Page 1

Chapter Page

Table of

1 Introduction 1

1.1 Description 1

2 Calibration 3

2.1 Wet Calibration 3

2.2 Calibration Procedure 4

2.3 Installing Optional Display Board 5

2.4 Display Board Range Adjustment 6

3 Installation 7

3.1 General 7

3.2 Positioning 7

3.3 In-Line Installations 8

3.4 In-line Fitting Options 8

3.5 Submersible Installations 10

3.6 Electrical Installation 11

4 Conductivity Sensor Maintenance 13

4.1 Maintenance Tips 13

4.2 Troubleshooting Guide 14

Specifications 15

Dimensional View 16

Warranty 19

Contents

Page 2

SAFETY INSTRUCTIONS

1. Do not remove from pressurized lines.

2. Do not exceed maximum temperature/pressure

specifications.

3. Do not install/service without following

installation instructions (see sensor manual).

4. Wear safety goggles and faceshield during

installation/service.

5. Do not alter product construction.

6. Failure to follow safety instructions could result

in severe personal injury!

-XX refers to electronic range

options:

• CDTX-80 =

0 to 20 µS, 0.5 cell

• CDTX-81 =

0 to 200 µS, 0.5 cell

• CDTX-82 =

0 to 2,000 µS, 2.0 cell

• CDTX-83 =

0 to 10,000 µS, 2.0 cell

Unpacking and Inspection

The following items are included in your

Conductivity transmitter package:

• CDTX-80 Series Conductivity Transmitter

• Instruction manual

Page 3

This manual contains description, instructions and

specifications for the installation, calibration and

care of the CDTX-80 Series Conductivity

Transmitter.

1.1 Description

The CDTX-80 Series Conductivity Transmitter is

used in conjunction with an insertion type sensor

that continuously measures the conductivity (total

dissolved solids or gases) of a solution in a wide

variety of process applications.

The Conductivity Transmitter consists of a

conductivity sensor and an electronics package

(transmitter). The electronics package is housed in

a NEMA 4X/IP65 enclosure.

