Page 1

CY7/670 Series Temperature Sensors

Application Notes

M-4447/0307

INSTALLATION AND OPERATION

Three aspects of using a temperature sensor are

critical to its optimum performance:

• the proper electrical and thermal installation of

the connecting leads that run to the sensor

• the actual mounting of the sensor to the sample

assembly

• the measurement electronics used for reading

and recording temperature data from the sensor

Connecting Leads

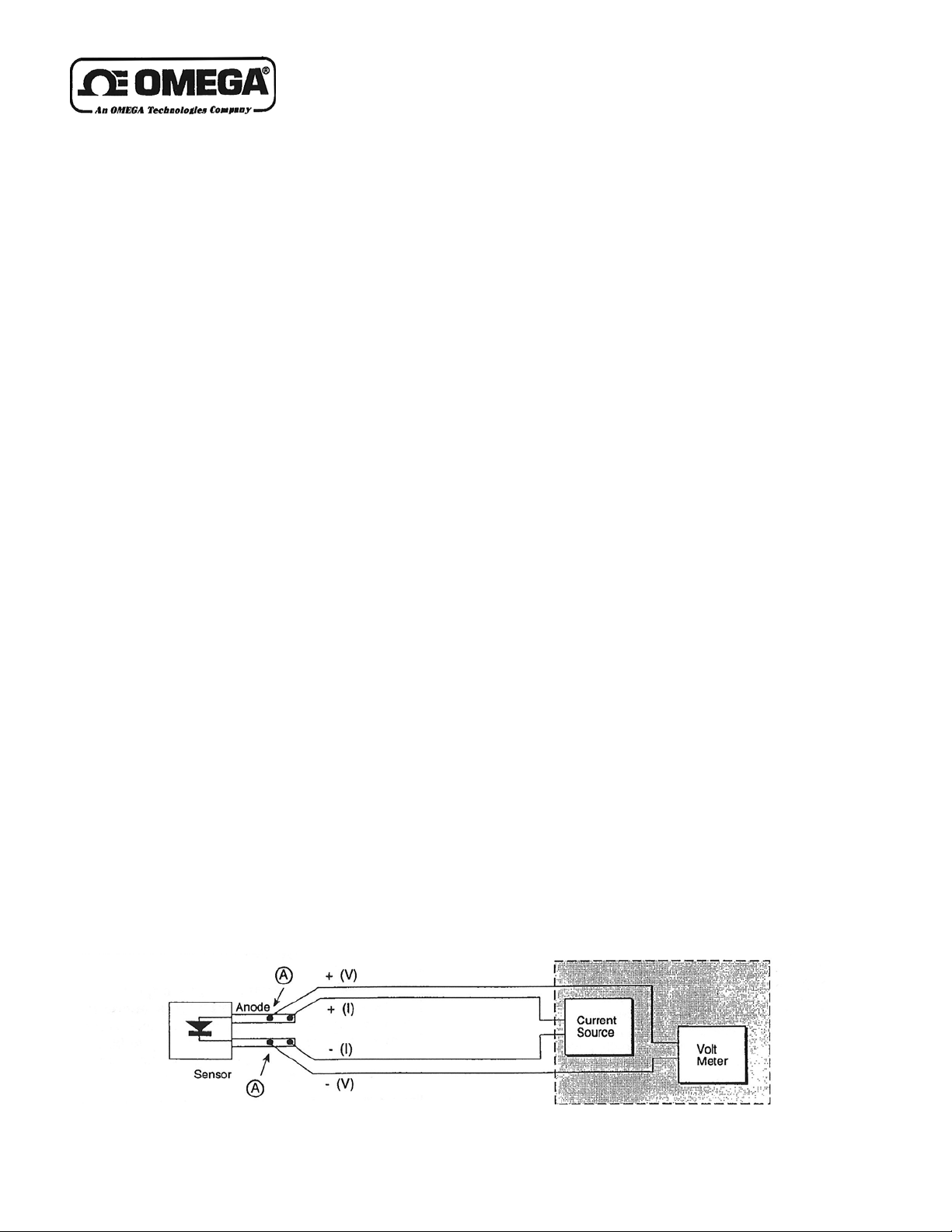

Although the majority of the CY7/CY670 series

sensors are two-lead devices, measurements are

preferably made using a four-wire configuration to

avoid all uncertainties associated with lead

resistance. This is done by using four connecting

leads to the device and connecting the V+ and I+

leads to the anode and the V– and I– leads to the

cathode as shown in Figure 1. The exact point at

which the connecting leads are soldered to the

device leads results in negligible temperature

measurement uncertainties.

