Page 1

TEMPERATURE

MU

Thermocouple, RTD & Thermistor

Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN

AND FORCE

M

U

Transducers & Strain Gauges

MU

Load Cells & Pressure Gauges

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters

& Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

M

U

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators

& Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition &

Engineering Software

MU

Communications-Based

Acquisition Systems

MU

Plug-in Cards for Apple, IBM

& Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND

CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater

Treatment

MU

pH, Conductivity & Dissolved

Oxygen Instruments

Where Do I Find Everything I Need for Process

Measurement and Control? OMEGA…Of Course!

M0144/0297

Page 2

CL-300, CL-301, CL-302, CL-303

Portable Simulators

http://www.omega.com

e-mail: info@omega.com

User’s Guide

Page 3

OMEGAnetSMOn-Line Service Internet e-mail

http://www.omega.com info@omega.com

Benelux:

Postbus 8034, 1180 LA Amstelveen,

The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic:

Ostravska 767, 733 01 Karvina

Tel: 420 (69) 6311627 FAX: 420 (69) 6311114

e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

Servicing Europe:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

SM

Customer Service: 1-800-622-2378 / 1-800-622-BEST

SM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

SM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

USA: ISO 9001 Cer

tified

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Servicing North America:

For immediate technical or application assistance:

Mexico and Latin America:

Tel: (95) 800-TC-OMEGA

SM

FAX: (95) 203-359-7807

En Espan~ol: (203) 359-1660 ext: 2203

e-mail: espanol@omega.com

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: ISO 9002 Cer

tified

•25 Swannington Road, Broughton Astley,

Leicestershire, LE9 6TU, England

Tel: 44 (1455) 285520 FAX: 44 (1455) 283912

•P.O. Box 7, Omega Drive, Irlam,

Manchester, M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

Canada:

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: canada@omega.com

Page 4

WARRANTY

OMEGA warrants this unit to be free of defects in materials and workmanship and to

give satisfactory service for a period of 37 months from date of purchase. OMEGA

Warranty adds an additional one (1) month grace period to the normal three (3)

year product warranty to cover handling and shipping time. This ensures that

OMEGA’s customers receive maximum coverage on each product. If the unit should

malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon

phone or written request. Upon examination by OMEGA, if the unit is found to be

defective it will be repaired or replaced at no charge. However, this WARRANTY is

VOID if the unit shows evidence of having been tampered with or shows evidence of

being damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components which wear or which are damaged by

misuse are not warranted. This includes contact points, fuses, and triacs.

OMEGA is glad to offer suggestions on the use of its various products.

Nevertheless, OMEGA only warrants that the parts manufactured by it will be as

specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTA TIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on

contract warranty, negligence, indemnification, strict liability or otherwise, shall

not exceed the purchase price of the component upon which liability is based. In

no event shall OMEGA be liable for consequential, incidental or special damages.

Every precaution for accuracy has been taken in the preparation of this manual;

however, OMEGA ENGINEERING, INC. neither assumes responsibility for any

omissions or errors that may appear nor assumes liability for any damages that result

from the use of the products in accordance with the information contained in the

manual.

SPECIAL CONDITION: Should this equipment be used in or with any nuclear

installation or activity, purchaser will indemnify OMEGA and hold OMEGA harmless

from any liability or damage whatsoever arising out of the use of the equipment in

such a manner.

Page 5

Notes

Page 6

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may

not be copied, photocopied, reproduced, translated, or reduced to any electronic medium

or machine-readable form, in whole or in part, without prior written consent of OMEGA

ENGINEERING, INC

.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST

OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper

packaging to prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available

BEFORE contacting OMEGA:

1. P.O. number under which the product

was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific prob-

lems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have

the following information available

BEFORE contacting OMEGA:

1. P.O. number to cover the COST of the

repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific prob-

lems relative to the product.

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations

that apply. OMEGA is constantly pursuing certification of its products to the European

New Approach Directives. OMEGA will add the CE mark to every appropriate device

upon certification.

The information contained in this document is believed to be correct but OMEGA

Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to

alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient

connected applications.

