Page 1

M789-038A 15 June 1999

Page 2

OMEGA Model CYD201/CYD208 User’s Manual

WARRANTY

OMEGA warrants this unit to be free of defects in materials and workmanship and to give

satisfactory service for a period of 13 months from date of purchase. OMEGA Warranty adds an

additional one (1) month grace period to the normal one (1) year product warranty to cover handling

and shipping time. This ensures that our Customers receive maximum coverage on each product. If

the unit should malfunction, it must be returned to the factory for evaluation. Our Customer Service

Department will issue an Authorized Return (AR) Number immediately upon phone or written

request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or

replaced at no charge. However, this WARRANTY is VOID if the unit shows evidence of having

been tampered with or shows evidence of being damaged as a result of excessive current, heat,

moisture, vibration, or misuse. Components which wear or which are damaged by misuse are not

warranted. These include contact points, fuses, and triacs.

THERE ARE NOT WARRANTIES EXCEPT AS STATED HEREIN. THERE ARE NO OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND OF F ITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL OMEGA ENGINEERING, INC. BE LIABLE FOR CONSEQUENTIAL,

INCIDENTAL, OR SPECIAL DAMAGES. THE BUYER'S SOLE REMEDY FOR ANY BREACH OF

THIS AGREEMENT BY OMEGA ENGINEERING, INC. , OR ANY BREACH OF ANY WARRANTY

BY OMEGA ENGINEERING, INC., SHALL NOT EX CEED THE PURCHASE PRICE PAID BY THE

PURCHASE TO OMEGA ENGINEERING, INC. FOR THE UNIT OR UNITS OR EQUIPMENT

DIRECTLY AFFECTED BY SUCH BREACH.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

Call toll free in the USA and Canada: 1-800-622-2378; FAX: 203-359-7811.

International:

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA,

(AR) NUMBER FROM OUR CUSTOMER SERVICE DEPARTMENT IN ORDER TO AVOID

PROCESSING DELAYS

return package and on any correspondence.

FOR WARRANTY RETURNS:

OMEGA:

1. P.O. Number under which the product was PURCHASED.

2. Model and serial number of the product under warranty.

3. Repair instruction and/or specific problems you are having with the product.

FOR NON-WARRANTY REPA IRS OR CALIB4RATIONS:

repair/calibration charges. Have the following information BEFORE contacting OMEGA:

1. Your P.O. Number to cover COST of the repair/calibration..

2. Model and serial number of the product under warranty.

3. Repair instruction and/or specific problems you are having with the product.

Every precaution for accuracy has been taken in the preparation of this manual, however, OMEGA

ENGINEERING, INC. neither assumes responsibility for any omissions or errors that may appear

nor assumes liability for any damages that result from the use of the products in accordance with

the information contained in the manual.

OMEGA policy is to make running changes, not model changes, whenever an improvement is

possible. That way, our Customers get the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

203-359-1660; FAX; 203-359-7806.

OBTAIN AN AUTHORIZED RETURN

. The assigned AR number should then be marked on the outside of the

Please have the following information available BEFORE contacting

Consult OMEGA for current

© 1998 and 1999 OMEGA ENGINEERING, INC. All rights reserved including illustrations. Nothing

in this manual may be reproduced in any manner, either wholly or in part for any purpose

whatsoever without written permission from OMEGA ENGINEERING, INC. Printed in U.S.A.

A

Page 3

OMEGA Model CYD201/CYD208 User’s Manual

TABLE OF CONTENTS

Chapter/Paragraph Title Page

1 INTRODUCTION..........................................................................1-1

1.0 General.......................................................................1-1

1.1 Model CYD201/CYD208 System Description.............1-1

1.2 Handling Liquid Helium and Liquid Nitrogen..............1-3

1.2.1 Handling Cryogenic Storage Dewars......................1-3

1.2.2 LHe and LN

1.2.3 Recommended First Aid .........................................1-4

1.3 Electrostatic Discharge...............................................1-4

1.3.1 Identifying ESDS Components ...............................1-5

1.3.2 Handling ESDS Components..................................1-5

1.4 Safety Summary.........................................................1-5

1.5 Safety Symbols...........................................................1-6

2 INSTALLATION...........................................................................2-1

2.0 General.......................................................................2-1

2.1 Inspection and Unpacking..........................................2-1

2.2 Repackaging For Shipment........................................2-1

2.3 Power and Ground Requirements..............................2-2

2.4 Sensor Installation Recommendations.......................2-2

2.4.1 Two-Lead Vs. Four-Lead Measurements................2-3

2.4.2 Connecting Leads to the Sensor.............................2-4

2.4.3 Sensor Mounting.....................................................2-4

2.4.4 Measurement Errors Due to AC Noise....................2-5

2.5 Sensor Input Connections..........................................2-6

2.6 Sensor Curve Definition..............................................2-7

2.7 Rack Mounting............................................................2-7

2.8 Initial Power Up Sequence.........................................2-9

2.9 Power Up Errors.........................................................2-9

Safety Precautions............................1-3

2

3 OPERATION................................................................................3-1

3.0 General.......................................................................3-1

3.1 Units Key....................................................................3-1

3.2 Channel Key (Model CYD208 Only)...........................3-2

3.3 Scan Mode .................................................................3-2

3.4 Setting Dwell Times....................................................3-2

3.5 Alarm Operation .........................................................3-2

3.5.1 Alarm Setpoint ........................................................3-2

3.5.2 Latched and Unlatched Alarms...............................3-3

3.5.3 Alarm Fix Function (Model CYD208 Only)..............3-3

3.6 SoftCal™ Compensations..........................................3-3

3.6.1 SoftCal™ Calibration Procedure.............................3-4

3.6.2 Verifying SoftCal™ Operation.................................3-5

3.6.3 Erasing SoftCal™ Compensations .........................3-5

Table of Contents i

Page 4

OMEGA Model CYD201/CYD208 User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

4 REMOTE OPERATION................................................................4-1

4.0 General.......................................................................4-1

4.1 Serial Interface ...........................................................4-1

4.1.1 Serial Interface Connections...................................4-1

4.1.2 Serial Interface Operation.......................................4-3

4.1.3 Sample Basic Program ...........................................4-3

4.1.4 Sample QuickBasic 4.0 Program............................4-4

4.2 Serial Interface Command Summary..........................4-4

5 SERVICE......................................................................................5-1

5.0 General.......................................................................5-1

5.1 Model CYD201 Rear Panel Connections ...................5-1

5.2 Model CYD208 Rear Panel Connections ...................5-2

5.3 Error Code Troubleshooting .......................................5-3

5.4 General Maintenance.................................................5-3

5.5 Fuse Replacement .....................................................5-4

5.6 Line Voltage Configuration.........................................5-4

5.7 Recalibration...............................................................5-5

5.7.1 Current Source Calibration......................................5-5

5.7.2 A/D Converter Calibration.......................................5-6

5.8 Serial Interface Cable and Adapters...........................5-6

6 OPTIONS AND ACCESSORIES..................................................6-1

6.0 General.......................................................................6-1

6.1 Accessories................................................................6-1

6.2 Wires ..........................................................................6-2

6.3 Sensors ......................................................................6-3

APPENDIX A – CURVE TABLES...................................................... A-1

A1.0 General......................................................................A-1

ii Table of Contents

Page 5

OMEGA Model CYD201/CYD208 User’s Manual

LIST OF ILLUSTRATIONS

Figure No. Title Page

1-1 Typical Cryogenic Dewar..........................................................1-3

2-1 Model CYD201 Sensor Connector J1 Details...........................2-6

2-2 Model CYD208 Sensor Connector J1 Details...........................2-6

2-3 Model 2090 Rack Mounting......................................................2-8

3-1 Model CYD201 Front Panel......................................................3-1

3-2 Model CYD208 Front Panel......................................................3-1

4-1 Serial I/O (RJ-11) Connector Pin Definitions............................4-2

4-2 Serial Interface Connections.....................................................4-2

5-1 Model CYD201 Rear Panel Connections..................................5-1

5-2 Model CYD208 Rear Panel Connections..................................5-2

5-3 Line Voltage Jumper Configuration ..........................................5-4

5-4 Calibration Connections............................................................5-5

5-5 Model CYD200-J10 RJ-11 Cable Assembly Wiring Details......5-6

5-6 Model CYD200-D RJ-11 to DB-25 Adapter Wiring Details.......5-6

5-7 Model CYD200-B RJ-11 to DE-9 Adapter Wiring Details .........5-3

6-1 Serial Interface Adapters..........................................................6-3

LIST OF TABLES

Table No. Title Page

1-1 Model CYD201/CYD208 Specifications....................................1-2

2-1 Line Voltage and Fuse Rating Selection...................................2-2

2-2 Model CYD201/CYD208 Temperature Curves.........................2-7

4-1 Serial Interface Specifications ..................................................4-1

A-1 Curve 0 - DT-500DI-8B Voltage-Temp. Characteristics........... A-1

A-2 Curve 1 - DT-500DI-8A Voltage-Temp. Characteristics........... A-2

A-3 Curve 2 - DT-500DRC-D Voltage-Temp. Characteristics ........ A-3

A-4 Curve 3 - DT-500DRC-E1 Voltage-Temp. Characteristics.......A-4

A-5 Curve 4 - CTI Diode Voltage-Temp. Characteristics................ A-5

A-6 Curve 5 - DT-500DI-8C Voltage-Temp. Characteristics .......... A-6

A-7 Curve 6 - CY-7 Voltage-Temp. Characteristics........................A-7

Table of Contents iii

Page 6

OMEGA Model CYD201/CYD208 User’s Manual

This Page Intentionally Left Blank

iv Table of Contents

Page 7

OMEGA Model CYD201/CYD208 User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

This chapter covers a general description of the Model CYD201/CYD208

(Paragraph 1.1), Handling Liquid Helium and Liquid Nitrogen (Paragraph 1.2),

Electrostatic Discharge (Paragraph 1.3), Safety Summary (Paragraph 1.4),

and Safety Symbols (Paragraph 1.5).

Due to the OMEGA commitment to continuous product improvement,

modifications may occur to the Model CYD201/CYD208 software with time.

Some of these changes result from Customer feedback about operation on

various cryogenic systems. We encourage comments or suggestions

regarding this instrument. Please return the instrument warranty card to

ensure receipt of future software updates.

1.1 MODEL CYD201/CYD208 GENERAL DESCRIPTION

Model CYD201/CYD208 Digital Thermometers are ideal to monitor critical

temperatures in chemical and materials research, superconductivity

measurements, and low temperature physics. The units feature:

• Broad Temperature Range: 1.4 K to 475 K (–272 °C to 202 °C).

• Single Channel (CYD201) and Eight Channel (CYD208) Models.

• For use with CY-7 Series, DT-500 Series, and other Silicon Diode

Sensors.

