Page 1

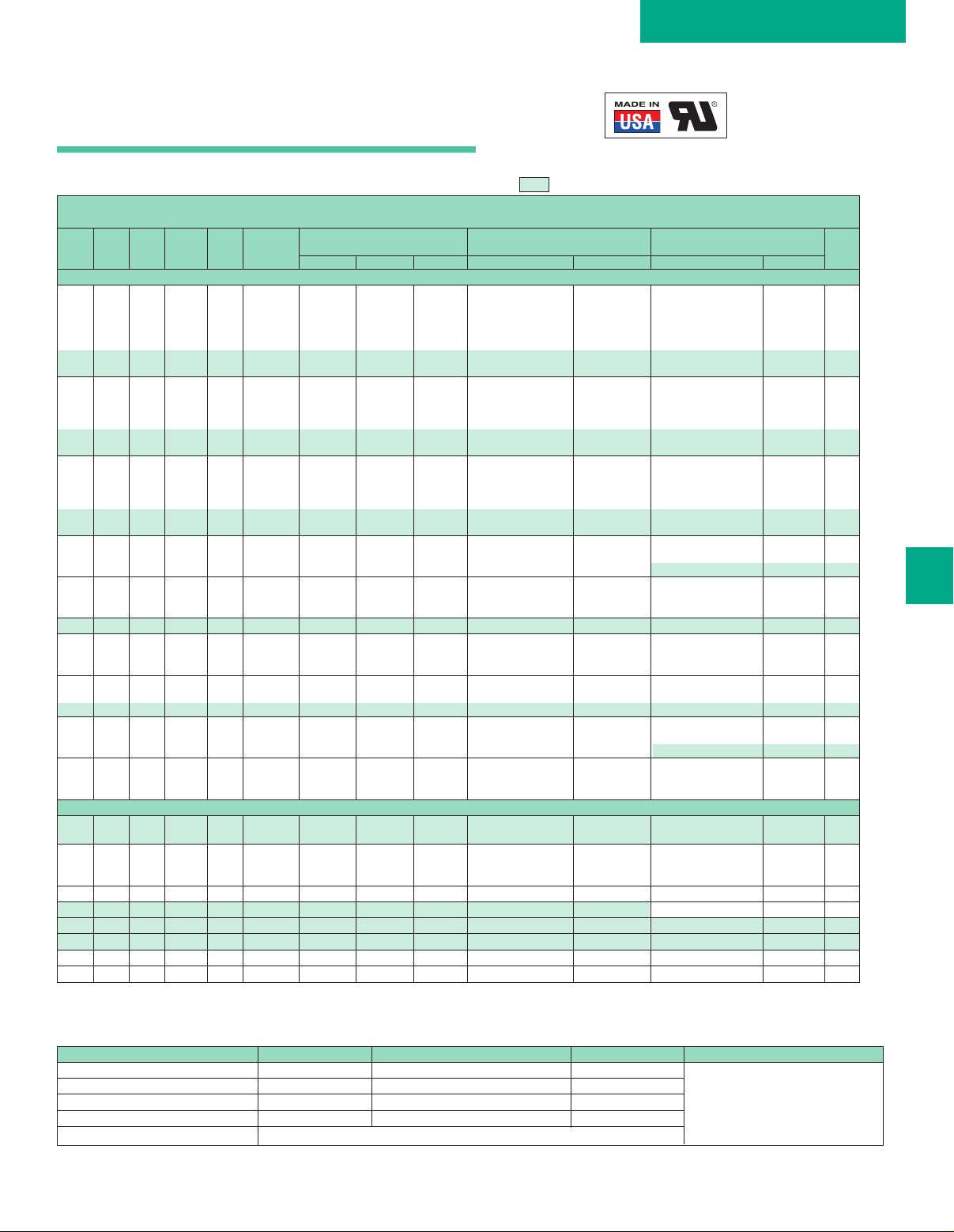

LOW

Single Row

Double Row

Triple Row

Based on 1-5/8" spacing

and 4.7 fins per linear inch

5 fps0

0.001

0.003

0.005

0.007

0.01

0.03

0.05

0.07

0.1

0.3

0.5

10 fps 15 fps 20 fps 25 fps 30 fps 35 fps

300fpm0 600 fpm 900 fpm 1200 fpm 1500 fpm 1800 fpm 2100 fpm

1.0

Pressure Drop — Inches of Water

Air Velocity (Standard Air)

