Page 1

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

D6000 SERIES

Digital Transmitters,

Modbus RTU, RS-485 Output

Shop online at

omega.com

®

User’s Guide

Extended Warranty

Program

SM

MADE IN

Page 2

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047 USA

Toll Free: 1-800-826-6342 TEL: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico/ En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America: info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/ Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Table of Contents:

1.0 Introduction

2.0 Configuration

2.1 Getting Started

3.0 Communications

3.1 RS-485 Serial

4.0 Module Types

4.1 D6100 Seven Channel Voltage Input Module

4.1.1 Analog to Digital Converter

4.1.2 Connector Pin Assignments

4.1.3 Factory Initial Values

4.1.4 Features Register Assignments

4.1.5 Calibration Procedure

4.2 D6200 Seven Channel Current Input Module

4.2.1 Analog to Digital Converter

4.2.2 Connector Pin Assignments

4.2.3 Factory Initial Values

4.2.4 Features Register Assignments

4.2.5 Calibration Procedure

4.3 D6300 Seven Channel Thermocouple Module

4.3.1 Analog to Digital Converter

4.3.2 Connector Pin Assignments

4.3.3 Factory Initial Values

4.3.4 Features Register Assignments

4.3.5 Calibration Procedure

4.4 D6400 Seven Channel Voltage, Thermocouple, Current Input Module

4.4.1 Analog to Digital Converter

4.4.2 Features Register Assignments

4.4.3 Factory Initial Values

4.4.4 Calibration Procedure

4.4.5 Connector Pin Assignments

4.4.6 D6400 Current Channel Enable

4.5 D6500 Two Channel Analog Output Module

4.5.1 Analog Outputs

4.5.2 Features Register Assignments

4.5.3 Factory Initial Values

4.5.4 Voltage Output Calibration Procedure

4.5.5 Current Output Calibration Procedure

4.5.6 Analog Output Calibration Register Tables and Values

4.6 D6710 Fifteen Bit Digital Input Module

4.6.1 Digital Inputs

4.6.2 Connector Pin Assignments

4.6.3 Factory Initial Values

4.6.4 Features Register Assignments

4.7 D6720 Fifteen Bit Digital Output Module

4.7.1 Digital Outputs

4.7.2 Connector Pin Assignments

4.7.3 Factory Initial Values

4.7.4 Features Register Assignments

4.7.5 Communications Watchdog Timer

1

Page 4

5.0 Modbus Protocol

5.0 Functions

5.1 Function 01 – Read Coil Status

5.2 Function 02 – Read Input Status

5.3 Function 03 – Read Holding Registers

5.4 Function 04 – Read Input Registers

5.5 Function 05 – Force Single Coil

5.6 Function 06 – Preset Single Register

5.7 Function 0F – Force Multiple Coils

5.8 Function 10 – Preset Multiple Registers

6.0 Modbus Exception Error Codes

6.0 Modbus Register Assignments

6.1 Seven Channel Voltage Input Register Assignments

6.2 Seven Channel Current Input Register Assignments

6.3 Seven Channel Thermocouple Input Register Assignments

6.4 Seven Channel Voltage, Thermocouple and Current Input Register Assignments

6.5 Two Channel Analog Voltage and Current Output Register Assignments

6.6 Fifteen Bit Digital Output Register Assignments

6.7 Fifteen Bit Digital Input Register Assignments

7.0 Calibration Procedures

7.1 Seven Channel Voltage Input Module

7.2 Seven Channel Current Input Module

7.3 Seven Channel Thermocouple Input Module

7.4 Seven Channel Voltage, Thermocouple and Current Input Module

7.5 Two Channel Analog Voltage and Current Output Module

7.6 Fifteen Bit Digital Output Module

7.7 Fifteen Bit Digital Input Module

2

Page 5

1.0 Introduction

The D6000 series RS-485 serial interface modules are a complete family of data acquisition

modules. The family of modules includes multi-channel analog input measurement modules,

multiple channel analog output modules, and digital modules.

The D6000 series modules communicate using the Modbus RTU protocol. This protocol very

popular in the data acquisition market and is supported by almost every commercial data

acquisition program in the market today. Thus providing access to wide variety of software control

programs that can meet almost any application budget.

The D6000 series analog input modules contain seven differential analog input channels and can

measure voltages, current, and thermocouples. There are four versions available, the D6100,

D6200, D6300 and the D6400. The D6100 module can measure DC voltage signals. The D6200

module can measure seven 4-20mA current loops. The D6300 series can measure eight userselectable thermocouple types. The D6400 series can measure six selectable voltage input

ranges, one current input range, and eight selectable thermocouple types.

The D6500 series analog output modules contain two output channels for generating either a

voltage or current output signal. Each analog output channel is user-selectable as either a voltage

or a current output. These analog output signals can be used as control inputs for items such as

motor controls, valve controls, and other control devices. Each analog output channel also

contains a programmable communications watchdog timer for instances when communications to

the module is lost.

The D6700 series digital input and output modules each contain 15-bits of input or output. The

digital input modules contain internal pull-ups on each bit for direct connection of dry contact

switches. The digital outputs are open-collector outputs that can be connected up to 30Vdc and

can sink 100mA per bit. The open-collector allows the modules to be used in a wider variety of

control applications. The digital output module also contains a programmable watchdog timer for

instances where communications to the module is lost.

Mixing and matching the D6000 series modules together in an application provides a user with all

the measurement and control hardware for a complete process control system.

3

Page 6

1.0 Configuration & Getting Started

Default Mode

All D6000 series modules contain an EEPROM (Electrically Erasable Programmable Read Only

Memory) to store setup information and calibration constants. The EEPROM replaces the usual

array of switches and pots necessary to specify baud rate, address, parity, etc. The memory is

nonvolatile which means that the information is retained even if power is removed. No batteries

are used so it is never necessary to open the module case.

The EEPROM provides tremendous system flexibility since all of the module’s setup parameters

may be configured remotely through the communications port without having to physically change

switch and pot settings. There is one minor drawback in using EEPROM instead of switches;

there is no visual indication of the setup information in the module. It is impossible to tell just by

looking at the module what the baud rate, address, parity and other settings are. It is difficult to

establish communications with a module whose address and baud rate are unknown. To

overcome this, each module has an input pin labeled DEFAULT*. By connecting this pin to

Ground, the module is put in a known communications setup called Default Mode.

The Default Mode settings are: 9600 baud, one start bit, eight data bits, one stop bit, no parity,

any address is recognized. The module will answer to address “01” in the Default Mode.

Grounding the DEFAULT* pin does not change any of the setups stored in EEPROM. The setup

information may be read back to determine all of the setups stored in the module.

Setup information in a module may be changed at will in the Default Mode. The baud rate and

parity setups may be changed without affecting the Default Mode values of 9600 baud and no

parity. When the DEFAULT* pin is released, the module automatically performs an internal reset

and configures itself to the baud rate and parity stored in the setup information.

The Default Mode should only be used with a single module connected to a computer for the

purpose of identifying and modifying setup values. In most cases, a module in Default Mode may

not be used in a string with other modules.

Communications Connections

The D6000 series module must be connected to a host computer with an RS-485 serial port for

configuration. For computers that contain an internal RS-232 port then the A1000 RS-232 to RS485 serial converter can be used to connect the module to a computer. For computers without

internal serial ports then a USB to RS-485 converter can be used to connect the module to a

computer. The RS-485 serial connections for both devices are detailed below.

A1000 RS-485 Connections

A1000 RS-485 Out Connector D6000 Module Connector

(B) GND GND

(R) +VS +VS

(G) DATA- DATA(Y) DATA+ DATA+

USB to RS-485 Connections

Your USB Connector D6000 Module Connector

Ground GND

Data- DATA-

Data+ DATA+

Note: When using the USB converter a separate power supply will be

required and connected between the +VS and GND terminals.

4

Page 7

DEFAULT Mode Connection

For simplicity, we recommend performing all the setups while in the Default Mode. Place the

D6000 in Default Mode by connecting the DEFAULT* terminal to the GND terminal using a

jumper wire. When the module is in the Default Mode the serial parameters are internally set to:

9600 Baud, 8 data bits, no parity and one stop bit. The module will respond to Modbus Slave

address “01”.

Note: No other wiring connections are required on the analog or digital I/O pins to perform the

module configuration.

1.1 Getting Started

The first step towards “Getting Started” with your D6000 series module is to connect the module

to an RS-485 serial port using the wiring connections above. Included within the wiring

connections is the “Default*” line being connected to the power supply ground. This connection

places the module in the “Default Mode”. The Default Mode forces the module into a known

communications state and is best utilized for configuring the module. The Default Mode serial

communications parameters are: 9600 baud, eight data bits, no parity and one stop bit. The

module will answer to Modbus Slave address “1” (0x01).

The D6000 series modules require a software program to change the setup register values. Since

the modules communicate via the Modbus RTU protocol, a Modbus Master program or the

D6000 series Utility Software will be required to change the module configuration.

The D6000 Series Utility Software is the best program to use when configuring a module. The

utility software reads the module information, displays the information in easy to understand

terms, allows changes to be made via drop-down list boxes and then writes the new values back

to the module. The module parameters can also be stored to disk and recalled at a later date.

The D6000 series Utility Software is provided free of charge on CDROM with a purchase order

and the latest version is always downloadable from www.omega.com. The utility software runs on

Windows based computers. Simply insert the CDROM into the CDROM drive, or download the

Setup.Exe file from the website, and then run the SETUP.EXE installation file. The software will

install and create a menu section called “Omega Utility Software” and the Utility Software will be

under that selection.

From the computer desktop select the “start” button, select “all programs”, select “Omega Utility

Software” and then select “D6000 Series Utility Software” to run the utility software. When the

software opens the first step is to select, configure and open the host serial communications port

where the module is connected.