• System Accuracy (Instrument with Sensor) with SoftCal™ to within

±0.1 °C or better.

• Temperature display in °C, °F, K, or Sensor Voltage.

• High/Low Alarm Setpoint with Interfacing Alarm Contacts.

• Standard RS-232C Output of Temperature, Input of Settings, and

Alarm Status for Remote Operation.

Introduction 1-1

Page 8

OMEGA Model CYD201/CYD208 User’s Manual

Table 1-1. Model CYD201/CYD208 Specifications

Display:

Resolution:

Four-digit LED display

0.1 for values > 100 or < –100

0.01 for values between -100<T<100

Temperature Range:

1.4 K to 475 K without probe

23 K to 473 K with probe

System Accuracy:

To within ±0.1K from 177 K to 313 K.

To ±0.2 K or better from 30 K to 373 K.

±1.0 K above 373 K.

Sensor Excitation:

Repeatability:

Input Range:

Hi/Lo Alarm Setpoint:

Alarm Relay:

10 µA constant current

<50 mK

0 to 3 volts with a resolution of 0.1 mV

0.1° resolution

Single SPDT relay, rated 28 VDC or Peak AC, 0.25 A

(3 W max.)

Scan/Dwell:

The Model CYD208 automatically scans all eight channels

with selectable dwell times of 0 (skip), 5, 10, 30 and 60

seconds for each channel.

Connections:

Response Curves*:

Four-lead sensor connection (2 current, 2 voltage).

Standard Curve 10, DT-500DI-8A

(also -8B and -8C), DT-500DRC-D,

DT-500DRC-E1, and CTI Curve C.

* SOFTCAL™ qualified only for CY-7 Series diode sensors.

COMPUTER INTERFACE

Type:

RS-232C Serial Three Wire (Refer to Table 4-1).

MECHANICAL

Ambient Temperature Range:

18 to 28 °C (64 to 82 °F),

or 15 to 35 °C (59 to 95 °F) with reduced accuracy.

Power Requirements:

Dimensions:

Weight:

41 x 106 x 164 mm (1.61 x 4.18 x 6.45 inches).

0.5 kilogram (1.1 Pounds)

90-125 or 210-250 VAC, 50/60 Hz, 3 watts.

NOTES

Product Specifications subject to c hange without notice.

1.

System electronic temperature accurac y in a gi ven temperature range is the

2.

sum of the specifications given for input and out put. Sensor calibration errors

are not included.

1-2 Introduction

Page 9

OMEGA Model CYD201/CYD208 User’s Manual

1.2 HANDLING LIQUID HELIUM AND LIQUID NITROGEN

Helium and Nitrogen are colorless, odorless, and tasteless gases. They

liquefy when properly cooled. Liquid helium (LHe) and liquid nitrogen (LN

)

2

may be used in conjunction with the Model CYD201 or CYD208. Although

not explosive, there are certain safety considerations in the handling of LHe

and LN

.

2

1.2.1 Handling Cryogenic Storage Dewars

Operate all cryogenic containers (dewars) in

accordance with manufacturer instructions. Safety

instructions are normally posted on the side of

each dewar. Keep cryogenic dewars in a wellventilated place, protected from the weather, and

away from heat sources. Figure 1-1 shows a

typical cryogenic dewar.

1.2.2 LHe and LN2 Safety Precautions

Transfer LHe and LN2 and operate storage dewar

controls in accordance with manufacturer/supplier

instructions. During transfer, follow all safety

precautions written on the storage dewar and

recommended by the manufacturer.

WARNING

• Liquid helium is a potential asphyxiant and can cause rapid

suffocation without warning. Store and use in an adequately

ventilated area. DO NOT vent the container in confined spaces. DO

NOT enter confined spaces where gas may be present unless area

is well-ventilated. If inhaled, remove to fresh air. If not breathing,

give artificial respiration. If breathing is difficult, give oxygen. Get

medical attention.

• Liquid helium can cause severe frostbite to exposed body parts. DO

NOT touch frosted pipes or valves. For frostbite, consult a

physician immediately. If a physician is unavailable, warm the

affected parts with water that is near body temperature.

Two essential safety aspects of handling LHe are adequate ventilation and

eye and skin protection. Although helium and nitrogen gases are non-toxic,

they are dangerous because they replace air in a normal breathing

atmosphere. Liquid helium is an even greater threat because a small

amount of liquid evaporates to create a large amount of gas. Store and

operate cryogenic dewars in open, well-ventilated areas.

Figure 1-1. Typical

NON-

MAGNETIC

NON-

LIQUID

FLAMMABLE

HELIUM

KEEP

UPRIGHT

Cryogenic Dewar

Introduction 1-3

Page 10

OMEGA Model CYD201/CYD208 User’s Manual

When transferring LHe and LN2, protect eyes and skin from accidental

contact with liquid or the cold gas issuing from it. Protect eyes with full face

shield or chemical splash goggles; safety glasses (even with side shields)

are inadequate. Always wear special cryogenic gloves (Tempshield

Cryo-Gloves

®

or equivalent) when handling anything that is, or may have

been, in contact with the liquid or cold gas, or with cold pipes or equipment.

Wear long sleeve shirts and cuffless trousers long enough to prevent liquid

from entering shoes.

1.2.3 Recommended First Aid

Post an appropriate Material Safety Data Sheet (MSDS) obtained from the

manufacturer/distributor at every site that stores and uses LHe and LN

MSDS specifies symptoms of overexposure and first aid.

If a person exhibits symptoms of asphyxia such as headache, drowsiness,

dizziness, excitation, excessive salivation, vomiting, or unconsciousness,

remove to fresh air. If breathing is difficult, give oxygen. If breathing stops,

give artificial respiration. Call a physician immediately.

If exposure to cryogenic liquids or cold gases occurs, restore tissue to

normal body temperature (98.6°F) by bathing it in warm water not exceeding

105 °F (40 °C). DO NOT rub the frozen part, either before or after

rewarming. Protect the injured tissue from further damage and infection and

call a physician immediately. Flush exposed eyes thoroughly with warm

water for at least 15 minutes. In case of massive exposure, remove clothing

while showering with warm water. The patient should not drink alcohol or

smoke. Keep warm and rest. Call a physician immediately.

. The

2

1.3 ELECTROSTATIC DISCHARGE

Electrostatic Discharge (ESD) may damage electronic parts, assemblies,

and equipment. ESD is a transfer of electrostatic charge between bodies at

different electrostatic potentials caused by direct contact or induced by an

electrostatic field. The low-energy source that most commonly destroys

Electrostatic Discharge Sensitive (ESDS) devices is the human body, which

generates and retains static electricity. Simply walking across a carpet in

low humidity may generate up to 35,000 volts of static electricity.

Current technology trends toward greater complexity, increased packaging

density, and thinner dielectrics between active elements, which results in

electronic devices with even more ESD sensitivity. Some electronic parts

are more ESDS than others. ESD levels of only a few hundred volts may

damage electronic components such as semiconductors, thick and thin film

resistors, and piezoelectric crystals during testing, handling, repair, or

assembly. Discharge voltages below 4000 volts cannot be seen, felt, or

heard.

1-4 Introduction

Page 11

OMEGA Model CYD201/CYD208 User’s Manual

1.3.1 Identifying ESDS Components

Below are some industry symbols used to label components as ESDS:

1.3.2 Handling ESDS Components

Observe all precautions necessary to prevent damage to ESDS components

before installation. Bring the device and everything that contacts it to ground

potential by providing a conductive surface and discharge paths. At a

minimum, observe these precautions:

1.

De-energize or disconnect all power and signal sources and loads used

with unit.

2.

Place unit on a grounded conductive work surface.

3.

Ground technician through a conductive wrist strap (or other device)

using 1 M series resistor to protect operator.

4.

Ground any tools, such as soldering equipment, that will contact unit.

Contact with operator's hands provides a sufficient ground for tools that

are otherwise electrically isolated.

5.

Place ESDS devices and assemblies removed from a unit on a

conductive work surface or in a conductive container. An operator

inserting or removing a device or assembly from a container must

maintain contact with a conductive portion of the container. Use only

plastic bags approved for storage of ESD material.

6.

Do not handle ESDS devices unnecessarily or remove from the

packages until actually used or tested.

1.4 SAFETY SUMMARY

Observe these general safety precautions during all phases of instrument

operation, service, and repair. Failure to comply with these precautions or

with specific warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended instrument use. OMEGA assumes no

liability for Customer failure to comply with these requirements.

Ground The Instrument

To minimize shock hazard, connect instrument chassis and cabinet to an

electrical ground. The instrument comes with a 3-conductor AC power

cable. Plug it into an approved three-contact electrical outlet or use a threecontact adapter with the green ground wire firmly secured to an electrical

ground (safety ground) at the power outlet. The power cable jack and

mating plug meet Underwriters Laboratories (UL) and International

Electrotechnical Commission (IEC) safety standards.

Introduction 1-5

Page 12

OMEGA Model CYD201/CYD208 User’s Manual

t

Y

Do Not Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Refer component

replacement and internal adjustments to qualified maintenance personnel.

Do not replace components with power cable connected. To avoid injuries,

always disconnect power and discharge circuits before touching them.

Do Not Substitute Parts Or Modify Instrument

Do not install substitute parts or perform any unauthorized modification to

the instrument. Return the instrument to an authorized OMEGA Cryotronics,

Inc. representative for service and repair to ensure that safety features are

maintained.