TEMPERATURE

Terminal

Cover

AIR DUCT

HEATERS

CAB and CABB Styles

⻬

Side Terminals (Type CAB)

⻬ Bottom Terminals

(Type CABB)

⻬ 6 to 100 kW

⻬ 120, 208, 240 and 480V

⻬ 1 or 3 Phase

⻬ Rust-Resisting Iron or

Chrome Steel Sheath

Elements

⻬ 440°F Max Outlet Air Temp

Applications

⻬ Sole Heat Source

⻬ Booster Heater in Process and

Comfort Heating Ducts

⻬ Convert existing Forced Air

Dryers and Ovens

⻬ With Blower and Duct, can be

used to Fabricate simple

Forced Air Drying Unit

Features

Simple Duct Transition Sections may

be used to adapt standard heater sizes to

various duct sizes to increase air velocities

for better heat transfer, lower sheath

temperature and longer element life.

Field Wiring Terminals—Heavy duty

diameter bolts of either brass (iron sheath

units) or Stainless Steel (chrome steel

sheath units) with necessary hardware

are provided for field wiring connections.

Terminals are located on the side for CAB

units and on the bottom for CABB units,

and should be on the outside of ducting.

Fins of aluminized steel are provided

to improve heat transfer to the air.

Elements are individually replaceable.

Terminal Cover Option is available

to prevent accidental contact with live

electrical terminals (PCN 269720),

one (1) required per circuit

MONEL Sheath and MONEL Fins are

available for humid conditions. Model

TDH heaters, using Fintube elements

are also available.

Construction

Rugged Finstrip Elements are

mounted in a sturdy steel frame with

narrow side of elements and fins facing

the air flow.