5

Page 8

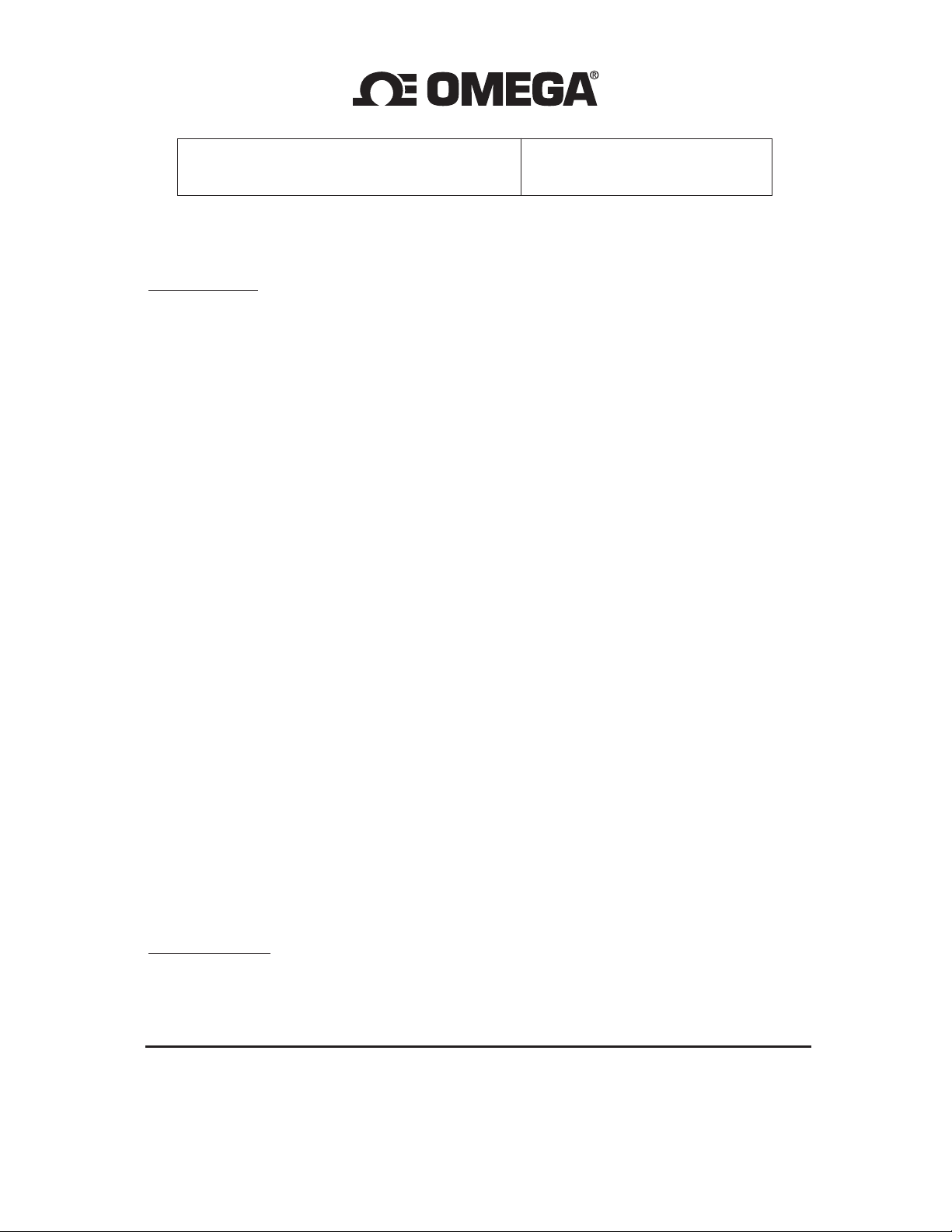

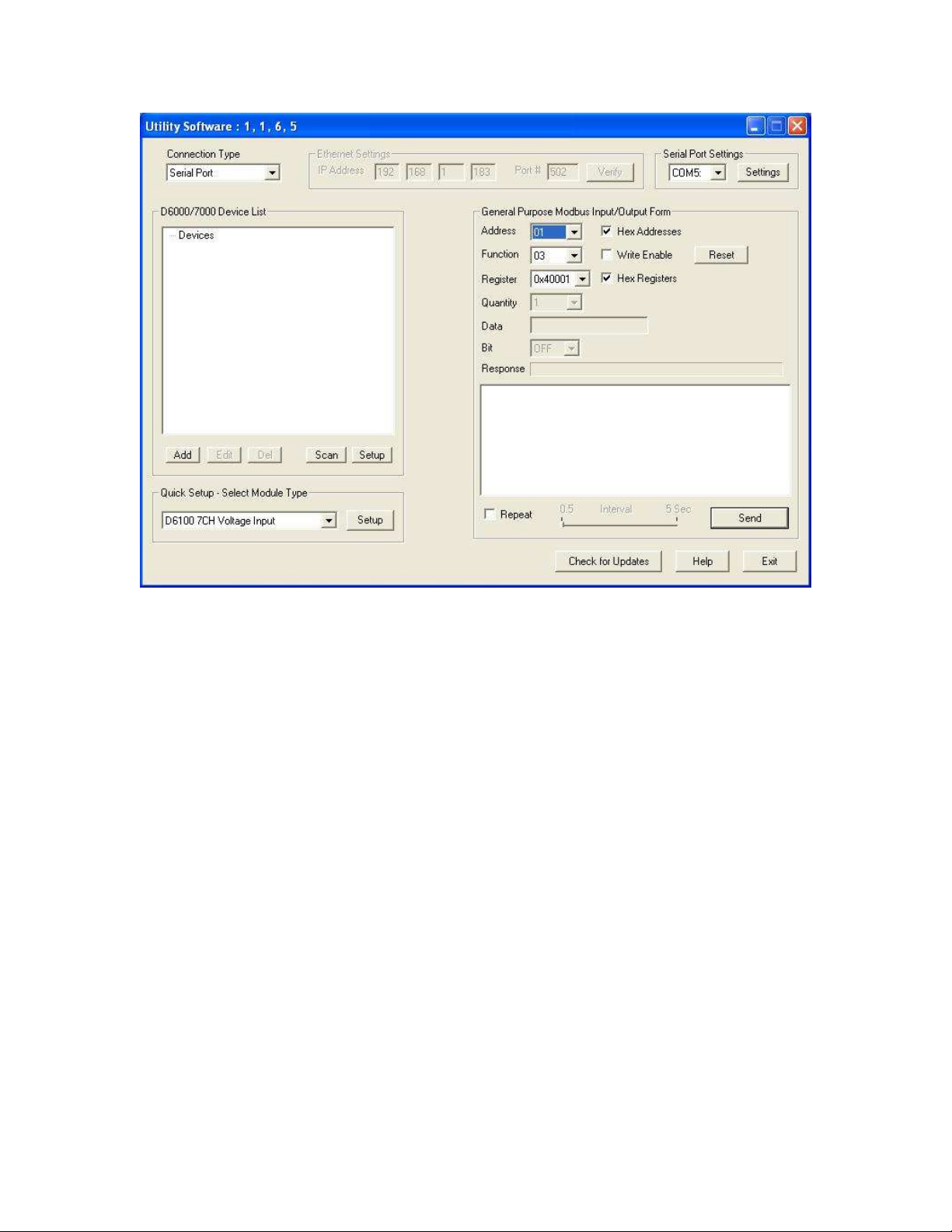

Select the “Serial Port” connection type in the upper left corner of the program screen and then

select the proper communications port in the upper right hand corner of the screen. Next, press

the Serial Port “Settings” button.

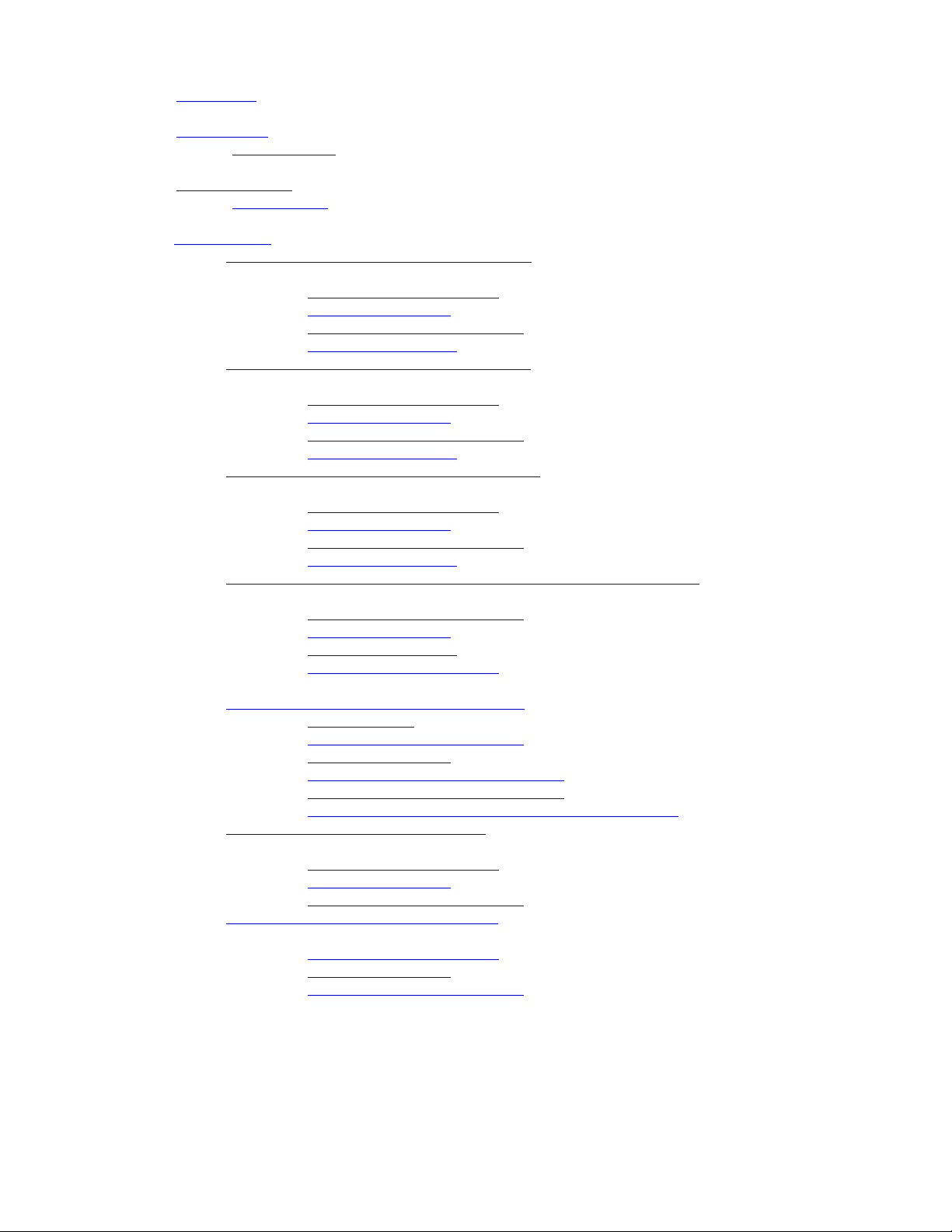

If the “Default*” line is connected to ground then select 9600 baud, no parity, eight data bits, one

stop bit, RTS Only handshaking and the Tx and Rx delays can be left in their default state.

Otherwise, adjust the communications settings to match the settings in the connected module.

Press the “Open Port” or “Update” button to complete the serial port configuration process.

Test Communications

After the utility software serial port has been configured the next step would be to check for valid

communications between the computer and the module. You must have valid communications

with the module before trying to perform the configuration process. To test the communications,

6

Page 9

set the Modbus Address to 01 in the “Default Mode” or set the Modbus Address to match the

setting in the module. Set the Function selector to 03 and the Register selector to 40001. Press

the “Send” button to verify communications. A module response will be shown in the figure below.

The figure above illustrates the Modbus function 03 being sent to Modbus Slave address 01. Both

the command and response messages are displayed beginning with CMD and RSP respectively.

This display format is provided for troubleshooting purposes as it displays each byte of

information being sent to and received from the module. This format can be a good

troubleshooting tool or a way to become familiar with the formatting of the Modbus RTU protocol.

The response data value from register 40001 is located in the RSP: line. The data value returned

is a 16-bit value located in the fourth and fifth bytes in the message (00 01). The “00 01” indicates

that the register value is 0001. From the 7CH Current Input Modbus Register map, register 40001

is the Modbus Slave address value. In the case the module slave address value is read back as

0001.

In the event that the module was not detected by the software then the RSP: line would say

“RSP: Timeout – No Response Detected!”. Several things can contribute to this problem. Some

examples are no power to the module, bad RS-485 wiring connection(s), invalid port settings, or

RS-485 half-duplex handshaking problems all can cause timeout errors. Timeout errors must be

corrected before attempting to configure a module.

Setup a Module

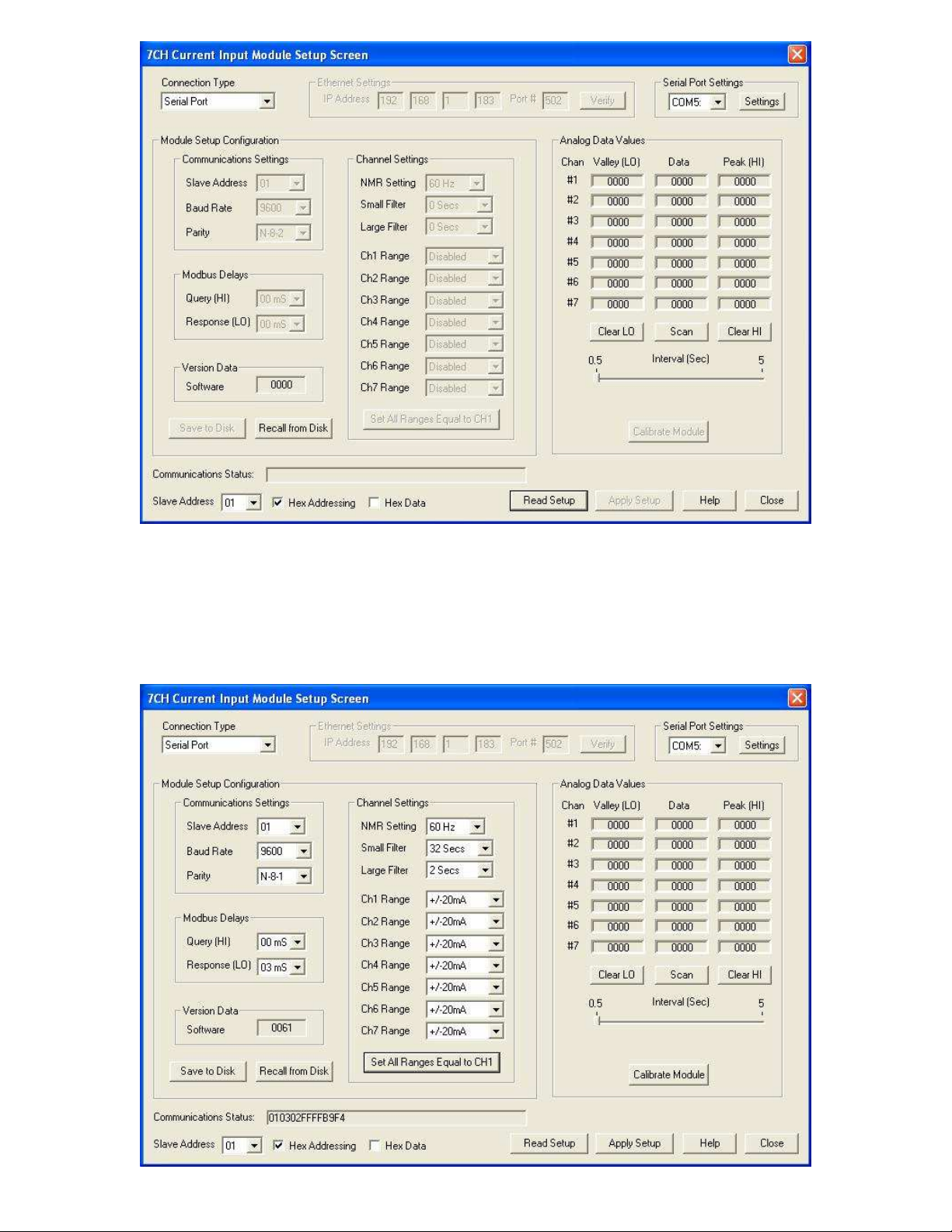

After a successful communications test has been performed then the module can be configured.

