The FIFO is located at Base +0 address and any

read from this location will yield 16-bit data to the CPU. This 16-bit data, which is right

justified, will have the upper four bits either 0 or 1 depending on whether it is positive or

negative. The data FIFO should always be emptied prior to data acquisition. When the FIFO

is emptied by the host, the empty flag is set to "1". If there are one or more samples left in the

data FIFO, the empty flag is set to "0".

Commencement of A /D conve r si on is initiate d by a tri g g er from the FPGA. The tr i g g er sour ce

can be a software trigger or an external trigger. The software trigger is generated by writing

an output command to I nd e x register 2 , (refer to Chapter 5: A d d r e ss Map) . Each time a trigger

occurs, conversion is initiated and data is acquired. One trigger that stimulates one A/D

conversion is referred to as single trigger mode. In continuous mode, the system continuously

performs A/D conversions at a specified rate once it is triggered. This rate is referred to as

sampling rate. The sampling rate is derived by cascading timer1 and timer2 together with a

2.5MHz clock connected to the input of timer1. The sampling rate is a maximum of 40 kHz.

If the analog si gnal is coming from a singl e channel, then the ana log multiplex er is fixe d. All

converted digitized data will belong to a single analog signal. To observe several channels

almost simultaneously, the scan operation must be performed. Scan operation requires

specifying the start and the end channels. This is completed by writing a byte consisting of

start and end channels to the FPGA register. When the scan sequence convenes, the trigger

signal starts the A/D sampl ing and simul taneously send s a signal to switch the mul tipl exer to

the next channel. The trigger signal starts A/D sampling and then signals the scan FIFO to

switch the multiplexer to the next channel. While waiting for A/D conversion to finish, the

next selected analog signal is settling down at the instrumentation amplifier. When the End Of

Conversion pulse (EOC) appears indicating A/D conversion is completed, the converted data

is written into the data F IFO. T he same proce ss r epeats until the end of the channel scan l ist i s

reached. In single trigger mode, the FPGA will scan once and stop. In continuous mode, the

FPGA scans fr om the start channel to the end cha nnel and then waits for the next sampling

clock. Sampl ed data is se que ntially stor ed in the data F I FO a nd read b y the pr oce ssor . Data for

each channel must be sorted out in continuous mode operation.

D/A operation is performed by sending 12-bit data through the data buffer to the selected

D/A channel. The strobe signal necessary for latching the 12-bit data to the register inside

D/A converter is ge nerate d by FPGA. The d ata sent to Base +8 goes to channel 0 and the da ta

sent to Base +A goes to channel 1.

4.2 Analog Input

The DAQ-801/802 provides 8 differential analog input channels. Single ended analog input

channels can be configured by wiring the (-) Chx input to analog ground. Selecting one of the

Page 36

8 channels for A/D conversion utilizes the DAQ-801/802 input multiplexer. The multiplexer

has input over-voltage protection circuit which protects the analog input circuit when

DAQ-800 Users Manual 36

transient voltage occurs. The output of the multiplexer is connected to the PGA which is

configurable for gains of 1, 10, 100 or 1000 for the DAQ-801 and gains of 1, 2, 4 or 8 for the

DAQ-802. The maximum voltage output of the PGA is limi ted to ±5V. The maximum analog

input range at the multi plex er i s al so ±5V, the refor e various g ains can b e selecte d to optimi ze

the accuracy of the input signal for data conversion. For instance, if the input signal falls

within ±40 mV, the DAQ-801 can be set for a gain of 100 which will yield a voltage ±4V at the

output of PGA. If the input signal is only ± 0.625V, then the DAQ-802 with a gain of 8 can be

chosen to get the maximum accuracy. The output of the PGA is then connected to the

sampling A/D converter.

The sampling A/D converter has a 12-bit 2s compleme nt binary output. The converter type is

successive approximation and its conversion time is 15. 2µs w i th non auto zero and 25.6µs wi th

the auto zero function. Thus, selecting the auto zero function will slow data acquisition. The

A/D converter can be calibrated across it's full range. This calibration is completed during the

initial system set up and is not required again once set up is finished.

4.3 Analog Output

The 12-bit data sent to Base +8 location by the processor will travel from the ISA bus to the

internal b us an d get to the latch at the D /A conve rte r of channel 0. Whe n the latch recei ves the

new data, it goes thr ough digital to analog conver sion and the analog voltage correspond ing

to the binary value appears. Each binary value will get a corresponding analog voltage. The

analog output voltage is then buf fered through operation amplifie r to pin 9 of the main I/O

connector. The buffered amplifier is used to increase the output driving capability. Any 12-bit

data sent by processor to address Base +A will terminate at the latch of D/A channel 1. The

same type of buffered circuit is attached to the output of channel 1 D/A converter.