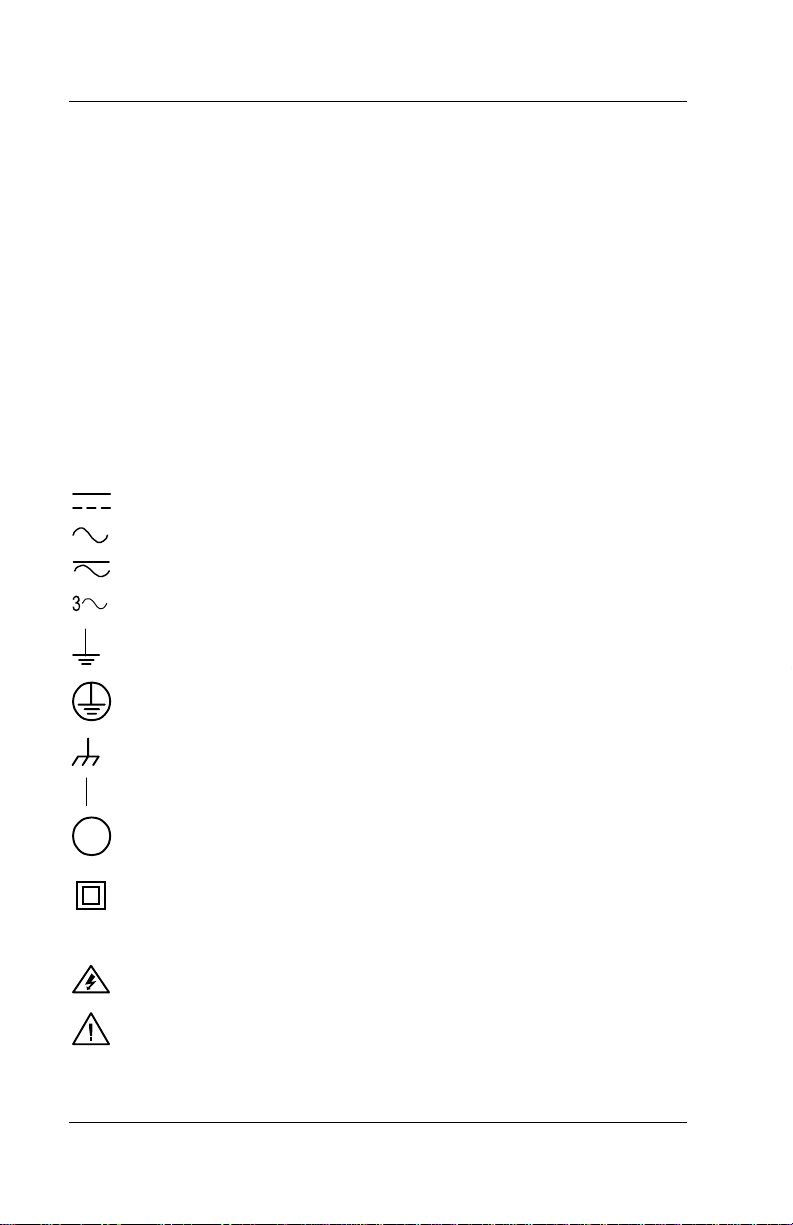

1.5 SAFETY SYMBOLS

Direct current (power line).

Alternating current (power line).

Alternating or direct current (power line).

Three-phase alternating current (power line).

Earth (ground) terminal.

Protective conductor terminal.

Frame or chassis terminal.

On (supply)

Off (supply)

Equipment protected throughout by double insulation or

reinforced insulation (equivalent to Class II of IEC 536 - see

annex H).

Caution: High voltages or temperatures. Background color:

Yellow; Symbol and outline: Black.

Caution or Warning - See instrument documentation.

Background color: Yellow; Symbol and outline: Black.

1-6 Introduction

Page 13

OMEGA Model CYD201/CYD208 User’s Manual

CHAPTER 2

INSTALLATION

2.0 GENERAL

This chapter covers Inspection and Unpacking (Paragraph 2.1),

Repackaging for Shipment (Paragraph 2.2), Sensor Installation

Recommendations (Paragraph 2.3) Power and Ground Requirements

(Paragraph 2.4), Sensor Curve Definitions (Paragraph 2.5), and Rack

Mounting (Paragraph 2.6).

2.1 INSPECTION AND UNPACKING

Remove packing list and verify receipt of all equipment. For question

about the shipment, please call OMEGA Customer Service Department at

1-800-622-2378 or (203) 359-1660.

Upon receipt, inspect container and equipment for damage. Note

particularly any evidence of freight damage. Immediately report any damage

to the shipping agent

NOTE:

saved for their examination. After examining and removing contents, save

packing material and carton in the event reshipment is necessary.

2.2 REPACKAGING FOR SHIPMENT

To return the Model CYD201/CYD208, sensor, or accessories for repair or

replacement, obtain a Authorized Return (AR) number from Technical

Service in the United States, or from the authorized sales/service

representative from which the product was purchased. Instruments may not

be accepted without a RGA number. When returning an instrument for

service, OMEGA must have the following information before attempting any

repair.

1. Instrument model and serial number.

2. User name, company, address, and phone number.

3. Malfunction symptoms.

4. Description of system.

5. Authorized Return (AR) number.

Repack the system in its original container (if available). Write AR number

on the outside of the container or on the packing slip. If not available,

consult OMEGA for shipping and packing instructions.

The carrier will not honor any claims unless all shipping material is

Installation 2-1

Page 14

OMEGA Model CYD201/CYD208 User’s Manual

2.3 POWER AND GROUND REQUIREMENTS

The Model CYD201/CYD208 requires a power source of 90 to 125 or 210 to

250 VAC, 50 or 60 Hz, single phase, 3 Watts. Three-prong detachable

power cord for 120 VAC operation included. Connect to rear panel

UL/IEC/ICEE standard plug. See Table 2-1 for fuse rating.

WARNING: To prevent electrical fire or shock hazards, do not expose

this instrument to rain or excess moisture.

CAUTION: Verify proper fuse installation and AC Line Voltage Selection

Wheel on the Model CYD201/CYD208 rear panel set to available AC line

voltage before inserting power cord and turning on the instrument.

Refer to Chapter 5 to change voltage configuration.

NOTE:

Do not attach the shield to earth ground at the sensor end. It may

introduce noise at the measurement end.

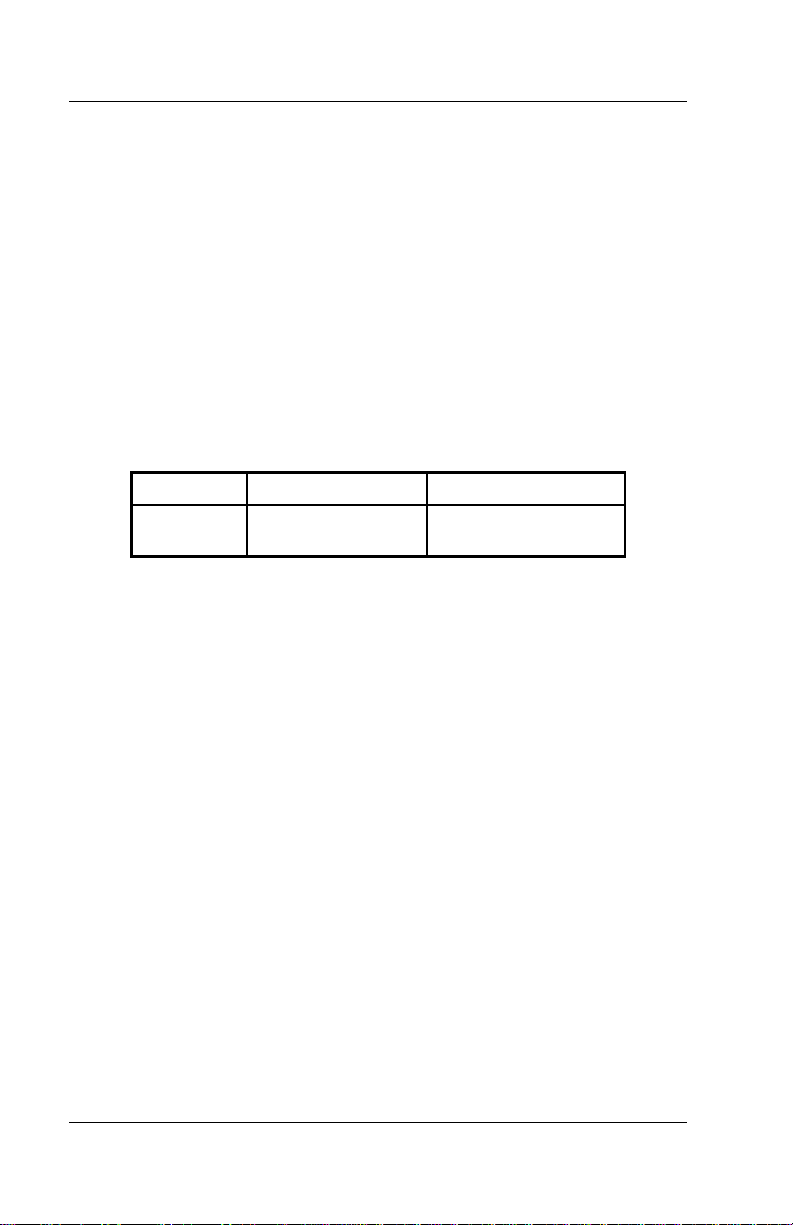

Table 2-1. Line Voltage and Fuse Rating Selection

Select Range Fuse

115

230

To protect operating personnel, the National Electrical Manufacturer’s

Association (NEMA) recommends, and some local codes require, grounded

instrument panels and cabinets. The 3-conductor power cable, when

plugged into an appropriate receptacle, grounds the instrument.

Grounding and shielding signal lines are major concerns when setting up

any precision instrument or system. The CYD201/CYD208 includes ground

isolation of sensor excitation to allow 4-wire measurement of diode voltage

and resistance. Improperly grounding sensor leads and shields can defeat

this feature.

Model CYD201/CYD208 digital logic ties directly to earth ground for

interface communication. The low side of the heater output connects directly

to earth ground. Shield sensor cables whenever possible. Attach the shields

to the connector shield pin.

90 – 125 VAC

210 – 250 VAC

0.2 A (Slow Blow)

0.1 A (Slow Blow)

2.4 SENSOR INSTALLATION RECOMMENDATIONS

See the OMEGA Product Catalog for sensor installation and specifications.

Call OMEGA for copies of application notes or sensor installation questions.

Below are general recommendations on sensor installation:

1. Do not ground the sensor.

2. Shield leads and connect shield wire to SHIELD on screw terminal

connector only. Do not connect shield at other end of cable.

2-2 Installation

Page 15

OMEGA Model CYD201/CYD208 User’s Manual

3. Keep leads as short as possible.

4. Use twisted-pair wire. Use Duo-Twist™ wire (or equivalent) for two-wire,

or Quad-Twist™ wire (or equivalent) for four-wire applications.

