Page 1

COMPACT CAL

M-2911

Page 2

Foreword

Note

Trademarks

Revisions

Thank you for purchasing the OMEGA CA100 COMPACT CAL. This User's Manual

contains useful information regarding the instrument's functions and operating

procedures as well as precautions that should be observed during use. To ensure proper

use of the instrument, please read the manual thoroughly before operating it. Keep the

manual in the carrying case for quick reference whenever a question arises.

• The contents of this manual are subject to change without prior notice as a result of

improvements in the instrument's performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy of

its contents. However, should you have any questions or find any errors, please

contact your nearest representative.

• Copying or reproduction of any or all of the contents of this manual without Omega's

permission is strictly prohibited.

• MS-DOS is a registered trademark of Microsoft Corporation.

• Company names and product names which appear in this manual are the trademarks

or registered trademarks of the respective companies.

1st Edition: March 1999

1

Page 3

Conventions Used in This Manual

Type Symbol Meaning

Cautionary note

To avoid injury, death of personnel or

damage to the instrument, the operator must

refer to an explanation in the User's Manual.

Calls attention to a procedure, practice or

condition, which, if not correctly performed,

adhered to, or maintained, could result in

injury or death.

Calls attention to a procedure, practice or

condition, which, if not correctly performed,

adhered to, or maintained, could result in

damage to, or destruction of part of the

product.

Note

Key [ ] key Represents a key on the front panel.

Checking the Contents of the Package

Unpack the box and check the contents. If the product is not the one you ordered, any

item is missing or damage to any item is found, contact the dealer from whom you

purchased the instrument.

Calls attention to information which is

important in the operation of the instrument.

2

Page 4

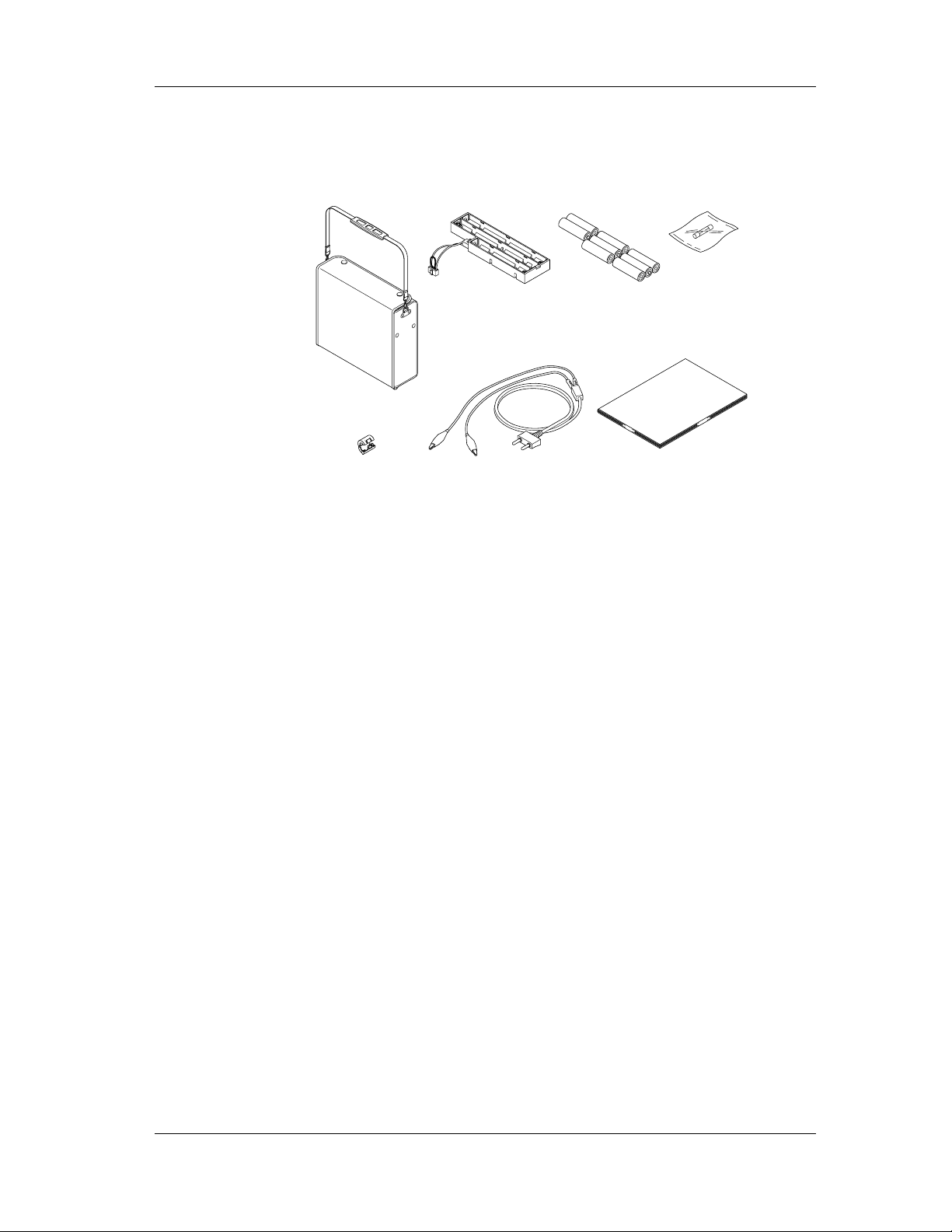

Standard Accessories

Carrying case Battery holder

2 Measurement leads

(CA100-ML)

User's Manual

(M-2911)

8 Alkaline dry cells

2 Ferrite core

(CA100-FC)

Fuse

The following standard accessories are supplied with the instrument. Make sure that all

items are present and undamaged. Note that the dry cell holder (B9914CV) comes

preinstalled in the main unit.

3

Page 5

Safety Precautions

Ths instrument is an IEC safety class I instrument (provided with a terminal for

protective grounding). The following general safety precautions must be observed

during all phases of operation, service and repair of this instrument. If this instrument is

used in a manner not specified in this manual, the protection provided by the instrument

may be impaired. Also, we assume no liability for the customer's failure to comply with

these requirements.

General definitions of safety symbols used on the instrument and in this

manual

To avoid injury, death of personnel or damage to the instrument, the operator must refer

to an explanation in the User's Manual.

This instrument is protected by double insulation.

DC (Direct current)

Ni-Cd

Recycle

Make sure to comply with the following safety precautions. Failure to do so

might result in a fatality or injury to personnel from such hazards as electrical

shock, or damage to the instrument.

WARNING

Prohibition of Using the Instrument in a Gaseous Environment

Do not operate the instrument in the presence of inflammable and

explosive gases or vapors. Operation of the instrument in such an

environment constitutes a safety hazard.

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or

disconnect the wiring of protective grounding terminal. Doing so

poses a potential shock hazard.

Defect in Protection Feature

Do not operate the instrument if there is a defect in protective

grounding or fuses. Before commencing operation, always make

sure that the protection feature is fault-free.

External Connection

After making sure that grounding is properly carried out, connect

the protective grounding before connecting to the measurement or

control unit. If you need to touch the circuit, you must turn off the

switch and make sure that no voltage is generated.

4

Page 6

Fuse

To prevent a fire, be sure to use fuses with the specified ratings

(voltage, current, type). Before replacing fuses, turn the power off

and disconnect the power source if you are using an AC power

supply kit. Do not short-circuit the fuse holder.

Removing Covers

There are some areas under high voltage. Do not remove the

cover if the power supply is connected. The cover should be

removed by qualified personnel only.

To use the AC power supply kit (optional) safely, please comply with the

following precautions.

WARNING

Protective Grounding

To prevent electrical shock, be sure to connect the protective

grounding before turning on the power.

Power Cord and Plug

To prevent electrical shock or fire, be sure to use the supplied

power cord. The main power plug can only be plugged in an outlet

with a protective grounding terminal. Do not invalidate protection

by using an extension cord without protective grounding.

Power Supply

Ensure that the source voltage matches the voltage of the power

supply before turning on the power.

5

Page 7

Safety Precautions for Using Ni-Cd Battery

Storage

• Please remove the Ni-Cd batteries from the main unit when storing.

• Do not leave the batteries in a hot-temperature environment such as under direct sun

light, inside an automobile, or near fire, because this leads to leakage of the alkaline

electrolyte.

• For long-term storage (6 months to 2 years), select a location where the humidity is

low and the temperature is in the range from 10 to 25 °C.

• When charging for the first time after long-term storage, deactivation of the reactants

may have led to decreased battery capacity, but this problem is restored after several

cycles of charging and discharging.

• When storing the batteries for more than 6 months, please charge or discharge then

recharge the batteries at least once per year to prevent leakage and the decline of

performance.

Battery Life

The time of operation of the batteries gradually decreases with repeated use, even when

the batteries are fully charged. Though it depends on the condition of use, take 2 years

or 500 times as a measure to have the batteries replaced. (A typical battery life is 2

years or 500 times.) Please also note that prolonged storage leads to shortened battery

life.