Page 7

Notes

Page 8

Notes

Page 9

42

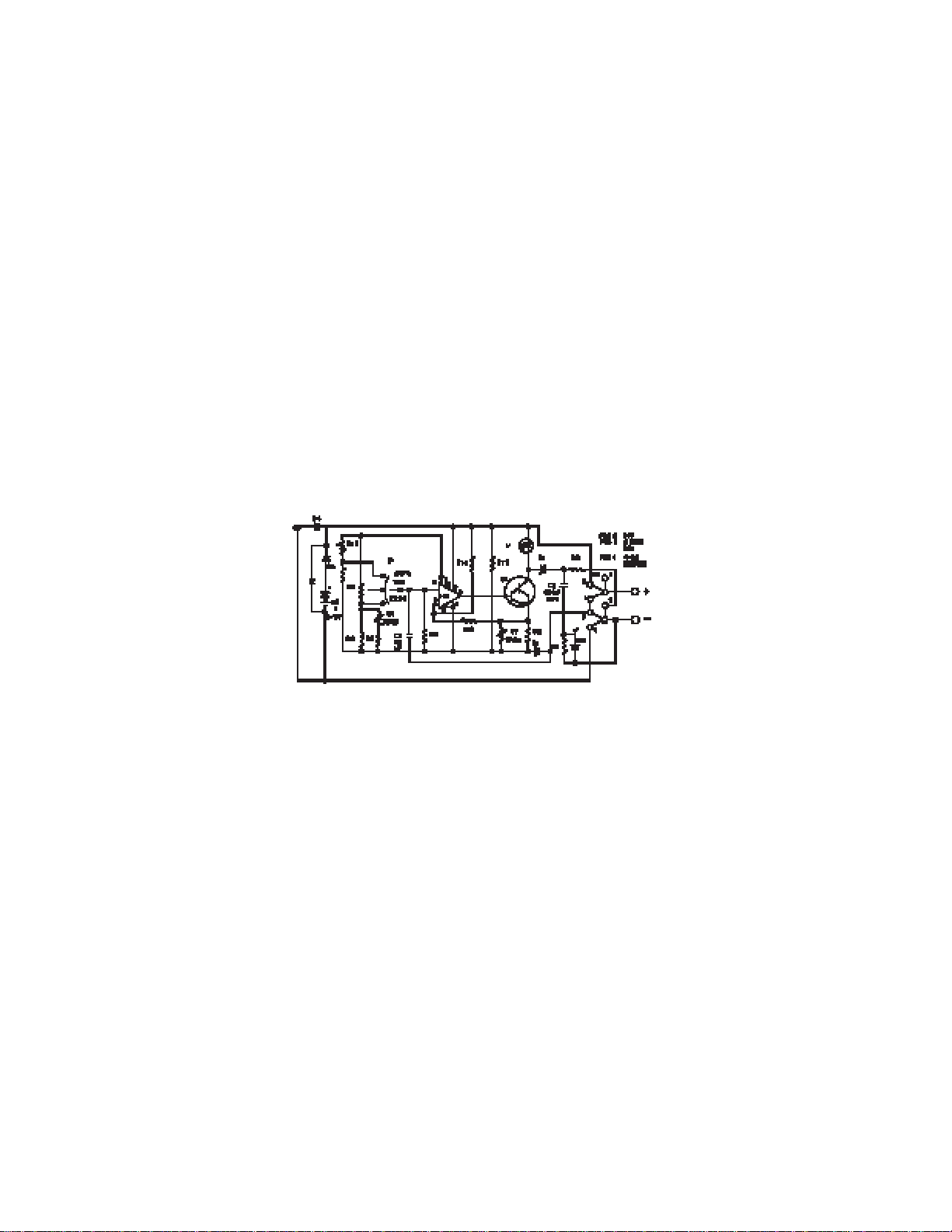

Schematic–OMEGA Model CL-303

Page 10

Table of Contents

Section Page

Model CL-300 Portable

Thermocouple Source..........................................11

Model CL-301 Portable RTD Simulator.................12

Model CL-302 Portable

Transmitter Simulator..........................................21

Model CL-303 Portable

mA Source/2-Wire Simulator..............................30

i

Page 11

Table of Contents

Model CL-300 Portable Thermocouple Source

Section Page

Section 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.1 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 4 Service Information . . . . . . . . . . . . . . . . . . .5

4.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Equipment Required for Calibration . . . . . . . . . . . . . . . . . . 5

4.3 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 5 Specifications . . . . . . . . . . . . . . . . . . . . . . .9

ii

Page 12

Section 5 Specifications CL-303

Internal Batteries: Three 9 Volt Alkaline, MN1604 or

equivalent

Battery Life: Source; 25-hours at 20 mAcontinuous

output, 2-wire Simulator infinite

Battery Status Indicator: LED pulse at turn-on, in source mode

Calibrated Accuracy: ±0.1%

Resolution: 0.02%

Temperature Effect: 0.01%/˚C

Output Drive Capability: 1200 ohms with fresh batteries, or

with optional ac adaptor; 800 ohms at

battery low limit

Power Supply Effect: 0.005%/Volt

Operating Ambient

Temperature: -10˚ to +140˚ F (-25 to +60˚C)

Storage Temperature Limits: -40˚ to +160˚F (-40˚ to +70˚C). Remove

batteries if stored for extended

period.

Warm-up Time: 2-seconds to rated accuracy

Dimensions: H: 4" (101 mm) x W: 2

1

/8" (54 mm)

x D: 2 1/4" (57 mm)

Weight: 11 oz. (0.3 kg)