5. Thermally anchor lead wires.

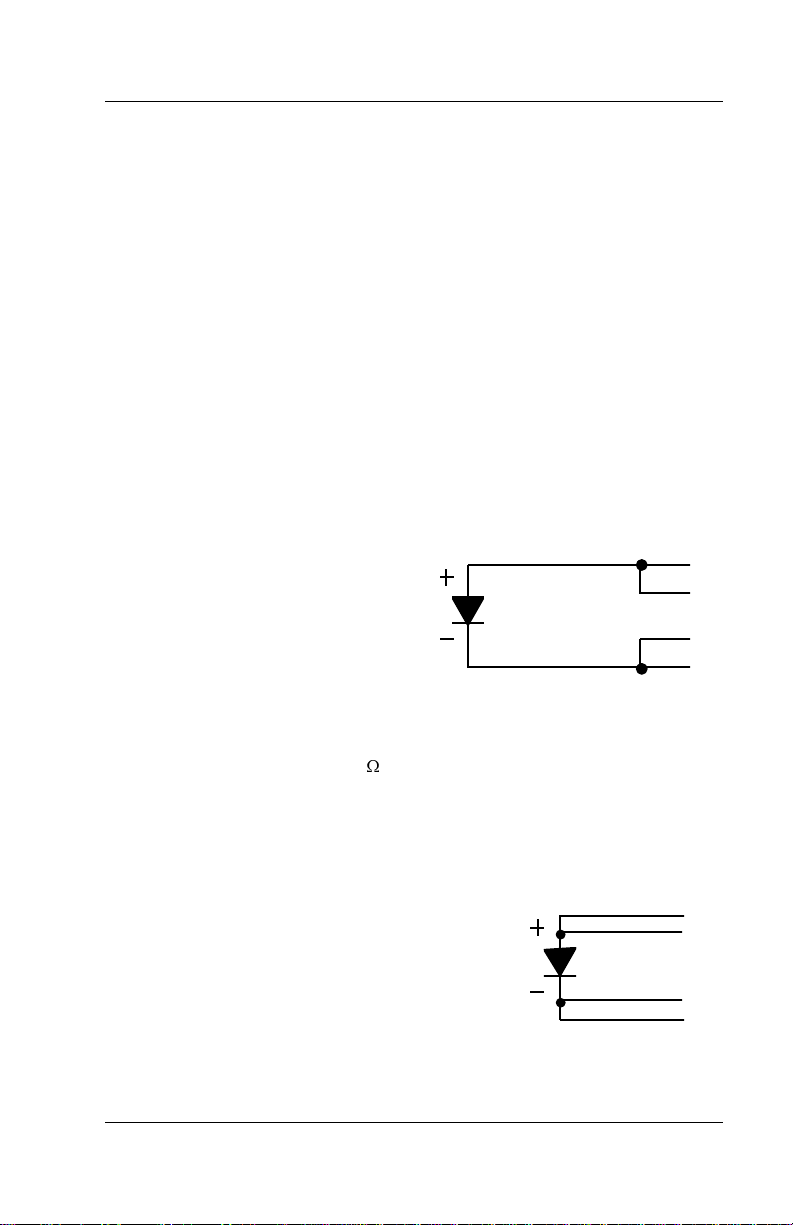

2.4.1 Two-Lead Vs Four-Lead Measurements

In two-lead measurement, the leads that measure sensor voltage also carry

the current. The voltage measured at the instrument is the sum of the

temperature sensor voltage and the IR voltage drop within the two current

leads. Since heat flow down the leads can be critical in a cryogenic

environment, wire of small diameter and significant resistance per foot is

preferred to minimize this heat flow. Consequently, a voltage drop within the

leads may exist.

Four-lead measurement confines current to one pair of leads and measures

sensor voltage with the other lead pair carrying no current.

2.4.1.1 Two-Lead Measurement

Sometimes system constraints dictate

two-lead measurement. Connect the

positive terminals (V+ and I+) together

and the negative terminals (V– and I–)

together at the instrument, then run

Two-Lead

Measurements

two leads to the sensor.

Expect some loss in accuracy; the

voltage measured at the voltmeter equals the sum of the sensor voltage and

the voltage drop across the connecting leads. The exact measurement error

depends on sensor sensitivity and variations resulting from changing

temperature. For example, a 10 lead resistance results in a 0.1 mV

voltage error. The resultant temperature error at liquid helium temperature is

only 3 mK, but, because of the lower sensitivity (dV/dT) of the diode at

higher temperatures, it becomes 10 mK at liquid nitrogen temperature.

I+

V+

V–

I–

2.4.1.2 Four-Lead Measurement

All sensors, both two-lead and four-lead devices,

can be measured in a four-lead configuration to

eliminate the effects of lead resistance. The exact

point at which the connecting leads solder to the

Four-Lead

Diode

two-lead sensor normally results in a negligible

temperature uncertainty.

Installation 2-3

I+

V+

V–

I–

Page 16

OMEGA Model CYD201/CYD208 User’s Manual

2.4.2 Connecting Leads To The Sensor

Excessive heat flow through connecting leads to any temperature sensor

may differ the temperature between the active sensing element and the

sample to which the sensor mounts. This reflects as a real temperature

offset between what is measured and the true sample temperature.

Eliminate such temperature errors with proper selection and installation of

connecting leads.

To minimize heat flow through the leads, select leads of small diameter and

low thermal conductivity. Phosphor-bronze or Manganin wire is commonly

used in sizes 32 or 36 AWG. These wires have a fairly low thermal

conductivity, yet electrical resistance is not large enough to create

measurement problems.

Thermally anchor lead wires at several temperatures between room

temperature and cryogenic temperatures to guarantee no heat conduction

through the leads to the sensor.

2.4.3 Sensor Mounting

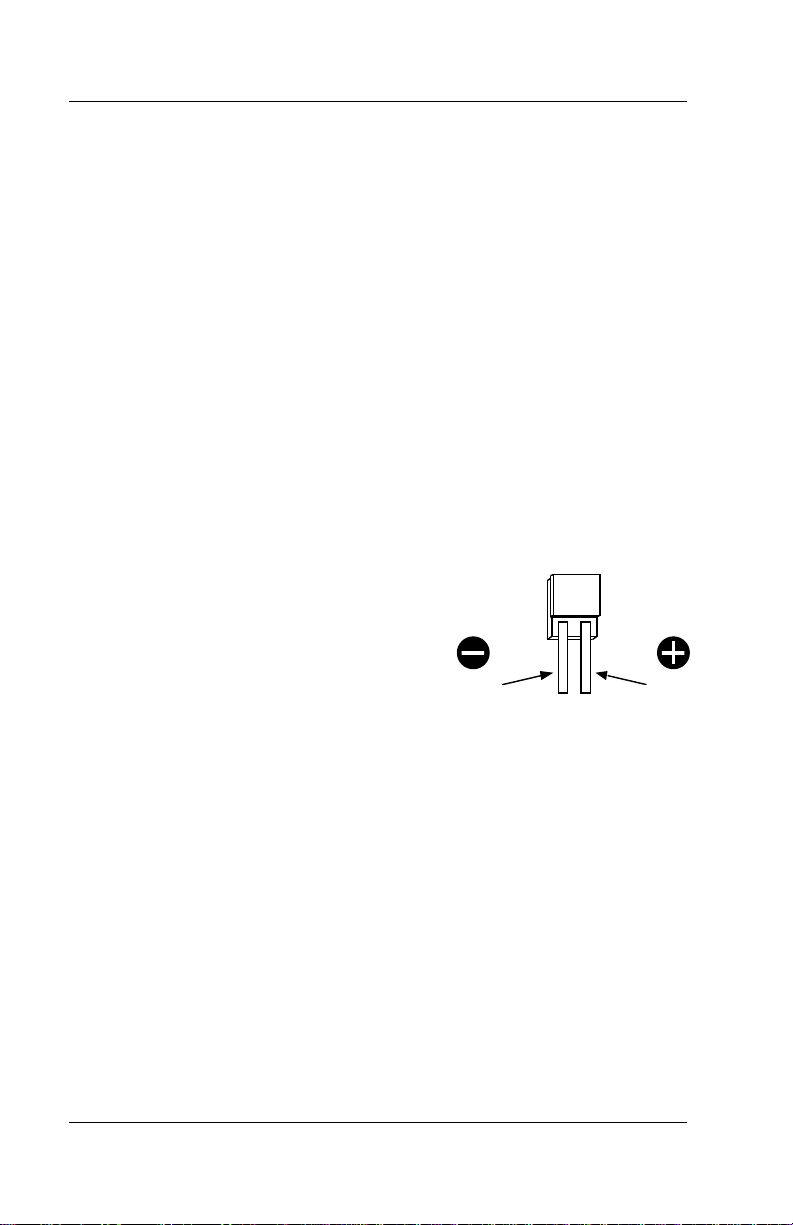

Before installing a diode sensor, identify

which lead is the anode and which is the

cathode. When viewed with the base down

and the leads towards the observer, the

anode is on the right and the cathode is on

the left. The OMEGA CY-7-SD silicon diode

sensor lead configuration is shown to the

right. For other sensors, read accompanying

literature or consult the manufacturer to

Cathode

positively identify sensor leads. Lead identification should remain clear even

after sensor installation. Record the sensor serial number and location.

On the CY-7-SD, the base is the largest flat surface. It is sapphire with gold

metalization over a nickel buffer layer. The base is electrically isolated from

the sensing element and leads; make all thermal contact to the sensor

through the base. A thin braze joint around the sides of the SD package

electrically connect to the sensing element. Avoid contact to the sides with

any electrically conductive material.

When installing the sensor, make sure there are no electrical shorts or

current leakage paths between the leads or between the leads and ground.

If IMI-7031 varnish or epoxy is used, it may soften varnish-type lead

insulations so that high resistance shunts appear between wires if

time for curing is not allowed

Slide Teflon

®

spaghetti tubing over bare leads when the possibility of

.

shorting exists. Avoid putting stress on the device leads and allow for

thermal contractions that occur during cooling which could fracture a solder

joint or lead if installed under tension at room temperature.

DT-470-SD

Diode Sensor Leads

Anode

sufficient

2-4 Installation

Page 17

OMEGA Model CYD201/CYD208 User’s Manual

For temporary mounting in cold temperature applications, apply a thin layer

of Apiezon

®

N Grease between the sensor and sample to enhance thermal

contact under slight pressure. The preferred method for mounting the

CY-7-SD sensor is the OMEGA CO Adapter.

CAUTION: OMEGA will not warranty replace any device damaged by

user-designed clamps or solder mounting.

®

For semi-permanent mountings, use Stycast epoxy instead of Apiezon

Grease.

NOTE:

Do not apply Stycast epoxy over the CY-7-SD package:

N

sensor stress may shift the readings. In all cases, periodically inspect the

sensor mounting to verify good thermal contact to the mounting surface is

maintained.

2.4.4 Measurement Errors Due To AC Noise

Poorly shielded leads or improperly grounded measurement systems can

introduce AC noise into the sensor leads. In diode sensors, the AC noise

shifts the DC voltage measurement due to the diode non-linear

current/voltage characteristics. When this occurs, measured DC voltage is

too low and the corresponding temperature reading is high. The

measurement error can approach several tenths of a kelvin.

this problem exists, perform either procedure below.

1. Place a capacitor across the diode to shunt induced AC currents.

Capacitor size depends on the noise frequency. If noise is related to

power line frequency, use a 10 µF capacitor. If AC-coupled digital noise

is suspected (digital circuits or interfaces), use a 0.1 to 1 µF capacitor. In

either case, if measured DC voltage increases, there is induced noise in

the measurement system.

2. Measure AC voltage across the diode with an AC voltmeter or

oscilloscope. Most voltmeters do not have the frequency response to

measure noise associated with digital circuits or interfaces (which

operate in the MHz range). For a thorough discussion of this potential

problem, and the magnitude of error which may result, request the paper

“Measurement System-Induced Errors In Diode Thermometry,” J.K.

Krause and B.C. Dodrill, Rev. Sci. Instr. 57 (4), 661, April, 1986.