Select the type of module using the drop-down list box under “Quick Setup” in the lower left hand

corner of the screen. Then press the “Setup” button. A new screen (see below) will appear that

contains list of all the user-selectable module values. Several different screens can appear. Each

screen is specific to the type of module connected. The screen below is for a seven channel

current input module.

7

Page 10

Ensure that the Module Address in the lower left corner is 01 and then press the “Read Setup”

button. The screen will now populate with the existing configuration data inside the module.

The user-selectable values will be displayed in an easy to understand format and new selections

can be made using the drop-down list boxes. The drop-down list boxes make the configuration

process easy and accurate because erroneous values cannot be entered.

8

Page 11

Once the new module configuration settings have been changed to meet the application

requirements then press the “Apply” button to transmit the new settings.

Scan Module Data Values

After the module has been properly configured, the analog input module configuration screens

can poll modules in order to verify the data from each channel. This feature is a good

troubleshooting or verification tool when the analog input signals are physically connected to the

module.

The analog input screens contain a “Scan” button that will start the scanning process. Each data

channel is read by requesting the data values from data registers within the module. The analog

input data registers can be found in the Modbus Register map and the data register locations are

specific to the module type.

The data values are returned in hexadecimal percentage of Full Scale format where a value of

0x0000 represents the minus full scale input of the module. A value of 0xffff represents the

positive full scale input of the module. These values can be used as check to ensure that the

channels are operating properly when analog input signals are applied to the input terminals.

The data values can also be displayed as a numerical value. The utility software knows the plus

and minus full scale input limits for each channel. Using the raw hexadecimal percentage of full

scale data values the software can convert these readings to millivolts, milliamps, or temperature

readings. Simply uncheck the “Display Hex Values” selection underneath the channel readings to

display the numeric values.

The scanning process will also log and display the highest (peak) and lowest (valley) readings

that were recorded during the scanning process. This is just for indication purposes only.

A scan interval slide control is also provided to speed up or slow down the scanning process. This

slide control allows the channels to be scanned at intervals from 0.5 to 5 seconds.

9

Page 12

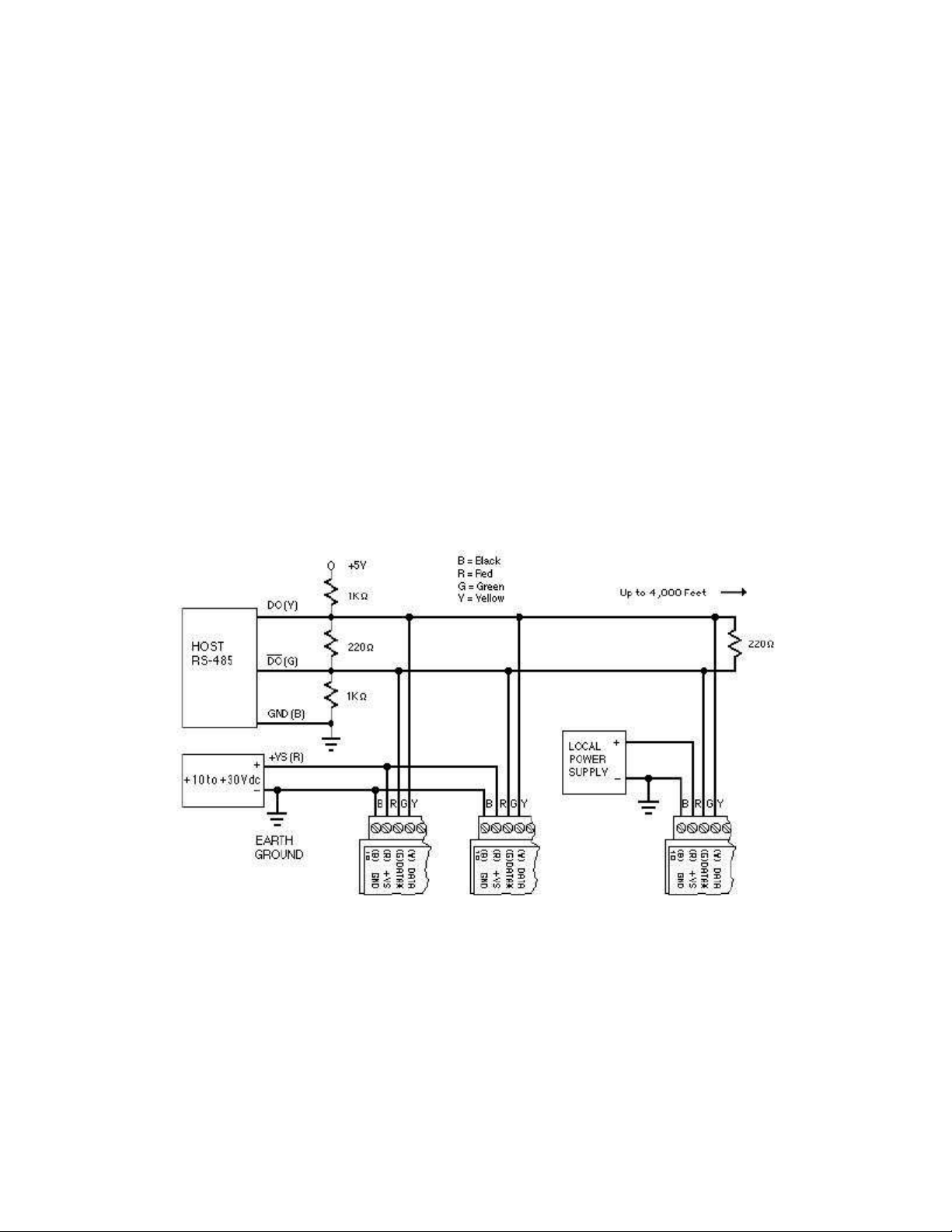

3.0 Communications

Each D6000 series module contains a two-wire RS-485 serial interface for communications. The

RS-485 communications standard was developed to satisfy the need for multi-dropped systems

that can communicate at high data rates over long distances. RS-485 is similar to RS-422 in that

it uses a balanced differential pair of wires switching from 0 to 5V to communicate data. RS-485

receivers can handle common mode voltages from -7V to +12V without loss of data, making them

ideal for transmission over great distances. RS-485 differs from RS-422 by using one balanced

pair of wires for both transmitting and receiving. Since an RS-485 system cannot transmit and

receive at the same time it is inherently a half-duplex system.

RS-485 offers many advantages:

1) balanced line gives excellent noise immunity

2) can communicate with modules at high baud rates

3) communicate at distances up to 4,000 feet.

4) true multi-drop configuration as the modules are connected in parallel

5) individual modules may be disconnected without affecting other modules

6) up to 32 modules on one segment of the communications line; 247 with repeaters

7) simplified wiring using standard telephone cable

Figure 2.0 below illustrates the wiring required for multiple-module RS-485 system. Notice that

every module has a direct connection to the host system. Any number of modules may be

unplugged without affecting the remaining modules. Each module must be setup with a unique

address and the addresses can be in any order. Also note that the connector pins on each

module are labeled with notations (B), (R), (G), and (Y).

Figure 2.0 Typical RS-485 Serial Communications System Architecture

This designates the colors used on standard 4-wire telephone cable:

(B) GND Black Wire

(R) V+ Red Wire

(G) DATA* Green Wire (RS-485 DATA-)

(Y) DATA Yellow Wire (RS-485 DATA+)

This color convention can be used to simplify installation. If standard 4-wire telephone cable is

used, it is only necessary to match the labeled pins with the wire color to guarantee correct

installation. The RS-845 data lines are designated on the label as DATA* and is the complement

of DATA (negative true). To minimize unwanted reflections on the transmission line, the bus

10

Page 13

should be arranged as a line going from one module to the next. ‘Tree’ or random structures of

the transmission line should be avoided. For wire runs greater than 500 feet, each end of the line

should be terminated with a 220 ohm resistor connected between DATA and DATA*.

When using a bi-directional RS-485 system, there are unavoidable periods of time when all

stations on the line are in receive mode. During this time, the communications lines are left

floating and are very susceptible to noise. To prevent the generation of random characters, the

lines should be biased in a MARK condition as shown in Figure 2.0. The 1K resistors are used to

keep the DATA line more positive than the DATA* line when none of the RS-485 communications

transmitters are on.

When enabled, the low impedance of an RS-485 driver easily overcomes the load presented by

the resistors. Special care must be taken with very long busses (greater than 1000 feet) to ensure

error-free operation. Long busses must be terminated as described above. The use of twisted

cable for the DATA and DATA* lines will greatly enhance signal fidelity.

In situations where many modules are used on a long line, voltage drops in the power leads

becomes an important consideration. The GND wire is used both as a power connection and the

common reference for the transmission line receivers in the modules. Voltage drops in the GND

leads appear as a common-mode voltage to the receivers. The receivers are rated for a

maximum of -7Vdc of common-mode voltage. For reliable operation, the common mode voltage

should be kept below -5V. To avoid problems with voltage drops, modules may be powered

locally rather than transmitting the power from the host.

Inexpensive ‘calculator’ type power supplies are useful in remote locations. When local supplies

are used, be sure to provide a ground reference with a third wire to the host or through a good

earth ground. With local supplies and an earth ground, only two wires for the data connections

are necessary.

11

Page 14

4.0 Module Types

The D6000 series RS-485 serial interface modules are a complete family of data acquisition

modules. Mixing and matching the D6000 series modules together in an application provides a

user with all the measurement and control hardware to build a complete process control system.

The family of modules includes multi-channel analog input measurement modules, multiple

channel analog output modules, and digital modules.

D6100 Voltage Input Module

The D6100 series analog input modules contain seven differential inputs for measuring DC

voltages. Each input can be individually configured to measure one of six different voltage

ranges. The input ranges are: +/-0.025V, +/-0.05V, +/-0.10V, +/-1V, +/-5V and +/-10V.

D6200 Current Input Module

The D6200 series analog input module contains seven differential inputs for measuring current

signals such as 4-20mA loops. The analog input range is factory configured for +/-20mA.

D6300 Thermocouple Input Module

The D6300 series analog input module contains seven differential inputs for measuring

thermocouple probes. Each input can be individually configured to measure one of eight different

thermocouple types. The supported thermocouple types are: J, K, T, E, R, S, B and C.

D6400 Voltage, Thermocouple and Current Input Module

The D6400 series analog input module contains seven differential inputs for measuring DC

voltages, thermocouples and current. Each input can be individually configured to measure one of

fourteen different ranges. The supported thermocouple types are: J, K, T, E, R, S, B and C. The

DC voltage input ranges are: +/-0.025V, +/-0.05V, +/-0.10V, +/-1V, +/-5V and +/-10V and the

current input range is +/-20mA.

D6500 Analog Output Module

The D6500 series analog output modules contain two analog output channels for generating

either a voltage or current output signal. Each analog output channel contains two user-selectable

voltage output ranges and two current output ranges. These analog output signals can be used

as control inputs for items such as motor controls, valve controls, and other control devices. Each

analog output channel also contains a programmable communications watchdog timer for

instances when communications to the module is lost.

D6700 Digital Inputs/Output Module

The D6700 series modules each contain 15-bits of digital inputs or digital outputs. The D6710 15bit digital input module contains internal pull-ups on each bit for direct connection to dry contact

switches.

The D6720 digital output modules contain fifteen open-collector outputs that can be connected up

to 30Vdc and can sink 100mA per bit. The open-collector outputs allow the modules to be used in

a wide variety of control applications. The digital output module also contains a programmable

communications watchdog timer for accidental instances where communication to the module is

lost.

12

Page 15

4.1 D6100 - Seven Channel Voltage Input Module

Overview

The D6100 series analog input modules contain seven differential analog inputs that can

measure six different DC voltage ranges. Each analog input channel is user programmable and

may be assigned to measure a different range. Any unused channels can be disabled.

Analog to Digital Converter

The D6100 series analog input modules contain a 16-bit analog to digital converter to perform the

signal conversion to digital information. The analog to digital converter performs a total of 25

conversions per second. Meaning, if all 7 channels were enabled the each channel would be

measured 3+ times per second. The conversion rate per channel can be improved by disabling

any unused channels.