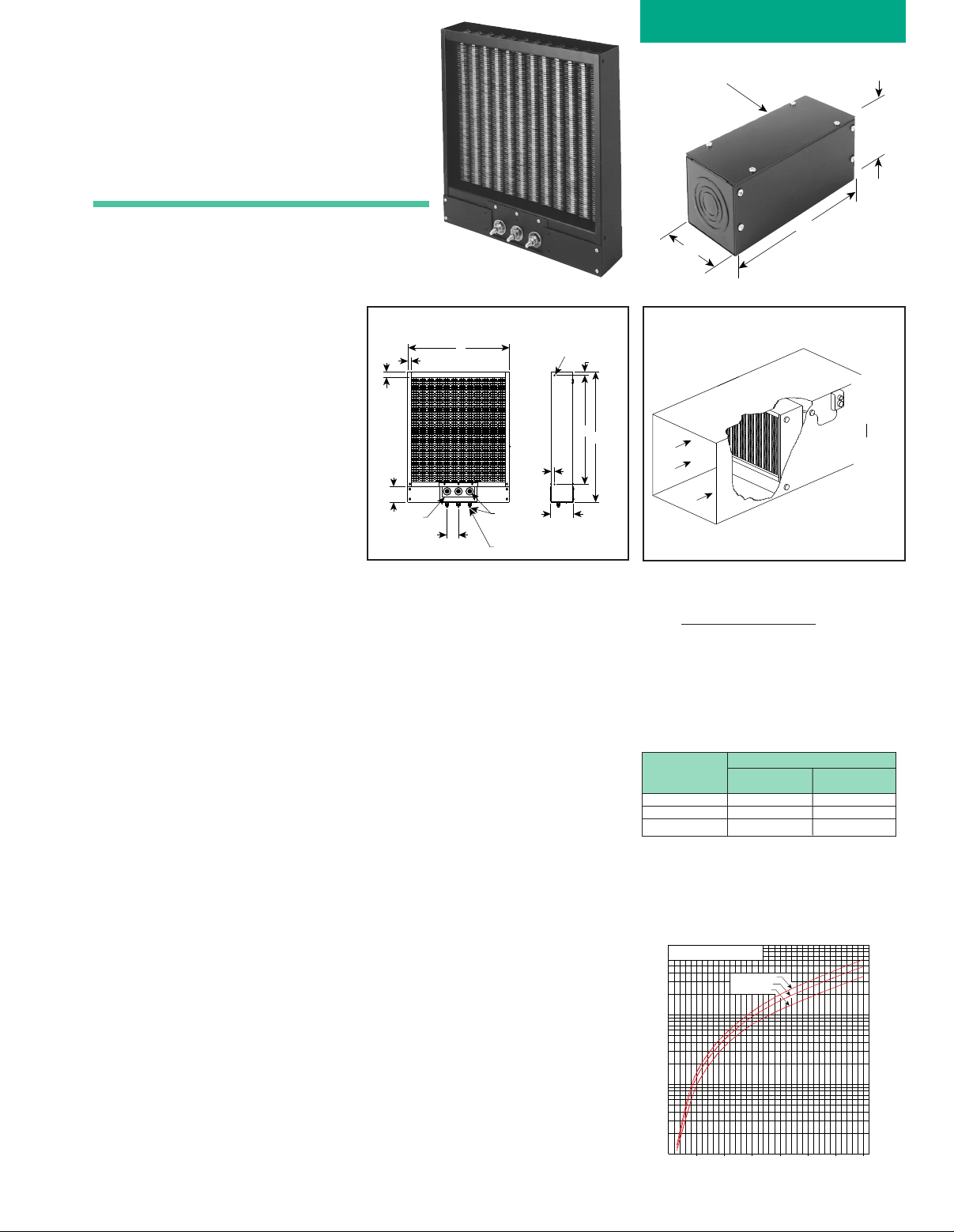

Dimensions: in

A

11/16

1-5/32

21/32

4-1/8

CAB

2-1/4

(Typ.)

1-5/8

Stud

Length

CABB

Finstrip Elements, Exclusive

Construction—High-quality, coiled

resistor wire is uniformly spaced over the

width and length of the Finstrip element,

then em bed ded in high-grade refractory

material which insulates the wire and

transfers heat rapidly. Refractory is then

compressed to rock hardness and

maximum density under tremendous

hydraulic pressure to improve heat transfer

from coil to sheath. Elements are oven

baked at high temperatures to semi-vitrify

and mature the refractory. Sheath material

3

⁄8"

is either rust-resisting iron or chrome steel.

Sturdy Steel Frame—14 gauge cold

rolled steel painted with high heat

resisting black enamel paint.

Internal Electrical Connections are

made using a combination of buss bars

and jumper straps consisting of either

Manganese-Nickel or MONEL.

Mounting

Always install heaters in duct work with

terminal box on bottom of heater. Type

CAB units should have field wiring

terminals facing upstream to provide

maximum cooling affect. Secure to duct

work using mounting holes on both

vertical sides of heater.

Application and Selection

Guidelines

Selection Heater Size — Refer to

Technical section for examples on

determining kW requirements. For quick

estimating purposes, the following

J-7

(2) 5/16-18

Tapped Mtg.

Holes (each side)

D

4-1/2

3/4

B

4-3/16

10

4-1/8

Overtemperature Protection

AIR

AIR

AIR

3/4, 1, 1-1/4, 1-1/2,

2, 2-1/2 Combination

K.O. (each end)

High Limit

Controller

Type ARC

(shown) or

Model 2383

Thermal Cutout

Sensor Located on

Downstream Side

Mtg. Bolts (2 each side)

formula may be used for air at standard

conditions:

kW = SCFM x Temp. Rise (°F)

3000

Maximum Work Temperatures—Type

CAB and CABB heaters can generally be

used at the following maximum

temperatures, provided the minimum air

velocity is maintained uniformly through

the heater.

Air Velocity Iron Chrome Steel

(ft/sec) Sheath Sheath

4—200

9 90 330

16 220 440

Note—Maximum temperatures are

based on 26 W/In

Max Outlet Air Temp

2

. If elements have a

lower watt density, work temperatures

may be increased; if watt density is

higher, work temperatures should be

lower.