To greatly reduce potential AC noise, connect twisted leads (pairs) between

the measurement instruments and the diode sensors. Use 32 or 36 AWG

OMEGA Duo-Twist™ Cryogenic Wire, which features phosphor bronze wire

twisted at 3.15 twists per centimeter (8 twists per inch). See the OMEGA

Product Catalog or contact OMEGA for further information.

To determine if

Installation 2-5

Page 18

OMEGA Model CYD201/CYD208 User’s Manual

2.5 SENSOR INPUT CONNECTIONS

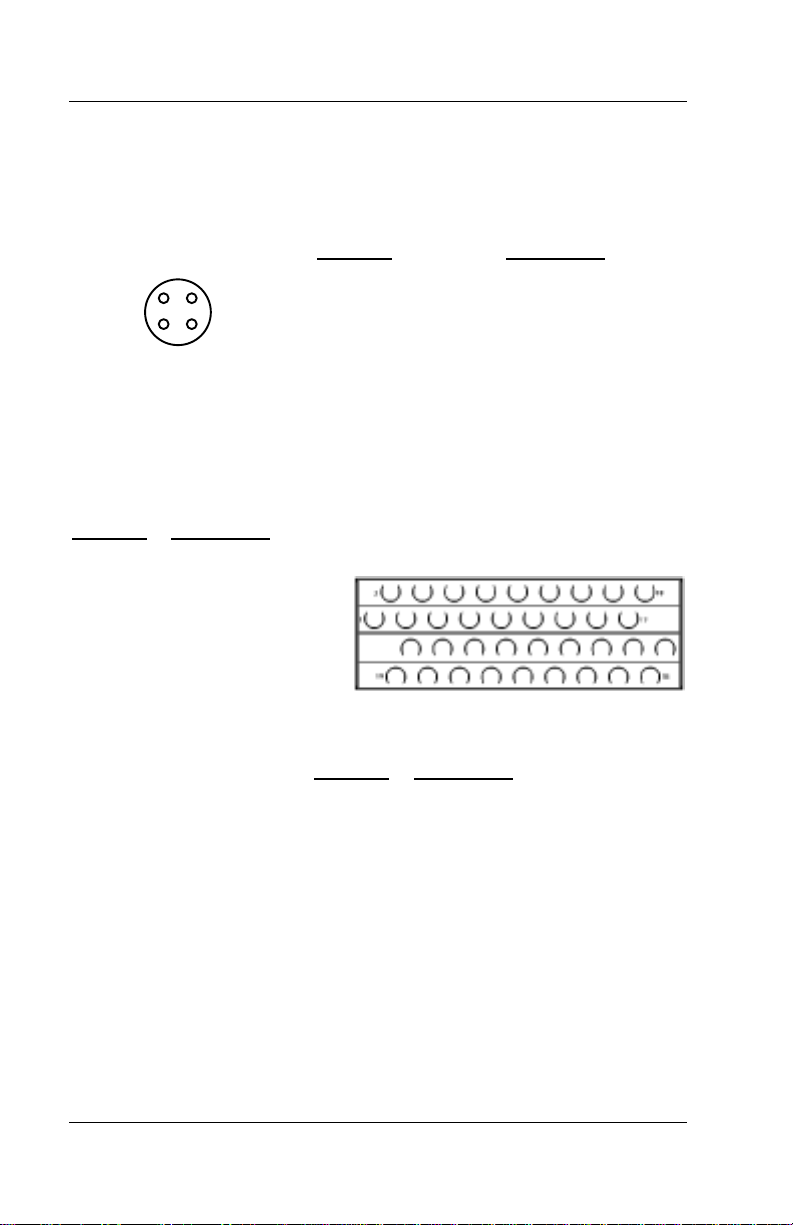

The Model CYD201 has one rear panel 4-pin sensor input connector

designated J1 INPUT 1. The connector pins, numbered 1 thru 4, are shown

below.

J1 INPUT 1

4

3

Figure 2-1. Model CYD201 Sensor Connector J1 Details

The Model CYD208 has a 36-pin “Miniature-D” style connector designated

J1 INPUTS for inputs 1 thru 8. A Model CYD208-D connector is included to

solder interfacing connections to J1. The pin configuration of the Model

CYD208-D is shown below.

Terminal Description

1 +V - Input 1

2 -V - Input 1

3 +V - Input 2

4 -V - Input 2

5 +V - Input 3

6 -V - Input 3

7 +V - Input 4

8 -V - Input 4

9 +V - Input 5

10 -V - Input 5

11 +V - Input 6

12 -V - Input 6

13 +V - Input 7 25 +I - Input 4

14 -V - Input 7 26 -I - Input 4

15 +V - Input 8 27 +I - Input 5

16 -V - Input 8 28 -I - Input 5

17 Shield 29 +I - Input 6

18 Shield 30 -I - Input 6

19 +I - Input 1 31 +I - Input 7

20 -I - Input 1 32 -I - Input 7

21 +I - Input 2 33 +I - Input 8

22 -I - Input 2 34 -I - Input 8

23 +I - Input 3 35 Shield

24 -I - Input 3 36 Shield

Figure 2-2. Model CYD208-D Sensor Connector Details

1

2

Terminal D

4 + Current Out

1 – Current Out

2 – Voltage Sense

3 + Voltage Sense

CASE Shield

123456789101112131415

1920212223242526272829303132333435

Terminal Description

escription

161718

36

2-6 Installation

Page 19

OMEGA Model CYD201/CYD208 User’s Manual

2.6 SENSOR CURVE DEFINITION

To display accurate temperature, select a response curve that matches the

installed sensor. There are seven standard curves stored within the Model

CYD201/CYD208 numbered 0 through 6 (see Appendix A). Different curves

may be assigned to each channel of the Model CYD208. Find the unit

factory curve configuration inside the front cover of this manual. Curve 6

(CY-7 Curve 10) is the standard curve configuration unless specified

differently upon order.

To determine current curve selection, press and hold

the rear panel SET switch (DIP switch 3). Release

displays the curve number in the display window. The Model CYD208

displays the curve number in the display window and the channel number in

the channel window. To display curves for other channel numbers in the

Model CYD208, press

To change the curve, press

through 6. In the Model CYD208, press

then press

After the new curve selection, turn the SET switch on the rear panel off (0).

The unit returns to normal operation.

UNITS

Table 2-2. Model CYD201/CYD208 Temperature Curves

Curve No. Range (K) Description

CHANNEL

to scroll through the curves.

to scroll through the eight channels.

UNITS

. The instrument scrolls through curves 0

CHANNEL

UNITS

UNITS

to select other channels,

and turn on (1)

key. The CYD201

0

1

2

3

4

5

6

2.7 RACK MOUNTING

The Models CYD201 and CYD208 can install in a standard “size” 1/4 panel

EIA rack space. If you ordered a CYD208-DIN rack mounting adapter, follow

the installation instructions below. See Figure 2-3.

1. Remove front feet on bottom of unit and attach lower rack piece by

threading two of the four screws provided into the front feet holes.

2. Locate the two mounting hole access covers on the top of the unit.

Attach the other rack with the remaining screws.

Installation 2-7

0 – 324.9

0 – 324.9

0 – 324.9

0 – 324.9

0 – 324.9

0 – 324.9

0 – 474.9

DT-500DI-8B

DT-500DI-8A

DT-500DRC-D

DT-500TDC-E1

CTI Curve C

DT-500DI-8C

CY-7 Curve 10

Page 20

OMEGA Model CYD201/CYD208 User’s Manual

0.265 (6.73)

AB

2.50

(63.5)

1.50

(38.10)

Hole Sizes:

A = 0.189 (0.480) Diameter - 4 Places

B = 0.169 (0.429) Diameter - 2 Places

Model CYD201 or CYD208 Front Panel

0.215 (5.46)

A

1.25

(31.75)

ABA

1.44

(35.58)

Figure 2-3. Model CYD208-DIN Rack Mounting

2-8 Installation

C

L

4.18 (106.17)

1.44

(35.58)

Page 21

OMEGA Model CYD201/CYD208 User’s Manual

2.8 INITIAL POWER UP SEQUENCE

The test sequence below occurs at power up.

1. All display segments light.

2. The unit displays “-201-” or “-208-”.

3. The instrument begins normal operation. Units currently selected flash.

Model CYD208s also indicate the current channel selected.

2.9 POWER UP ERRORS

On power up, the CYD201/CYD208 checks internal memory. If a problem

exists, an error message displays on the front panel of the instrument.

Er01

“

” indicates a hardware problem in the instrument memory. This error is

not user-correctable. First perform the procedure in Paragraph 5.3. If

unsuccessful, then call the factory.

Er02

“

” indicates a soft error in the instrument memory. To correct this error,

close dip switch 1 on the rear panel for at least 5 seconds, then open it.

Follow the calibration procedure described in Paragraph 5.3 after an error 2

reset.

“OL” indicates a voltage input overload. This can be caused by an open

sensor or diode sensor wired backwards.

Installation 2-9

Page 22

OMEGA Model CYD201/CYD208 User’s Manual

This Page Intentionally Left Blank

2-10 Installation

Page 23

OMEGA Model CYD201/CYD208 User’s Manual

CHAPTER 3

OPERATION

3.0 GENERAL

This chapter covers the Units Key (Paragraph 3.1), the Channel key

(Paragraph 3.2), Scan Mode (Paragraph 3.3), Setting Dwell Times

(Paragraph 3.4), Alarm Operation (Paragraph 3.5), SoftCal™

Compensations (Paragraph 3.6), Calibration (Paragraph 3.7), Verifying

SoftCal™ Operation (Paragraph 3.8), and Erasing SoftCal™

Compensations (Paragraph 3.9).

KV°C

UNITS

°F

ON

OFF

Figure 3-1. Model CYD201 Front Panel

KV°C

CYD201 THERMOMETER

UNITS

°F

CHANNEL

ON

OFF

Figure 3-2. Model CYD208 Front Panel

3.1 UNITS KEY

UNITS selects different units of measurement. The thermometer reads in

voltage or temperature (°C, °F, or K). Press

various selections.

UNITS

also determines if SoftCal™ is active. Press and hold

3 seconds. If SoftCal™ is not active, -000- appears in the display.

CYD208 THERMOMETER

UNITS

to scroll through the

UNITS

for

Operation 3-1

Page 24

OMEGA Model CYD201/CYD208 User’s Manual

3.2 CHANNEL KEY (Model CYD208 Only)

CHANNEL

scrolls through the eight possible sensor channels.

It also

determines if scan mode is activated. Hold 1 to 2 seconds to toggle scan

mode On or Off. A red light glows in the upper left channel display if scan

mode is active.