Features and Register Assignments

The D6100 series analog input modules contain many user-selectable features. The user can

select all features such as baud rate, parity type, analog range selection and digital filtering. The

complete list of features is illustrated in the “Seven Analog Voltage Input Register Assignments”

register map below. The register map format is used for consistency with the Modbus RTU

protocol. The register map contains the register numbers in decimal format, register description,

acceptable data values, and list of what each value means. These registers can be written to

using most any Modbus master program or using the D6000 series utility software.

Note: All Modbus Register values in the tables below are represented as “decimal” numbers.

Factory Initial Values

The D6100 series analog module features are initialized at the factory with a set of “Initial

Values”. A complete list of factory “Initial Values” can be found in the table below. For reference

purposes, the Modbus Slave address is preset to hex 0x01, the baud rate is 9600, Parity type is

None and the Stop Bits is “1”.

Calibration

The D6100 series analog input modules are shipped from the factory as fully calibrated devices.

Throughout the lifetime of the module there may be need to verify or adjust the calibration of the

device. The verification and adjustment process should only be completed using NIST traceable

calibration equipment. A D6100 series Calibration procedure is included below.

Connector Pin Designations

The D6100 series module uses two 3.81mm removable plugs for connecting signals to the

module. One six-pin connector is for the power supply and the host RS-485 data line

connections. A second sixteen-pin connector is used to connect analog input signals to the

module. The pin designations for each connector are printed on the module label and are listed in

a table below.

13

Page 16

4.1.2 Seven Voltage Input Pin Assignments and Specifications

Connections

Power & Serial Communications

Pin Number Pin Designator

1 GND - Power Supply

2 +VS + Power Supply

3 Data- RS-485 Data 4 Data+ RS-485 Data+

5 Default* Default*

6 GND - Power Supply

Analog Input Pin Assignments

Pin Number Pin Designator

1 CH1+ CH1 +Input

2 CH1- CH1 -Input

3 CH2+ CH2 +Input

4 CH2- CH2 -Input

5 CH3+ CH3 +Input

6 CH3- CH3 -Input

7 CH4+ CH4 +Input

8 CH4- CH4 -Input

9 CH5+ CH5 +Input

10 CH5- CH5 -Input

11 CH6+ CH6 +Input

12 CH6- CH6 -Input

13 CH7+ CH7 +Input

14 CH7- CH7 -Input

15 ISO. GND Isolated GND

16 ISO. GND Isolated GND

Specifications

Analog Inputs 7 Channels

User Selectable Input Ranges

Bipolar Voltage 10V, 5V, 1V,

Differential Reading

CH to CH

Protocol

Serial Modbus RTU

Power Supply

Voltage +10-30Vdc

Power 1.4W

Connectors

Spacing 3.81mm

Max Wire Size 14-24 AWG

Max Current 8 Amperes

Serial LED Displays

Transmit (Top) Serial TxData

Receive (Bottom) Serial RxData

0.1V, 0.05V,

0.025V

14

Page 17

4.1.3 Seven Voltage Input Initial Values

Module Parameter Value

Slave Address 1

Baud Rate 9600

Parity Type None

Modbus Response Delay 3mS

Modbus Query Delay 0mS

Conversion Rate 60Hz

Large Signal Filter 0 Seconds

Small Signal Filter 0 Seconds

Channel 0 Range +/-10Vdc

Channel 1 Range +/-10Vdc

Channel 2 Range +/-10Vdc

Channel 3 Range +/-10Vdc

Channel 4 Range +/-10Vdc

Channel 5 Range +/-10Vdc

Channel 6 Range +/-10Vdc

15

Page 18

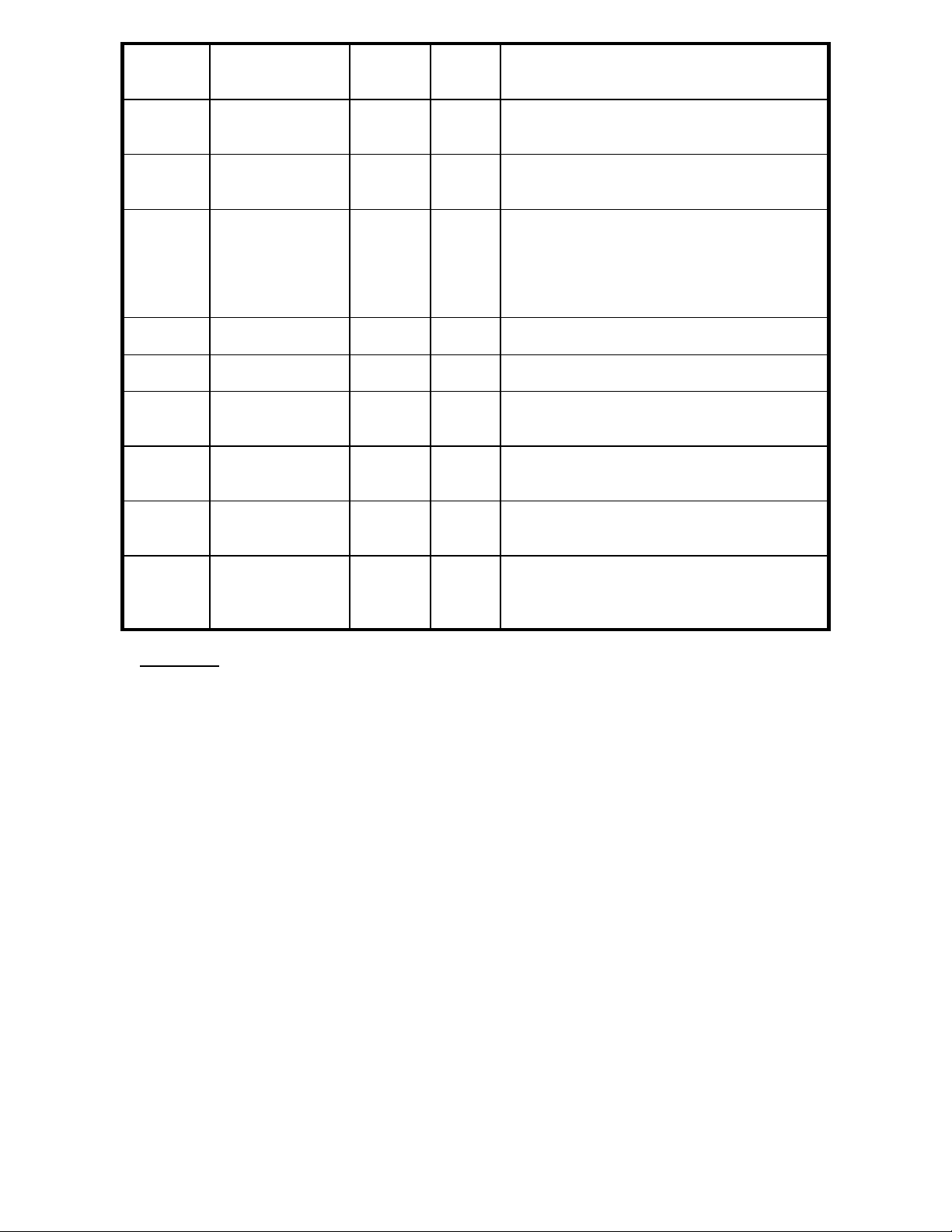

4.1.4 Seven Voltage Input Register Assignments

Register Description Function Value Description

40001 Slave Address R/W 1-DF Factory set to 0x0001.

40002 UART Setup R/W Bits 0-4 Baud Rate

5=9600

6=19.2K

7=38.4K

8=57.6K

9=115.2K

Bits 5-6 Parity

0=No Parity, 8-N-2

1=Odd

2=Even

3=No Parity, 8-N-1

Factory set to 0x0035 = 9600, 8, N, 1.

40003 Modbus Delays R/W 0-303F Bits 0-7

The Response Delay in milliseconds. This is

required when the RS-485 adapter cannot

tri-state immediately after the last character

is transmitted from the host. Maximum value

is 63mS. Factory default value is 3.

Bits 8-15

The End of Query Delay in milliseconds

(48mS max). This is an additional time that

the module will wait prior to marking the end

of the message. Slower host computers may

not be able transmit a continuous message

stream, thereby creating gaps between

characters exceeding the normal 3.5

character times limit. Factory default value is

0.

Factory set, 0x0003.

40033 Software Version R Factory set, Code Version.

40048 Last Converted

Chan,

Conversion

Counter

40049 Channel 0 Data R 0-FFFF Data - Ch 0, Offset binary, zero=0x8000.

40050 Channel 1 Data R 0-FFFF Data - Channel 1

40051 Channel 2 Data R 0-FFFF Data - Channel 2

40052 Channel 3 Data R 0-FFFF Data - Channel 3

40053 Channel 4 Data R 0-FFFF Data - Channel 4

40054 Channel 5 Data R 0-FFFF Data - Channel 5

40055 Channel 6 Data R 0-FFFF Data - Channel 6

R 0-06FF Bits 0-7

The counter increments each conversion and

rolled over after FF. The Conversion Counter

indicates when the data registers have been

updated.

Bits 8-10

Input channel last conversion stored. The

information is useful when all channel data is

read back with 1 query. The user can identify

which channels have been converted since

the last query as long as the time between

queries is less than 8 conversion times.

Initialized to ‘0x0000’ on device reset.

16

Page 19

40095 Misc. Setup R/W 0-1 Bit 0 – Normal Mode Rejection Setting

0 – 60Hz, 25 Hz Conversion Speed.

1 – 50Hz, 20 Hz Conversion Speed.

Factory set to 0x0000.

40096 Signal Filtering R/W 0-3F This register controls all channels. Time

constants are only approximate values.

Bits 0-3 Small Filter Time Constant(Secs)

0 0

1 0.5

2 1

3 2

4 4

5 8

6 16

7 32

Bits 4-7 Large Filter Time Constant(Secs)

0 0

1 0.5

2 1

3 2

4-7 Reserved

Factory set to 0x0000.

40097 Setup Channel 0 R/W 0-F Channel 0 range. Non-volatile write

protected register. If the EEPROM cannot be

written because of not being enabled, it

replies with a Negative Acknowledge

Exception response 07h. Modbus function

code 10h is limited to 4 data values.

Range: Bits 0-7 Hex

Disable Channel 00

+/-10V 01

+/-5V 02

+/-1V 03

+/-0.100V 04

+/-0.050V 05

+/-0.025V 06

Factory set to 0x0001.

40098 Setup Channel 1 R/W 0-F Holds Channel 1 range.

Factory set to 0x0001.

40099 Setup Channel 2 R/W 0-F Holds Channel 2 range.

Factory set to 0x0001.

40100 Setup Channel 3 R/W 0-F Holds Channel 3 range.

Factory set to 0x0001.

40101 Setup Channel 4 R/W 0-F Holds Channel 4 range.

Factory set to 0x0001.

40102 Setup Channel 5 R/W 0-F Holds Channel 5 range.

Factory set to 0x0001.

40103 Setup Channel 6 R/W 0-F Holds Channel 6 range.

Factory set to 0x0001.

40114 Trim Zero, 10V

Range

40115 Trim Zero, 5V

Range

40116 Trim Zero, 1V

Range

WP 0 Forces all Channel Data Registers to 8000h,

with input signal equal to zero. Apply

calibration signal at least 15 seconds prior to

calibrating to all channels. Calibration

Acknowledge Exception Response.

Calibration takes 20 seconds.

WP 0 Refer to Modbus register 40114.

WP 0 Refer to Modbus register 40114.

17

Page 20

40117 Trim Zero, 0.1V

Range

40118 Trim Zero, 0.05V

Range

40119 Trim Zero,

0.025V Range

40146 Trim FS, 10V

Range

40147 Trim FS, 5V

Range

40148 Trim FS, 1V

Range

40149 Trim FS, 0.1V

Range

40150 Trim FS, 0.05V

Range

40151 Trim FS, 0.025V

Range

40241 Control Register

Functions:

R Read Only

R/W Read/Write

WP Write-Protected

WP 0 Refer to Modbus register 40114. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

WP 0 Refer to Modbus register 40114. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

WP 0 Refer to Modbus register 40114. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

WP D000-

FFFE

WP D000-

FFFE

WP D000-

FFFE

WP D000-

FFFE

WP D000-

FFFE

WP D000-

FFFE

W

Forces all Channel Data Registers to written

value, with appropriate input signal. Apply

calibration signal at least 15 seconds prior to

calibrating to all channels. Acknowledge

Exception Response. Calibration takes 20

seconds. See note 1.

See Modbus Register 40146.

See Modbus Register 40146.