The D/A converter is a multiplying D/A converter which requires a reference voltage. This

reference vol tage is provided by a ±5V anal og output with the buffer stage confi gured for a

gain of 1. When the buffer stage is set to a gain of 2, the output will have a maximum of ±10V.

Jumper configuration can enable the user to select a unipolar output. The reference voltage

can also be injected from an external circuit via jumper selection and does not have to be a

constant voltage. If a time var ying signal is used, then multiplyi ng this voltage with the D/A

output will result in a complex signal. Not only does the analog value sent by processor

change but the maximum magnitude also changes. If the reference voltage is not a time

varying signal, then adjusting the reference voltage will only change the D/A output range.

The D/A output voltage can thus be customized by feeding in the appropriate reference

voltage.

Page 37

4.4 Digital I/O

DAQ-800 Users Manual 37

The digital I/O function of the DAQ-801/802 provides a 4-bit TTL compatible input and

output. Both are accessed through the main I /O connector. Digital data fl ow is controlled by

the FPGA. In addition to the 4 bit digital I/O, there is a 82C55 programmable peripheral

interface chip on the board which supplements 24 additional digital I/O lines. The 82C55 is

located at Base +C and occupies four consecutive I/O addresses. The 24 bit digital I/O is

divided into three 8-bit ports and each port can be configured for either input or output.

There are three modes of operation for 82C55: mode 0 for basic input/output, mode 1 for

digital I/O with handshake lines and mode 2 for bi-directional data transfer. The mode is

determined by the control word of the 82C55 located at Base +F. All three ports are accessed

through the auxiliary D37 connector. At power up these three ports are configured as input

ports but their configuration can be altered by writing a value to the control word register. For

detailed discussion of the 82C55 interface chip, consult the applicable Intel® data manual.

4.5 Timer/Counter

The 82C54 interface chip has three timer/counters. Timer1 and timer2 are cascaded to

generate the sampl ing clock. Only timer 0 i s available for the user. The timer/counter has a

clock input, gate control input and pulse output. When the gate control signal is low, the

timer/counter is disabled. (See Chapter 6 for detailed explanation of the 8254 timer/counter).

Page 38

5 Address Map

The address map of the DAQ-801/802 occupies 16 I/O locations. It starts from Base +0 and

Read/Write Disable/Enable DAQ-801/802

Base + 8000

82C55 8-bit Read/Write

Base + C..F

16-bit Write only D/A channel 1

Base + A..B

16-bit Write only D/A channel 0

Base + 8..9

8-bit Read/Write Scan channel register

Base + 7

8-bit Read/Write 4-bit digital I/O

Base + 6

8-bit Read only Interrupt status register

Base + 5

8-bit Read/Write Status register

Base + 4

8-bit Read/Write

Base + 3

Read 8-bit Index Register

Base + 2

Read 16-bit Data FIFO

Base + 0, 1

DAQ-800 Users Manual 38

ends with Base +F. The actual addressable registers in DAQ-801/802 are more than 16

locations. This is done by using an index register at Base +2. The contents of the index register

will address to different sets of locations when writing to or reading from Base +3. The

following table lists the address map for the DAQ-801/802.

Write 8-bit Scan FIFO

Base +0: Gain for channels 0 - 3

Base +1: Gain for channels 4 - 7

Write 8-bit Index Register

Index 0 Configuration register

1 Interru p t level s election register

2 Auxiliary control register

3 Interrupt enable register

4-7 82C54 timer/counter

Table 5-1. DAQ-800 Series Address Map

Page 39

5.1 Base + 0 / 1, Data FIFO

11

8

1,000

10

4

1000121000

1

1

DAQ-800 Users Manual 39

Read: 16-bit data will be read from the DATA FIFO into the PC. This is a 16-bit

data transfer in 2s complement format.

For positive numbers, the data format is: 0000XXXX XXXXXXXX.

For negative numbers, the data format is: 1111XXXX XXXXXXXX.

Write: Writing to Base +0 will select the gain settings for channels 0 - 3. Writing

to Base +1 will select the gain settings for channels 4 - 7. (See Table 5-2).

Gain value (GN)DAQ-802DAQ-801

Table 5-2. Data FIFO Gain Values

Each channel has 4 different gain selections and therefore two bits are required for each

channel.

Base +0 D7 D6 D5 D4 D3 D2 D1 D0

GN3 GN3 GN

2 GN2

GN

1 GN1 GN0 GN0

Gain selection for CH0 = D1/D0, CH1 = D3/D2, CH2 = D5/D4 and CH3 = D7/D6.