41

Page 13

40

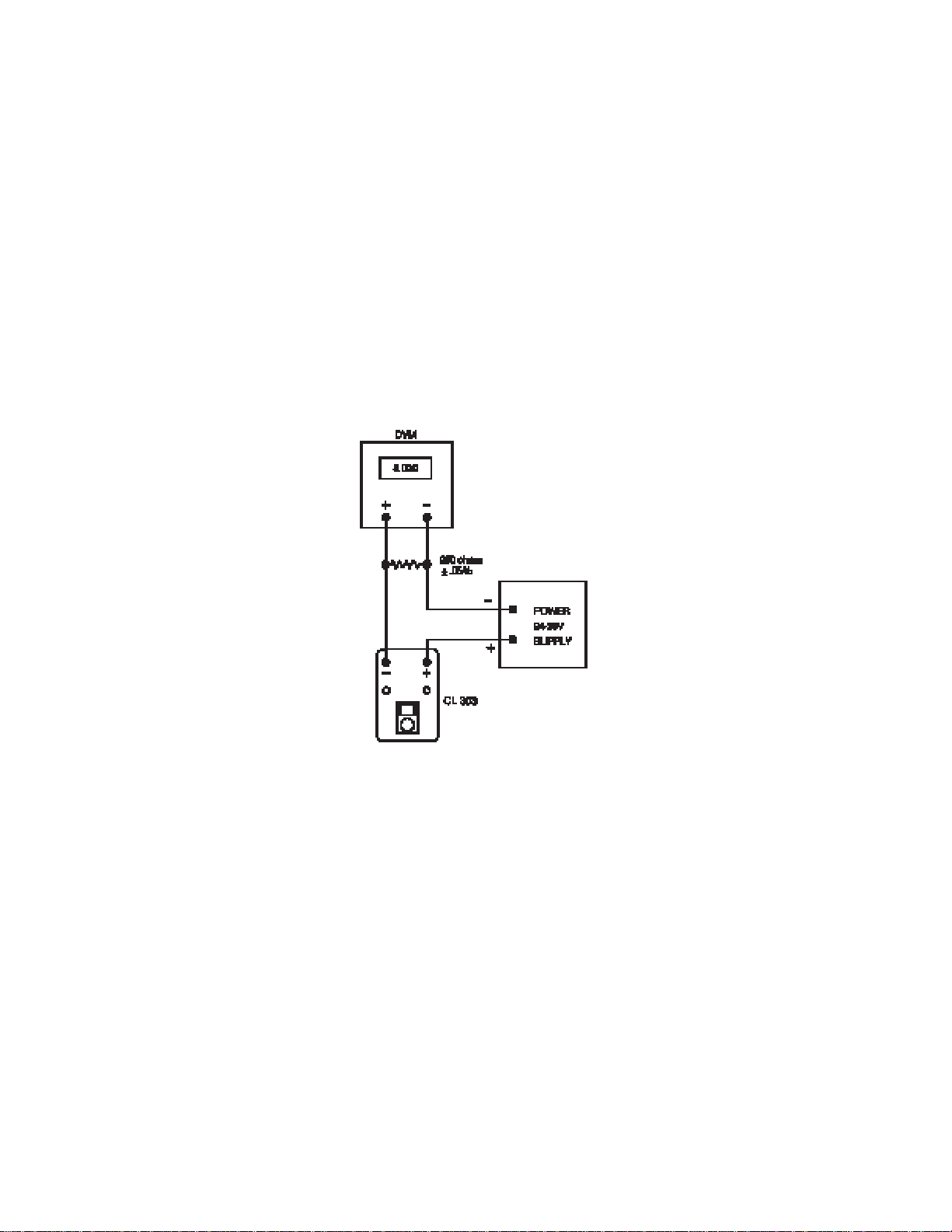

Figure 4-3. 2-Wire Simulator Hookup

Page 14

Section 1 Introduction

1.1 Description

The OMEGA®Model CL-300 Thermocouple Source provides 22 precise

temperature equivalent millivolt signals to transmitters, recorders,

controllers, alarms, data acquisition, and computer systems. Model

CL-300 is cold-junction compensated for ambient temperature

variations and provides a thermocouple connector output. Cables are

available in the desired length and terminal types to exactly duplicate

the thermocouples in the system being tested. Conformity to the

particular thermocouple vs millivolt curve is in accordance with the

latest ASTM and IPTS standards for exact temperature simulation.

Linear millivolt models are also available.

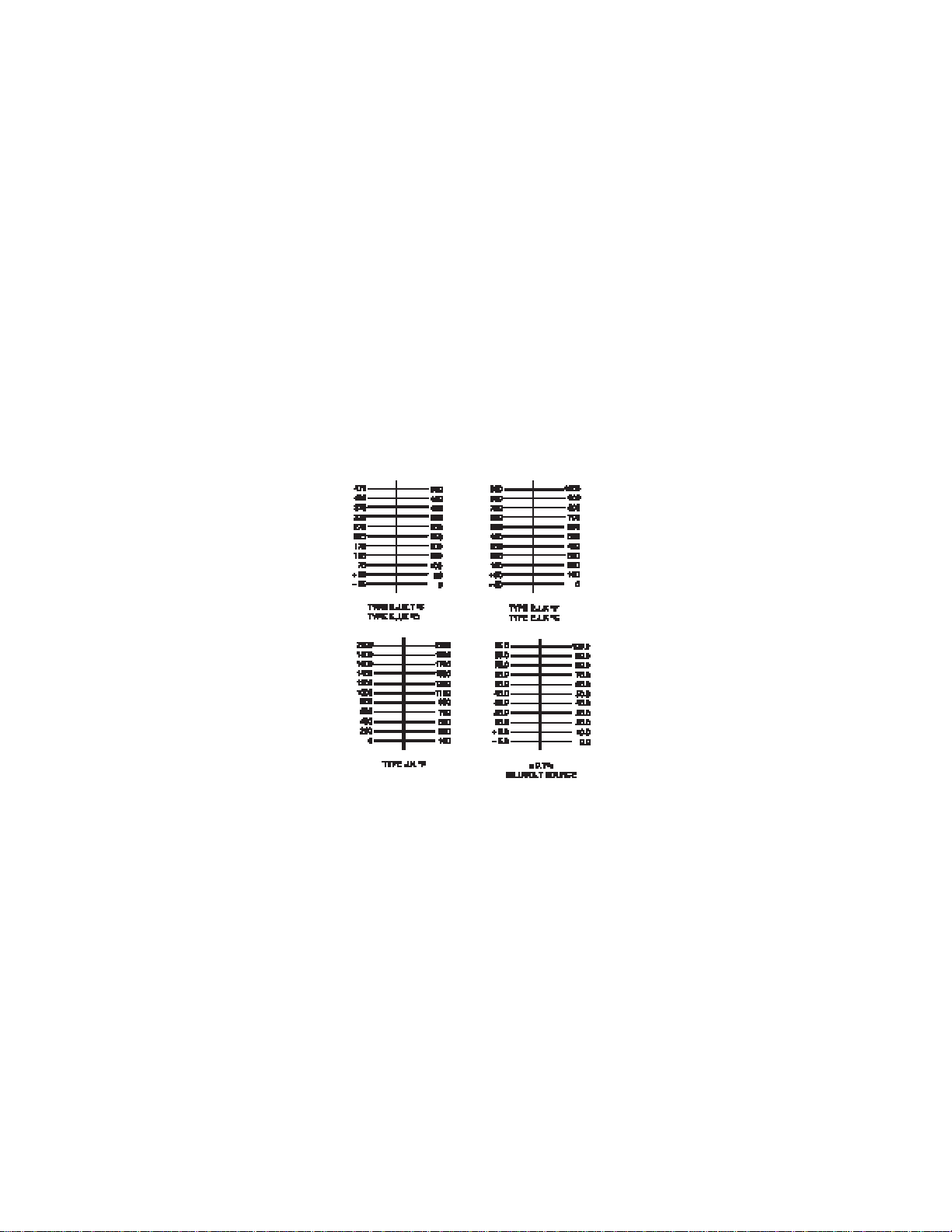

Thermocouple types E, J, K, and T are available in both ˚F and ˚C.