3.3 SCAN MODE (Model CYD208 Only)

The thermometer can scan 8 channels or monitor 1 channel. To enable

scan mode, press

CHANNEL

for 1 to 2 seconds to toggle scan mode On or

Off. If a light appears in upper left of channel display window, then scan

mode is On. If the light does not appear, the thermometer is in singlechannel mode. Repeat action to reverse mode.

3.4 SETTING DWELL TIMES (Model CYD208 Only)

Set the time the thermometer pauses on each channel (dwell) for 5, 10, 30,

or 60 seconds. A dwell time of 0 instructs the thermometer to skip that

particular channel. To set the dwell:

1. Hold

2. While still pressing

CHANNEL

for 3 seconds. Do not release.

CHANNEL

, use

UNITS

to select the desired time;

0 (skip), 5, 10, 30, or 60 seconds.

3. Repeat procedure for each desired channel. Default channel dwell is

5 seconds.

3.5 ALARM OPERATION

This section covers Alarm Setpoint (Paragraph 3.5.1), Latched and

Unlatched Alarms (Paragraph 3.5.2.), and the Alarm Fix Function

(Paragraph 3.5.3).

3.5.1 Alarm Setpoint

The alarm setpoint is a temperature which activates the alarm relay. Set it to

warn of temperatures rising above (high alarm) or falling below (low alarm) a

certain point.

NOTE:

Alarm setpoints work for temperatures, not voltage. If in voltage

mode while setting an alarm setpoint, the thermometer defaults to kelvin for

the alarm setpoint.

To display the alarm setpoint, move the SET switch on the rear panel to

position 1. To change the setpoint:

1. Make sure the SET switch is in position 1.

3-2 Operation

Page 25

OMEGA Model CYD201/CYD208 User’s Manual

2. Hold

3. Release UNITS when the desired setpoint displays. For a Model

4. Move the SET switch back to position 0 to enable the alarm. When it

The alarm can be connected to another device which triggers when the

alarm activates. The 3-contact terminal block is present on the rear panel as

J3 ALARM. The alarm contacts are designated 1 COM 2 with 1 representing

the normally open state and 2 representing the normally closed state.

UNITS

it is released and pressed again, the temperature direction reverses. If

the temperature display increases, the alarm is a high setpoint. If the

temperature display decreases, the alarm is a low setpoint.

CYD208, press

window and repeat the steps above to set the alarm for each channel

triggers, an alarm status light appears in the upper left of the

temperature display.

until the desired temperature displays.

CHANNEL

to display the desired channel in the channel

UNITS

is a toggle; if

3.5.2 Latched And Unlatched Alarms

Alarms are either latched or unlatched. The alarm is latched when the

LATCH switch is in position 1: the alarm turns On when triggered by the

alarm setpoint, but will

returns to within the high and low setpoint range. The alarm is unlatched

when the LATCH switch is in position 0; the alarm turns On when triggered

by the alarm setpoint, and automatically turns Off when temperatures return

to within the high and low setpoint range.

not

automatically turn Off when the temperature

3.5.3 Alarm Fix Function (Model CYD208 Only)

Set the FIX switch on the Model CYD208 rear panel to OFF (position 0) to

continuously update the alarm relay, depending on the alarm setpoint and

sensor temperature. If the FIX switch is ON (position 1), the relay updates

only when channel 1 input is active.

3.6 SOFTCAL™ COMPENSATIONS

SoftCal™ is a simple, instrument-configured software calibration that

improves system accuracy over a specified temperature range. It reduces

the error between a CY-7 diode and the Standard Curve 10 used by the

instrument. In short, SoftCal™ generates inexpensive calibrations for CY-7

sensors used with OMEGA temperature controllers and monitors.

Operation 3-3

Page 26

OMEGA Model CYD201/CYD208 User’s Manual

SoftCal™ calibrations are made at three temperature points: liquid helium

(4.2 K), liquid nitrogen (about 77 K), and 305 K. Below is the accuracy* of

the CY-7-SD-13 sensor:

+0.5 K 2 K to <30 K +

+0.25 K 30 K to <60 K +1.0 K 375 K to 475 K

+0.15 K 60 K to <345 K

* These values generally apply to all silicon diode sensors. Only two-point

SoftCal™ calibrations appropriate for CY-7 series Band 11, 11A sensors.

This section covers the SoftCal™ Calibration Procedure (Paragraph 3.6.1),

Verifying SoftCal™ Operation (Paragraph 3.6.2), and Erasing SoftCal™

Compensations (Paragraph 3.6.3).

0.25 K 345 K to <375 K

3.6.1 SoftCal™ Calibration Procedure

1. Turn on thermometer 30 minutes prior to operation.

2. Place the SET switch in position 1.

3. Hold

4. Press

5. Hold

6. Verify sensor stabilization at calibration temperature.

7. Press

8. To enter more than one point, go back to step 5.

9. Return the SET switch to position 0.

UNITS

acts as a toggle. If the display rises, release and press again.

"-SOF-" to indicate the unit is ready to erase the current SoftCal™

calibration. Within 2 seconds press

display changes from "-SOF-" to the current SoftCal™ setting.

setting SoftCal™ for liquid helium, the display reads 4.2 K. If setting for

ice point, the display reads 0 °C.

ready to accept the calibration point. Within 2 seconds, press

enter a new calibration point. (If

the display returns to the alarm temperature). After 15 seconds, the

alarm setpoint temperature displays.

be entered between 1.4 K to 9.9 K. No point may be entered between

10 K and 40 K. Two points may be entered above 40 K.

until 0 kelvin (or equivalent in °C or °F) displays. The key

CAL ENABLE

UNITS

until the sensor temperature displays. For example, if

CAL ENABLE

on rear panel with a pen tip. The display reads

UNITS

again. The temperature

again. "-SOF-" again displays to indicate the unit is

UNITS

is not pressed within 2 seconds,

NOTE:

UNITS

to

One point may

3-4 Operation

Page 27

OMEGA Model CYD201/CYD208 User’s Manual

3.6.2 Verifying SoftCal™ Operation

Check the status of SoftCal™ by holding

SoftCal™ is not in operation, "-000-" displays.

If the first digit of the display is 1, SoftCal™ is set for below 28 K. If either

the second or third digit is 1, SoftCal™ is set for above 28 K.

UNITS

for 2-3 seconds. If

3.6.3 Erasing SoftCal™ Compensations

When SoftCal™ compensations are erased, the thermometer returns to

normal operation.

1. Move the SET switch to position 1.

2. Hold

3. Press

4. Move the SET switch to position 0.

UNITS

display moves in the wrong direction, release and press again.

from 0 to "-SOF-". The alarm setpoint displays after erasing SoftCal™

compensation.

until the front panel displays 0. This key is a toggle. If the

CAL ENABLE

on rear panel using a pen tip. The display changes

Operation 3-5

Page 28

OMEGA Model CYD201/CYD208 User’s Manual

This Page Intentionally Left Blank

3-6 Operation

Page 29

OMEGA Model CYD201/CYD208 User’s Manual

CHAPTER 4

REMOTE OPERATION

4.0 GENERAL

The Model CYD201/CYD208 Digital Thermometer Serial Interface can be

used for both operation and service. This chapter covers the Serial Interface

(Paragraph 4.1) and Serial Interface Commands (Paragraph 4.2).

4.1 SERIAL INTERFACE

The Model CYD201/CYD208 has a serial interface for RS-232C

communications with a host computer. RS-232C is an unbalanced (single

ended), non-terminated line used over short distances (typically 10 feet or

less). The Model CYD201/CYD208 serial interface complies with the

electrical format of the RS-232C Interface Standard. The serial interface

connector is a standard 6 wire RJ-11 modular (telephone) jack.

This section covers Serial Interface Specifications (Table 4-1), Serial

Interface Connections (Paragraph 4.1.1), Serial Interface Hardware

Configuration and Adapters (Figures 4-1 & 4-2), Serial Interface Operation

(Paragraph 4.1.2), and Sample Basic and QuickBasic Programs

(Paragraphs 4.1.3 & 4.1.4 respectively).

Table 4-1. Serial Interface Specifications

Transmission:

Connector:

Timing Format:

Transmission Mode:

Baud Rate:

Bits per Character:

Parity Type:

Data Interface Levels:

Terminator:

Three-Wire

RJ-11 Modular (Telephone) Socket

Asynchronous

Half Duplex

300

1 Start, 7 Data, 1 Parity, 1 Stop

Odd

Transmits/Receives Using EIA Levels

LF (0AH)

4.1.1 Serial Interface Connections

The serial interface connector is a standard 6 wire RJ-11 modular

(telephone) jack. OMEGA Model CYD200-J10 data cables, which maintain

pin 1 polarity, simplify interconnection. OMEGA offers the Model CYD200-D

RJ-11 to DB-25 adapter and Model CYD200-B RJ-11 to DE-9 adapter to

connect to the host computer. See Figure 4-2.

Remote Operation 4-1

Page 30

OMEGA Model CYD201/CYD208 User’s Manual

J2 SERIAL I/O

PIN DESCRIPTION

1

654321

RS-232C In (RxD)

2

RS-232C In (RxD)

3

RS-232C Ground

4

RS-232C Ground

5

RS-232C Out (TxD)

6

RS-232C Out (TxD)

Figure 4-1. Serial I/O (RJ-11) Connector Pin Definitions

Model CYD200-B RJ-11

to DB-2 5 Adapt er

RS-232C

Interface Output

on rear of Model

CYD201 or

CYD208

To Customer Supplied Computer

DB-25 Serial Interface Connector

Mode l CYD200-B

RJ-11 to DE-9 Adapter

DB-9 Serial Interface Connector

To Cust ome r Supp lie d Compute r

Use whichever adapter that

matches your computer

serial interface connector

RJ-11 Cable Assembly

J2 SERIAL I/O

Model CYD200-J10

Figure 4-2. Serial Interface Connections

4-2 Remote Operation

Page 31

OMEGA Model CYD201/CYD208 User’s Manual

4.1.2 Serial Interface Operation

Remotely control all thermometer functions, except SoftCal™

compensations from a computer with communications software and modem.

Located on the rear panel is a RJ-11 modular socket designated J2 SERIAL

I/O for host computer connection. Accessories CYD200-J10 (RS-232C

phone cord) and CYD200-D (RJ-11 to DB-25 adapter), as well as a null

modem adapter may be required to link the serial port of the host computer

directly to the thermometer. When programming a Model CYD201/CYD208

from the serial interface, consider the following:

• Type commands in all CAPS.

• The term

appropriate place in the string of digits.

[term]

•

where they appear on a returning character string from the unit.

• Leading zeros and zeros following a decimal point are not needed in a

command string, but they are sent in response to a query.

• Enter temperature to 0.1 degrees. Greater precision truncates.

Temperature is limited from 0 to 475 K.