Page 2

LOW TEMPERATURE

AIR DUCT HEATERS

CAB and CABB Styles

MOST POPULAR MODELS HIGHLIGHTED!

To Order (Specify Model Number)

Rust-Resisting Iron Sheath Chrome Steel Sheath

Amps/ No. No. inches Temperatures to 750°F Temperatures to 950°F Wt.

kW Volts Phase Circ. Circ. Elem.

CAB—Side Terminals (26 W/in2)

6 120 1 50 1 6 10

6 208 1 28.9 1 6 103⁄4 157⁄8 111⁄2 CAB-62/208 850 CAB-611/208 950 25

6 240 1 25 1 6 103⁄4 157⁄8 111⁄2 CAB-62/240 850 CAB-611/240 950 25

6 480 1 12.5 1 6 103⁄4 157⁄8 111⁄2 CAB-62/480 850 CAB-611/480 950 25

6 208 3 16.7 1 6 103⁄4 157⁄8 111⁄2 CAB-62/208/3P 850 CAB-611/208/3P 950 25

6 240 3 14.5 1 6 103⁄4 157⁄8 111⁄2 CAB-62/240/3P 850 CAB-611/240/3P 950 25

6 480 3 7.2 1 6 103⁄4 157⁄8 111⁄2 CAB-62/480/3P 850 CAB-611/480/3P 950 25

12 208 1 57.7 1 9 15

12 240 1 50 1 9 153⁄8 181⁄2 141⁄8 CAB-122/240 1300 CAB-1211/240 1425 35

12 480 1 25 1 9 153⁄8 181⁄2 141⁄8 CAB-122/480 1300 CAB-1211/480 1425 35

12 208 3 33.4 1 9 153⁄8 181⁄2 141⁄8 CAB-122/208/3P 1300 CAB-1211/208/3P 1425 35

12 240 3 28.9 1 9 153⁄8 181⁄2 141⁄8 CAB-122/240/3P 1300 CAB-1211/240/3P 1425 35

12 480 3 14.5 1 9 153⁄8 181⁄2 141⁄8 CAB-122/480/3P 1300 CAB-1211/480/3P 1425 35

15 208 1 72.1 1 9 15

15 240 1 62.5 1 9 153⁄8 215⁄8 171⁄4 CAB-152/240 1550 CAB-1511/240 1900 40

15 480 1 31.3 1 9 153⁄8 215⁄8 171⁄4 CAB-152/480 1550 CAB-1511/480 1900 40

15 208 3 41.7 1 9 153⁄8 215⁄8 171⁄4 CAB-152/208/3P 1550 CAB-1511/208/3P 1900 40

15 240 3 36.1 1 9 153⁄8 215⁄8 171⁄4 CAB-152/240/3P 1550 CAB-1511/240/3P 1900 40

15 480 3 18.1 1 9 153⁄8 215⁄8 171⁄4 CAB-152/480/3P 1550 CAB-1511/480/3P 1900 40

20 208 3 55.6 1 12 20

20 240 3 48.2 1 12 201⁄8 215⁄8 171⁄4 CAB-202/240 2000 CAB-2011/240 2350 55

20 480 3 24.1 1 12 201⁄8 215⁄8 171⁄4 CAB-202/480 2000 CAB-2011/480 2350 55

25 208 3 69.5 1 12 20

25 240 3 60.2 1 12 201⁄8 261⁄8 213⁄4 CAB-252/240 2350 CAB-2511/240 2850 65

25 480 3 30.1 1 12 201⁄8 261⁄8 213⁄4 CAB-252/480 2350 CAB-2511/480 2850 65

30 480 3 18.1 2 18 291⁄2 215⁄8 171⁄4 — — CAB-3011/480 $2900 75

40 208 3 55.6 2 18 29

40 240 3 48.2 2 18 291⁄2 273⁄8 23 CAB-402/240 3000 CAB-4011/240 3500 90

40 480 3 24.1 2 18 291⁄2 273⁄8 23 CAB-402/480 3000 CAB-4011/480 3500 90

50 208 3 69.5 2 18 29

50 240 3 60.2 2 18 291⁄2 331⁄8 283⁄4 CAB-502/240 3750 CAB-5011/240 4450 110

50 480 3 30.1 2 18 291⁄2 331⁄8 283⁄4 CAB-502/480 3750 CAB-5011/480 4450 110