Charging

• Do not charge the batteries in any other instrument.

• Only charge batteries that are completely discharged. Charging batteries that are

partially charged results in overcharging. This shortens battery life.

• Avoid overcharging the batteries, because this leads to shortened battery life.

• Charging the batteries for a long time may cause leakage of gases and electrolytes.

WARNING

• Do not disassemble or alter the batteries in any way.

The electrolyte inside the batteries is strong alkaline which can

damage skin and clothes. Be especially careful of the electrolyte

entering the eye, because it may cause blindness.

• Never short the batteries. Heat generated by the batteries may

cause burns.

• Never heat or throw the batteries into fire. The batteries can

rupture or the electrolyte may spray out.

• Never put water on the batteries or immerse them in water.

Such actions can cause heat to be generated or lead to rusting

as well as the loss of ability to function.

• Do not use the batteries in any other instrument. The difference

in the specification can cause damage to the other instrument.

• Do not pull the cable of Ni-Cd battery back or connector with

excessive force.

6

Page 8

Contents

Foreword

Conventions Used in This Manual

Checking the Contents of the Package

Safety Precautions

Components and Their Functions

Block Diagram .......................................................................................................................................... 9

Functions ................................................................................................................................................... 9

Front Panel .............................................................................................................................................. 10

Side Panel ................................................................................................................................................ 12

Rear Panel ............................................................................................................................................... 13

Before Starting Generation or Measurement

Usage Precautions ................................................................................................................................... 14

Installation Conditions ............................................................................................................................ 15

Installing Ferrite Core ............................................................................................................................. 15

Installing Dry Cells ................................................................................................................................. 16

!

Supplying AC Power (Optional) ............................................................................................................. 17

!

Attaching and Charging Optional Ni-Cd Battery Pack ........................................................................... 18

!

Turning the Power Switch On and Off ................................................................................................... 20

Turning Backlighting On and Off ........................................................................................................... 20

Averaging, Key Type, International Temperature, Temperature Unit Settings ...................................... 21

Generation

Connecting the Output Terminal ............................................................................................................. 23

!

Before Generation ................................................................................................................................... 23

DC Voltage, DC Current, Resistance ...................................................................................................... 24

Thermocouple, Resistance Temperature Detector .................................................................................. 26

Frequency, Pulse Signal .......................................................................................................................... 28

Measurement

Connecting the Input Terminal ............................................................................................................... 30

Measuring the DC Voltage, DC Current, and Resistance ....................................................................... 31

24 V DC Power Supply

Connecting the Output Terminal ............................................................................................................. 32

!

Turning Output On and Off .................................................................................................................... 32

Using the RS-232-C Interface

RS-232-C Interface functions ................................................................................................................. 33

Specifications .......................................................................................................................................... 33

Connecting the RS-232-C Interface Cable .............................................................................................. 34

Settings for Communication ................................................................................................................... 35

Before Programming ............................................................................................................................... 39

Using Talk-Only or Printer Mode ........................................................................................................... 39

Troubleshooting

Items to be Checked in the Case of an Abnormality ...............................................................................40

Error Codes and Corrective Actions ....................................................................................................... 40

Maintenance

Calibration ............................................................................................................................................... 41

Replacing the Ni-Cd Batteries ................................................................................................................ 50

Replacing the Backlighting EL ............................................................................................................... 50

Replacing the Fuse .................................................................................................................................. 50

!

7

Page 9

Specifications

Generation Functions .............................................................................................................................. 51

Measurement Function ............................................................................................................................ 53

Generation Section .................................................................................................................................. 54

Measurement Section .............................................................................................................................. 54

24 V DC Supply Section ......................................................................................................................... 54

Communications Function ...................................................................................................................... 54

Common Specifications .......................................................................................................................... 54

External Dimensions ............................................................................................................................... 55

Appendix

Communication Commands .............................................................................................................. App-1

Status Byte Format (for <ESC> command) ...................................................................................... App-5

Output Format of Measured Data ..................................................................................................... App-5

Output Format for Talk-Only or Printer Mode ................................................................................. App-6

Output Format for Setting Information ............................................................................................. App-6

Sample Program ................................................................................................................................ App-7

Index

8

Page 10

Components and Their Functions

Block Diagram

RS-232-C

Power source/communication part

RS-232-C

driver

Source/CPU part

DC/DC

converter

Display

Reference

voltage

source

CPU

DCV

DCA

Ω

Setting

Current/voltage

conversion

Memory

FRQ

Excess voltage

protection

Current

detection

Ω

DCA

DCV

Excess current

protection

Components and Their Functions

OUT PUT

Hi

SOURCE

Lo

15V DC

BATT.

Functions

Battery

circuit

Constant

current

source

Input

circuit

Shunt resistance

TC

Ω

FUSE

DC/DC

converter

Power

source

control

Measurement

part

24V OUT

AD

converter

Reg.

24V Output part

• Generation Functions

A specified value (in five digits) in function units of voltage, current, resistance,

thermocouple, resistance temperature detector (RTD), frequency, or pulse signal can

be generated.

Function Description

DC voltage Available in three ranges: 100 mV, 1 V, or 10 V

Direct current Available in 20-mA range. SINK function is also available.

Resistance Available in 3 ranges: 500 Ω, 5 kΩ, or 50 kΩ

Thermocouple Thermoelectromotive force can be generated according to the

Resistance temperature detector A resistance can be generated according to the temperature of PT100

Frequency and pulse signal Frequency is in four ranges: 100 Hz, 1000 Hz, 10 kHz, or 50 kHz.

temperature of type K, E, J, T, N, R or B thermocouple.

resistance temperature detector.

Voltage is in the same range as the 10 V range for voltage generation.

Pulse signals with a specified number of bursts (1 to 60000) are

available as well as the above.

R.J.INPUT

Hi

mA MEASURE

Lo

+

24V OUT

-

• Measurement Function

Voltage, current, or resistance can be measured and displayed in 4.5 digits

independent of the generation function.

Function Description

DC voltage Available in three ranges: 500 mV, 5 V, 35 V

Direct current Available in two ranges: 20 mA, 100 mA. An overrange input protection

fuse comes built into the current-input terminal.

Resistance Available in three ranges: 500 Ω, 5 kΩ, or 50 kΩ

9

Page 11

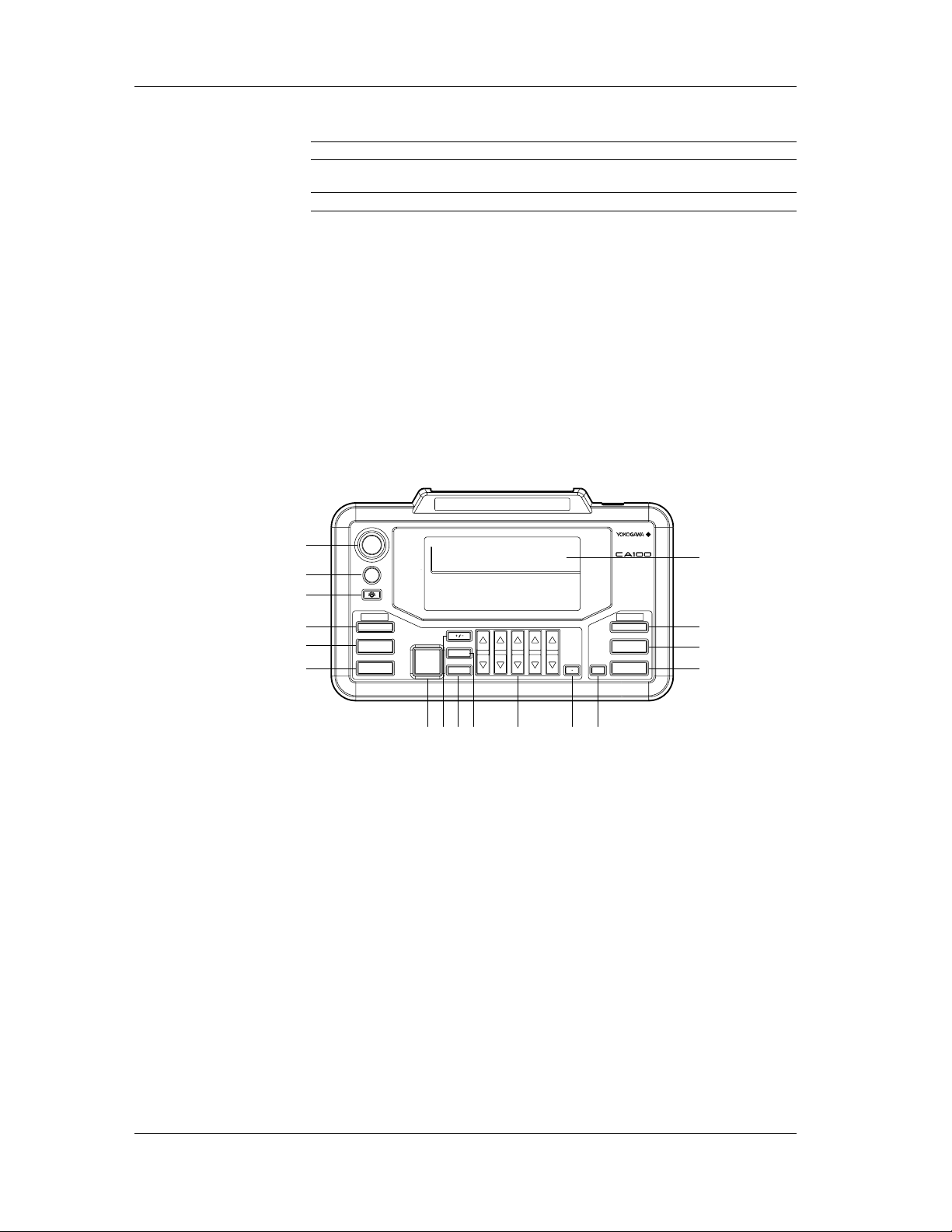

Front Panel

General View

The following functions can be selected:

Function Description

Averaging Displays the results of moving averages of measured data. This is useful if the measured

data are unstable or poor due to noise. (See page 21.)

Display hold Halts updating of the displayed measured value.

• 24 V DC power supply

This is a floating output. Available up to 24 V/22 mA DC max.

• Communications function

Using this function, the instrument can be controlled or measured data can be

transferred to a personal computer via an RS-232-C interface (D-sub 9 pin). This

function also allows the output of setting information or measured data to an ESC/Psupport printer.

• Three-way power supply

Three types of power supply: AA cells, AC adapter (free selection of AC voltages,

optional), and Ni-Cd battery pack (optional) are available.

SOURCE

MEASURE 24V OUT

1

2

3

4

5

6

POWER

CHARGE

SOURCE

24V OUT

FUNCTION

DCV

DCA

Ω Ω

TC

RTD

FRQ

PULSE

SOURCE MEASURE

1

CLR

ZERO

SOURCE

RANGE

ON

ENTER

NEXT

67890

2345

COMPACT CAL

DCV

DCA

MEASURE

ON

FUNCTION

RANGE

HOLD

LCD screen

16

15

14

1312111097 8

1 Power switch

Turns the power on and off.

2 Charging start key

Begins the charging of the Ni-Cd battery pack (optional).

3 Backlight key

Turns backlighting on and off.

Operation keys for generation

4 24 V DC power supply key

Turns the 24 V DC power supply on and off.

5 Function selection key

Selects one of the generation functions: voltage, current, resistance, thermocouple,

RTD, frequency, and pulse.

6 Range selection key

Selects the range for setting generation values. For thermocouple or RTD, selects

TC or RTD type.

10

Page 12

7 Output on and off key

Turns output on and off.

8 +/- key

Toggles the polarity of the output value.

9 NEXT ENTER key

This switches the associated settings when setting the output values for the

frequency and pulse signal. It also fixes the entered value when using the numeric

keypad (refer to the following description).

10 ZERO CLR key

This resets the output value set to zero when using the up/down key (refer to the

following description). When using the numeric keypad (refer to the following

description), the value being entered is canceled and the previous set value is

restored.

11 Output value setting keys

This sets the output value for the generation function. Either of the following two

key modes can be selected from the menu. The up/down key mode is selected as the

factory default setting.

Up/down key: This increments or decrements the values by one count for each digit

corresponding to the [ ]/[ ]. If you try to increment or decrement using this key

with value 9 or 0, the current digit moves up or down by one digit.

Numeric keypad: This enters numbers 0 to 9 directly from the keypad.

12 Decimal point key

This enters the decimal point when using the numeric keypad (refer to the above

description). When this key is pressed, the digits to the left of the decimal point

move to the positions specified on a range basis. When using the up/down key, this

key is unavailable.

Components and Their Functions

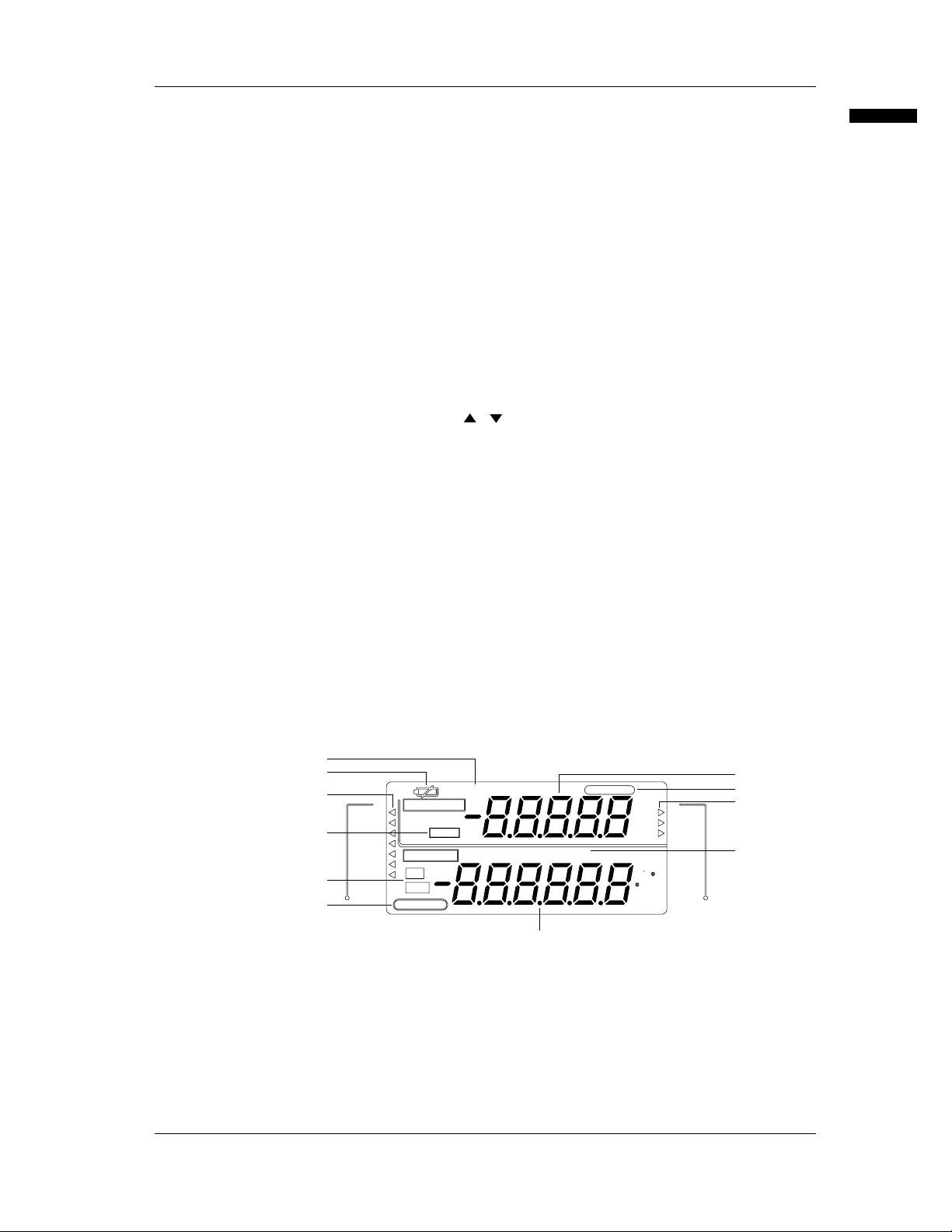

LCD Screen

Operation keys for measurement

13 Display hold key

This retains displayed values as they are.

14 Range selection key

This selects the measurement range.

15 Function selection key

This selects one of the measuring functions: voltage, current, or resistance.

16 Measurement on and off key

This turns measurement on and off.

1

2

3

DCV

4

5

6

DCA

ΩΩ

TC

RTD

FRQ

PULSE

SOURCE

MEASURE

HOLD

SOURCE

ON

OFF

24V OUT

CHARGE END

ITS-90 IPTS-68

INT RJC BRKE JTN

AVERAGE

Pt100

mV

mA

k

Ω

mV

mA

Ω

k C

F

kHz

CYCLES

DCV

DCA

MEASURE

11

10

7

1 State-of-charge indicator

When using Ni-Cd batteries (optional), this indicates its charge status (CHARGE

indicates charging is taking place and CHARGE END indicates charging has

completed).

2 Low-battery indicator

This lights up when the battery becomes weak.

9

8

11

Page 13

3 Generation function indicator

indicates the currently selected generation function. Each press of the

FUNCTION key changes the function from DCV to DCA, Ω, TC, RTD, FRQ, and

PULSE in order.