T able 1-1 lists the standard ranges. Resolution is 25˚, 50˚, or 100˚

corresponding to full scale output of 500˚, 1000˚, and 2100˚ respectively.

Dual ranges, with an individual “ON” position for each range, allow

quick, easy settings for any output. Calibrated accuracy is ±0.1% of

span ±1 degree. For negative temperatur es, add ±2 degrees.

T wo internal AAcells provide power for approximately one year of

everyday use. Afront panel LED pulses every time the unit is turned

on to indicate proper battery voltage.

1

Page 15

Table 1-1

Model CL-300 Standard Ranges

2

Page 16

39

Figure 4-2. Adjustment of Span Potentiometer , Model CL-303

Page 17

38

Figure 4-1. Measuring mA Output

Page 18

3

1.2 Features

• Calibrate and T roubleshoot T emperature Systems

• Simulates Thermocouples J, K, E, T, R, S, or mV Sour ce

• Choice of Cable Length and T ype

• T wenty-two Precise T est Points

• Portable, Long Battery Life

• Simple to Use, Inexpensive to Own

Section 2 Installation

2.1 Unpacking

Remove the Packing List to check off actual equipment received.

If you have any questions about the shipment, please call OMEGA’s

Customer Service Department.

Upon receipt of shipment, inspect the container for any signs of

damage in transit. T ake particular note of any evidence of rough

handling in transit. Immediately report any damage to the shipping

agent.

NOTE

The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing contents,

save packing material and carton in the event shipment is necessary.

Page 19

Section 3 Operation

3.1 Operating Instructions

Select the Model CL-300 for the correct thermocouple type, the desired

temperature scale (F or C), and range, the ordered lead type(s).

Connect the Thermocouple Source to the thermocouple input terminals

of the instrument or system to be tested.

Cold-junction compensation and instantaneous automatic

standardization and built into the instrument.

Set the temperature selection switch to the desired temperature and

slide the “ON” switch left or right to the selected scale. The battery

check LED will pulse once indicating proper battery voltage. If no

pulse is seen, the batteries should be replaced with two AAcells.

Alkaline cells are preferred for longest life and widest operating

temperature range.

End point calibration temperatures of the instrument are then selected

on the Model CL-300 and any required adjustments are made.

Intermediate points may then be selected to verify instrument linearity

or check critical points.

4

Page 20

37

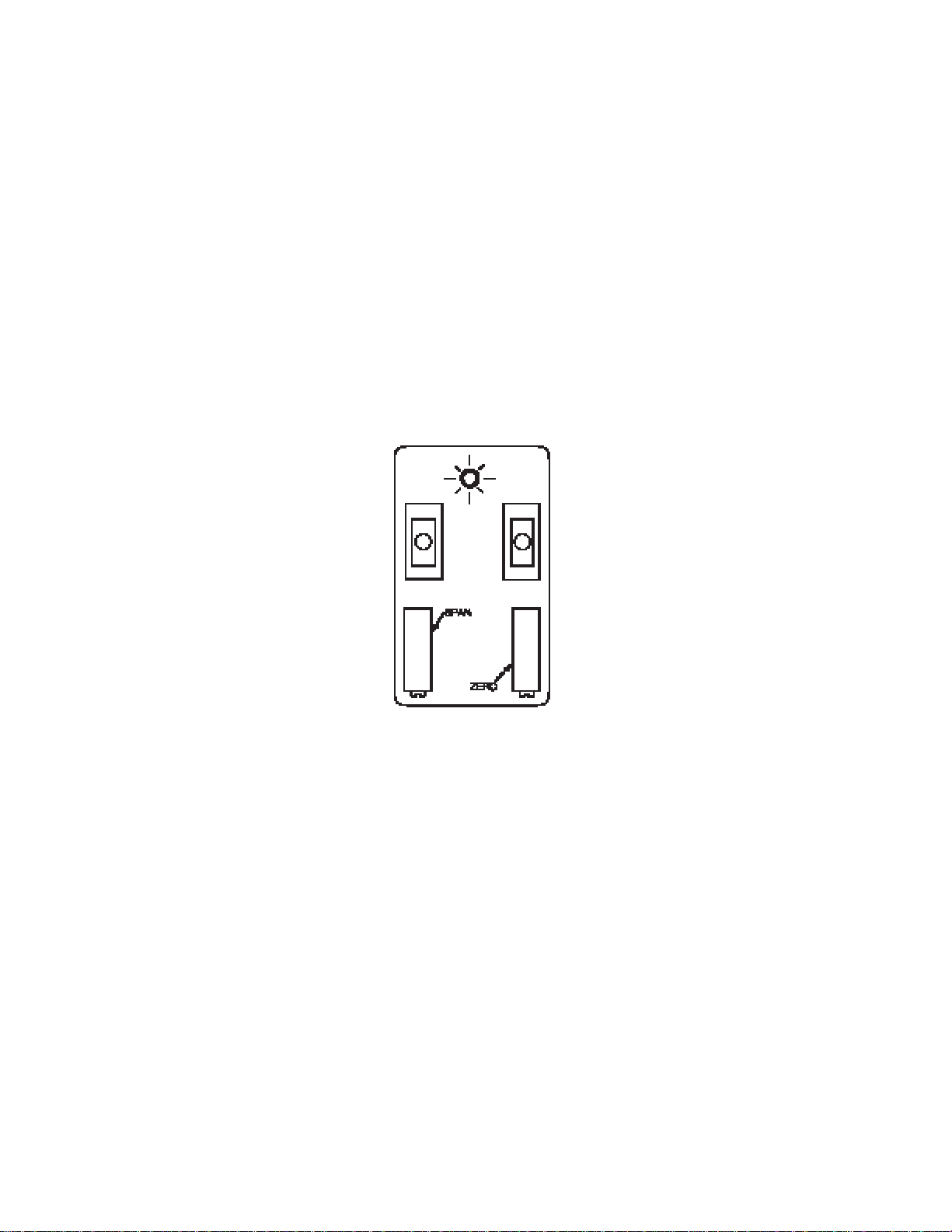

2. The span potentiometer (Figure 4-2) should now be adjusted so

that the meter reads 5,000 volts.