See Modbus Register 40146. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

See Modbus Register 40146. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

See Modbus Register 40146. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

0 – Normal operation (NOP)

1 – Remote Reset (write protected)

2 – Write Enable

5 – Initialize Host Communication setup

18

Page 21

4.1.5 Seven Channel Voltage Input Module Calibration Procedure

Required Equipment:

1. Computer running the D6000 Utility Software or another Modbus Master program.

2. A NIST traceable DC Voltage Standard with +/-10Vdc range.

Setup Steps – Perform Calibration Steps in Order Listed:

1. Allow unit to warm up for 15 minutes.

2. Short all the +Input pins together using short jumper wires.

3. Short all the -Input pins together using short jumper wires.

4. Connect the +Input wires to the Positive terminal on the DC voltage calibrator.

5. Connect the -Input wires to the Negative terminal on the DC voltage calibrator.

6. Install the D6000 Utility Software or another Modbus Master Program to communicate

with, and calibrate with the module via serial port or a TCP/IP connection.

Trim Zero:

1. Set the DC calibrator voltage output to +0.0000Vdc.

2. Use the D6000 Utility Software or a Modbus Master program to perform steps #3 & #5.

3. Set all channels to the same range. Start with +/-10Vdc range, work downward as per

values in Table 1.0.

4. Trim Zero on all channels.

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Retrieve Trim Zero register value for specific range from Table 2.0 below.

c. Write value of 0x00h to Range Trim Zero register, (ie. 40114 for +/-10V).

d. Perform steps #4a through #4c to trim zero on each range.

Trim Span:

1. Set the DC calibrator voltage output to +10.000Vdc.

2. Use the D6000 Utility Software or a Modbus Master program to perform steps #3 & #5.

3. Set all channels to the same range. Start with +/-0.025Vdc range, work upward as per

values in Table 3.0.

4. Trim Span on each channel.

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Retrieve Trim Span register value for specific range from Table 2.0 below.

c. Write value of 0xfffe to Trim Span register, (ie. 40146 for +/-10V).

d. Perform steps #4a through #4c to trim span on each range.

19

Page 22

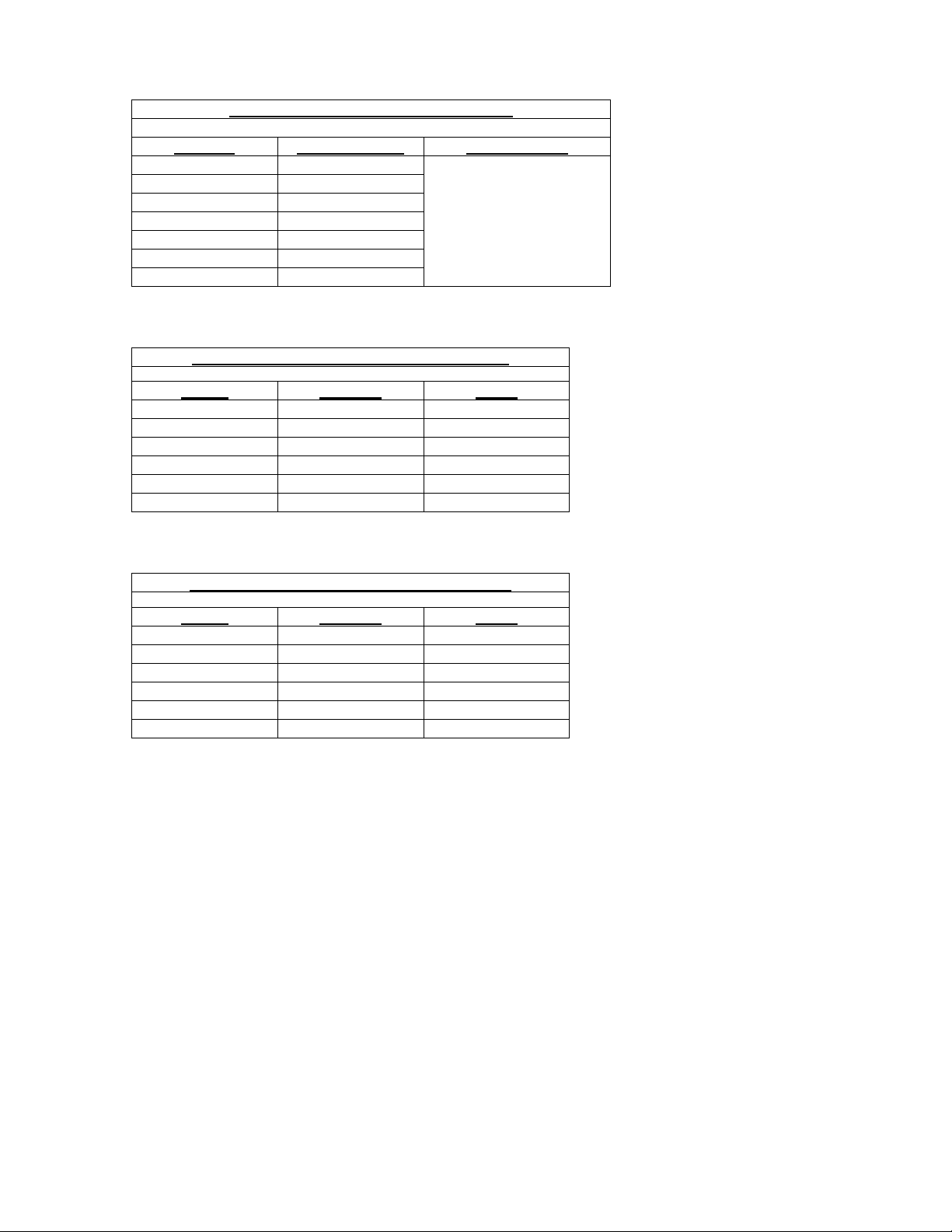

4.1.6 Seven Channel Voltage Input Calibration Tables:

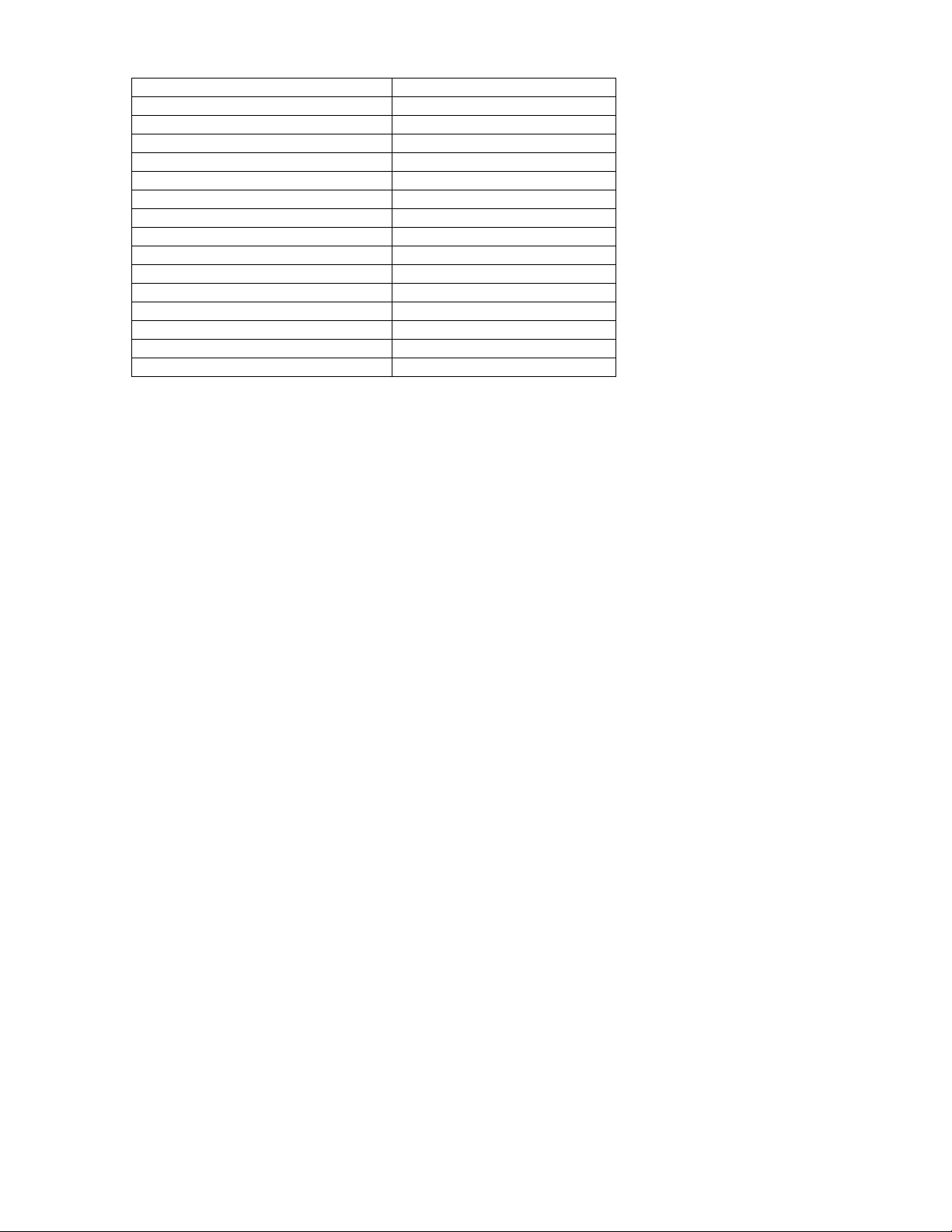

Seven Channel Range Register Values

Channel Range Control Range Values

Channel 0 40097

Channel 1 40098

Channel 2 40099

Channel 3 40100

Channel 4 40101

Channel 5 40102

Channel 6 40103

Table 1.0 Register Setup Values.

00 Disabled

01 +/-10V

02 +/-5V

03 +/-1V

04 +/-0.1V

05 +/-0.05V

06 +/-0.025V

Trim Zero Registers and Calibration Values

Range Register Value

+/-10Vdc 40114 0000

+/-5Vdc 40115 0000

+/-1Vdc 40116 0000

+/-0.1Vdc 40117 0000

+/-0.05Vdc 40118 0000

+/-0.025Vdc 40119 0000

Table 2.0 Trim Zero Registers and Values.

Trim Span Registers and Calibration Values

Range Register Value

+/-0.025Vdc 40151 FFFE

+/-0.05Vdc 40150 FFFE

+/-0.1Vdc 40149 FFFE

+/-1Vdc 40148 FFFE

+/-5Vdc 40147 FFFE

+/-10Vdc 40146 FFFE

Table 3.0 Trim Span Registers and Values.

20

Page 23

4.2 D6200 - Seven Channel Current Input Module

Overview

The D6200 series analog input module contains seven differential analog inputs for measuring

current signals such as 4-20mA loops. Each analog input channel can measure current signals

up to +/-20mA. Any unused channels can be disabled.

Analog to Digital Converter

The D6200 series analog input modules contain a 16-bit analog to digital converter to perform the

signal conversion to digital information. The analog to digital converter performs a total of 25

conversions per second. Meaning, if all 7 channels were enabled the each channel would be

measured 3+ times per second. The conversion rate per channel can be improved by disabling

any unused channels.

Features and Register Assignments

The D6200 series analog input modules contain many user-selectable features. The user can

select all features such as baud rate, parity type, analog range selection and digital filtering. The

complete list of features is illustrated in the “Seven Channel Analog Current Input Register

Assignments” register map below. The register map format is used for consistency with the

Modbus RTU protocol. The register map contains the register numbers in decimal format, register

description, acceptable data values, and list of what each value means. These registers can be

written to using most any Modbus master program or using the D6000 series utility software.

Note: All Modbus Register values in the tables below are represented as “decimal” numbers.

Factory Initial Values

The D6200 series analog module features are initialized at the factory with a set of “Initial

Values”. A complete list of factory “Initial Values” can be found in the table below. For reference

purposes, the Modbus Slave address is preset to hex 0x01, the baud rate is 9600, Parity type is

None and the Stop Bits is “1”.

Calibration

The D6200 series analog input modules are shipped from the factory as fully calibrated devices.

Throughout the lifetime of the module there may be need to verify or adjust the calibration of the

device. The verification and adjustment process should only be completed using NIST traceable

calibration equipment. A D6200 series Calibration procedure is included below.

Connector Pin Designations

The D6200 series module uses two 3.81mm removable plugs for connecting signals to the

module. One six-pin connector is for the power supply and the host RS-485 data line

connections. A second sixteen-pin connector is used to connect analog input signals to the

module. The pin designations for each connector are printed on the module label and are listed in

a table below.

