Page 1

T

PRODUCT INSTRUCTION SHEET

CDE-45T1 and CDE-45T3 Toroidal Conductivity Sensors

Introduction

®

®

Modern conductivity measurement devices include a class of

sensors which use an electrodeless system to determine the

conductivity of a fluid. Electrodeless probes function by first

exciting a toroid with an AC voltage to produce a magnetic

flux in the core. This flux then produces an alternating current

flow in the fluid, which passes as a loop through the center of

the core. A second toroid then acts as a sensor by using the

fluid’s current to produce a magnetic flux in its core which,

in turn creates current flow in its windings. The current flow

in the fluid and subsequently the detector toroid’s windings,

depends on the conductivity of the solution, thereby giving an

accurate measurement without contacting the fluid directly.

Your Electrodeless Conductivity Sensor provides a very linear

voltage output signal versus the conductivity of the solution

within which it is placed. The overall output is proportional to

the excitation signal driven into the driver toroid, the amount

of gain provided by the output signal amplifier, and the

conductivity of the medium being measured. Thus, calibration must be done with a known conductivity solution and the

electronics.

Mechanical Installation

Your toroidal sensor can be installed in 2 ways:

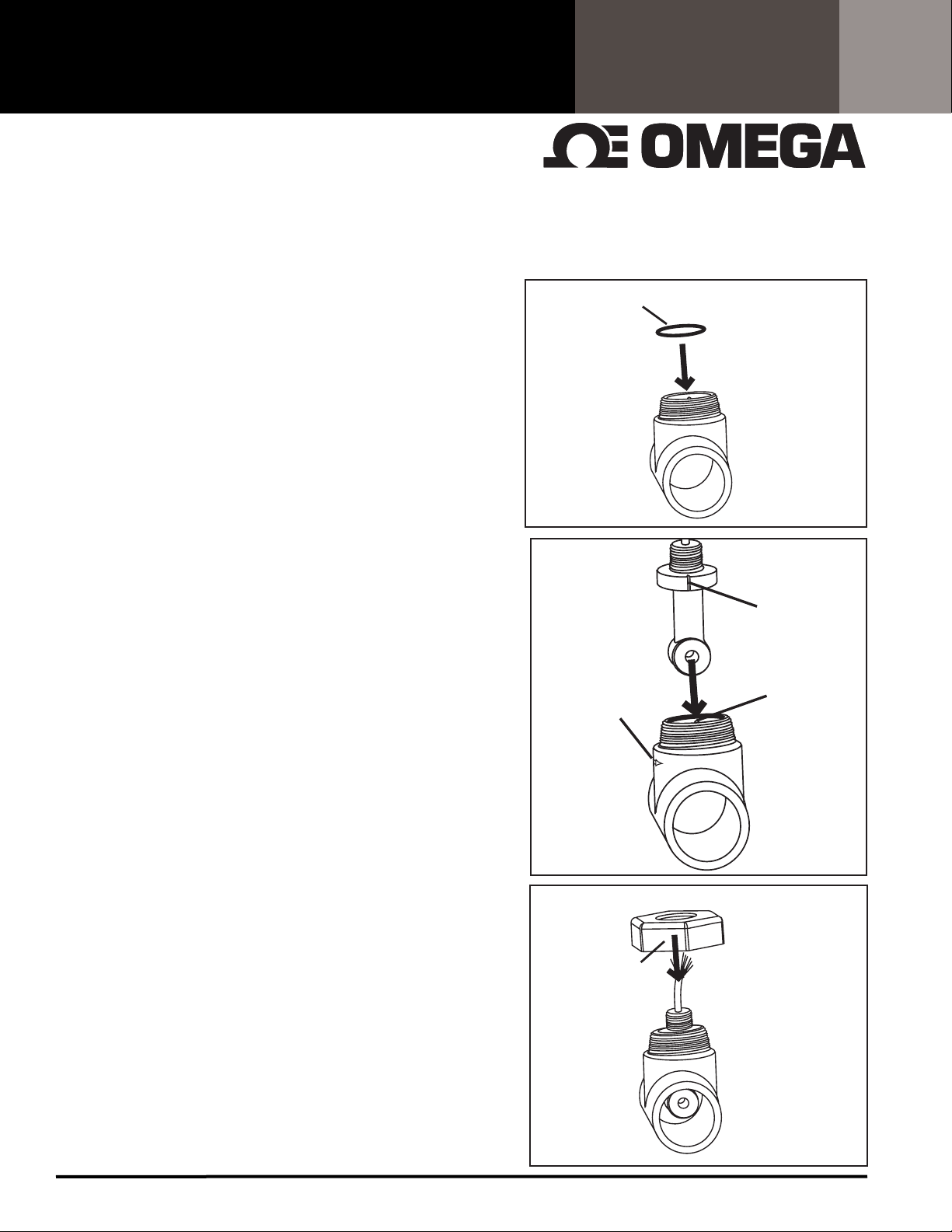

FIG. 1

FIG. 1

FIG. 2

O-RING

SEAL

FLOW DIRECTION

ARROWS x 2

OWARD SENSOR

ALIGNMENT TAB)

(POINT

SENSOR

ALIGNMENT

NOTCH

SENSOR

ALIGNMENT

TAB

1. Submersion mount: Mount sensor into rigid or flexible

conduit using a 3/4" NPT coupling and attaching to the 3/4"

NPT threads near the sensor's cable. Be sure to seal conduit to

avoid fluid build up in conduit.

2. In-Line mount:

a. Plumb flow cell CDTX-45T-PT into line. Flow cell is provided

FIG. 3

with 2" slip fittings. For threaded connection install a 2" slip x

NPT female adapter (CPVC SCH 80).

b. Install o-ring into CDTX-45T-PT as shown in FIG. 1

NUT

c. Install CD-45T1 toroidal sensor into CDTX-45T-PT. Match

notch on flange of sensor with tab of flow cell as show in FIG. 2.

d. Install nut onto threads of flow cell and turn clockwise. DO

NOT USE TEFLON TAPE OR SEALANT ON THREADS!