3. The right-hand switch is now moved to the 00.0% position.

4. The zero potentiometer should now be adjusted so that the meter

reads 1.000 volts.

5. Check and readjust the span and zero controls until no further

adjustments are necessary.

6 Move the right-hand switch to the Dial position. The meter

should read between 1.996 V and 2.004 V when the dial is set at

25.0 (Note: decimal points are not shown on the dial). Other

readings are 2.996 V to 3.004 V at a setting of 50.0% and 3.98 V to

4.004 V at a setting of 75.0%. The dial has been mechanically set at

the factory and should need no adjustment under normal

operating conditions.

4.3.2.1 2-Wire Simulator Mode Check

To check the 2-wire Simulator of the CL-303:

1. Reconnect the test set-up to that shown in Figure 4-3.

2. Move the left-hand switch to the “2-wire” position.

3. Place a 24-30 V dc power source in series with the Model CL-303

and the 250 ohm resistor . The 100%, 00.0% and dial readings

should all be within ±0.1% F .S. ±1˚ of those found in the source

mode.

Page 21

36

4.3 Calibration Procedure

Both the mA output and the span and zero adjustments must be

calibrated, as specified below .

4.3.1 mA Output, Source Mode Calibration

Proceed as follows:

1. Before any adjustments to the Model CL-303 are made, fresh

alkaline batteries MN1604, should be placed in the unit.

2. Switch the left-hand switch to position mA OUT while observing

the LED. The LED should flash once, indicating proper battery

voltage. If the LED does not flash, check each battery for proper

voltage and for correct connection.

3. Set the meter to a range which covers one to five V dc with

sufficient resolution.

4. Place the 250 ohm (±0.05%) resistor in series with the Model CL-303

output. The meter will read 1 to 5 volts corresponding to 4-20 mA

through the resistor. See Figure 4-1.

4.3.2 Span and Zero Adjustments

Make the necessary calibration adjustments as indicated below.

1. Set the left-hand switch to position mA OUT and the right-hand

switch to position 100%.

Page 22

Section 4 Service Information

4.1 Maintenance

The OMEGA CL-300 Thermocouple Source requires little servicing.

Should measurement inaccuracies be discovered, perform the

adjustment and calibration procedure to recalibrate the instrument.

4.2 Equipment Required for Calibration

Digital thermometer, ±0.5˚ accuracy with 0.1˚ r esolution or equivalent.

Digital voltmeter, 0.05% accuracy, 10-microvolt resolution or

equivalent.

The recommended technique for calibrating a Model CL-300 requires

two meters. The digital thermometer is used to calibrate the output.

The digital voltmeter is needed to calibrate the built-in cold-junction

compensation.

4.3 Calibration Procedure

It is suggested that each time a unit is recalibrated, fresh AAbatteries

(MN-1500-2) should be substituted for used batteries.

1 Switch the unit to each “ON” positions, making sure that the

battery check LED flashes.

2 Connect the digital thermometer, using the pr oper type thermo-

couple wire, directly to the exposed ends of the Model CL-300’s

output wires.

5

Page 23

3. Connect the DVM to calibrate the cold-junction compensation as

follows: The meter’s positive input is connected to the negative

output of the Model CL-300 and the negative lead of the meter is

connected to the outermost lead. Resistor R17 at the opposite end of

the board. See Figure 4-1.

4. Before the cold-junction compensation can be adjusted, the ambient

temperature of the Model CL-300 must be obtained. For highest

accuracy, this is done by taking a reading on the meter that is

already connected to the thermocouple output leads. With the

range/power switch in the center “OFF” position, the meter will

read the temperature at the internal Model CL-300 terminals.

5. To set the cold-junction compensation, move the range/power

switch to the right-hand “ON” position, and the temperature

selector to the highest output position.

6. The compensation potentiometer is then adjusted to the value

shown in T able 4-1. The span (highest mV output) of the unit is now

adjusted by means of the span potentiometer for the highest

temperature reading of the unit being calibrated. See figure 4-1.

7. The cold-junction compensation should again be checked, and if

readjusted, the span should be rechecked.

8. There are two separate zero (lowest mV output) adjustments. With

the range/power switch still in the right-hand “ON” position, move

the temperature selector switch to the lowest output position. The

right-hand zero is then adjusted by means of the right-hand zero

potentiometer. See Figur e 4-1.

6

Page 24

Section 4 Service Information

4.1 Maintenance

The CL-303 mA Source/2-wire Simulator requires little servicing.

Should measurement inaccuracies be discovered, perform the

adjustment and calibration procedures to recalibrate the instrument.

4.2 Equipment Required for Calibration

Digital voltmeter, 4 1/2" digit, 0.05% or better accuracy, with a precision

(±0.5%) 250 ohm resistor . As a less accurate alternative, a dc millimeter

may be used directly–which eliminates the 250 ohm resistor.

35

Figure 3-2. As a Milliamp Source

Page 25

3.1.2 Directions for Source Mode

Disconnect any existing input wires from the device to be checked or

calibrated. T urn the mode selector switch (left-side) to the mAout

position. The LED will pulse brightly once if the battery voltage is

sufficient. If the LED does not pulse, turn it off and check the batteries.

Connect the red positive (+) lead to the positive input of the device to

be checked or calibrated. Connect the black negative (-) lead to the

negative terminal. See Figure 3-2. The LED will glow steadily when

current is flowing. If no glow appears, check the hookup and

connections.

The 00.0% (4.00 mA) and 100% (20.00 mA) Dial adjustments are

selected with the right-hand switch. Fast zero and full scale checks can

be made by means of the 00.0% and the 100% positions. Athird quick

check position may be established by adjusting the digital dial to the

desired percent value and locking it in place. The continuous

adjustment dial reads directly in percent of the 4-20 mAsignal. For

example, a dial setting of 500 is 50% of span or 12mA. Complete the

adjustments and turn the instrument off. Reconnect any wires that

were removed for the check out.