21

Page 24

4.2.2 Seven Channel Current Input Specifications

Connections

Power & Serial Communications

Pin Number Pin Designator

1 GND - Power Supply

2 +VS + Power Supply

3 DATA- RS-485 Data 4 DATA+ RS-485 Data+

5 Default* Default*

6 GND - Power Supply

Analog Input Pin Assignments

Pin Number Pin Designator

1 CH1+ CH1 +Input

2 CH1- CH1 -Input

3 CH2+ CH2 +Input

4 CH2- CH2 -Input

5 CH3+ CH3 +Input

6 CH3- CH3 -Input

7 CH4+ CH4 +Input

8 CH4- CH4 -Input

9 CH5+ CH5 +Input

10 CH5- CH5 -Input

11 CH6+ CH6 +Input

12 CH6- CH6 -Input

13 CH7+ CH7 +Input

14 CH7- CH7 -Input

15 ISO. GND Isolated GND

16 ISO. GND Isolated GND

Specifications

Analog Inputs 7 Channels

Input Range

Current +/-20mA

Differential Reading

CH to CH +/-10Vdc

Protocol

Serial Modbus RTU

Power Supply

Voltage +10-30Vdc

Power 1.4W

Connectors

Spacing 3.81mm

Max Wire Size 14-24 AWG

Max Current 8 Amperes

Serial LED Displays

Transmit (Top) TxData

Receive (Bottom) RxData

22

Page 25

4.2.3 Seven Channel Current Input Module Initial Values

Module Parameter Value

Slave Address 1

Baud Rate 9600

Parity Type None

Modbus Response Delay 3mS

Modbus Query Delay 0mS

Conversion Rate 60Hz

Large Signal Filter 0 Seconds

Small Signal Filter 0 Seconds

Channel 0 Range +/-20mA

Channel 1 Range +/-20mA

Channel 2 Range +/-20mA

Channel 3 Range +/-20mA

Channel 4 Range +/-20mA

Channel 5 Range +/-20mA

Channel 6 Range +/-20mA

23

Page 26

4.2.4 Seven Channel Current Input Register Assignments

Register Description Functions Value Description

40001 Slave Address R/W 1-DF Factory set to 0x0001.

40002 UART Setup R/W Bits 0-4 Baud Rate

5=9600

6=19.2K

7=38.4K

8=57.6K

9=115.2K

Bits 5-6 Parity

0=No Parity, 8-N-2

1=Odd

2=Even

3=No Parity, 8-N-1

Factory set to 0x0035 = 9600, 8, N, 1.

40003 Modbus Delays R/W 0-303F Bits 0-7

The Response Delay in milliseconds. This is

required when the RS-485 adapter cannot

tri-state immediately after the last character

is transmitted from the host. Maximum value

is 63mS. Factory default value is 3.

Bits 8-15

The End of Query Delay in milliseconds

(48mS max). This is an additional time that

the module will wait prior to marking the end

of the message. Slower host computers may

not be able transmit a continuous message

stream, thereby creating gaps between

characters exceeding the normal 3.5

character times limit. Factory default value is

0.

Factory set, 0x0003.

40033 Software Version R Factory set, Code Version.

40048 Last Converted

Chan,

Conversion

Counter

40049 Channel 0 Data R 0-FFFF Data - Ch 0, Offset binary, zero=0x8000.

40050 Channel 1 Data R 0-FFFF Data - Channel 1

40051 Channel 2 Data R 0-FFFF Data - Channel 2

40052 Channel 3 Data R 0-FFFF Data - Channel 3

40053 Channel 4 Data R 0-FFFF Data - Channel 4

40054 Channel 5 Data R 0-FFFF Data - Channel 5

40055 Channel 6 Data R 0-FFFF Data - Channel 6

R 0-06FF Bits 0-7

The counter increments each conversion and

rolled over after FF. The Conversion Counter

indicates when the data registers have been

updated.

Bits 8-10

Input channel last conversion stored. The

information is useful when all channel data is

read back with 1 query. The user can identify

which channels have been converted since

the last query as long as the time between

queries is less than 8 conversion times.

Initialized to ‘0x0000’ on device reset.

24

Page 27

40095 Misc. Setup R/W 0-1 Bit 0 – Normal Mode Rejection Setting

0 – 60Hz, 25 Hz Conversion Speed.

1 – 50Hz, 20 Hz Conversion Speed.

Factory set to 0x0000.

40096 Signal Filtering R/W 0-3F This register controls all channels. Time

constants are only approximate values.

Bits 0-3 Small Filter Time Constant(Secs)

1 0

1 0.5

2 1

3 2

4 4

5 8

6 16

7 32

Bits 4-7 Large Filter Time Constant(Secs)

0 0

1 0.5

2 1

3 2

4-7 Reserved

Factory set to 0x0000.

40097 Setup Channel 0 R/W 0-F Channel 0 range. Non-volatile write

protected register. If the EEPROM cannot be

written because of not being enabled, it

replies with a Negative Acknowledge

Exception response 07h. Modbus function

code 10h is limited to 4 data values.

Range: Bits 0-7 Hex

Disable Channel 00

+/-20mA 03

Factory set to 0x0003.

40098 Setup Channel 1 R/W 0-F Holds Channel 1 range.

Factory set to 0x0003.

40099 Setup Channel 2 R/W 0-F Holds Channel 2 range.

Factory set to 0x0003.

40100 Setup Channel 3 R/W 0-F Holds Channel 3 range.

Factory set to 0x0003.

40101 Setup Channel 4 R/W 0-F Holds Channel 4 range.

Factory set to 0x0003.

40102 Setup Channel 5 R/W 0-F Holds Channel 5 range.

Factory set to 0x0003.

40103 Setup Channel 6 R/W 0-F Holds Channel 6 range.

Factory set to 0x0003.

40116 Trim Zero,

+/-20mA Range

40148 Trim FS,

+/-20mA Range

40241 Control Register

Functions:

R Read Only

R/W Read/Write

WP Write-Protected

WP 0 Force all channel data to 0x8000, input

signal = 0. Wait 15 Secs, Write 0x0000.

WP D000-

FFFE

W

Force all channel data to top of range, Wait

15 Sec, Write value (0xfffe if +F.S.).

0 – Normal operation (NOP)

1 – Remote Reset (write protected)

2 – Write Enable

5 – Initialize Host Communication setup

25

Page 28

4.2.5 Seven Channel Current Input Calibration Procedure

Required Equipment:

1. Computer running the D6000 Utility Software or another Modbus Master program.

2. A NIST traceable DC Current Standard with +/-20mA range.

Setup Steps – Perform Calibration Steps in Order Listed:

1. Allow unit to warm up for 15 minutes.

2. Connect the positive lead of DC current calibrator to Ch1 +Input terminal.

3. Connect the Ch1 –Input terminal the Ch2 +Input terminal.

4. Connect the Ch2 –Input terminal the Ch3 +Input terminal.

5. Connect the Ch3 –Input terminal the Ch4 +Input terminal.

6. Connect the Ch4 –Input terminal the Ch5 +Input terminal.

7. Connect the Ch5 –Input terminal the Ch6 +Input terminal.

8. Connect the Ch6 –Input terminal the Ch7 +Input terminal.

9. Connect the negative lead of the DC current calibrator to Ch7 –Input terminal.

10. Install the D6000 Utility Software or another Modbus Master Program to communicate

with, and calibrate with the module via serial port or a TCP/IP connection.

11. Using the D6000 Utility Software configure all channels for the +/-20mA range using the

data values in Table 1.0 below.

Trim Zero:

1. Set the DC calibrator current output to +0.00mA. Wait 30 seconds.

2. Trim Zero on all channels.

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Trim Zero on all seven channels by writing a value of 0x0000h to Trim Zero

register 40116. See Table 2.0 below.

Trim Span:

1. Set the DC calibrator current output to +20.000mA. Wait 30 seconds.

2. Trim Span on all channels.

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Trim Span on all seven channels by writing a value of 0xfffe to Trim Span register

40148. See Table 3.0 below.

26

Page 29

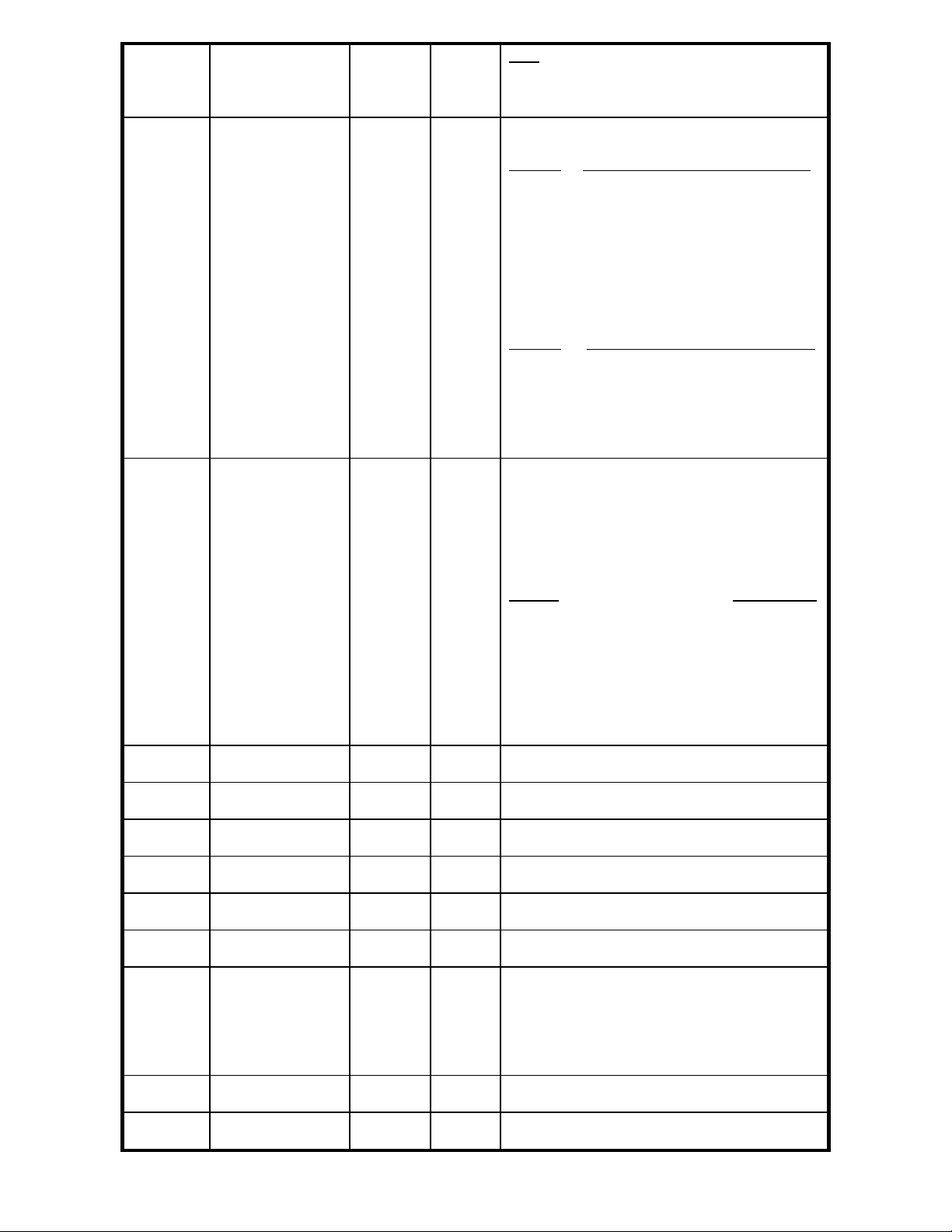

4.2.6 Seven Channel Current Input Calibration Tables:

Seven Channel Current Register Values

Channel Range Control Range Values

Channel 0 40097

Channel 1 40098

Channel 2 40099

Channel 3 40100

Channel 4 40101

Channel 5 40102

Channel 6 40103

Table 1.0 Register Setup Values.

0 = Disabled

3 = +/-20mA

Trim Zero Register and Calibration Value

Range Register

+/-20mA 40116 0000

Table 2.0 Trim Zero Register and Value.

Value

Trim Span Register and Calibration Value

Range Register

+/-20mA 40148 FFFE

Table 3.0 Trim Span Register and Value.

Value

27

Page 30

4.3 D6300 - Seven Channel Thermocouple Input Module

Overview

The D6300 series analog input module contains seven differential inputs for measuring

thermocouple signals. Each analog input channel is user programmable and may be assigned to

measure one of 8 different thermocouple types. The D6300 can measure thermocouple types J,

K, T, E, R, S, B and C. Any unused channels can be disabled.

Analog to Digital Converter

The D6300 series analog input modules contain a 16-bit analog to digital converter to perform the

signal conversion to digital information. The analog to digital converter performs a total of 25

conversions per second. Meaning, if all 7 channels were enabled the each channel would be

measured 3+ times per second. The conversion rate per channel can be improved by disabling

any unused channels.

Features and Register Assignments

The D6300 series analog input modules contain many user-selectable features. The user can

select all features such as baud rate, parity type, analog range selection and digital filtering. The

complete list of features is illustrated in the “Seven Channel Analog Thermocouple Input Register

Assignments” register map below. The register map format is used for consistency with the

Modbus RTU protocol. The register map contains the register numbers in decimal format, register

description, acceptable data values, and list of what each value means. These registers can be

written to using most any Modbus master program or using the D6000 series utility software.

Note: All Modbus Register values in the tables below are represented as “decimal” numbers.