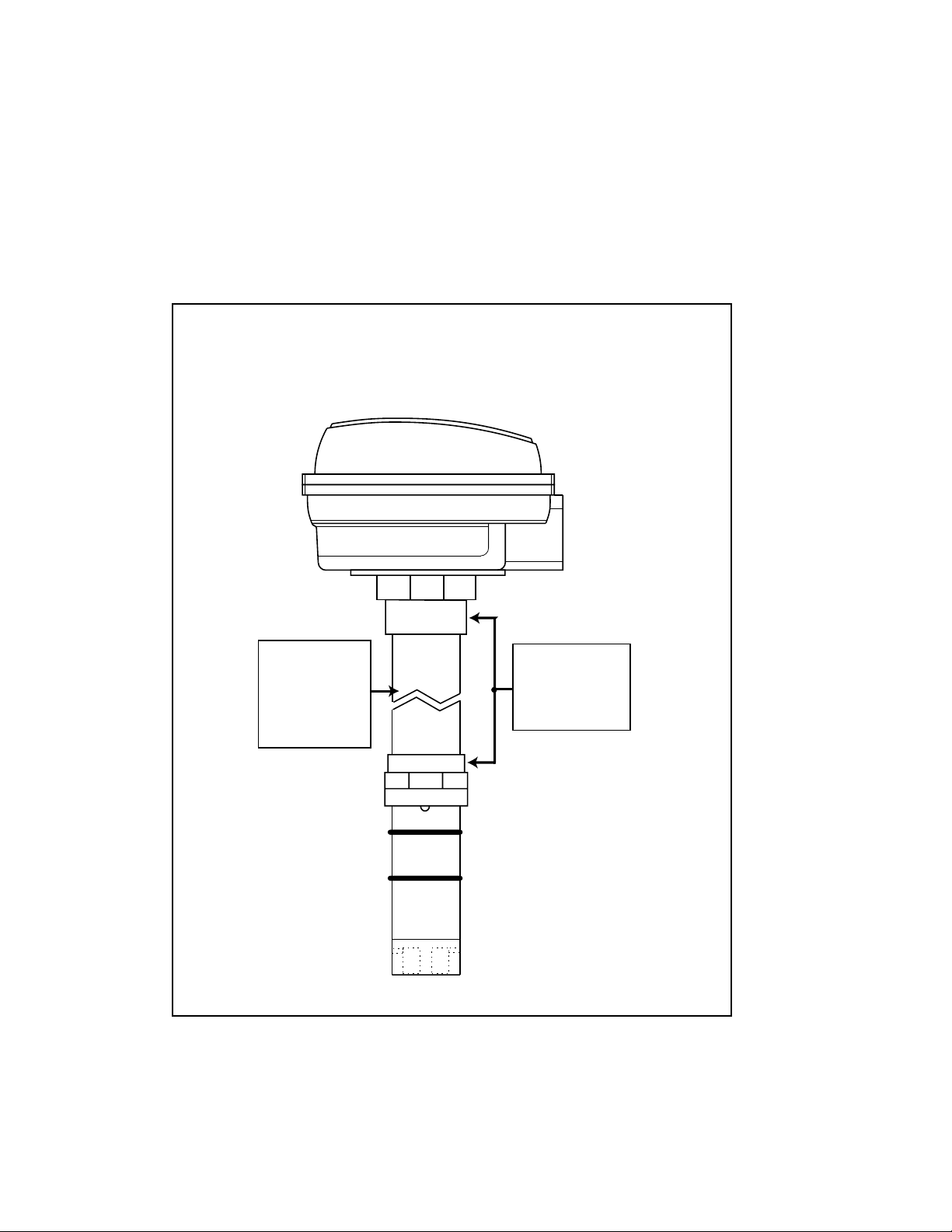

The CDTX-80 Series Condutivity Transmitter can be

converted for submersible applications such as

water wells, tanks etc. Optional submersion kit,

PHCN-86S includes the necessary parts and

assembly instructions for extending the sensor

length up to 12 ft. The submersible kit requires a

3/4 inch pipe with male NPT threads on both

ends, (customer supplied) that is used to physically

extend the sensors' length (See figure 1 page 2).

Chapter 1

Introduction

1

Page 4

Figure 1

Transmitter submersion kit

and required extension

cable.

CDTX-80 Series Conductivity

Transmitter with Submersion Kit

Customer

supplied pipe

with 3/4 in.

NPT threads

Submersion

Kit/Assembly

Instructions

PHCN-86S

both ends

2

Page 5

2.1 Wet Calibration

Your CDTX-80 Series Conductivity Transmitter has

been electronically calibrated at the factory before

shipment. You will need to perform a wet

calibration to compensate for electrode variations.

Wet calibration compares the output of the

transmitter against the conductivity value of a test

solution.

Wet Calibration should be performed while the

CDTX-80 Series Conductivity Transmitter is being

permanently installed. When done carefully, you

can trim the transmitter accuracy to within ±1% of

full scale.

P4

Chapter 2

Calibration

P2

Figure 2

Adjustment pots

and connectors

R-R+

12

R26

R17

Zero Pot

(R26)

Gain/Span

Pot (R17)

3

Page 6

Figure 3

R+ R-

ZERO

SPAN

12

R26

R17

Zero Pot

(R26)

Span

Pot (R17)

+

+

-

-

10 to 30 VDC

Power

Supply

A

Ammeter

Transmitter Hook-up

NOTE:

The current output can be

monitored in several ways

(see Figure 8)

Equipment Required

• Small screwdriver

• Power supply (10 to 30 VDC)

• Ammeter

2.2 Calibration Procedure

1. Connect power supply to transmitter input

placing an ammeter in series with the input

power, see Figure 3.

2. With the Conductivity electrode in the air

(0 conductance) adjust the Zero pot (R26) for

4.00 mA.

3. Place the electrode into a solution of known

conductance and adjust the Span pot (R17) for

the corresponding mA value.

mA =

[(Known Cond./Full Scale Cond.) • 16 mA] + 4 mA

4. Remove the sensor from solution and verify that

the sensor reads 4.00 mA.