4 Hold indicator

This indicates the measured value is held.

5 Output on and off indicator

On: indicates the output is turned on.

Off: indicates the output is turned off.

6 24 V DC power supply indicator

This indicates 24 V DC power is being supplied via the 24 V DC output terminal.

7 Generation range and output display

For voltage, current, resistance, frequency, and pulse: This indicates the decimal

place and unit available for setting when selecting a range. Use the up/down key or

numeric keypad to specify a value.

For thermocouple or resistance temperature detector: This indicates the type of TC,

either thermocouple (TC) or resistance temperature detector (RTD), and the

temperature available for setting (e.g., ˚C), when selecting a range.

Use the up/down key or numeric keypad to specify the temperature.

8 International temperature standard display

This displays the international temperature standard currently selected.

9 Measurement function display

displays the measuring function currently selected. Pressing the FUNCTION key

changes the function from DCV to DCA and Ω.

10 Averaging indicator

This indicates that the averaging function is active.

11 Measurement range and measured value display

This indicates the decimal place and unit available for setting when selecting a

range. When the measuring function is activated, the measured value is displayed.

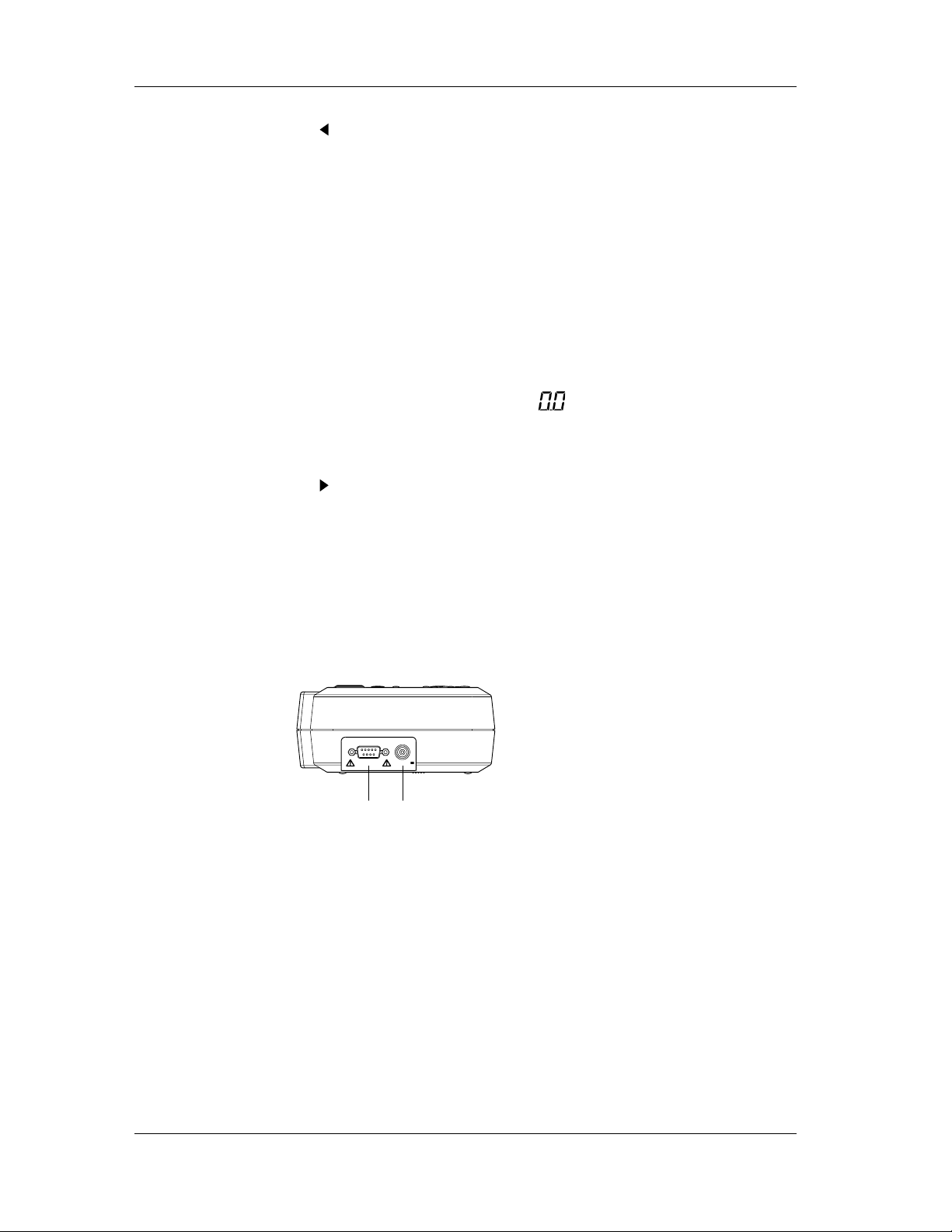

Side Panel

Left side as viewed from the front

The following diagram shows the state when the cover is opened:

1 RS-232-C connector

RS-232-C communication interface connector

2 AC adapter jack (input)

This connects to an optional AC adapter.

Rated input voltage 15 V DC

Maximum rated input current 0.5 A DC

RS-232-C 15V DC

1 2

12

Page 14

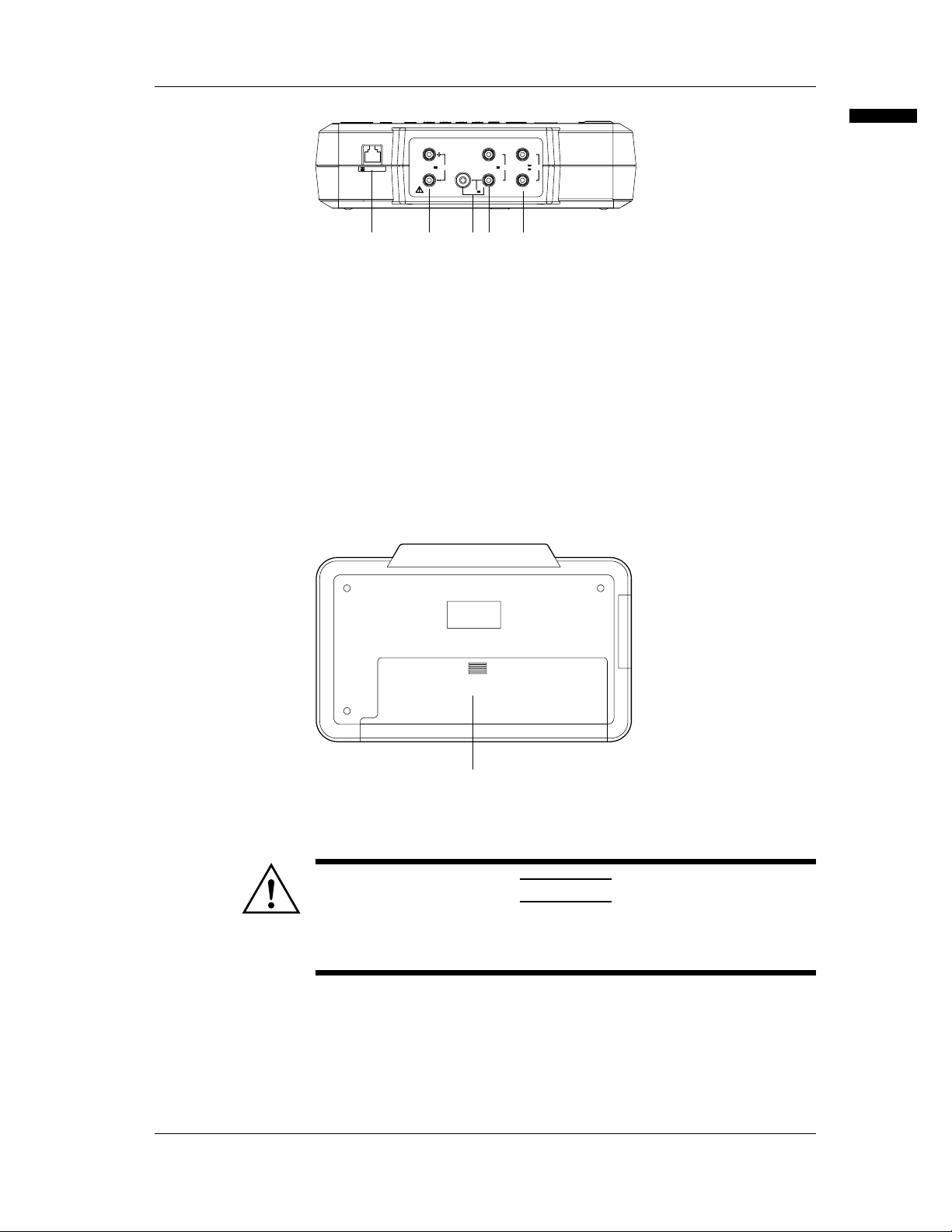

Terminal Side

Rear Panel

MEASURE

R.J. INPUT

24V OUT SOURCE

mA

FUSE

22mA MAX

250V F 125mA

120mA MAX

42V MAX

Lo Lo

ALL TERMINALS 42V

PEAK MAX TO GND.