Factory Initial Values

The D6300 series analog module features are initialized at the factory with a set of “Initial

Values”. A complete list of factory “Initial Values” can be found in the table below. For reference

purposes, the Modbus Slave address is preset to hex 0x01, the baud rate is 9600, Parity type is

None and the Stop Bits is “1”.

Calibration

The D6300 series analog input modules are shipped from the factory as fully calibrated devices.

Throughout the lifetime of the module there may be need to verify or adjust the calibration of the

device. The verification and adjustment process should only be completed using NIST traceable

calibration equipment. A D6300 series Calibration procedure is included below.

Connector Pin Designations

The D6300 series module uses two 3.81mm removable plugs for connecting signals to the

module. One six-pin connector is for the power supply and the host RS-485 data line

connections. A second sixteen-pin connector is used to connect analog input signals to the

module. The pin designations for each connector are printed on the module label and are listed in

a table below.

28

Page 31

4.3.2 Seven Channel Thermocouple Input Specifications

Connections

Power & Serial Communications

Pin Number Pin Designator

1 GND - Power Supply

2 +VS + Power Supply

3 DATA- RS-485 Data 4 DATA+ RS-485 Data+

5 Default* Default*

6 GND - Power Supply

Analog Input Pin Assignments

Pin Number Pin Designator

1 CH1+ CH1 +Input

2 CH1- CH1 -Input

3 CH2+ CH2 +Input

4 CH2- CH2 -Input

5 CH3+ CH3 +Input

6 CH3- CH3 -Input

7 CH4+ CH4 +Input

8 CH4- CH4 -Input

9 CH5+ CH5 +Input

10 CH5- CH5 -Input

11 CH6+ CH6 +Input

12 CH6- CH6 -Input

13 CH7+ CH7 +Input

14 CH7- CH7 -Input

15 ISO. GND Isolated GND

16 ISO. GND Isolated GND

Specifications

Analog Inputs 7 Channels

Input Type

Thermocouple J,K,T,E,R,S,B,C

Differential Reading

CH to CH +/-10Vdc

Protocol

Serial Modbus RTU

Power Supply

Voltage +10-30Vdc

Power 1.4W

Connectors

Spacing 3.81mm

Max Wire Size 14-24 AWG

Max Current 8 Amperes

Serial LED Displays

Transmit (Top) TxData

Receive (Bottom) RxData

29

Page 32

4.3.3 Seven Channel Thermocouple Input Module Initial Values

Module Parameter Value

Slave Address 1

Baud Rate 9600

Parity Type None

Modbus Response Delay 3mS

Modbus Query Delay 0mS

Conversion Rate 60Hz

Large Signal Filter 0 Seconds

Small Signal Filter 0 Seconds

Channel 0 Range J-Tc Type

Channel 1 Range J-Tc Type

Channel 2 Range J-Tc Type

Channel 3 Range J-Tc Type

Channel 4 Range J-Tc Type

Channel 5 Range J-Tc Type

Channel 6 Range J-Tc Type

30

Page 33

4.3.4 Seven Channel Thermocouple Input Register Assignments

Register Description Functions Value Description

40001 Slave Address R/W 1-DF Factory set to 0x0001.

40002 UART Setup R/W Bits 0-4 Baud Rate

5=9600

6=19.2K

7=38.4K

8=57.6K

9=115.2K

Bits 5-6 Parity

0=No Parity, 8-N-2

1=Odd

2=Even

3=No Parity, 8-N-1

Factory set to 0x0035 = 9600, 8, N, 1.

40003 Modbus Delays R/W 0-303F Bits 0-7

The Response Delay in milliseconds. This is

required when the RS-485 adapter cannot

tri-state immediately after the last character

is transmitted from the host. Maximum value

is 63mS. Factory default value is 3.

Bits 8-15

The End of Query Delay in milliseconds

(48mS max). This is an additional time that

the module will wait prior to marking the end

of the message. Slower host computers may

not be able transmit a continuous message

stream, thereby creating gaps between

characters exceeding the normal 3.5

character times limit. Factory default value is

0.

Factory set, 0x0003.

40033 Software Version R Factory set, Code Version.

40048 Last Converted

Chan,

Conversion

Counter

40049 Channel 0 Data R 0-FFFF Data - Ch 0, Offset binary, zero=0x8000.

40050 Channel 1 Data R 0-FFFF Data - Channel 1

40051 Channel 2 Data R 0-FFFF Data - Channel 2

40052 Channel 3 Data R 0-FFFF Data - Channel 3

40053 Channel 4 Data R 0-FFFF Data - Channel 4

40054 Channel 5 Data R 0-FFFF Data - Channel 5

40055 Channel 6 Data R 0-FFFF Data - Channel 6

R 0-06FF Bits 0-7

The counter increments each conversion and

rolled over after FF. The Conversion Counter

indicates when the data registers have been

updated.

Bits 8-10

Input channel last conversion stored. The

information is useful when all channel data is

read back with 1 query. The user can identify

which channels have been converted since

the last query as long as the time between

queries is less than 8 conversion times.

Initialized to ‘0x0000’ on device reset.

31

Page 34

40095 Misc. Setup R/W 0-1 Bit 0 – Normal Mode Rejection Setting

0 – 60Hz, 25 Hz Conversion Speed.

1 – 50Hz, 20 Hz Conversion Speed.

Factory set to 0x0000.

40096 Signal Filtering R/W 0-3F This register controls all channels. Time

constants are only approximate values.

Bits 0-3 Small Filter Time Constant(Secs)

2 0

1 0.5

2 1

3 2

4 4

5 8

6 16

7 32

Bits 4-7 Large Filter Time Constant(Secs)

0 0

1 0.5

2 1

3 2

4-7 Reserved

Factory set to 0x0000.

40097 Setup Channel 0 R/W 0-F Channel 0 range. Non-volatile write

protected register. If the EEPROM cannot be

written because of not being enabled, it

replies with a Negative Acknowledge

Exception response 07h. Modbus function

code 10h is limited to 4 data values.

Range: Bits 0-7 Hex

Disable Channel 00

J-Tc (-200-760C) 21

K-Tc (-150-1250C) 22

T-Tc (-200-400C) 23

E-Tc (-100-1000C) 24

R-Tc (+0-1750C) 25

S-Tc (+0-1750C) 26

B-Tc (+0-1820C) 27

C-Tc (+0-2315C) 28

Factory set to 0x0003.

40098 Setup Channel 1 R/W 0-F Holds Channel 1 range.

Factory set to 0x0003.

40099 Setup Channel 2 R/W 0-F Holds Channel 2 range.

Factory set to 0x0003.

40100 Setup Channel 3 R/W 0-F Holds Channel 3 range.

Factory set to 0x0003.

40101 Setup Channel 4 R/W 0-F Holds Channel 4 range.

Factory set to 0x0003.

40102 Setup Channel 5 R/W 0-F Holds Channel 5 range.

Factory set to 0x0003.

40103 Setup Channel 6 R/W 0-F Holds Channel 6 range.

Factory set to 0x0003.

40116 Trim Zero,

+/-20mA Range

40148 Trim FS,

+/-20mA Range

40241 Control Register

WP 0 Force all channel data to 0x8000, input

signal = 0. Wait 15 Secs, Write 0x0000.

WP D000-

FFFE

W

Force all channel data to top of range, Wait

15 Sec, Write value (0xfffe if +F.S.).

0 – Normal operation (NOP)

1 – Remote Reset (write protected)

2 – Write Enable

5 – Initialize Host Communication setup

32

Page 35

4.3.5 Seven Channel Thermocouple Input Calibration Procedure

Required Equipment:

1. Computer running the D6000 Utility Software or another Modbus Master program.

2. A NIST traceable DC Voltage Standard.

Setup Steps – Perform Calibration Steps in Order Listed:

1. Allow unit to warm up for 15 minutes.

2. Connect the positive lead of DC current calibrator to Ch1 +Input terminal.

3. Connect the Ch1 –Input terminal the Ch2 +Input terminal.

4. Connect the Ch2 –Input terminal the Ch3 +Input terminal.

5. Connect the Ch3 –Input terminal the Ch4 +Input terminal.

6. Connect the Ch4 –Input terminal the Ch5 +Input terminal.

7. Connect the Ch5 –Input terminal the Ch6+Input terminal.

8. Connect the Ch6 –Input terminal the Ch7 +Input terminal.

9. Connect the negative lead of the DC current calibrator to Ch7 –Input terminal.

10. Install the D6000 Utility Software or another Modbus Master Program to communicate

with, and calibrate with the module via serial port or a TCP/IP connection.

11. Using the D6000 Utility Software configure all channels for the +/-20mA range using the

data values in Table 1.0 below.

Trim Zero:

1. Set the DC calibrator current output to +0.00mV. Wait 30 seconds.

2. Trim Zero on all channels.

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Trim Zero on all seven channels by writing a value of 0x0000h to Trim Zero

register 40116. See Table 2.0 below.

Trim Span:

1. Set the DC calibrator current output to +20.000mA. Wait 30 seconds.

2. Trim Span on all channels.

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b.

Trim Span on all seven channels by writing a value of 0xfffe to Trim Span register

40148. See Table 3.0 below.

Trim CJC’s:

1. Set the input signal to -----.

2. Set all module channels to the J-Thermocouple range.

3. Use the D6000 Utility Software or a Modbus Master program to perform steps #4 & #5.

4. Trim Zero on each input channel

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Write a value of 0x0000h to register 40114.

5. Apply input signal to each channel from Table x.xx.

a. Wait 1 minute.

b. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

c. Write a value of 0xfffe

33

Page 36

Trim Thermocouples:

1. Set the input signal to -----.

2. Set all module channels to the J-Thermocouple range.

3. Use the D6000 Utility Software or a Modbus Master program to perform steps #4 & #5.

4. Trim Zero on each input channel

a. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

b. Write a value of 0x0000h to register 40114.

5. Apply input signal to each channel from Table x.xx.

a. Wait 1 minute.

b. Write a value of 0x0002h to Control Register 40241 to Write-Enable the module.

c. Write a value of 0xfffe

34

Page 37

4.3.5 Seven Channel Thermocouple Input Calibration Tables:

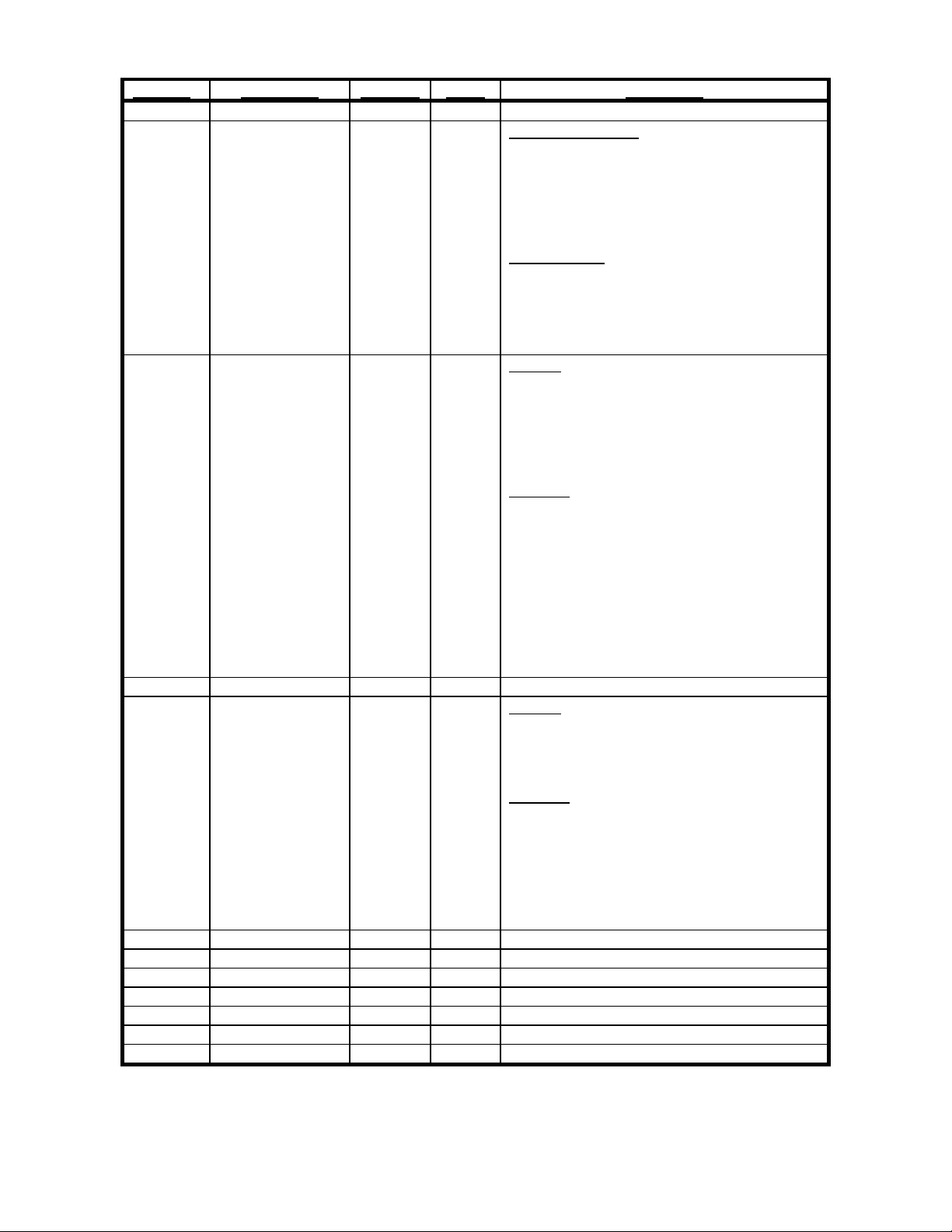

Seven Channel Range Register Values

Channel Range Control Range Values

Channel 0 40097

Channel 1 40098

Channel 2 40099

Channel 3 40100

Channel 4 40101

Channel 5 40102

Channel 6 40103

Table 1.0 Register Setup Values.