5. Repeat steps 2 through 4 as necessary.

4

Page 7

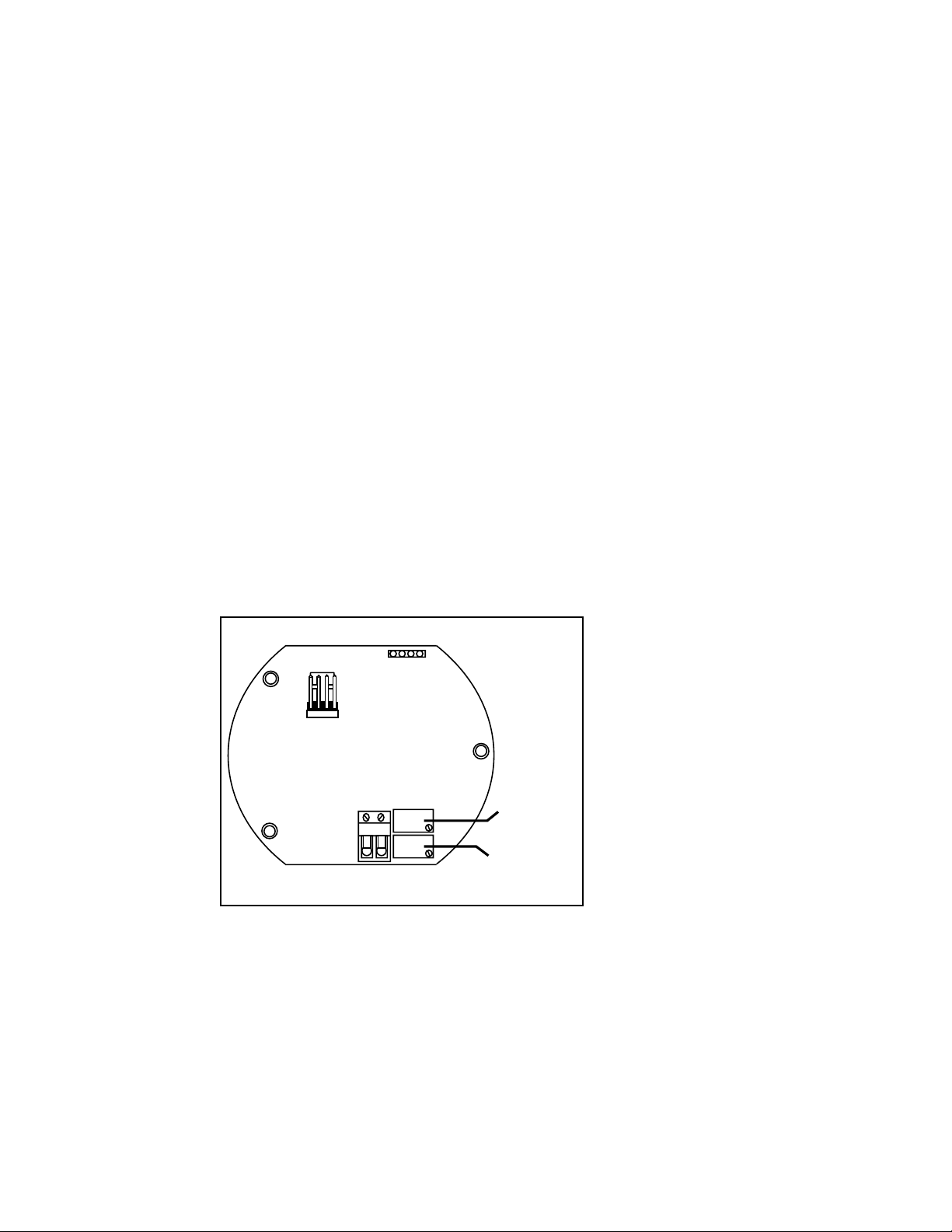

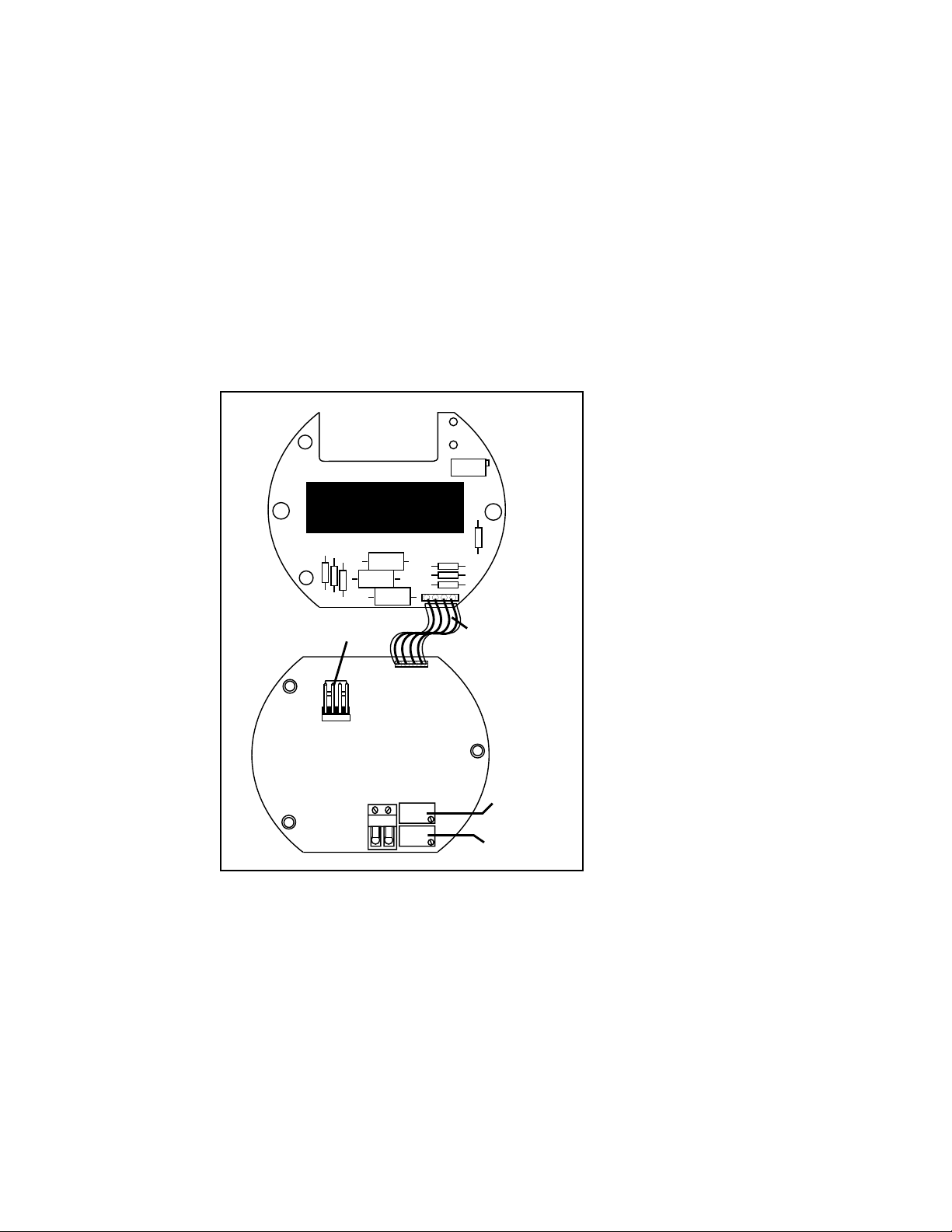

2.3 Installing Optional Display Board

The addition of the display board option

(CDTX-80-D) to the conductivity transmitter is

done in the following manner.

1. Remove snap-on cover allowing access to the

P4 connector.

2. Plug the four conductor ribbon cable into the

P4 connector, see Figure 4.

Display Board (Bottom View)

R2

RANGE

P3

Figure 4

Display Board

Installation Drawing

part no. CDTX-80-D

Sensor

connector

P2

P+

T+

SHLD

Pin 1 P+

12

1

R-R+

R26

R17