HiHi

28V

MAX

22mA

1 2 4 53

1 RJC sensor input connector

This connects to an RJC sensor (optional).

2 24 V output terminal

This supplies 24 V DC power.

3 Current input terminal

This is used when measuring current.

4 Voltage/resistance input terminal

This is used when measuring voltage or resistance.

5 Output terminal

This outputs the specified source.

This instrument falls under Overvoltage category II (CAT II). Overvoltage

(installation) category indicates the impulse withstand voltage level which is regulated

by IEC1010-1.

Components and Their Functions

1

1 Battery storage

This holds the attached dry cells or the optional Ni-Cd battery pack.

CAUTION

• Before turning on the power switch, make sure the battery

housing is shut with the cover on properly. Do not open the

cover while the instrument is in operation.

13

Page 15

Before Starting Generation or Measurement

Usage Precautions

Safety Precautions

• Before using this instrument, thoroughly read the "Safety Precautions" on pages 4 and

5.

• Do not remove the cover from the instrument.

Some parts of the instrument use high voltage, which is extremely dangerous. When

the instrument needs an internal inspection or calibration, contact your nearest

representative.

• In case of abnormality

If you notice smoke or the instrument seems to be acting abnormally, for example, it

generates smoke or emits a strange odor, immediately turn the instrument off and, if

an AC power supply kit is in use, disconnect the power cord from the AC outlet. Also

turn off the object connected to the input terminal. If the instrument seems to be

abnormal, contact your nearest reperesentative.

• AC adapter and power cord

Use the dedicated AC adapter. Nothing should be placed on the AC adapter or power

cord; also, it should be kept away from any heat sources. When unplugging the power

cord from the AC outlet, never pull the cord itself. Always hold the plug and pull it. If

the power cord is damaged, contact your dealer. Refer to page 3 for the part number

to use when placing an order.

General Precautions when Handling the Instrument

• When moving the instrument

Turn off the power to the object connected to the instrument. Turn off the power to

this instrument and, if an AC power supply kit is in use, disconnect the power cord

from the AC outlet. When carrying the instrument, always use the carrying case.

• Keep input terminals away from electrically charged articles as they may damage the

internal circuitry.

• Do not allow volatile chemicals to come into contact with the case or operation panel.

Also do not leave them in contact with any rubber or vinyl products for prolonged

periods. The operation panel is made of thermoplastic resin, so take care to avoid

contact with any heated articles such as a soldering iron.

• Before cleaning the case and operation panel, make sure that the power cord is

disconnected from the AC outlet if the AC power supply kit is used. Dampen a clean

soft cloth with water and wipe the surface of the case and panel. Water that gets inside

the instrument may result in breakdown.

• If the AC power supply kit will not be used over a long period, unplug the power cord

from the outlet.

• For handling dry cells, refer to the section, "Installing Dry Cells," on page 16.

• Do not use the instrument with the cover for the battery housing left open.

• Gently wipe the surface with a soft and dry cloth. Do not use chemicals such as

benzene or thinner, because these may cause discoloration and deformation.

• Do not stack the instrument.

14

Page 16

Installation Conditions

• Guide the cable through the clamp

filter and lock the core.

• Thread the supplied band through

the opening of the clamp filter to

fasten the core, and then cut away

any extra length of the band.

The instrument must be installed in a place where the following conditions are met.

• Ambient temperature and humidity

Ambient temperature: 5 to 40°C (5 to 30°C for charging during generation or

measurement)

Ambient humidity: 20 to 80% RH (no condensation)

• Flat horizontal location

Set the instrument in a level, stable place.

Never install the instrument.:

• In direct sunlight or near sources of heat

• Where the level of mechanical vibration is high

• Near noise sources such as high-voltage equipment or power lines

• Near strong magnetic field sources

• Where an excessive amount of soot, steam, dust or corrosive gases are present.

• In an unstable place

• Where explosions caused by inflammable gases or the like are possible

Note

• To ensure high measurement accuracy, the instrument should be used under the following

conditions:

Ambient temperature: 23 ± 5°C

Ambient humidity: 20 to 80% RH (no condensation)

When using the instrument in temperature ranges of 5 to 18°C or 28 to 40°C, add the temperature

coefficient specified in the "Specifications" on page 51 to the accuracy.

• If the ambient humidity of the installation site is 30% or below, use an anti-static mat to prevent

static electricity.

• Internal condensation may occur if the instrument is moved to another area where both the ambient

temperature and humidity are higher, or if the room temperature changes rapidly. In such cases,

acclimatize the instrument to the new environment for at least one hour before starting operation.

Before Starting Generation or Measurement

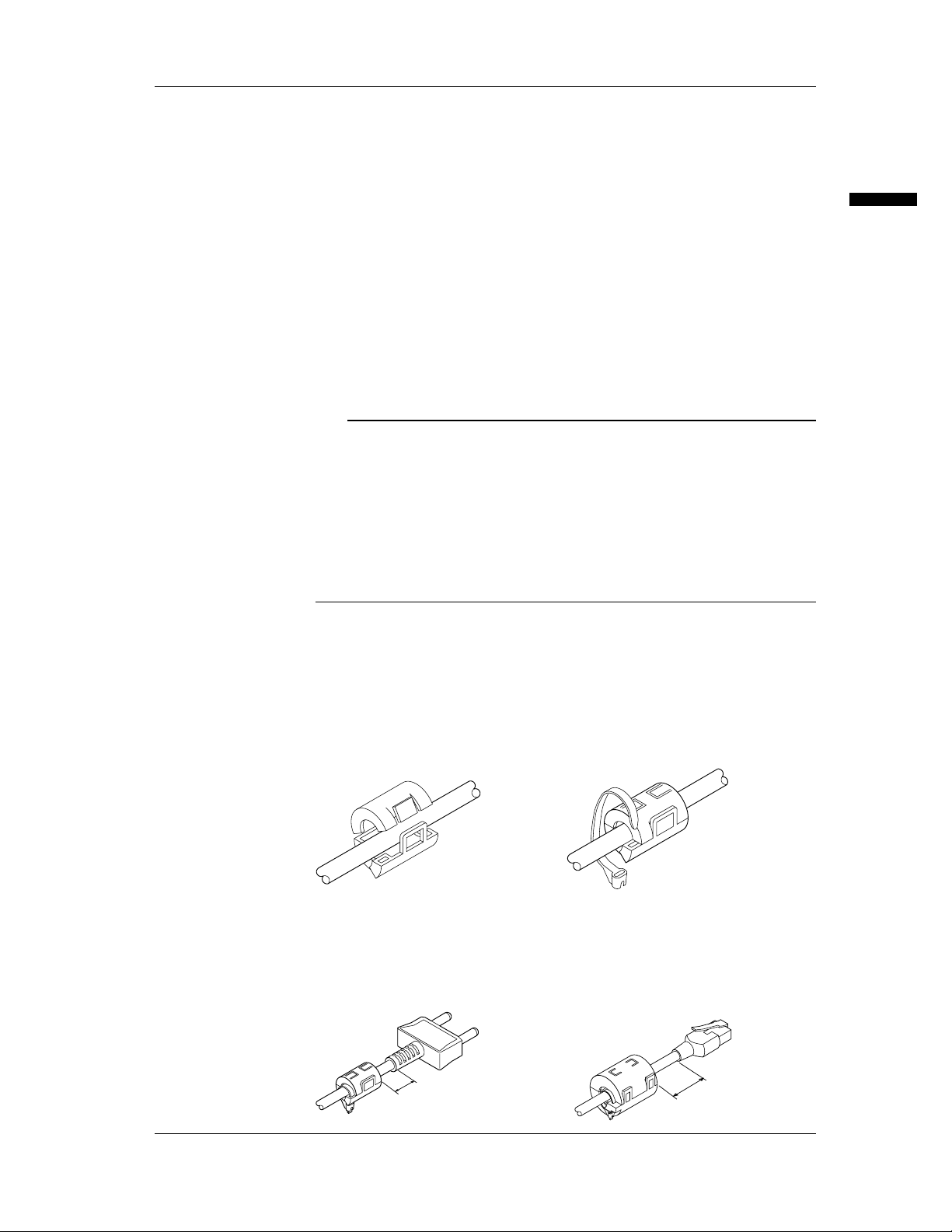

Installing Ferrite Core

This instrument is CE Mark compliant. When using the measurement lead, make sure

to attach the accessory clamp filter on it according to the directions indicated below. In

addition, when purchasing the optional measurement lead or RJC sensor, make sure to

purchase the clamp filter also and attach it according to the directions indicated below.