34

Figure 3-1. As a 2-Wire Simulator with Self Powered Unit

Page 26

19. To calibrate the left-hand zero, select the left-hand “ON” position.

For the highest accuracy, the left-hand zero should be calibrated at

the second lowest setting (+25˚ on 500˚ units; +50˚ on 1000˚ units,

+200˚ on 2100˚ units). The left-hand zero is then adjusted by means

of the left-hand zero potentiometer . (See Figure 4-1).

10. Recheck the span at the highest output. When the span and both

zeros have been calibrated, check the other output positions to

assure that the Model CL-300 is operating properly.

The allowable variation in 2100˚ and 3100˚ units is ±3˚. For 1000˚ units,

it is ±2˚. For the 500˚ units, the allowable tolerance is ±1.5˚. Add 1˚ to

tolerances for negative temperatures.

Table 4-1

Cold Junction Compensation Set Points

Degrees C

20

21

22

23

24

25

26

27

28

29

30

T ype E

18.151

18.211

18.272

18.333

18.394

18.455

18.516

18.577

18.638

18.699

18.760

T ype J

15.409

15.460

15.512

15.564

15.615

15.667

15.719

15.770

15.822

15.874

15.926

T ype K

12.071

12.111

12.152

12.192

12.233

12.273

12.314

12.354

12.395

12.435

12.476

T ype T

12.130

12.170

12.211

12.252

12.292

12.333

12.374

12.414

12.455

12.496

12.537

T ype R& S

1.788

1.794

1.800

1.806

1.812

1.818

1.824

1.830

1.836

1.842

1.848

7

Page 27

8

Figure 4-1. Calibration Hook-Up, Model CL-300

Page 28

Section 3 Operation

3.1 Operating Instructions

Outlined below is the operating protocol for the two modes of

operation.

3.1.1 Directions for 2-Wire Simulator Mode

Disconnect any existing 2-wire transmitter from the loop to be checked

or calibrated. (Only one of the two wires need be disconnected). Leave

the power source and the receiver in place.

Place the mode selector switch into the 2-wire position. Connect the red

clip lead of the Model CL-303 to the positive (+) terminal of the field

connections. Connect the black lead to the negative (-) terminal. See

Figure 3-1.

The LED will glow steadily when current flows. If no glow appears,

recheck all external connections. Internal batteries are not used in this

mode.

The 00.0% (4.00 mA) and 100% (20.00 mA) Dial adjustments are

selected with the right-hand switch. Fast zero and full scale checks can

be made by means of the 00.0% and the 100% positions. Athird quick

check position may be established by adjusting the digital dial to the

desired percent value and locking it in place. The continuous

adjustment dial reads directly in percent of the 4-20 mAsignal. For

example, a dial setting of 750 is 75% of span or 16mA. Complete the

adjustments and turn the instrument off.

33

Page 29

32

1.2 Features

• Calibrate or T est 4-20 mAdc Systems

• Precise 4-20 mAdc Source

• Simulates Loop Powered Transmitter

• Continuous 0 to 100% settings

• Quick Check 0% to 100% switch

Section 2 Installation

2.1 Unpacking

Remove the Packing List to check off actual equipment received.

If you have any questions about the shipment, please call OMEGA’s

Customer Service Department.

Upon receipt of shipment, inspect the container for any signs of

damage in transit. T ake particular note of any evidence of rough

handling in transit. Immediately report any damage to the shipping

agent.

NOTE

The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing contents,

save packing material and carton in the event shipment is necessary.

Page 30

Section 5 Specifications CL-300

Batteries: Two “AA” alkaline cells provide

approximately one year of use

Battery Indicator: LED light pulse at turn-on in either

range

Accuracy: ±0.1% of span ±1˚. For negative

temperatures, add ±2˚.

Cold-junction Compensation: Built-in for specified thermocouple

type

Cold-junction Temperature

Effect: Within ±0.25 degrees at 75˚F (20˚C)

±0.025 degrees/degree change in

ambient

Operating Ambient

Temperature: -10˚ to +130˚F (-25˚ to +55˚C)

Ambient Temperature Effect: Zero included in cold-junction effect.

Span: ±0.01% of span/degree

Storage Temperature Limits: -40˚ to +160˚F (-40˚ to +70˚C)

Output Impedance: Fixed, 50 ohms nominal

Dimensions: H: 4" (101 mm) x W: 2

1

/8" (54 mm)

x D: 2 1/4" (57 mm)

Weight: 6 oz. (0.15 kg)

9

Page 31

10

Schematic–OMEGA Model CL-300

Page 32

Table 1-1

CL-303 Dial Settings and Output

Dial Setting Output Current

% Milliamps

00.0 4.00

05.0 4.80

10.0 5.60

15.0 6.40

20.0 7.20

25.0 8.00

30.0 8.80

35.0 9.60

40.0 10.4

45.0 11.2

50.0 12.0

55.0 12.8

60.0 13.6

65.0 14.4

70.0 15.2

75.0 16.0

80.0 16.8

85.0 17.6

90.0 18.4

95.0 19.2

100.0 20.0

NOTE: Decimal point not shown on instrument’s dial.

31

Page 33

Section 1 Introduction

1.1 Description

The dual function OMEGA®CL303 Simulator combines a selfcontained 4-20 mA source with a 2-wire Simulator in one pocketsized instrument.

Internal batteries are used in the source mode to provide continuously

adjustable 4-20 mA into any load from 0-800 ohms. An optional ac

adaptor allows full-time bench use.

The 2-wire Simulator mode utilizes external loop power to pass

precisely adjustable 4-20 mA. Loop power may vary from 6 to 45 V dc.

In addition to the 0.1% accurate digital dial adjustments, switch

selected signals are provided at 4.00 mA(00.0%) and 20.00 mA(100%)

for “quick check” zero and full scale settings in both modes (refer to

T able 1-1).