P4

Display/

Main bd.

Interface

Cable

Zero Pot

(R26)

Span

Pot (R17)

3. If necessary use a small blade (e.g Exacto knife)

to remove any conformal coating from the standoff

holes or calibration pot access holes.

4. Carefully snap the display board onto the

three standoffs.

5. Re-calibrate the instrument as explained in

section 2.2.

5

Page 8

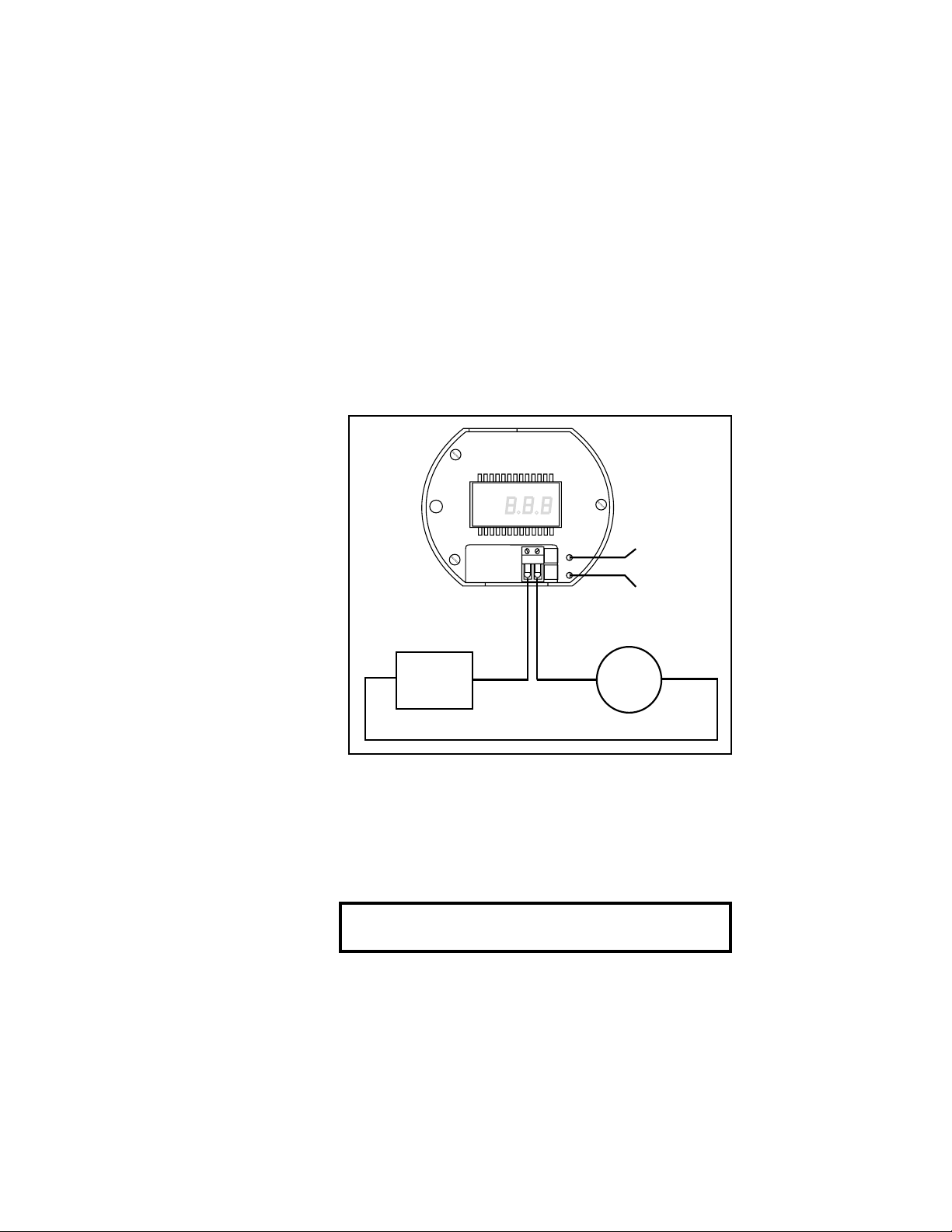

ZERO

SPAN

Interface cable

connection to main

PC board. Located

on underside of LCD

board

Range Potentiometer;

Located on underside

of LCD board. Can be

adjusted through the

hole in the electronics

housing.