Note that if the clamp filter is not properly attached or used, the standard cannot be

satisfied.

Installation

Installation location

• Measurement lead • RJC sensor connection cable

50 mm or less

50 mm or less

15

Page 17

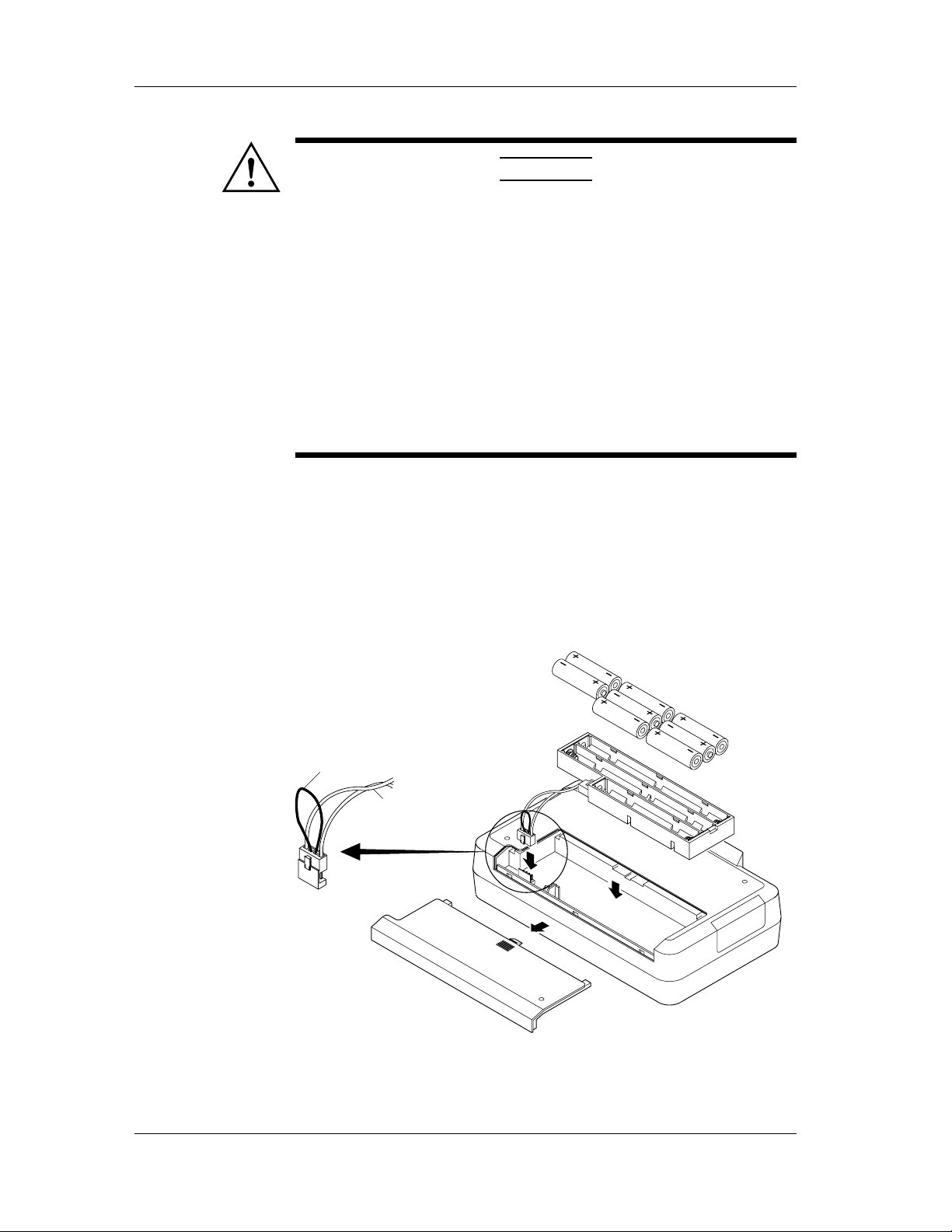

Installing Dry Cells

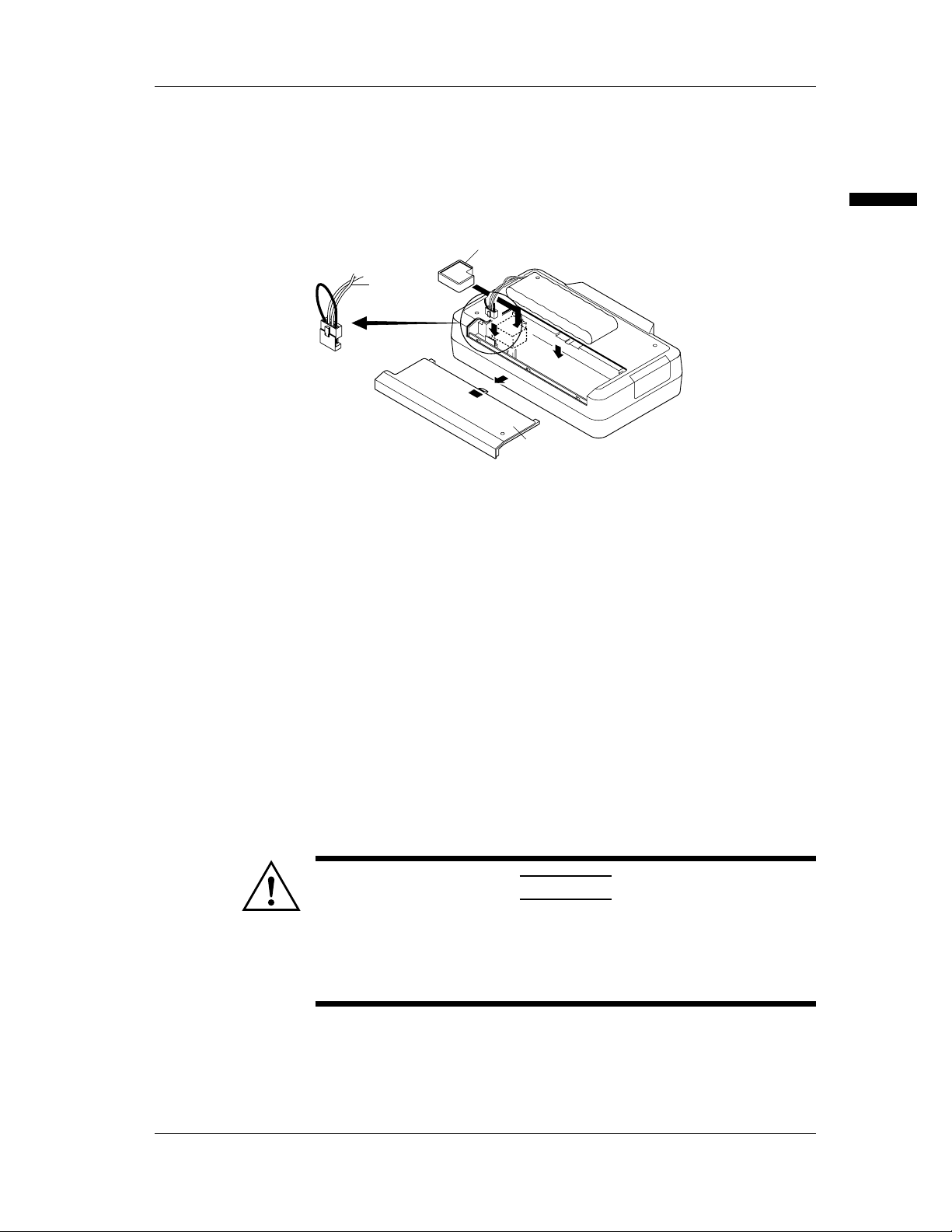

Installation

CAUTION

When using dry cells, observe the following precautions:

• The use of AA alkaline cells is recommended.

• When inserting a battery, observe the polarity; otherwise, a liquid

spill or explosion may occur.

• Before operating the instrument, make sure that the dry cell

holder is inserted into the body and the back cover is closed.

• Do not disassemble, heat, or throw a battery into a fire.

• Do not short out a cell.

• Do not charge a dry cell.

• Do not solder a line onto a dry cell.

• Use new dry cells from the same manufacturer.

• When dry cells become weak, replace all eight cells with new

ones.

• If the instrument will not be used for a long time, remove the dry

cells.

1 Make sure that the power switch on the front panel is turned off and no AC power

supply kit is connected..

2 Remove the cover of the dry cell storage on the back of the body.

3 Insert the eight dry cells into the dry cell holder. Make sure that they are seated in

the correct indicated direction of polarity (refer to the following diagram).

4 Attach the dry cell holder to the body and push the connector until it hits the bottom

of the receiving side of the body (refer to the following diagram).

5 Reassemble the cover.

16

Strap

Cable

To remove dry cells, pull the strap to unplug the connector from the dry cell storage and

remove the dry cell holder. Do not pull on the cable of the connector.