CDE-45 Page 1 of 4

Page 2

PRODUCT INSTRUCTION SHEET

Sensor Wiring

®

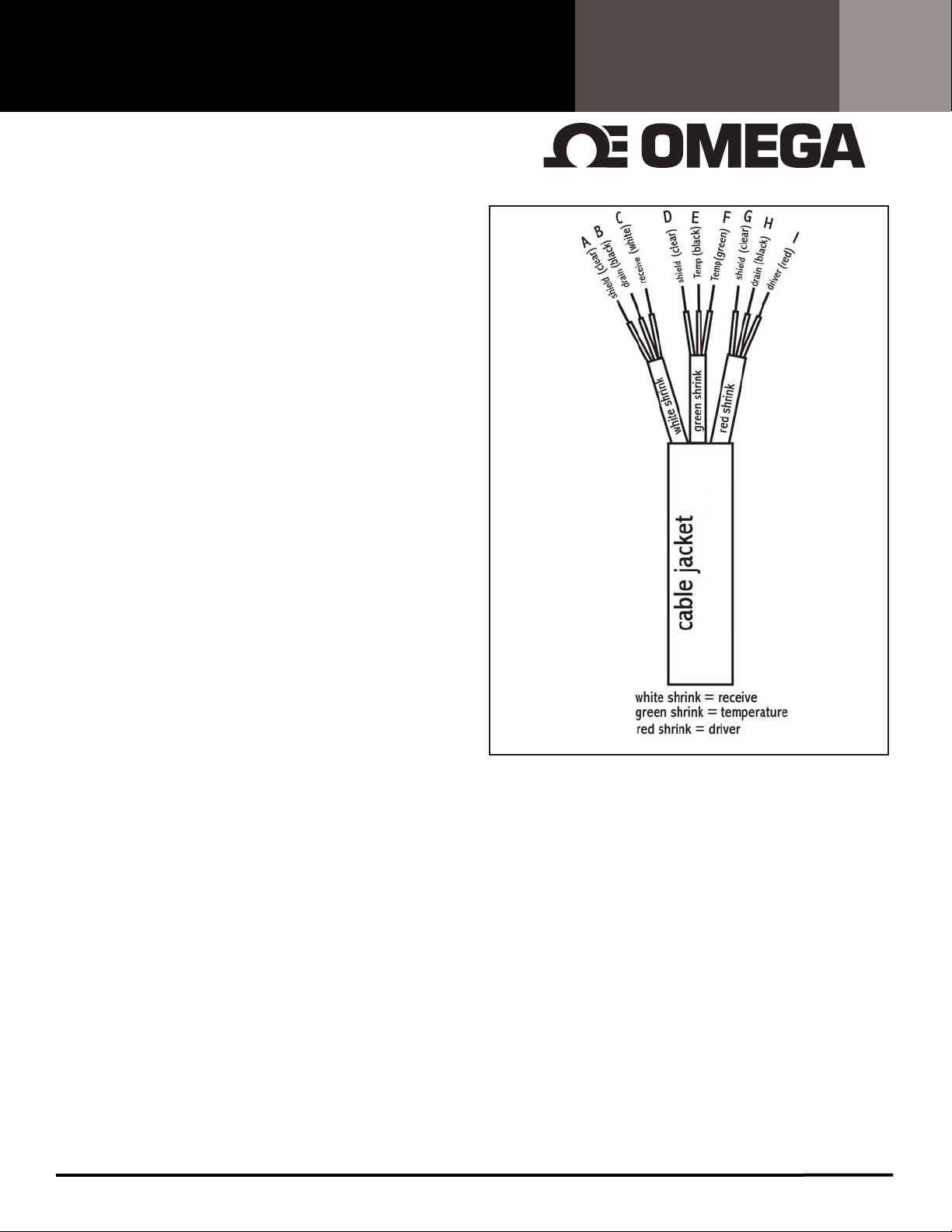

The probe has 9 total leads (see FIG. 4).

The driver toroid is connected to the red and black leads with

the red shrink tubing around them. When using the probe

with various controllers, it is important that the red lead be

connected to an AC DRIVER or VOLTAGE IN position while the

black lead is connected to a GROUND or DRIVER RETURN line.

The detector toroid is connected to the white and black leads

with the white shrink tubing around them. The white lead is

typically connected to the SIGNAL IN location and the black

lead is connected to a GROUND or SIGNAL RETURN line.

The temperature element is connected to the green and black

leads with the green shrink tubing around them. Connect

these to the TEMPERATURE INPUT locations. The polarity is not

important.

The 3 bare leads, which supply individual pair shielding

throughout the cable, should typically be connected to a

ground or drain line. Note: The shield leads are not connected

to one another, they are all individual shields for the three

bundles of wires.

Refer to your controller manual for specific wiring details.

FIG. 4

CDE-45T1

Cable Considerations

The cable uses PVC to protect the wires during use. If the cable

comes in contact with the working fluid, the temperature and

pressure ratings must be adjusted to allow for the lower temperature limits of the cable.

C (DRY) but should only be subjected to 70 deg C when immersed in a fluid.

by liquid (raising the possibility of shorting) and all attempts

should be made to keep the cable out of the fluid environment. Do not run cable in the same conduit with any other A.C.

power wiring nor routed close to any high current demanding

equipment. Seal conduit to avoid build-up of moisture. Do not

cut cable. Shorter or longer cables can be provided.

The jacket becomes significantly weakened

The cable can withstand 105 deg

CDE-45 Page 2 of 4

Page 3

)

PRODUCT INSTRUCTION SHEET

Sensor Calibration

®

After the sensor is properly connected, the system should

be calibrated. The typical calibration procedure uses a “low”

and a “high” known standard conductivity solution. The "low"

solution is often DI water or air and is used to calibrate the

zero point of the controller. Plotting these two points will create a straight line, which can be used to find the conductivity

valueof any solution in the range. Make sure probe is immersed in the calibration fluid such that the toroids are totally

submerged. A sample plot is provided in FIG. 5 to show the

approximate values, which will be encountered during calibration.

Note: The values in the plot are arbitrary, each probe will

require unique linear equation values.