Base +1 D7 D6 D5 D4 D3 D2 D1 D0

GN7 GN7 GN

6 GN6

GN

5 GN5 GN4 GN4

Gain selection for CH4 = D1/D0, CH5 = D3/D2, CH6 = D5/D4 and CH7 = D7/D6.

5.2 Base + 2, Index Register

Write: 00000XXX. Writing a byte to this location sets an index in the index

register. The last 3 bits represent the index number ranging from 0 through 7.

Read: 11111XXX. The last 3 bits is the index number written. Indexing

operation occupies two I/O locations, first writing an index to the index register at address

Base +2. If the index is 0, the next byte written to Base +3 goes to the index 0 register.

Page 40

5.3 Base + 3, Index Registers

DAQ-800 Users Manual 40

After writing to the index register at Base +2, the next write to Base +3 is directed to different

index registers.

Index 0 : Configuration register, X X X X D3 D2 D1 D0, WRITE/READ:

X: not used

D3: 1 -- digital trigger digital signal can come from IP0/external

clock or from IP1/GS0/Trig

(see Base +6, bit D5)

0 -- analog trigger *see example at the end of this chapter

D2: 1 -- single trigger mode / 0 -- continuous mode

D1: 1 -- internal trigger / 0 -- external trigger

D0: 1 -- rising edge trigger / 0 -- trailing edge trigger

Index 1: Interrupt level selection register, D7 D6 D5 D4 X X X X, WRITE/READ:

D7 D6 D5 D4 IRQ Level

0000 disabled

0001 disabled

0010 disabled

0011 IRQ3

0100 IRQ4

0101 IRQ5

0110 IRQ6

0111 IRQ7

1000 disabled

1001 IRQ9

1010 IRQ10

1011 IRQ11

1100 IRQ12

1101 disabled

1110 IRQ14

1111 IRQ15

X not used

Page 41

Index 2: Auxiliary control register, D7 D6 D5 D4 D3 D2 D1 D0, WRITE ONLY:

D7: 1 -- software trigger / 0 -- no software trigger

DAQ-800 Users Manual 41

Index 3: Interrupt enable register, D7 D6 D5 D4 D3 D2 D1 D0, WRITE/READ:

D6: reserved

D5: 1 -- flush data FIFO - reset FIFO pointer / 0 -- no action

D4: 1 -- Full scale calibration uses the status bit at Base +4 to indicate

calibration. When the bit is set, calibration is completed in 5.58ms.

0 -- no action

D3: Setting thi s bit to "1" stops the scan operation i n continuous trig ger

mode. The scan function does not stop immediate l y upon se tti ng the bit to

1, it continues A /D conversion until the scan sequence is completed . A f ter

ceasing operation, continuous mode is remains set waiting for a trigger.

D2: not used

D1: not used

D0: not used

D7: 1 -- global enable (must be 1 for any interrupt) / 0 -- disable

D6: not used

D5: not used

D4: 1 -- timer0 interrupt enable / 0 -- disable

D3: 1 -- external trigger interrupt enable / 0 -- disable

D2: 1 -- FIFO full interrupt enable / 0 -- disable

D1: 1 -- FIFO half full interrupt enable / 0 -- disable

D0: 1 -- end of scan interrupt enable / 0 -- disable

Index 4.7: Read/Write 8254 timer/counter

Index 4: Read/Write timer0/counter0

Index 5: Read/Write timer1/counter1

Index 6: Read/Write timer2/counter2

Index 7: Write control word register of 8254

Page 42

5.4 Base + 4, Status Register

DAQ-800 Users Manual 42

Read: D7 D6 D5 D4 D3 D2 D1 D0

D7: 1 -- end of conversion / 0 -- EOC not finished

D6: 0 -- always 0 bipolar mode

D5: 1 -- auto zero (AZ) / 0 -- no AZ

D4: 1 -- FIFO empty / 0 -- FIFO not empty

D3: 1 -- FIFO half full / 0 -- FIFO not half full

D2: 1 -- FIFO full / 0 -- FIFO not full

D1: 1 -- BUSY. This bit is set to 1 during full scale calibration or

when the scan sequence is not yet completed.

0 -- not busy

D0: 1 -- A/D enable / 0 -- disable

Write: X X D5 X X X X D0

X: not used

D5: 1 -- AZ. Perform auto zero for each A/D conversion. Time

required: 25.6µs (slows the sampling rate if each point uses AZ

calibration).

0 -- no AZ

D0: 1 -- arming A/D conversion, awaiting trigger to start

0 -- disarm

Page 43

5.5 Base + 5 , Interrupt Status Register

D7 D6 D5 D4 D3 D2 D1 D0, READ ONLY:

DAQ-800 Users Manual 43

Read: Interrupt status bit : 1 = interrupt occurred, 0 = no interrupt

D7: not used

D6: not used

D5: not used