Page 18

Low-Battery Indicator

If the dry cells become weak, appears in the upper-left of the display. When this

happens, immediately replace the old batteries with new eight alkaline batteries.

Life of Alkaline Batteries

The life of alkaline batteries varies depending on the operating conditions. Refer to the

following table:

Generated Output Measurement 24 V DC Backlight Life (when used

20 mA (with 1 kΩ load) on on on Approx. 2 hours

5 V DC (with 500 Ω load) on off off Approx. 10 hours

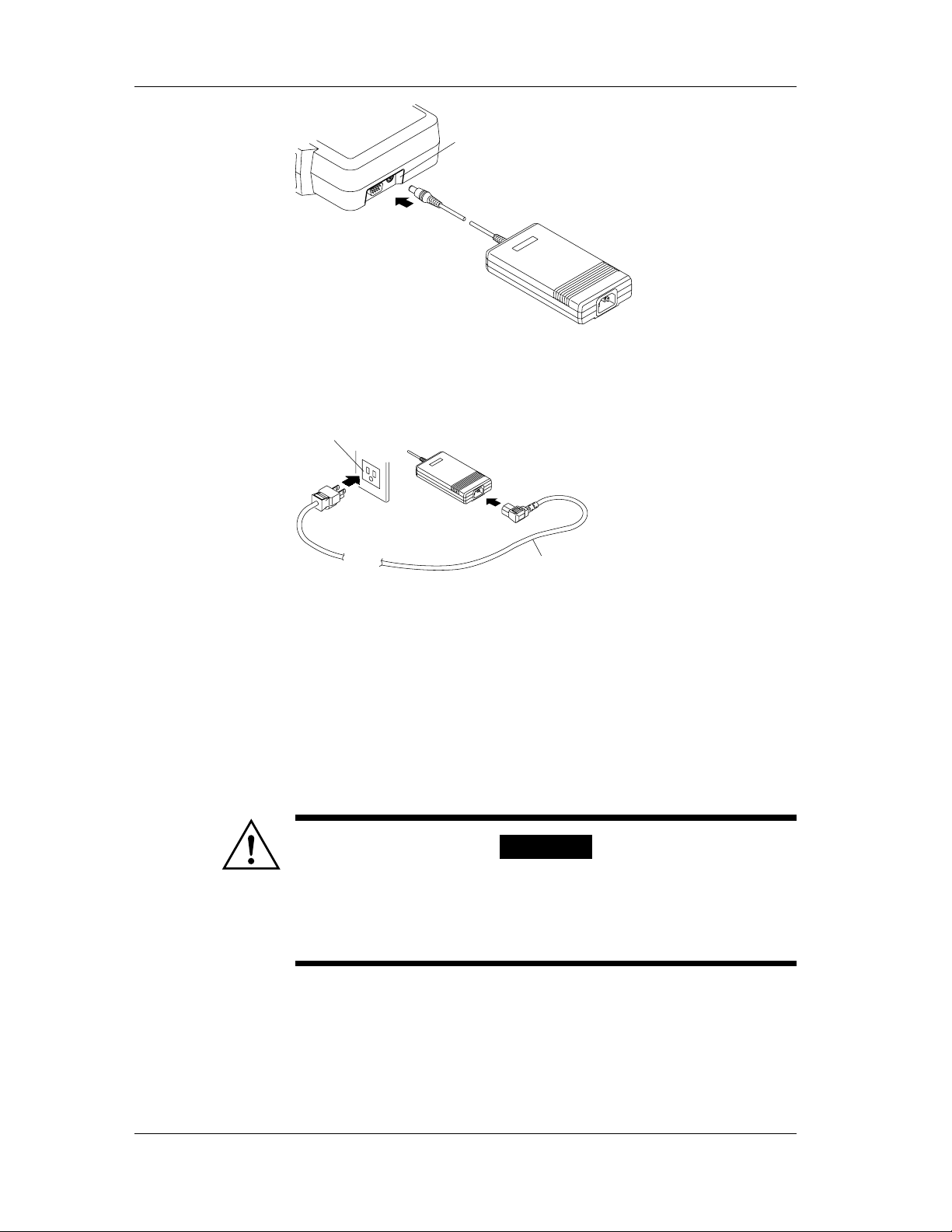

Supplying AC Power (Optional)

Connecting the Power Cord

Make sure that you perform the following steps before connecting the power. Failure to

do so may cause electrical shock or cause damage to the instrument.

• Always use protective grounding to prevent electrical shock.

• Since the power cord supplied with the AC power supply kit has

a 3-prong grounded plug, the AC outlet to which the power cord

is to be connected must be a 3-slot grounded terminal.

• Before connecting the power cord, make sure that the power

supply voltage complies with the rated electrical power voltage

for the instrument.

• Before connecting the power cord, make sure that the

instrument's power switch is turned off.

• Never use an extension cord that does not have protective

grounding; otherwise, the protection feature will be negated.

• Do not use any AC power supply other than the power supply kit

(model 366969) from Omega.

Before Starting Generation or Measurement

Function Power Supply continuously)

WARNING

Connecting the AC Power Supply

1 Make sure that the instrument's power switch is turned off.

2 Connect the optional AC adapter to the AC adapter jack.

17

Page 19

AC adapter jack

AC adapter

3 Connect the power cord included in the AC power supply kit to the AC power

supply adapter.

4 Plug the other end of the power cord into an AC outlet that meets the following

conditions. The AC outlet must be a 3-slot grounded terminal.

3-prong AC outlet

Power cord

Power Rating

Rated supply voltage: 100 to 120 V AC/200 to 240 V AC

Permitted supply voltage range: 90 to 132 V AC/180 to 264 V AC

Rated supply voltage frequency: 50/60 Hz

Permitted supply voltage frequency range: 48 to 62 Hz

Maximum power consumption: 60 VA or below

Rated output voltage for AC adapter: 15 V DC

Maximum rated output current for AC adapter: 1.33 A

Attaching and Charging Optional Ni-Cd Battery Pack

Attaching the Ni-Cd Battery Pack to the Main Unit

To attach the battery pack to the instrument, follow the next procedure:

WARNING

• Before replacing the Ni-Cd battery pack, be sure to turn off the

power switch on the front panel and remove the power cord from

the AC outlet to avoid such possible hazards as short-circuiting

in the battery-charging circuitry.

• Use only an Ni-Cd battery pack from Omega.

18

Page 20

1 Make sure that the power switch on the front panel is turned off.

2 Disconnect the power cord from the AC outlet.

3 Remove the cover of the dry cell storage compartment on the back of the body.

4 Insert the spacer on the cable side of the battery pack.

5 Insert the connector of the attached Ni-Cd battery pack until it hits the bottom of the

receiving side of the body (refer to the following diagram).

6 Reassemble the cover.

When removing the Ni-Cd battery pack, pull the strap to unplug the connector from the

battery housing. Do not pull on the cable of the connector.

Precautions in Charging

• Since an optional Ni-Cd battery pack is not charged prior to shipment, fully charge

the battery pack before operating the instrument for the first time.

• Before charging the battery pack, make sure that it is discharged completely. If

charging is started on a battery which has not been discharged completely or on a

battery for which charging has been stopped halfway through, the life of the battery

pack will be reduced.

• The internal temperature of the instrument rises during charging since the internal

power consumption increases. This may cause a degraded accuracy in generation or

measurement compared with a normal condition. For accuracy, refer to the section,

"Specifications," on page 51.

• This instrument allows charging during generation or measurement operations. In this

case, keep the ambient temperature between 5 to 30°C, or the battery pack will

become extremely degraded.

• If the AC power supply is interrupted during charging, the instrument waits up to

about 30 minutes for restoration of the AC power supply. If the power is not restored

by that time, the instrument aborts the charging sequence and automatically turns off.

It resumes charging of the battery pack if the power is restored within the given time.

Cable

Before Starting Generation or Measurement

Spacer

Be careful of

the direction

of the spacer.

Cover

CAUTION

• Use only the AC power supply kit (model: 366969) from Omega

for charging.

• When charging, keep the instrument horizontal. Make sure that

there is no obstruction around the instrument, so that heat

generated in the instrument is properly dissipated.

19

Page 21

Charging the Battery Pack

1 Supply the instrument with AC power via the method described above.

2 Turn on the power switch.

3 Press the [CHARGE] key.

"CHARGE" is displayed. The instrument then momentarily shows the remaining

time every minute. The battery pack is fully charged in about 10 hours, and

"CHARGE END" is displayed.

4 Turn off the power switch.

5 Disconnect the power cord and the AC adapter from the instrument.

Display Indicating Low Battery

After a certain length of operation has passed and the battery power weakens, "

appears in the upper-left of the screen. When you see this display, immediately charge

the pack.