In a two-wire measurement configuration, the

voltage connections (point A in Figure 1) are made

near or at the current source, so only two leads

are actually connected to the device. Some loss in

accuracy can be expected since the voltage

measured at the voltmeter is the sum of the diode

voltage and the voltage drop across the

connecting leads. The exact temperature

uncertainty will depend on the temperature range

and lead resistance. For a 10-ohm lead

resistance, the diode voltage will be offset by 0.1

mV, which gives a negligible temperature error at

liquid helium temperature but a 50 mK error near

liquid nitrogen temperature. Note the PI and CY

adapter can be used only in a two-wire

configuration.

An excessive heat flow through the connecting

leads to any temperature sensor can create a

situation where the active sensing element (for the

CY7/670 series this is the diode chip) is at a

different temperature than the sample to which the

sensor is mounted. This is then reflected as a real

temperature offset between what is measured and

the true sample temperature. Such temperature

errors can be eliminated by proper selection and

installation of the connecting leads.

In order to minimize any heat flow through the

leads, the leads should be of small diameter and

low thermal conductivity. Phosphor-bronze or

manganin wire is commonly used in sizes 32 or 36

AWG. These wires have a fairly poor thermal

conductivity yet the resistivities are not so large as

to create any problems in four-wire

measurements.

Lead wires should also be thermally anchored at

several temperatures between room temperature

and cryogenic temperatures to guarantee that heat

is not being conducted through the leads to the

sensor. A final thermal anchor at the sample itself

is a good practice to assure thermal equilibrium

between the sample and the temperature sensor.

Note that the CU, CY, SO, and DI mounting

adapters serve as their own sample thermal

anchor.

I the connecting leads have only a thin insulation

such as vinyl acetal or other varnish type coating,

a simple thermal anchor can be made by winding

the wires around a copper post or other thermal

mass and bonding them in place with a thin layer

of CYAV varnish. There are a variety of other

ways in which thermal anchors can be fabricated;

a number of guidelines can be found in detail in

the following references.

Figure 1. Four-Wire Configuration for CY7/670 Series Sensor Installation

Page 2

Sensor Mounting

General Comments

Before installing the CY7/670 series sensor,

identify which lead is the anode and which lead is

the cathode by referring to the accompanying

device drawings. Be sure that lead identification

remains clear even after installation of the sensor,

and record the serial number and location.

The procedure used to solder the connecting

leads is not very critical and there is very little

danger in overheating the sensor. If for some

reason the leads need to be cut short, they should

be heat sunk with a copper clip or needle-nose

pliers before soldering. Standard rosin-core

electronic solder (m.p. 180C) is suitable for most

applications. Applications involving the use of the

SD package up to 200 °C require a higher melting

point solder. A 90% Pb 10% Sn solder has been

used quite successfully with a rosin flux.

For all adapters except the CY, CU, and DI, the

leads are gold-plated Kovar. Prolonged soldering

times may cause the solder to creep up the goldplated leads as the solder and the gold alloy. This

is not detrimental to the device performance.

When installing the sensor:

• Make sure there are no shorts or leakage

resistance between the leads or between the

leads and ground. CYAV varnish or epoxy may

soften varnish-type insulations so that high

resistance shunts appear between wires if

sufficient time for curing is not allowed. Teflon

spaghetti tubing is useful for sliding over bare

leads when the possibility of shorting exists.

• Avoid putting stress on the device leads and

allow for the contractions that occur during

cooling that could fracture a solder joint or lead if

installed under tension at room temperature.

The CY7/670 series sensor is designed for easy

removal for recalibration checks or replacement,

and the following discussions for each of the

adapters are geared in this direction. If semipermanent mountings are desired, the use of OBCY10 or OB-CY20 low temperature epoxy can

replace the use of CYAG grease. In all cases, the

mounting of the sensor should be periodically

inspected to verify that good thermal contact to the

mounting surface is maintained.

CY7/670-SD

The SD version is the basic package for the

CY7/670 series sensor line, from which all other

configurations are made using the appropriate

adapter. The base of the device has a gold

metallized surface and is the largest flat surface

on the sensor. The base is electrically isolated

from the sensing element and leads, and all

thermal contact to the sensor must be made

through the base.

A thin braze joint around the sides of the SD

package is electrically connected to the sensing

element. Contact to the sides with any electrically

conductive material must be avoided. When

viewed base down and with leads towards the

observer, the positive lead (anode) is on the right.