If the sensor is to be used in a submersion application, calibrate the sensor in a large glass or plastic beaker with all sides

of the sensor at least one inch away from the wall

(FIG. 6). If the production installation is a pipe (plastic or metal),

calibration should be performed in a similar pipe arrangement.

All Electrodeless (Toroidal) sensors have a wall effect, which

must be taken into account during calibration. If the non-conductive (plastic) wall is within 1 inch of the sensor, the sensor’s

reading will be reduced due to the insulator interaction with

the current path. If the sensor is within 1 inch of a conductive

(metal) wall, the sensor’s reading will be increased due to the

shorting effect of the conducting wall. These wall effects can

be calibrated out of the system by simulating the application’s

mounting configuration. A plot showing the effects of insulating and conducting walls on the output can be seen in FIG.7.

During calibration and production installation (especially in

a submersion environment), it is important to dislodge any

air bubbles, paying special attention to the center hole of the

toroids. Also make sure toroids are totally covered with fluid

when calibrating (FIG. 6).

Plot of Sensorex DC Output Versus Conventional

FIG. 5

DC Output vs. Conventional Conductivity Meter

20

15

10

(mS)

5

0

Conductivity Meter Output

Conductivity Meter Output

123

Sensorex Output (V)

FIG. 6

> 1”

> 1”

Series1

Linear (Series1

y = 6.0498x - 5.435

2

= 1

R

Liquid must totally

cover toroids (be

above this line)

Please refer to your controller's manual for specific calibration

instructions.

Sensor Maintenance

The major advantage of the Electrodeless (Toroidal) Sensor

is almost no maintenance is required. The only maintenance

required during normal operational life of the sensor is to

prevent the toroidal opening from being plugged with debris.

Use a soft brush or rag to remove any debris in the core opening. If that does not work, try a mild detergent or weak acid

(5-10% HCl).

Plot of Normalized Output as a Function of Probe

FIG. 7

2.55

2.5

2.45

2.4

2.35

2.3

2.25

2.2

Normalized Output (V/V)

2.15

024681012

Distance from Wall

Wall Distance (In)

CDE-45 Page 3 of 4

Conducting wall

Insulating Wall

Page 4

PRODUCT INSTRUCTION SHEET

®

Sensor Troubleshooting

If your sensor is not reading as expected check resistance of

leads as shown in FIG. 8. Check temperature leads as shown in

FiG 9.

Sensor Specifications

Installation Type: Submersion via 3/4" NPT or in-line

via CDTX-45T-PT flow cell

Conductivity Range: 500-2,000,000 uS

Maximum Temperature:

Electrode:: 105 deg C

Flow cell: 100C

Cable:: 105 deg C (Dry)

70 deg C (wet)

Maximum Pressure: 100 psig

Wetted Materials:

Sensor: Polypropylene (black)

Flow cell: CPVC

O-ring: Viton

Temperature Compensation: via Pt1000 RTD

FIG. 8

SHRINK COLOR WIRE COLOR RESISTANCE

RED RED

1 TO 2 MEGOHMS

RED BLACK

>20 MEGOHMS (OPEN)

RED CLEAR

WHITE WHITE

1 TO 2 MEGOHMS

WHITE BLACK

> 20 MEGOHMS (OPEN)

WHITE CLEAR

GREEN GREEN

109 or 1090 OHMS**

GREEN BLACK

< 2 OHMS

GREEN CLEAR

0.5

0.5

>20 MEGOHMS (OPEN)

FIG. 9

RTD TYPE TEMP. (deg C/deg F) RESISTANCE(Ohms)

1000Ohm RTD 18/64.4 1069

1000 Ohm RTD 19/66.2 1073

1000Ohm RTD 20/68 1077

1000 Ohm RTD 21/69.8 1081

1000 Ohm RTD 22/71.6 1084

1000 Ohm RTD 23/73.4 1089

1000 Ohm RTD 24/75.2 1092

1000 Ohm RTD 25/77.0 1096

1000 Ohm RTD 26/78.8 1100

1000 Ohm RTD 27/80.6 1104

* * *

Note: There is approximately 3.9Ohm/ Deg C change for Pt1000RTD.

CDE-45 Page 4 of 4

Loading...

Loading...