(Solution value ÷ Full Range) • 100 = Percentage

Figure 5

Range Potentiometer Location

2.4 Display Board Range Adjustment

The display board displays from zero to one

hundred percent of range. This PCB has a

one-point calibration which may need to be done

at installation.

1. Re-calibrate per section 2.2

2. Calculate percentage of full scale and adjust

Range pot on display board so that the display

shows the proper percent of Full Scale.

Model no. Full Range

CDTX-80 20 µS

CDTX-81 200 µS

CDTX-82 2,000 µS

CDTX-83 10,000 µS

T

he display board draws

approx. 200 µA of current.

When added, the transmitter

requires recalibration.

6

Page 9

3.1 General

This transmitter may be installed in harsh

environmental locations. However, when possible

the transmitter should be located so as to minimize

the effects of temperature gradients and to avoid

vibration and shock.

3.2 Positioning

In order to achieve good repeatable results care

must be taken in the placement of the sensor. It is

important that the sensor electrodes are fully

immersed in the process fluid. Flow rates around

the sensor must be limited so as not to produce air

pockets which will affect the signal path through

the fluid. We recommend that you do not mount

completely upside-down as sediments may become

trapped in the sensor and that you do not mount at

the very top of the pipe because the pipe might

not always be full.

8 O'clock 4 O'clock

Chapter 3

Installation

The information provided

on sensor positioning are

recommendations only. The

primary consideration is that

the electrodes are in full

contact with the process fluid.

If sediments are present we

recommend avoiding the 6

O'clock position.

OMEGA PHA-86

pipe adaptor

(1-1/4 in. NPT)