For a removable mount, the SD sensor can be

held against the mounting surface with the CO

adapter (see below) or similar clamping

mechanism. Any method of clamping the sensor

must avoid excessive pressure and should be

designed so that thermal contractions or

expansions do not loosen contact with the sensor.

For uses restricted to below 325 K, a thin layer of

CYAG grease should be used between the sensor

and sample to enhance thermal contact.

The SD package can also be bonded with a low

temperature epoxy. The sensor should be pressed

firmly against the surface during curing to assure a

thin epoxy layer and a good thermal contact. The

device may be removed in the future by using the

appropriate epoxy stripper.

The SD adapter can be soldered using a rosin flux

(non-corrosive) if extreme care is exercised.

1. Tin the base of the sensor using a low

wattage, temperature controlled soldering iron

that will not exceed 200 °C. Use only a

minimal amount of solder. Tin the surface to

which the sensor is to be bonded and again,

avoid an excessive thickness of solder. Clean

both the sensor and the mounting surface of

any residual flux.

2. Reheat the mounting surface to the melting

point of the solder, press the device into

position and allow the sensor to warm to the

melting point of the solder.

3. After both tinned surfaces have flowed

together, remove the heat source and let the

sample and sensor cool.

Under no circumstance should the sensor be

heated above 200 °C and the solder must be

limited to only the base of the sensor. Excess

solder running up the sides of the SD package can

create shorts. Repeated mounting and

demounting of a soldered sensor may eventually

cause wetting deterioration and ruin the thermal

contact to the sensing element, although the nickel

buffer layer should minimize these problems.

CAUTION

The preferred method for mounting the SD

sensor is either the CO adapter or bonding

with epoxy. Omega Engineering, Inc. will not

warranty replace any device damaged by a

user-designed clamp or damaged through

solder mounting.

2

Page 3

CY7/670-LR

The gold-coated copper LR adapter is designed

for insertion into a 1/8-inch diameter tube. A thin

layer of CYAG grease should be applied to the

copper adapter before insertion. This eases

installation at room temperature and enhances the

thermal contact.

CY7/670-CU/DI/CY

The gold-coated copper CU, DI and CY adapters

serve as both a sensor and a thermal anchor

assembly. These adapters are designed to be

mounted to a flat surface using a 4-40 brass

screw. Avoid over-tightening the screw; use only

enough force to firmly hold the sensor in place.

Brass is recommended for the screw as the

differential thermal contraction between the

adapter and the screw will cause the mounting

assembly to tighten as opposed to loosen when

the system is cooled. A thin layer of CYAG grease

should be used to enhance the thermal contact

between the adapter and the mounting surface.

The CU adapter has four color-coded leads: red

(I–), green (V–), clear (V+), and blue (I+). The CY

adapter has two color-coded leads: yellow (+) and

green (–). The green lead on the DI adapter is the

cathode.

CY7/670-ET/MT

Both adapters are gold-plated copper hex head

bolts with the SD package mounted in a slot on

the adapter head. The ET adapter screws into a ¼

inch deep, 6-32 threaded hole while the MT

adapter screws into a 6 mm deep, 3 × 0.5 mm

threaded hole. Before assembly, the threads

should be lightly greased with CYAG grease. Do

not over-tighten, since the threads are copper and

can be easily sheared. Finger-tight should be

sufficient.

3. Lift the edge of the clip using a small pair of

pliers or screwdriver.

4. Slide the SD package into place underneath

the clip and gently lower the clip onto the lid of

the SD package. Note that a slot is cut

underneath the clip to accept the SD package.

Refer to the drawing for details.

If the device is to be used only below 325 K, a

layer of CYAG grease should be used between

the SD package and mounting surface to enhance

the thermal contact.

Sensor Operation

Temperature controllers and thermometer

instrumentation offered by Omega Engineering,

Inc. are designed to be directly compatible with the

CY7/670 series sensor to give optimum

performance and accuracy together with direct

temperature readouts. Simply follow the

instructions provided with the instrument

concerning sensor connection and instrument

operation. If a user-supplied current source,

voltmeter, or other instrumentation is going to be

used with the CY7/670 series sensor, special

attention should be given to the following details.