75 208 3 69.5 3 27 44

75 240 3 60.2 3 27 447⁄16 421⁄8 373⁄4 CAB-752/240 5600 CAB-7511/240 6050 200

75 480 3 30.1 3 27 447⁄16 421⁄8 373⁄4 CAB-752/480 5600 CAB-7511/480 6050 200

100 208 3 92.6 3 27 44

100 240 3 80.3 3 27 447⁄16 471⁄2 431⁄8 CAB-1002/208 7150 CAB-10021/208 7500 220

100 480 3 40.1 3 27 447⁄16 471⁄2 431⁄8 CAB-1002/480 7150 CAB-10021/480 7500 220

CABB—Bottom Terminals (26 W/in2)

6 240 3 14.5 1 6 10

6 480 3 7.2 1 6 103⁄4 157⁄8 111⁄2 — — CABB-611/480 1050 25

12 208 3 33.4 1 9 15

12 240 3 28.9 1 9 153⁄8 181⁄2 141⁄8 — — CABB-1211/240 1550 35

12 480 3 14.5 1 9 153⁄8 181⁄2 141⁄8 — — CABB-1211/480 1550 35

20 480 3 24.1 1 12 201⁄8 215⁄8 171⁄4 — — CABB-2011/480 2550 55

25 480 3 30.1 1 12 291⁄2 261⁄8 213⁄4 CABB-252/480 $2500 CABB-2511/480 3000 65

40 480 3 24.1 2 18 291⁄2 273⁄8 23 CABB-402/480 3200 CABB-4011/480 3700 90

50 480 3 30.1 2 18 291⁄2 331⁄8 283⁄4 CABB-502/480 4100 CABB-5011/480 4650 110

75 480 3 30.1 3 27 447⁄16 421⁄8 373⁄4 CABB-752/480 6000 CABB-7511/480 6450 200

100 480 3 40.1 3 27 44

Ordering Examples: CAB-611/120, chrome steel sheath heater, 6 kW, 120V, $950.

CAB-252/480, rust-resisting iron sheath heater, 25 kW, 480V, $2350.

A B D Model No. Price Model No. Price (lb)

3

⁄4 157⁄8 111⁄2 CAB-62/120 $850 CAB-611/120 $950 25

3

⁄8 181⁄2 141⁄8 CAB-122/208 $1300 CAB-1211/208 $1425 35

3

⁄8 215⁄8 171⁄4 CAB-152/208 $1550 CAB-1511/208 $1900 40

1

⁄8 215⁄8 171⁄4 CAB-202/208 $2000 CAB-2011/208 $2350 55

1

⁄8 261⁄8 213⁄4 CAB-252/208 $2350 CAB-2511/208 $2850 65

1

⁄2 273⁄8 23 CAB-402/208 $3000 CAB-4011/208 $3500 90

1

⁄2 331⁄8 283⁄4 CAB-502/208 $3750 CAB-5011/208 $4450 110

7

⁄16 421⁄8 373⁄4 CAB-752/208 $5600 CAB-7511/208 $6050 200

7

⁄16 471⁄2 431⁄8 CAB-1002/208 $7150 CAB-10021/208 $7500 220

3

⁄4 157⁄8 111⁄2 — — CABB-611/240 $1050 25

3

⁄8 181⁄2 141⁄8 — — CABB-1211/208 1550 35

7

⁄16 471⁄2 431⁄8 — — CABB-10021/480 8000 220

J

Free Area for Air Flow

Model No. Square Feet Model No. Square Feet

CAB-62 & 611 0.500 CAB-402 & 4011 3.29 Note — The volume of air being

CAB-122 & 1211 0.927 CAB-502 & 5011 4.13

CAB-152 & 1511 1.19 CAB-752 & 7511 8.25

CAB-202 & 2011 1.63 CAB-1002 & 10021 9.38

CAB-252 & 2511 2.07

J-8

circulated along with the free

area for air flow (in table above)

will enable you to calculate the

air velocity over the heater.

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...