Figure 6

I

n-line Sensor

Positioning Diagram

7

Page 10

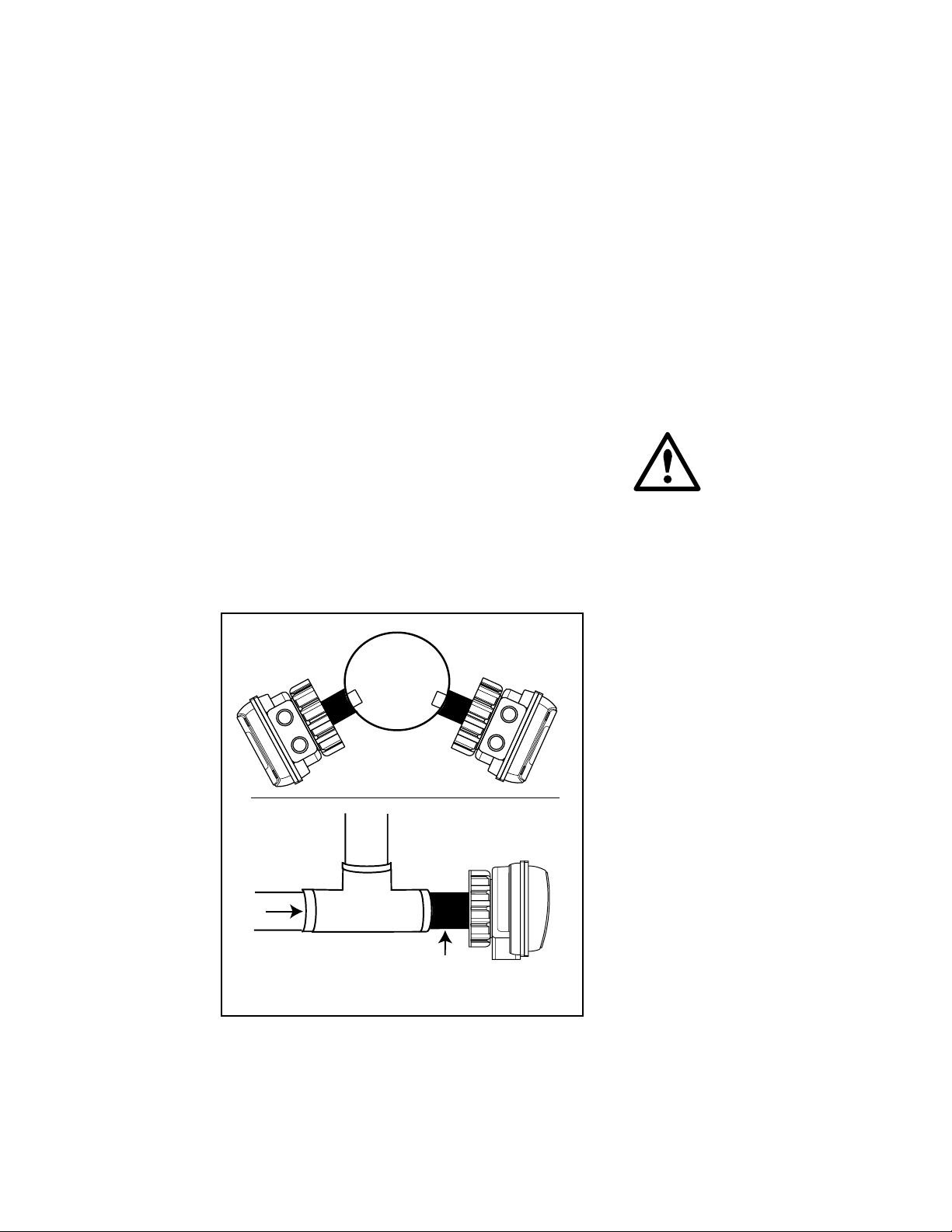

3.3 In-Line Installations

The CDTX-80 Series Conductivity Transmitter

sensor system is designed for installation into a

pipe using standard OMEGA Engineering fittings

(up to 4 inch), or the optional PHA-86 pipe

adaptor fitting. Refer to section 3.4 for additional

information.

Caution:

installing saddle

fittings, depressurize and drain pipe

before drilling fitting hole.

P

lastic "glue-on" Tee Fitting

Plastic "glue-on" Saddle

Fitting

When

3.4 In-line Fitting Options

These fittings provide the proper installation

parameters that are critical to the calibration of the

conductivity system.

Fitting Installation/Plastic Fittings

Tees:

• All tee fittings sold by OMEGA Engineering are

"glue-on" type except for the PVDF tees which

are thermally fused. Be aware that PVC and

CPVC tees require different types of primer and

cement.

• Tee fittings are available for pipes from 0.5 to

4 inches in diameter.

Saddles:

• Plastic "glue-on" saddles are available for lines

from 2 to 4 inches in diameter.

• 2 to 4 inch "glue-on" saddles require a 1-7/16

inch hole in the pipe. (O-ring not used with

glue-on type)

• The hole must be completely deburred to be

free of any projections.

• When assembling plastic saddles, the arrows

on the wedges must match the direction of the

arrows on the pipe saddle.

Misc:

OMEGA Engineering also offers a pipe adaptor

specifically designed for installing

8

Page 11

OMEGA Engineering analytical sensors into in-line

applications (PHA-86). This pipe adaptor can be

installed in any standard 1-1/4 inch FNPT pipe

fitting.

Fitting Installation/Metal Fittings

Welded fittings MUST be installed by a certified

welder.

The plastic sensor insert in the Weldolet fitting

MUST be removed during the welding process.

When reinstalled, it is important that the insert

be threaded to the proper height "H" dimension

to ensure full insertion of the sensor electrodes,

see page 10.

• 2 to 4 inch Weldolet fittings require a 1-7/16

inch hole in the pipe.

• The hole must be completely deburred to be

free of any projections before installing the

Weldolet fitting.

Pipe Tees: Metal Pipe Tees are available for 0.5

to 2 inch metal pipes. Materials include iron,

carbon steel, stainless steel, and copper or

bronze. All tees are threaded with NPT threads

except for copper and bronze tees, which have

solder or braze type fittings.

"Weld-on" Weldolet Fitting

Metal Pipe Tee Fitting

• Use thread sealant compound on fittings with

threaded connections.

9

Page 12

"H"

Weldolet "H" dimension

part number inches

FP-5325CS 2.33

FP-5330CS 2.32

FP-5340CS 2.30

FP-5325 2.33

FP-5330 2.32

FP-5340 2.30

Weldolet Fitting

10

3.5 Submersible Installations

CDTX-80 Series Conductivity Transmitter sensor

system can be made submersible through the use

of the submersible kit PHCN-86S and extension

cable cable length from -01 to -12 ft. (see

Figure 1 page 2).