The CY7/670 series sensors are designed to

operate at a constant current of 10 µA while the

voltage variation with temperature measurement

depends directly on the specifications of the

current source and the voltmeter. A current source

operating at the level of +0.01 µA (±0.01 K) is

probably suitable for most applications. The

voltmeter resolution required can be estimated

from the sensitivity (dV/dT) of the CY7/670 sensor:

Temperature Sensitivity

(K) (mV/K)

305 2.4

77 1.9

4.2 33

CY7/670-BO

The BO adapter should be mounted in the same

manner as the CU. The BO adapter contains its

own thermal anchor and is an epoxy-free

assembly.

CY7/670-CO

The CO adapter is used to attach the CY7/670-SD

package to a flat surface. The adapter is a springloaded clamp designed to maintain pressure on

the SD package as the temperature is varied.

1. Remove the hold down cap that holds the

three-piece CO assembly together. The CO

assembly should appear as shown in the

accompanying drawings.

2. Bolt the assembly into a 4-40 threaded hole.

The stop on the brass screw should rest

against the mounting surface and it also

prevents overcompressing the spring.

Multiplying the above sensitivity by the desired

temperature resolution in K will give the required

voltage resolution in mV.

The static impedance of the CY7/670 series

sensor operating at 10 µA current is on the order

of 100,000 ohms. Therefore, the input impedance

of the voltmeter must be significantly larger than

this to avoid measurement errors. Voltmeters with

input impedances of greater than 109 or 1010

ohms should be used.

Good quality instrumentation must be used and all

instrumentation and wiring should be properly

grounded and shielded. Temperature

measurement errors will result if there is excessive

AC noise or ripple in the circuitry. Further details

can be found in the article by Krause and Dodrill

given in the references.

Note: All materials mentioned above that are used

in sensor installation are available from OMEGA

Engineering, Inc.

3

Page 4

REFERENCES

Krause, J.K. and Swinehart, P.R. (1985). Demystifying Cryogenic Temperature Sensors. Photonics Spectra. August, 61–68.

Krause, J.K. and Dodrill, B.C. (1986). Measurement System Induced Errors in Diode Thermometry. Review of Scientific

Instruments 57 (4), 661–665.

Sparks, L.L. (1983). Temperature, Strain, and Magnetic Field Measurements. In Material at Low Temperatures, Ed. By R.P. Reed

and A.F. Clark. American Society of Metals, Metals Park, 515–571.

White, G.K. (1979). Experimental Techniques in Low Temperature Physics. Clarendon Press, Oxford.

CY7/670-SD

Basic sensor package style.

Temperature range: 1.4 to 475 K

Mass: 0.03 g

CY7/670-CO

Basic sensor with spring-loaded

brass clamp to hold sensor to

Temperature range: 1.4 to 475 K

Mass (without sensor): 1.7 g

sample.

CY7/670-ET

Basic sensor soldered onto SAE-

threaded copper adapter.

Temperature range: 1.4 to 325 K

Mass: 1.4 g

CY7/670-CY

Basic sensor epoxied into

relatively large copper disk. 30

AWG stranded copper lead pair is

thermally anchored to disk.

Temperature range: 1.4 to 325 K

Mass (excluding leads): 4.3 g

CY7/670-BO

Basic sensor soldered onto bolt-on

copper block with leads thermally

anchored to block.

Temperature range: 1.4 to 325 K

Mass: 1.5 g

CY7/670-LR

Basic sensor soldered into

cylindrical copper adapter.

Temperature range: 1.4 to 325 K

Mass: 0.15 g

CY7/670-CU/DI

Basic sensor mounted into

bolt-on disk with leads thermally

anchored to disk with low

temperature epoxy. CU version is

4-lead. DI is 2-lead.

Temperature range: 1.4 to 325 K

Mass (excluding leads): 4.3 g

CY7/670-MT

Basic sensor soldered into metric-

threaded copper adapter.

Temperature range: 1.4 to 325 K

Mass: 1.4 g

Servicing USA and Canada:

Call OMEGA Toll Free

OMEGA Engineering, Inc.

One Omega Drive, Box 4047

Stamford, CT 06907-0047 U.S.A.

Headquarters: (203) 359-1660

Sales: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering: 1-800-872-9436 / 1-800-USA-WHEN

FAX: (203) 359-7700 TELEX: 996404

EASYLINK 62968934 CABLE OMEGA

Servicing Europe: United Kingdom Sales

and Distribution Center

OMEGA Technologies Ltd.

25 Swannington Road, Broughton Astley, Leicestershire

LE9 6TU, England

Telephone: 44 (0455) 285520 FAX: 44 (0455) 283912

Loading...

Loading...