Small size is made possible through state-of-the-art design which

includes a precision reference, an ultra-stable amplifier, and high-gain

power Darlington output. Accuracy, stability and low power

consumption are combined through he use of the latest microcircuitry.

Continuous adjustability with memory lock assures fast, precise

settings of current trips, recorders, data loggers, controllers, computers,

and final control elements. Long life batteries allow complete

portability for checkout and calibration of all milliamp input devices.

30

Page 34

Table of Contents

Model CL-301 Portable RTD Simulator

Section Page

Section 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 4 Service Information. . . . . . . . . . . . . . . . . . . 16

4.1 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Equipment Required for Calibration. . . . . . . . . . . . . . . . . . 16

4.3 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 5 Specifications . . . . . . . . . . . . . . . . . . . . . . . 19

11

Page 35

Section 1 Introduction

1.1 Description

The OMEGA®Model CL-301 Platinum RTD Simulator provides eleven

precise temperatures for inputs to transmitters, recorders, contr ollers,

alarms, data acquisition, and computer systems. Model CL-301 allows

2, 3, or 4-wire connections. Conformity to the particular RTD curve is in

accordance with the latest DIN 43760 standard.

Calibrations are available in both ˚F and ˚C and standard ranges are

listed in T able 1-1. Other ranges and curves are available as options.

Resolution is 25˚, 50˚, or 100˚, corresponding to the full scale output of

250˚, 500˚, and 1000˚ respectively.

Positive switch selection allows quick, easy settings for any output.

Calibrated accuracy is ±0.05% of span ±0.25˚.

1.2 Features

• Calibrate and T roubleshoot 2, 3, or 4-wire RTD systems

• Simulates 100 ohm RTD, alpha = .00385

* Choice of Output T erminal

• Eleven Precise Test Points

• Portable, No Battery or Power Required

• Simple to Use, Inexpensive to Own

12

Page 36

Table of Contents

Model CL-303 Portable mA Source/

2-Wire Simulator

Section Page

Section 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 30

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Section 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Section 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1 Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1.1 Directions for 2-Wire Simulator Mode . . . . . . . . . . . . . . . . 33

3.1.2 Directions for Source Mode. . . . . . . . . . . . . . . . . . . . . . . . . . 34

Section 4 Service Information. . . . . . . . . . . . . . . . . . . 35

4.1 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2 Equipment Required for Calibration. . . . . . . . . . . . . . . . . . 35

4.3 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.1 mA Output, Source Mode Calibration . . . . . . . . . . . . . . . . 36

4.3.2 Span and Zero Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.2.1 2-Wire Simulator Mode Check . . . . . . . . . . . . . . . . . . . . . . . 37

Section 5 Specifications . . . . . . . . . . . . . . . . . . . . . . . 41

29

Page 37

28

Schematic–OMEGA Model CL-302

Page 38

Table 1-1

Model CL-301 Standard Ranges

Section 2 Installation

2.1 Unpacking

Remove the Packing List to check off actual equipment received. If you

have any questions about the shipment, please call OMEGA’s

Customer Service Department.

Upon receipt of shipment, inspect the container for any signs of

damage in transit. T ake particular note of any evidence of rough

handling in transit. Immediately report any damage to the shipping

agent.

13

Page 39

14

Section 3 Operation

3.1 Operating Instructions

Select the particular OMEGAModel CL-301 for the desired

temperature scale (F or C), and appropriate temperature range. Then

choose the cable type (2, 3, or 4-wire) that is equivalent to the RTD

you are simulating . See Figure 3-1.

Connect the RTD Simulator leads to the input terminals of the

instrument or system to be tested. Typically the CL-301 might feed a

recording system, a controller, a datalogger, and a computer interface.

Set the temperature selection switch on the CL-301 to the desired

temperature. End point calibration temperatures of the instrument are

then selected on the CL-301 and any required adjustments are made.

Intermediate points on the CL-301 may then be selected to verify

instrument linearity or to check critical points.

NOTE

The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing contents,

save packing material and carton in the event shipment is necessary.

Page 40

Section 5 Specifications CL-302

Calibrated Accuracy: ±0.1% of span

Precise Switch Settings: 0, 25, 50, 75, 100% of full scale

equivalent to 4, 8, 12, 16, 20 mA

Temperature Effect: ±0.01%/˚C

Loop Voltage Rating: Any between 6 and 45 volts

Voltage Drop: 6 V and 20 mA

Dimensions: H: 3

1

/4" (82 mm) x W: 2 1/8"

(54 mm) x D: 1 1/8" (29 mm)

Weight: 3 oz. (85 grams)

27

Page 41

26

Figure 4-2. Zero and Span Controls, Model CL-302

Figure 4-1. Calibration Check

Page 42

15

Figure 3-1. Connecting the RTD Simulator to Transmitter

or Receiver

Page 43

16

Section 4 Service Information

4.1 Maintenance

The OMEGA CL-301 RTD Simulator requires little servicing. Should

measurement inaccuracies be discovered, perform the adjustment and

calibration procedure to recalibrate the instrument.

4.2 Equipment Required for Calibration

Digital ohmeter, 0.025% accuracy with 4-wir e ohm connections

(OMEGA Model 881 or equivalent).

4.3 Calibration Procedure

Calibrate the instrument in the following manner:

1 Connect the unit to the meter in a 3-wire hookup.

2. Move the slide switch to the lowest temperature position (position

1) and adjust corresponding potentiometer (Pot 1, Figure 4-1)

according to the resistance value obtained form Table 4-1.

3. Move the switch to the next temperature position (2) and adjust

corresponding potentiometer (Pot 2).

4. Continue this procedure for all remaining temperature positions in

ascending order .

Page 44

25

4.3.2 Span and Zero Adjustment Procedures

1 Set the switch on the Model CL-302 to the 209 mA (100%) position.

2. The span potentiometer is adjusted so that the meter reads 5.000

volts. See Figure 4-2.