00 Disabled

04 +/-0.1V

05 +/-0.05V

06 +/-0.025V

21 J-Type TC

22 K-Type TC

23 T-Type TC

24 E-Type TC

25 R-Type TC

26 S-Type TC

27 B-Type TC

28 C-Type TC

Trim Zero Registers and Calibration Values

Range Register Value

+/-10Vdc 40114 0000

+/-5Vdc 40115 0000

+/-1Vdc 40116 0000

+/-0.1Vdc 40117 0000

+/-0.05Vdc 40118 0000

+/-0.025Vdc 40119 0000

Table 2.0 Trim Zero Registers and Values.

Trim Span Registers and Calibration Values

Range Register Value

+/-0.025Vdc 40151 FFFE

+/-0.05Vdc 40150 FFFE

+/-0.1Vdc 40149 FFFE

+/-1Vdc 40148 FFFE

+/-5Vdc 40147 FFFE

+/-10Vdc 40146 FFFE

Table 3.0 Trim Span Registers and Values.

CJC Calibration Registers and Values

Channels Register Increase Value Decrease Value

0..3 40129 0001 0000

4..6 40130 0001 0000

Table 4.0 Trim CJC Registers and Values.

35

Page 38

4.4 D6400 - Seven Channel Voltage, Thermocouple, Current Input Module

Overview

The D6400 series analog input module contains seven analog inputs for measuring voltages,

thermocouples and current. Each analog input channel is user programmable and may be

assigned to different input types.

When measuring voltages or thermocouples, simply use the Utility Software to select the type of

signal and range. When configuring any channel to measure current loops or 4-20mA signals

then the Input range can be set to either the +/-1Vdc or +/-20mA selections. The module uses the

+/-1Vdc range to measure current up to 20mA.

When measuring current signals then a measurement sense resistor must be enabled via

jumpers inside the module. Each channel has a jumper strip that must be shorted using a

provided shorting bar to enable the sense resistor. The sense resistor is internally connected

directly across the channel+ and channel- input pins. See the D6400 board layout below for

instructions on taking the module and enabling the jumpers.

Analog to Digital Converter

The D6400 series analog input modules contain a 16-bit analog to digital converter to perform the

signal conversion to digital information. The analog to digital converter performs a total of 25

conversions per second. Meaning, if all 7 channels were enabled the each channel would be

measured 3+ times per second. The conversion rate per channel can be improved by disabling

any unused channels.

Features and Register Assignments

The D6400 series analog input modules contain many user-selectable features. The user can

select all features such as baud rate, parity type, analog range selection and digital filtering. The

complete list of features is illustrated in the “Seven Channel Voltage, Thermocouple and Current

Input Register Assignments” register map below. The register map format is used for consistency

with the Modbus RTU protocol. The register map contains the register numbers in decimal format,

register description, acceptable data values, and list of what each value means. These registers

can be written to using most any Modbus master program or using the D6000 series utility

software.

Note: All Modbus Register values in the tables below are represented as “decimal” numbers.

Factory Initial Values

The D6400 series analog module features are initialized at the factory with a set of “Initial

Values”. A complete list of factory “Initial Values” can be found in the table below. For reference

purposes, the Modbus Slave address is preset to hex 0x01, the baud rate is 9600, Parity type is

None and the Stop Bits is “1”.

Calibration

The D6400 series analog input modules are shipped from the factory as fully calibrated devices.

Throughout the lifetime of the module there may be need to verify or adjust the calibration of the

device. The verification and adjustment process should only be completed using NIST traceable

calibration equipment. A D6400 series Calibration procedure is included below.

Connector Pin Designations

The D6400 series module uses two 3.81mm removable plugs for connecting signals to the

module. One six-pin connector is for the power supply and the host RS-485 data line

connections. A second sixteen-pin connector is used to connect analog input signals to the

module. The pin designations for each connector are printed on the module label and are listed in

a table below.

36

Page 39

4.4.1 Seven Channel Voltage, Thermocouple, Current Input Pin Assignments and

Specifications

Connections

Power & Serial Communications

Pin Number Pin Designator

1 GND - Power Supply

2 +VS + Power Supply

3 Data- RS-485 Data 4 Data+ RS-485 Data+

5 Default* Default*

6 GND - Power Supply

Analog Input Pin Assignments

Pin Number Pin Designator

1 CH1+ CH1 +Input

2 CH1- CH1 -Input

3 CH2+ CH2 +Input

4 CH2- CH2 -Input

5 CH3+ CH3 +Input

6 CH3- CH3 -Input

7 CH4+ CH4 +Input

8 CH4- CH4 -Input

9 CH5+ CH5 +Input

10 CH5- CH5 -Input

11 CH6+ CH6 +Input

12 CH6- CH6 -Input

13 CH7+ CH7 +Input

14 CH7- CH7 -Input

15 ISO. GND Isolated GND

16 ISO. GND Isolated GND

Specifications

Analog Inputs 7 Channels

User Selectable Input Ranges

Bipolar Voltage 10V, 5V, 1V,

0.1V, 0.05V,

0.025V

Thermocouple J,K,T,E,R,S,B,C

Current +/-20mA

Differential Reading

CH to CH

Protocol

Serial Modbus RTU

Power Supply

Voltage +10-30Vdc

Power 1.4W

Connectors

Spacing 3.81mm

Max Wire Size 14-24 AWG

Max Current 8 Amperes

Serial LED Displays

Transmit (Top) Serial TxData

Receive (Bottom) Serial RxData

37

Page 40

4.4.2 Seven Channel Voltage, Thermocouple and Current Input Initial Values

Module Parameter Value

Slave Address 1

Baud Rate 9600

Parity Type None

Modbus Response Delay 3mS

Modbus Query Delay 0mS

Conversion Rate 60Hz

Large Signal Filter 0 Seconds

Small Signal Filter 0 Seconds

Channel 1 Range +/-10Vdc

Channel 2 Range +/-10Vdc

Channel 3 Range +/-10Vdc

Channel 4 Range +/-10Vdc

Channel 5 Range +/-10Vdc

Channel 6 Range +/-10Vdc

Channel 7 Range +/-10Vdc

38

Page 41

4.4.3 Seven Channel Voltage, Thermocouple and Current Input Register Assignments

Register Description Functions Value Description

40001 Slave Address R/W 1-DF Factory set to 0x0001.

40002 UART Setup R/W Bits 0-4 Baud Rate

5=9600

6=19.2K

7=38.4K

8=57.6K

9=115.2K

Bits 5-6 Parity

0=No Parity, 8-N-2

1=Odd

2=Even

3=No Parity, 8-N-1

Factory set to 0x0035 = 9600, 8, N, 1.

40003 Modbus Delays R/W 0-303F Bits 0-7

The Response Delay in milliseconds. This is

required when the RS-485 adapter cannot

tri-state immediately after the last character

is transmitted from the host. Maximum value

is 63mS. Factory default value is 3.

Bits 8-15

The End of Query Delay in milliseconds

(48mS max). This is an additional time that

the module will wait prior to marking the end

of the message. Slower host computers may

not be able transmit a continuous message

stream, thereby creating gaps between

characters exceeding the normal 3.5

character times limit. Factory default value is

0.

Factory set, 0x0003.

40033 Software Version R Factory set, Code Version.

40048 Last Converted

Chan,

Conversion

Counter

40049 Channel 1 Data R 0-FFFF Data - Ch 1, Offset binary, zero=0x8000.

40050 Channel 2 Data R 0-FFFF Data - Channel 2

40051 Channel 3 Data R 0-FFFF Data - Channel 3

40052 Channel 4 Data R 0-FFFF Data - Channel 4

40053 Channel 5 Data R 0-FFFF Data - Channel 5

40054 Channel 6 Data R 0-FFFF Data - Channel 6

40055 Channel 7 Data R 0-FFFF Data - Channel 7

R 0-06FF Bits 0-7

The counter increments each conversion and

rolled over after FF. The Conversion Counter

indicates when the data registers have been

updated.

Bits 8-10

Input channel last conversion stored. The

information is useful when all channel data is

read back with 1 query. The user can identify

which channels have been converted since

the last query as long as the time between

queries is less than 8 conversion times.

Initialized to ‘0x0000’ on device reset.

39

Page 42

40095 Misc. Setup R/W 0-1 Bit 0 – Normal Mode Rejection Setting

with

input signal equal to zero. Apply

0 – 60Hz, 25 Hz Conversion Speed.

1 – 50Hz, 20 Hz Conversion Speed.

Factory set to 0x0000.

40096 Signal Filtering R/W 0-3F This register controls all channels. Time

constants are only approximate values.

Bits 0-3 Small Filter Time Constant(Secs)

3 0

1 0.5

2 1

3 2

4 4

5 8

6 16

7 32

Bits 4-7 Large Filter Time Constant(Secs)

0 0

1 0.5

2 1

3 2

4-7 Reserved

Factory set to 0x0000.

40097 Setup Channel 1 R/W 0-F Channel 1 range. Non-volatile write

protected register. If the EEPROM cannot be

written because of not being enabled, it

replies with a Negative Acknowledge

Exception response 07h. Modbus function

code 10h is limited to 4 data values.

Range: Bits 0-7 Hex

Disable Channel 00

+/-10V 01

+/-5V 02

+/-1V 03

+/-0.100V 04

+/-0.050V 05

+/-0.025V 06

J-Tc (-200-760C) 21

K-Tc (-150-1250C) 22

T-Tc (-200-400C) 23

E-Tc (-100-1000C) 24

R-Tc (+0-1750C) 25

S-Tc (+0-1750C) 26

B-Tc (+0-1820C) 27

C-Tc (+0-2315C) 28

+/-20mA Current 03 (Special)

Factory set to 0x0001.

40098 Setup Channel 2 R/W 0-F Holds Channel 2 range.

Factory set to 0x0001.

40099 Setup Channel 3 R/W 0-F Holds Channel 3 range.

Factory set to 0x0001.

40100 Setup Channel 4 R/W 0-F Holds Channel 4 range.

Factory set to 0x0001.

40101 Setup Channel 5 R/W 0-F Holds Channel 5 range.

Factory set to 0x0001.

40102 Setup Channel 6 R/W 0-F Holds Channel 6 range.

Factory set to 0x0001.

40103 Setup Channel 7 R/W 0-F Holds Channel 7 range.

Factory set to 0x0001.

40114 Trim Zero, 10V

Range

WP 0 Forces all Channel Data Registers to 8000h,

40

Page 43

calibration signal at least 15 seconds prior to

calibrating to all channels. Calibration

Acknowledge Exception Response.

Calibration takes 20 seconds.

40115 Trim Zero, 5V

Range

40116 Trim Zero, 1V

Range

40117 Trim Zero, 0.1V

Range

40118 Trim Zero, 0.05V

Range

40119 Trim Zero, 0.025V

Range

40129 Trim CJC 0 WP 0-1 Pre-calibrate appropriate mV range. Attach

40130 Trim CJC 1 WP 0-1 Pre-calibrate appropriate mV range. Attach

40146 Trim FS, 10V

Range

40147 Trim FS, 5V

Range

40148 Trim FS, 1V

Range

40149 Trim FS, 0.1V

Range

40150 Trim FS, 0.05V

Range

40151 Trim FS, 0.025V

Range

40241 Control Register

Functions:

R Read Only

R/W Read/Write

WP Write-Protected

WP 0 Refer to Modbus register 40072.

WP 0 Refer to Modbus register 40072.

WP 0 Refer to Modbus register 40072. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

WP 0 Refer to Modbus register 40072. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

WP 0 Refer to Modbus register 40072. Apply

calibration signal at least 1 minute prior to

calibrating to all channels.

thermocouple to channel 1, with

measurement end in ice bath. Writing a 1 will

increase Modbus TC output. Writing a 0 will

decrease Modbus TC output.

No Trim for R, S, B, C Types.

thermocouple to channel 5, with