• Place no space between commands and the variable being sent.

free field

in examples indicates terminating characters placed by the user or

indicates a floating decimal point placed any

4.1.3 Sample Basic Program

10 OPEN “COM1:300,O,7,1,RS” AS #1 ‘Open COM port

11 PRINT “TYPE ‘QUIT’ TO EXIT” ‘Print QUIT message

12 PRINT ‘Print blank line

20 INPUT “ENTER COMMAND”;A$ ‘Get command to send

21 IF A$ = “QUIT” THEN GOTO 100 ‘Look for QUIT then quit

30 A$ = A$ +CHR$(13)+CHR$(10) ‘Adding CR and LF

40 PRINT #1,A$; ‘Sending command string

45 R = INSTR(A$,”W”) ‘Scan CMD for W/QUERRY

46 IF R = 0 THEN GOTO 90 ‘If not a QUERRY skip PRINT

50 FOR Z = 1 TO 500: NEXT Z ‘Short delay

60 LINE INPUT#1,B$ ‘Read back CYD201/CYD208 response

70 PRINT B$; ‘PRINT instrument response

90 GOTO 11 ‘Jump back to the beginning

100 CLOSE #1 ‘Close COM port

101 END ‘End program

Remote Operation 4-3

Page 32

OMEGA Model CYD201/CYD208 User’s Manual

4.1.4 Sample Quick Basic 4.0 Program

STARTUP: OPEN “COM1:300,O,7,1,RS” FOR RANDOM AS #1

PRINT “TYPE ‘QUIT’ TO EXIT” ‘print ‘QUIT’ message

RESTART: PRINT ‘print blank line

INPUT “ENTER COMMAND”; A$ ‘get command to send

IF A$ = “QUIT” THEN GOTO FINISH ‘check for quit request

A$ = A$ + CHR$(13) + CHR$(10) ‘adding CR and LF

PRINT #1, A$; ‘sending command string

R = INSTR(A$, “W”) ‘scan for W/query

IF R = 0 THEN GOTO REJUMP ‘if not query skip pri nt

FOR Z = 1 TO 500: NEXT Z ‘short delay

LINE INPUT #1, B$ ‘read back CYD201/CYD208 response

PRINT B$; ‘print instrument response

REJUMP: GOTO RESTART ‘jump back to beginning

FINISH: CLOSE #1 ‘close serial port

END ‘end/exit program

4.2 SERIAL INTERFACE COMMAND SUMMARY

Command Function Command Function

F0 Sensor Units for Setpoint Y Scan Dwell Time *

H High Alarm Setpoint YC Scanner Channel Selection *

L Low Alarm Setpoint YH Scan Disable *

R Reset Alarm YS Scan Enable *

WA Switch ID & Alarm Dat a Query WY Scan and Dwell Query *

WS Sensor Reading & Alarm Status Query

* Model CYD208 Only.

‘open the serial port

Below is an explanation of the command list structure.

Command Name

Syntax of user input.

Information returned in

response to query.

Explanation of

returned data.

Brief Description of Function

Alarm Reset.

R

Nothing

Used to reset

R

Input:

Returned:

Remarks:

the alarm.

4-4 Remote Operation

Page 33

OMEGA Model CYD201/CYD208 User’s Manual

F0 Sets Sensor Units for Temperature Display.

Input:

Returned:

Remarks:

F0x

Nothing

Sets sensor units for the temperature display, where

x

= C (Celsius), F (Fahrenheit), K (kelvin), or V (volts).

H Select High Alarm Setpoint Value.

Input:

Returned:

Remarks:

Example: H300[term]

Hxxx.x

Nothing

Sets high alarm setpoint, where

in units specified by F0 command. If the instrument is set for

volts, the alarm defaults to kelvin.

sets a high alarm setpoint of 300 degrees.

xxx.x

= temperature setpoint

L Select Low Alarm Setpoint Value.

Input:

Returned:

Remarks:

Example: L31.2[term]

Lxxx.x

Nothing

Sets low alarm setpoint, where

in units specified by F0 command. If the instrument is set for

volts, the alarm defaults to kelvin.

sets a low alarm setpoint of 31.2 degrees.

xxx.x

= temperature setpoint

R Alarm Reset.

Input:

Returned:

Remarks:

R

Nothing

Resets the alarm.

Y Channel Dwell Time

Input:

Returned:

Remarks:

Example: Y23[term]

Remote Operation 4-5

Yab

Nothing

Sets dwell time for a given channel, where a = channel 1 - 8,

and b = the dwell time parameter as follows:

0

= zero seconds, 1 = 5 seconds, 2 = 10 seconds,

3

= 30 seconds, 4 = 60 seconds

Setting a dwell time of 0 skips the specified channel in the

sequence.

sets the dwell time for channel 2 to 30 seconds.

(Model CYD208 Only)

.

Page 34

OMEGA Model CYD201/CYD208 User’s Manual

YC Channel Scanner Channel

Input:

Returned:

Remarks:

YH End Scanning

Input:

Returned:

Remarks:

YS Begin Scanning

Input:

Returned:

Remarks:

YCx

Nothing

Asynchronously selects a scanner channel for readout

independent of scan feature, where x = channel 1 - 8.

(Model CYD208 Only)

YH

Nothing

Halts input scan at current input channel. Place scanner on

hold when sending any other commands to scanner or

unpredictable results may occur.

(Model CYD208 Only)

YS

Nothing

Starts input scan from current input channel. The instrument

skips every channel with a dwell time of zero.

WA Switch ID and Alarm Data.

Input:

Returned:

Remarks:

WA

For a Model CYD201, returns:

[switch ID],[high or low alarm],[alarm sign],[alarm

setpoint](CR)(LF)

For a Model CYD208, returns:

[switch ID],[high or low alarm],[alarm sign],[alarm

setpoint],[active channel number](CR)(LF)

Provides the switch ID and alarm data. The switch ID

parameter is 0 through 3 for the Model CYD201. It is the sum

of 1 if the alarm set enable is set, plus 2 if relay latching is

desired. The switch ID parameter is 0 through 7 for the Model

CYD208. It is the sum of 1 if the alarm set enable is set, plus

2 if relay latching is desired, plus 4 if the alarm fix is enabled.

High or Low Parameter: H = high alarm, L = low alarm.

(Model CYD208 Only)

.

.

.

4-6 Remote Operation

Page 35

OMEGA Model CYD201/CYD208 User’s Manual

WS Sample Sensor Reading and Alarm Status.

Input:

Returned:

Remarks:

WS

For a Model CYD201, returns:

[sign],[sensor reading],[units],[alarm status] (CR)(LF)

For a Model CYD208, returns:

[current channel],[sign],[sensor reading],[units], [alarm

status](CR)(LF)

Returns the sample sensor reading and alarm status, where

A

= active and I = inactive.

WY Scan Status

Input:

Returned: [scan status],[current channel number],[channel which

Remarks:

WY

caused the alarm state], [channel 1 dwell time],[channel 2

dwell time],...[channel 8 dwell time](CR)(LF)

Returns instrument scan status (scanning or holding),

channel dwell information, and scan position. Scan Status

Parameter: H = holding, S = scanning. Channel Which

Caused the Alarm State Parameter = 1 through 8 or "-" if

alarm is inactive. Channel dwell times are in seconds.

Sending this command with a Model CYD201 returns N to

signify no scanner.

(Model CYD208 Only)

.

Remote Operation 4-7

Page 36

OMEGA Model CYD201/CYD208 User’s Manual

This Page Intentionally Left Blank

4-8 Remote Operation

Page 37

OMEGA Model CYD201/CYD208 User’s Manual

CHAPTER 5

SERVICE

5.0 GENERAL

This chapter covers Model CYD201/CYD208 maintenance: Model CYD201

Rear Panel Connections (Paragraph 5.1), Model CYD208 Rear Panel

Connections (Paragraph 5.2), Error Code Troubleshooting (Paragraph 5.3),

General Maintenance (Paragraph 5.4), Fuse Replacement (Paragraph 5.5),

Line Voltage Selection (Paragraph 5.6), Calibration (Paragraph 5.7), and

Serial Interface Cable and Adapters (Paragraph 5.8).

5.1 MODEL CYD201 REAR PANEL CONNECTIONS

Figure 5-1. Model CYD201 Rear Panel Connections

J1 INPUT 1

J2 SERIAL I/O

computer. May require accessories CYD200-J10 (RJ-11 phone cord) and

CYD200-D (RJ-11 to DB-25 adapter).

J3 ALARM

device. Contact 1 is normally open, contact 2 is normally closed.

Switch

LATCH

indicated by temperature change. When off (position 0), turns alarm off or

on (unlatched).

SET

CAL ENABLE

Calibration. See Paragraph 5.7.2.

I ADJ

Calibration. See Paragraph 5.7.1.

Service 5-1

: Accepts circular 4-pin connector temperature sensor (201-MC).

: RJ-11 jack for serial remote communications to a host

: Relay responds to alarm setpoints and can trigger another

: Not used.

switch: When on (position 1), turns alarm on but not off (latched) as

switch: Used in setting alarm setpoints and recalibration.

(Calibration Enable) pushbutton: Used during A/D Converter

(Current Adjust) trim potentiometer: Used during Current Source

Page 38

OMEGA Model CYD201/CYD208 User’s Manual

5.2 MODEL CYD208 REAR PANEL CONNECTIONS

Figure 5-2. Model CYD208 Rear Panel Connections

J1 INPUTS

adapters. Adapter sits on top of thermometer and accepts up to 8

temperature sensors. Adapter designed for either circular 4-pin (2084) or

stripped wire (2081) sensors.

J2 SERIAL I/O

computer. May require accessories CYD200-J10 (RS-232C phone cord)

and CYD200-D (RJ-11 to DB-25 adapter).

J3 ALARM

device. Contact 1 is normally open, contact 2 is normally closed.

FIX

switch: Switches alarm functions between monitoring all channels

(position 0) or monitoring channel 1 only (position 1).

LATCH

indicated by temperature change. When off (position 0), turns alarm off or

on (unlatched).

SET

CAL ENABLE

Calibration. See Paragraph 5.7.2.

I ADJ

Calibration. See Paragraph 5.7.1.

: Accepts 36-pin “D” style connector (208-MC) and multi-sensor

: RJ-11 jack for serial remote communications to a host

: Relay responds to alarm setpoints and can trigger another

switch: When on (position 1), turns alarm on but not off (latched) as

switch: Used in setting alarm setpoints and recalibration.

(Calibration Enable) pushbutton: Used during A/D Converter

(Current Adjust) trim potentiometer: Used during Current Source

5-2 Service

Page 39

OMEGA Model CYD201/CYD208 User’s Manual

5.3 ERROR CODE TROUBLESHOOTING

On power up, the CYD201/CYD208 checks internal memory. If a problem

exists, an error message displays on the front panel of the instrument.

Er01

indicates a hardware problem in the instrument memory. This error is

not user-correctable.