Page 13

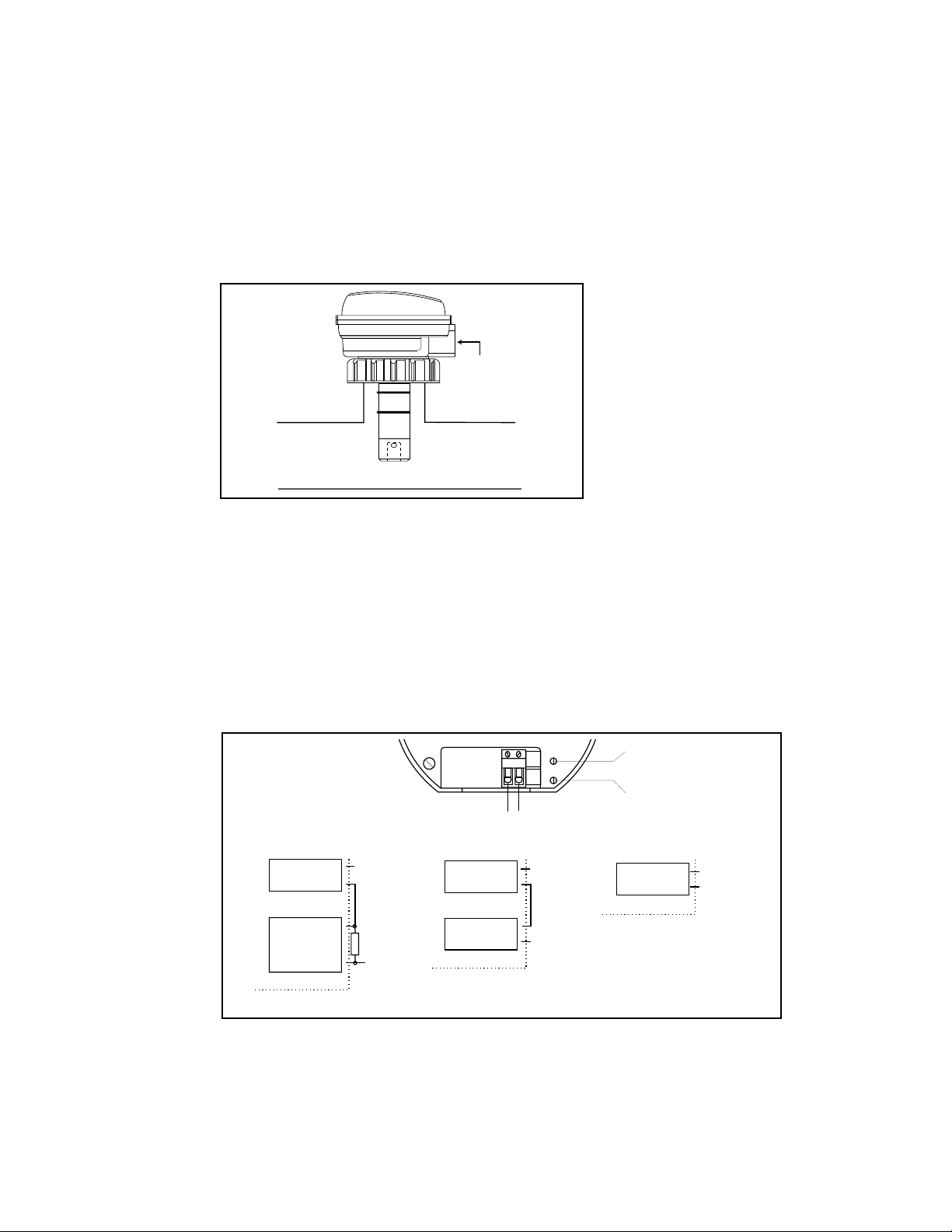

3.6 Electrical Installation

The transmitter has a 1/2 inch conduit opening

for power/signal wiring, see Figure 7.

1/2 in. NPT for

conduit (2 places)

DIN Version:

PG 13.5 metric

thread

The sensor input connection is located on the

lower PCB (below optional Display PCB). To

access the connector, remove the housing cover

followed by the electronics cover (snap on/off).

The connector is now accessible between the

Display PCB (if installed) and the Main PCB.

Signal wiring to the R+ and R- terminals need not

be shielded, but 2-conductor shielded twisted-pair

cable should be used for best results (Min. #22

AWG).

Figure 7

CDTX-80 Series Conductivity

Transmitter In-line Installation

Figure 8

Transmitter Connection

Diagram

Connection to device

with separate power supply

10 to 30

VDC

Measuring

device with

1 to 5 VDC

input

Voltage = Resistance • Current

+

+

-

-

R+

Resistor

250 Ω*

R-

*Note

ZERO

R26

12

SPAN

R17

R+ R-

Connection to device

with separate power supply

+

10 to 30

VDC

Measuring

device

R+

-

R-

+

Zero Pot

(R26)

Span

Pot (R17)

Connection to device

with internal power supply

+

Measuring

device

R+

-

R-

11

Page 14

Signal wiring should not run in conduit

or in open trays with HVAC wiring and should not

be run near heavy electrical equipment. Leads

should be color coded for polarity identification.

The conduit connection on the transmitter housing

should be sealed or plugged to avoid accumulation of moisture in the housing. If the conduit is not

sealed, the transmitter should be mounted with the

opening downward for draining.

Signal wiring may be ungrounded or grounded at

any place in the signal loop. Power supply regulation is not critical. Make sure that the power supply

source conforms to the requirements of the

transmitter and that the current rating of the supply

is not exceeded, particularly if more than one

transmitter is connected to the supply in parallel.

NOTE:

This transmitter is designed to eliminate ground

loops and other electrical interactions between

system components even if several transmitters are

powered by a common supply in parallel.