3. The switch is now moved to position 4 mA (0%).

4. The zero potentiometer is adjusted until the meter reads 1.000

volts.

5. Check and readjust the span and the zero controls until they are

within ±0.1% accuracy (±0.02% typical).

4.3.3 Linearity Test Protocol

1 Move the switch to position 8 mA (25%). The meter should read

between 1.996 V and 2.004 V.

2. With the meter set at 12 mA (50%), the meter should read between

2.996 V and 3.004 V.

3. Setting the meter at 16 mA ((75%), the meter should read between

3.996 V and 3.004 V.

Page 45

24

Section 4 Service Information

4.1 Maintenance

The OMEGA CL-302 Transmitter Simulator is long-lasting and

requires little servicing. Should measurement inaccuracies be

discovered, perform the adjustment and calibration procedures,

specified below , to recalibrate the instrument.

4.2 Equipment Required for Calibration

Digital voltmeter,4 1/2digit, 0.05% (or better) accuracy with a

precision (±0.05%) 250-ohm resistor.

4.3 Calibration Procedure

Calibration requires a hookup protocol, span and zero adjustments,

and a linearity test.

4.3.1 Calibration Hookup Protocol

1 Set the calibrating meter to a range which covers the 1 to 5 V dc

spectrum with sufficient resolution.

2. Place the 24 to 30 V dc power supply in series with the 250 ohm

(±0.05%) resistor and the Simulator which is to be calibrated. The

meter will read 1 to 5 volts corresponding to 4-20 mAthrough the

resistor . See Figure 4-1. The LED on the Simulator should be lit,

indicating that the connections are correct and that the unit is

functioning..

Page 46

17

5. Upon completion, move the switch back to position 1. Check and

readjust potentiometer (Pot 1), if necessary. In increasing order,

check and readjust each position as necessary to obtain specified

accuracy.

Each time a position is adjusted, ALL higher number positions must be

rechecked.

CAUTION

Figure 4-1. Potentiometer

Adjustments, Model CL-301

Page 47

Table 4-1

Adjustment Values

18

Material and Nominal Resistance Alpha (α) R (100˚C)/R (0˚C)

Platinum (PT.)* 1.3850 (DIN Standard 43760)

100 OHM 1.3926 (U.S. Laboratory)

200 OHM 1.3889 (Canadian)

500 OHM 1.3911 (U.S. Industrial)

1.3902 (U.S. Industrial)

Nickel 1.6720

120 OHM

600 OHM

Nickel-Iron 1.5188

604 OHM

Copper 1.4274

9.035 OHM (10 OHMS at 25˚C)

234 OHM

421.2 OHM

1000 OHM

2000 OHM (at 70˚F)

*If not specified DIN standard curve 43760 will be supplied.

Page 48

23

Figure 3-1. Alternative Hookup Methods

Page 49

Upon receipt of shipment, inspect the container for any signs of

damage in transit. T ake particular note of any evidence of rough

handling in transit. Immediately report any damage to the shipping

agent.

Section 3 Operation

3.1 Operating Instructions

First disconnect the transmitter form the loop, leaving the power

source and receiver in place.

Connect the two clip leads of the Simulator to the positive (+) and the

negative (-) field connections of the receiver or controller (to be

checked or calibrated) in place of the field 2-wire transmitter. See

Figure 3-1. An LED indicates current flowing through the calibrator.

The selector switch is then positioned at the 0% point. Exactly 4 mA

will pass through the loop. At this time, the zero of the r eceiver is

adjusted. Move the switch to allow 100% to pass and make the

required full scale adjustment. When both span and zero are corr ect,

the 25%, 50% and 75% settings are used to check linearity. Selected

settings are accurate within ±0.1% of span.

22

NOTE

The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing contents,

save packing material and carton in the event shipment is necessary.

Page 50

Section 5 Specifications CL-301

Accuracy: ±0.05% of span ±0.25 degree

Operating Ambient

Temperature: -10˚ to +130˚F (-25˚ to +55˚C)

Ambient Temperature Effect: ±0.01% degree (% of span)

Storage Temperature Limits: -40˚ to +160˚F (-40˚ to +70˚C)

Dimensions: H: 4" (101 mm) x W: 2

1

/8" (54 mm)

x D: 2 1/2" (38 mm)

Weight: 3 oz. (0.12 kg)

19

Schematic–OMEGA Model CL-301

Page 51

Table of Contents

Model CL-302 Portable Transmitter Simulator

Section Page

Section 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 21

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Section 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Section 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1 Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Section 4 Service Information. . . . . . . . . . . . . . . . . . . 24

4.1 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Equipment Required for Calibration. . . . . . . . . . . . . . . . . . 24

4.3 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.1 Calibration Hookup Procedure . . . . . . . . . . . . . . . . . . . . . . 24

4.3.2 Span and Zero Adjustment Procedures . . . . . . . . . . . . . . . 25

4.3.3 Linearity Test Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 5 Specifications . . . . . . . . . . . . . . . . . . . . . . . 27

20

Page 52

Section 1 Introduction

1.1 Description

The OMEGA®Model CL-302 T ransmitter Simulator provides lab

accuracy for a wide range of settings. Instant availability of data is

assured; no internal batteries or line cords are ever needed. Latest

microcircuitry includes a precision refer ence, ultra-stable comparator,

and a high-gain power Darlington output. Switch settings of 0%, 25%,

50%, 75%, and 100% allow fast full range check out of the instrument to

be calibrated. Low minimum voltage drop enables other devices to

remain in the loop while the receiving device is being calibrated.

1.2 Features

• Calibrate or T est, 4-20 mASystems

• Simulates Loop Powered Transmitter

• Five Precise Test Points

• Portable, 0.1% Accuracy

• No Batteries of Power Required

Section 2 Installation

2.1 Unpacking

Remove the Packing List to check off actual equipment received. If you

have any questions about the shipment, please call OMEGA’s

Customer Service Department.

21

Loading...

Loading...