Er02

indicates a soft error in the instrument memory. To correct this error,

use the following procedure.

1. Power up the unit and allow it to display Er02.

2. Close DIP Switch 1 (top of the switch pressed in). Leave the switch

closed for at least 5 seconds, then open DIP switch 1 (bottom of the

switch pressed in).

3. Verify the Model CYD201/CYD208 display goes through a normal power

up sequence and then displays 499.9 K.

4. The input(s) of the Model CYD201/CYD208 must now be recalibrated

per in procedure in Paragraph 5.7 before the unit can be used.

OL

indicates a voltage input overload. This can be caused by an open

sensor or diode sensor wired backwards.

Before calling the factory about a persistent problem, try the procedure

below:

WARNING: This procedure erases calibration constants stored in NonVolatile RAM. If this procedure is used, recalibrate the instrument.

1. With power turned Off, press and hold

While holding

2. If the Model CYD201/CYD208 displays

procedure in Paragraph 5.7. If

CYD201/CYD208 does not respond, contact OMEGA Service.

CAL ENABLE

, turn instrument power On.

Er01

CAL ENABLE

Er02

still displays or if the Model

, follow the Calibration

on the back panel.

5.4 GENERAL MAINTENANCE

Clean the CYD201/CYD208 periodically to remove dust, grease and other

contaminants. Clean the front and back panels and case with a soft cloth

dampened with a mild detergent and water solution.

NOTE:

Do not use aromatic hydrocarbons or chlorinated solvents to clean

the Model CYD201/CYD208. They may react with the silk screen printing on

the back panel.

Service 5-3

Page 40

OMEGA Model CYD201/CYD208 User’s Manual

5.5 FUSE REPLACEMENT

WARNING: To prevent shock hazard, turn off instrument and

disconnect it from AC line power and all test equipment before

replacing fuse.

1. Turn POWER switch Off and disconnect power cord from unit.

Disconnect all test equipment from unit.

2. Remove all screws from rear panel. Gently pull away rear panel and

remove enclosure cover by sliding it to the back.

3. Remove fuse with a fuse puller. The fuse is located behind the

transformer as shown in Figure 5.3.

4. Replace with a 0.2 A fuse for 110 V (115 VAC) operation or a 0.1 A fuse

for 220 V (230 VAC) operation. Use slow blow fuses.

CAUTION: Replace fuse with the same type and rating as specified by

the line voltage selected.

5. Replace enclosure cover, rear panel, and all screws.

5.6 Line Voltage Configuration

The rear-panel, 3-pronged line power connector permits Model

CYD201/CYD208 operation at either 110 or 220 VAC. The configuration is

indicated on rear panel in the Line Voltage Selection Block. Use the

procedure below to change line voltage.

WARNING: To prevent shock hazard, turn off instrument and

disconnect it from AC line power and all test equipment before

changing line voltage configuration.

1. Turn power switch OFF and disconnect the power cord from the unit.

Disconnect all test equipment from unit.

2. Remove all screws from rear

panel. Gently pull away rear

panel and remove enclosure

cover by sliding it to the back.

3. Modify jumper configuration to

desired line voltage (see

Figure 5-3).

4. Replace fuse to match new

voltage requirements.

5. Replace enclosure cover, rear

panel and all screws.

Figure 5-3

Jumper Configuration

Line Voltage

5-4 Service

Page 41

OMEGA Model CYD201/CYD208 User’s Manual

5.7 RECALIBRATION

OMEGA calibrates and certifies thermometers to original factory

specifications for a reasonable fee. You can recalibrate the thermometer to

original specifications, but OMEGA will not warrant these calibrations.

Recalibration requires a digital voltmeter (DVM) with 4½ digit resolution or

better; and 25 k and 125 k precision resistors with ±0.01% tolerance or

better.

Recalibration involves current source and analog/digital (A/D) converter

calibration. A/D calibration erases all SoftCal™ compensations; perform it

after current source calibration, not before.

5.7.1 Current Source Calibration

1. Allow 30 minute warm-up to achieve rated specifications.

2. Configure 125 k resistor as shown in Figure 5-4. Set Model CYD208 to

channel 1.

3. Connect DVM voltage leads across the resistor and adjust the I ADJ

trimpot (located on rear panel) until DVM displays a voltage of 1.2500

volts ±100 microvolts.

4. Remove DVM and resistor.

Model CYD201 Model CYD208

NOTE:

Do not use a voltmeter for A/D Converter Calibration.

Figure 5-4. Calibration Connections

Service 5-5

Page 42

OMEGA Model CYD201/CYD208 User’s Manual

5.7.2 A/D Converter Calibration

NOTE:

Current source calibration

calibration.

1. Allow 30 minute warm-up to achieve rated specifications.

2. Perform current source calibration.

3. Configure 125 k resistor as shown in Figure 5-4. Set Model 208s to

channel 1.

4. Wait 10 seconds for resistor voltage to settle.

5. Press

CAL ENABLE

, then within 2 seconds press

window shows "-CAL-" for approximately 15 seconds.

6. Repeat procedure with 25 k resistor.

7. For Model CYD208, repeat procedure for other 7 channels. See

Figure 2-2 for pin assignments.

5.8 SERIAL INTERFACE CABLE AND ADAPTERS

1234 56

Figure 5-5. Model CYD200-J10 RJ-11 Cable Assembly Wiring Details

TxD

Gnd

Gnd

RxD

must

be performed

YELLOW

GREEN

RED

BLACK

before

UNITS

A/D converter

. The display

123456

13121110987654321

25 24 23 22 21 20 19 18 17 16 15 14

DB-25 CONNECTOR

= NOT

USED

RxD

654321

Gnd

TxD

RJ-11

RECEPTACLE

Figure 5-6. Model CYD200-D RJ-11 to DB-25 Adapter Wiring Details

5-6 Service

Page 43

OMEGA Model CYD201/CYD208 User’s Manual

54321

9876

DE-9 CONNECTOR

= NOT

USED

RxD

Gnd

TxD

654321

RJ-11

RECEPTACLE

Figure 5-7. Model CYD200-B RJ-11 to DE-9 Adapter Wiring Details

Service 5-7

Page 44

OMEGA Model CYD201/CYD208 User’s Manual

This Page Intentionally Left Blank

5-8 Service

Page 45

OMEGA Model CYD201/CYD208 User’s Manual

CHAPTER 6

OPTIONS AND ACCESSORIES

6.0 GENERAL

This chapter lists options, accessories, sensors, wires, and special

equipment available for the Model CYD201/CYD208.

6.1 ACCESSORIES

MODEL DESCRIPTION OF ACCESSORY

201-MC

208-MC

CYD200-J10

CYD200-D

CYD200-B

2010

2080

2081

2082-1

2082-2

2082-3

2082-4

4-pin Mating Connector for Model CYD201 and Model

2084.

36-pin “D” Style Connector for Model CYD208.

RJ-11 to RJ-11 Phone Cord, 10 feet (3 meters). See

Figure 6-1.

RJ-11 to DB-25 Adapter. Connects RJ-11 to RS-232C

Serial Port on rear of computer. See Figure 6-1.

RJ-11 to DE-9 Adapter. Connects RJ-11 to RS-232C

Serial Port on rear of computer. See Figure 6-1.

Model CYD201 calibration connector.

Model CYD208 calibration connector.

Screw Terminal Adapter. Connects Model CYD208 to

multiple sensor/probe assemblies with stripped ends

and non- permanent wiring. Provision for attachment to

top of thermometer. Fitted with “D” type mating

connector.

Stainless steel Sensor Probe with 6-foot (1.83 m) cable

with 4 stripped ends. 4-inch (10 cm) long by

1

/8 inch

(3.2 mm) diameter probe.

Stainless steel Sensor Probe with 6-foot (1.83 m) cable

with 4-pin 201-MC mating connector. 4-inch (10 cm)

long by

Stainless steel Sensor Probe with 12-foot (3.7 m) cable

with 4 stripped ends. 6-inch (15 cm) long by

1

/8 inch (3.2 mm) diameter probe.

1

/8 inch

(3.2 mm) diameter probe.

Stainless steel Sensor Probe with 12-foot (3.7 m) cable

with 4-pin 201-MC mating connector. 6-inch (15 cm)

long by

1

/8 inch (3.2 mm) diameter probe.

Options and Accessories 6-1

Page 46

OMEGA Model CYD201/CYD208 User’s Manual

ACCESSORIES

(continued)

MODEL DESCRIPTION OF ACCESSORY

Sensor Probe. 12-foot (3.7 m) cable with CY-7-SD-13

sensor in CY mounting adapter, stripped ends. Tempera-

2083-1

ture limit: 325 K (52 °C). Diode sensor epoxied (Stycast)

into center of 0.564 inch (1.43 cm) diameter by 0.20 inch

(5 mm) thick copper disk. 30 AWG copper leads anchored

to disk. Mass (excluding leads): 4.3 grams.

Sensor Probe. 12-foot (3.7 m) cable with CY-7-SD-13

sensor in CY mounting adapter, with 4-pin CYD201-MC

mating connector. Temperature limit: 325 K (52 °C). Diode

2083-2

sensor epoxied (Stycast) into center of 0.564 inch (1.43

cm) diameter by 0.20 inch (5 mm) thick copper disk. 30

AWG copper leads anchored to disk. Mass (excluding

leads): 4.3 grams.

Multi-Connector Adapter. Required with Model CYD208

2084

when using multiple probe/cable assemblies and Model

201-MC mating connectors.

CYD208

-DIN

Mounting Adapter for Rack Installation. For installation in

¼

a

panel EIA rack space. See Figure 2-3.

6.2 MODEL CYD201/CYD208 WIRES

LSCI P/N DESCRIPTION OF CABLE

9001-005

Quad-Twist™ Cryogenic Wire.

phosphor-bronze wire, 36 AWG, 0.127 mm (0.005 inch)

Two twisted pairs,

diameter.

9001-006

Duo-Twist™ Cryogenic Wire.

phosphor-bronze wire, 36 AWG, 0.127 mm (0.005 inch)

Single twisted pair,

diameter.

9001-007

9001-008

—

Quad-Lead™ Cryogenic Wire

flat, 32 AWG, 0.203 mm (0.008 inch) diameter.

Quad-Lead™ Cryogenic Wire

flat, 32 AWG, 0.127 mm (0.005 inch) diameter.

Any quality dual shield twisted pair wire for dewar to

Model CYD201/CYD208 connector.

. Phosphor-bronze wire,

. Phosphor-bronze wire,

6-2 Options and Accessories

Page 47

OMEGA Model CYD201/CYD208 User’s Manual

6.3 MODEL CYD201/CYD208 SENSORS

SENSOR NO. DESCRIPTION OF SENSOR

The smallest silicon diode Temperature Sensor

Series DT-420

available. Installs on flat surfaces. Same silicon

chip as Series CY-7 and DT-471.