12

Make sure that electrical characteristics of the

remote output device are compatible with the

transmitter output: Total load resistance must not

exceed 700 ohms using a 24 VDC power

supply. Total load resistance is the sum of the

individual resistances of all devices which are

connected in series with the signal output lead.

Equation:

RL = VS-10/0.02

where

RL = Load Resistance in ohms

VS = Supply Voltage

10 = Minimum operating voltage

0.02 = 20 mA (maximum current)

Page 15

4.1 Maintenance Tips

The electrodes contact the solution and transfer a

signal through the solution being measured. It is

recommended that the electrodes maintain contact

with fluid. If allowed to air dry, precipitates may

form on the electrodes causing higher than normal

readings and possibly contaminating the process

fluid. If precipitates form, the electrodes may be

cleaned by immersing the sensor in warm water

and scrubbing the electrodes with a soft nylon

brush.

It is important that the sensor is not exposed to oils

which may coat the electrodes. This may seriously

affect the readings.

In extreme cases it may be necessary to clean

the sensor with alcohol to remove oils. We

recommend using a cotton swab and brushing the

electrode clean instead of dipping the entire

sensor body in acetone.

Chapter 4

Conductivity

Sensor

Maintenance

In submersible applications the sensor should be

located fully immersed and away from the

presence of any bubbles.

In some instances it may be necessary to devise

a periodic maintenance schedule to clean the

electrodes and verify calibration.

13

Page 16

4.2 Troubleshooting Guide

Problem ActionCause

•Application range exceeds the

electronics range.

Display/output

reads off scale

•Unit is not properly calibrated

• Check unit model number,

see Unpacking and Inspection

section (opposite page #1)

• Re-calibrate, see page 4

Display/output

reads zero

(4 mA)

Display is blank/

no current

Transmitter cannot

be calibrated

(insufficient Zero

adjust)

Transmitter cannot

be calibrated

(insufficient Gain

adjust)

•Range pot misadjusted

•Application range below

the electronics range

• Sensor not connected

• System power or ground OPEN

• Gain pot set too high

• Incorrect operating range

• Excessive Quiescent

current

• Incorrect operating range

• Unit not calibrated

• Output transistor damaged

• Re-calibrate display,

see page 5

•Check unit model number,

see Unpacking and Inspection

section (opposite page #1)

•Check sensor connection

• Check system wiring

• Reduce Gain/Span pot

adjust

• Check unit model number,

see Unpacking and

Inspection section (opposite

page #1)

• Send for repair

• Check unit model number,

see Unpacking and

Inspection section (opposite

page #1)

• Re-calibrate, see page 4

• Send for repair

Transmitter output

changes erratically

14

• Air bubbles contacting sensor

• Coated electrodes

• Leaking submersion kit

• Check installation

• Clean sensor, see page 11

• Clean/replace cable

install new seal

Page 17

Optional Display: 0 - 100%, 2-1/2 digit LCD

(factory installation recommended),

CDTX-80-D

Loop power: 10 to 30 VDC

Loop impedance:

• 1Ω @ 10 VDC

• 100Ω @ 12 VDC

• 1000Ω @ 30 VDC

Electronics operating temp:

• -15 to 50 °C (5 to 122 °F)

Max sensor pressure/temperature:

• 7 bar @ 20 °C (100 psi @ 68 °F)

• 1.7 bar @ 90 °C (25 psi @ 194 °F)

Operating ranges:

• CDTX-80 0 to 20 µS 0.05 cell

• CDTX-81 0 to 200 µS 0.05 cell

• CDTX-82 0 to 2,000 µS 2.0 cell

• CDTX-83 0 to 10,000 µS 2.0 cell

Current output: 2-wire, 4 to 20 mA signal

Accuracy: ±1% of range

Specifications

Relative Humidity: 0 to 95%, non-condensing

Enclosure materials:

• Electronics enclosure: Glass-filled PP, NEMA 4X/IP65

• Enclosure seal: Viton®

• Window: Polycarbonate

Wetted sensor materials:

• Sensor body: Glass-filled PP

• Electrodes: Titanium

• Sensor o-rings (2): Viton®

• Optional o-rings: EPR, FPP-1224-0021

Kalrez, FPP-1228-0021

Immunity: EN50082-1

Emissions: EN55011

Agency Approvals: CE

15

Page 18

Figure 9

4.2 in./

107 mm

3.5 in./

89 mm

1/2 in. NPT

For Conduit

(2 places)

DIN Version:

PG 13.5

metric thread

4.2 in./

107 mm

3.5 in./

89 mm

1/2 in. NPT

For Conduit

(2 places)

DIN Version:

PG 13.5

metric thread

CDTX-80 Series Conductivity

Transmitter Dimensional Views

0.05 Cell Constant

-1 (0 to 20 µS)

-2 (0 to 200 µS)

2.0 Cell Constant

-3 (0 to 2,000 µS)

-4 (0 to 10,000 µS)

16

Page 19

NOTES:

17

Page 20

NOTES:

18

Loading...

Loading...