Guideline for continuous operating time

The operating time of the Ni-Cd battery pack is approximately 7.5 hours when in

continuous use. Refer to the following table:

Generated Output Measurement 24 V DC Backlight Life (when used

Function Power Supply continuously)

20 mA (with 1 kΩ load) on on on Approx. 2.5 hr.

5 V DC (with 500 Ω load) on off off Approx. 7.5 hr.

Turning the Power Switch On and Off

Before Turning On the Power

For driving this instrument, AA dry cells, an AC power supply (optional), or a Ni-Cd

battery pack (optional) is available. Before turning the instrument on, prepare the

intended power supply following the above instructions.

"

Note

Before operating the instrument using dry cells or the Ni-Cd battery pack (i.e., battery driving),

disconnect the power cord and AC adapter. If the AC power source remains connected, the

instrument will operate on the AC power rather than on the batteries.

Turning the Power on and off

Pressing the power switch on the front panel alternates between on and off. When

turning the power switch on, the self-diagnosis function runs, and "OFF" that indicates

the output is turned off and " mV" appear on the lower line of the display.

Automatic Power Off

If the instrument has not received a key operation or sending/receiving request through

the communication interface for approximately 30 minutes, the power supply

automatically turns off. If necessary, turn the power switch back on.

Turning Backlighting On and Off

Backlighting can be turned on so that it is easy to see the screen even if generation/

measurement is done in a dark place. However, this will shorten the life of the batteries

when the instrument is being operated by battery.

1 Press the [ ] key.

2 To turn backlighting off, press the [ ] key again.

20

Page 22

Note

When backlighting the instrument, the internal power consumption increases, and the internal

temperature rises. This may cause a degraded accuracy in generation or measurement compared with

a normal condition. For accuracy, refer to the section, "Specifications," on page 51.

Averaging, Key Type, International Temperature, Temperature Unit Settings

Settings

This instrument allows the setting of Averaging, Key Type, International Temperature,

and Temperature Unit Settings from the maintenance menu.

Averaging setting: This specifies whether to enable (on) or disable (off) the moving

average of the measured data. If the measured data display

fluctuates due to noise, set the averaging setting to on to perform

the moving averages. The setting defaults to off.

Key-type selection: Either the up/down keys (UP-DN) or numeric keypad (TEN) is

available for the output value setting key. The setting defaults to

"UP-DN."

International temperature standard selection: Either of IPTS68 or ITS90 is available for

the international temperature standard. The setting defaults to

"ITS90."

Selection of temperature unit: Either ˚C or ˚F can be selected as the temperature unit.

The default setting is ˚C.

Setting

1 Press the [NEXT ENTER] key and the [ZERO CLR] key at the same time.

[SP FC] and [End] are displayed.

2 Press the [ ] or [ ] key until [End] on the lower line of the display changes to [Set

uP], and then press the [NEXT ENTER] key.

The setup menu is displayed.

Before Starting Generation or Measurement

3 Pressing the [ ] or [ ] key changes the bottom menu from [AVG] to [KEY] and [t

tYPE]. To set the averaging function, display [AVG] and press the [NEXT ENTER]

key.

4 Select [on] or [oFF] using [ ] or [ ] and press the [NEXT ENTER] key.

5 To specify the key type, display [KEY] using [ ] or [ ] and press the [NEXT

ENTER] key.

6 Select [uP-dn] or [tEn] using [ ] or [ ] and press the [NEXT ENTER] key.

7 To set the international temperature standard, display [t tYPE] using [ ] or [ ] and

press the [NEXT ENTER] key.

8 Select the [iPtS68] or [itS90] using the [ ] or [ ] and press the [NEXT ENTER]

key.

9 To set the temperature unit, display [t unit] using the [ ] or [ ] and press the

[NEXT ENTER] key.

10 Select [C] or [F] using the [ ] or [ ] and press the [NEXT ENTER] key.

21

Page 23

11 Press the [ ] to display [Set uP] on the lower line of the display.

12 Press the [ ] or [ ] to display [End] and press the [NEXT ENTER] key.

The measurement/generation screen is returned.

22

Page 24

Generation

SOURCE

Red

Black

Target device

Measurement lead

Hi

Lo

HL

+

-

Clip

g

n

Connecting the Output Terminal

1 Insert the plug of the measurement lead into the output terminal of the instrument.

2 Pinch the terminals on the target device with the clips on the other side of the lead.

Wiring generating resistance or RTD (3-line or 4-line wiring)

The use of optional input-terminal adapters makes it easy to implement 3-line or 4-line

wiring. Input-terminal adapter is an adapter for conversion from safety terminal to

binding post.

Prepare wire rods in stead of the typical measuring lead and connect it as shown in the

following figure (for a three-wire system).

CA100

SOURCE

Hi

Lo

Sense Lo

Generation

Measurin

Instrume

Hi

Lo

Before Generation

CAUTION

• Do not apply voltage to the output terminal except when the

instrument is in the current-generation mode. Otherwise, the

internal circuitry may be damaged.

• Since this instrument is calibrated with the voltage drop of the

measurement lead excluded, an error due to the resistance at

the measurement lead (approx. 0.08 Ω) must be considered.

For accurate generation, be sure to perform auto-zero calibration (i.e., cancel the offset

error) before generation.

Effects of executing auto-zero calibration

• During measurement: The displayed data of measurement are held until the auto-zero

calibration ends, and sampling is also interrupted if applicable.

• When averaging is enabled: The accumulated data for a moving average is discarded,

and a new averaging process starts as the auto-zero calibration ends.

1 Press the [FUNCTION] key on the SOURCE side until [CAL/no] is displayed.

2 Press the [ ] or [ ] key to change the lower display to [YeS].

3 Press the [NEXT ENTER] key to execute auto-zero calibration.

4 After completing auto-zero calibration, the function switches to DCV.

23

Page 25

DC Voltage, DC Current, Resistance

Type

Generation Range

Display Setting Range

DCV

100 mV

1 V

10 V

mV

V

V

-10 to 110 mV

-0.1 to 1.1 V

-1 to 11 V

DCA 20 mA mA 0 to 22 mA

Ω

500 Ω

5 kΩ

50 kΩ

Ω

kΩ

kΩ

0 to 550 Ω

0 to 5.5 kΩ

0 to 55 kΩ

The output terminal generates voltage, current or resistance at the specified value.

1 Press the [FUNCTION] key on the SOURCE side to align with the [DCV],

[DCA], or [Ω] that you want.

2 Press the [RANGE] key on the SOURCE side to select the generation range.

3 To change the polarity, press the [+/-] key.

Selecting "-" places a leading minus sign (-) before figures, while selecting "+"

places no leading sign.

4 Specify the output value.

• Using [ ] or [ ] (for initial setting)

Press [ ] or [ ] to specify the output value from the rightmost digit.

To reset the value to zero, press the [ZERO CLR] key.

• Using the numeric keypad (refer to page 21)

Enter an output value using the numeric keypad and the decimal point key, and

press the [NEXT ENTER]. The figure flickers when entering a value.

When entering decimals, press the decimal point key first and then the

appropriate key or keys on the numeric keypad.

If a value out of the generation range is specified, an error occurs. In this case,

press the [ZERO CLR] to reset to the previous value, and reenter a new value.

5 Press the [SOURCE ON] key to start generation.

[ON] is displayed.

To stop the output, press the [SOURCE ON] key again.

[OFF] is displayed.

[OFF]: Indicates that the relay on the output stage is open.

Voltage generation

CA100

Hi

Voltmeter

Vx Vx

Lo

V

Vx: Specified voltage

24

Current generation

CA100

Hi

Lo

Ix: Specified current

Ix

Ammeter

A

Resistance generation

CA100

Hi

Lo

Ohmmeter

V

Ix

(Constant

current

source)

Ix: Current from the constant current

source (measured current)

Rx:Specified value from this

instrument

Vx: Generated voltage value

represented as Ix*Rx

* This function is unavailable for the

constant voltage source.

Page 26

Note

• When outputting, if you change the generation function, generation range, or polarity (only for

current generation), output turns off automatically.

• The resistance generation of this instrument employs an "active impedance" scheme in order to

provide a dummy resistance. This scheme generates a DC voltage appropriate for the current being

measured that is supplied by a resistance meter such as a multimeter. The scheme, therefore, can

generate correct DC voltages only for the resistance meter used in the measuring method shown in

the figure on the previous page (i.e., the value of the supplied current being measured varies

depending on the range of resistance generation. For further details, see the specifications of

resistance on page 51). Note that connecting a low-impedance device (e.g., a voltage source,

capacitor, or resistor) to the output during resistance generation may cause oscillation.

• In the case of the resistance generation function, it takes 10 ms in a 500 Ω range (refer to the

specifications for other ranges) for the instrument-detected resistance measurement current to

settle within the given accuracy range. This means that the connecting time must be no less than

10 ms where a device that operates by electrically switching its signal input circuit is used.

• Providing any different type of setting with the [ZERO CLR] and [NEXT ENTER] keys during

resistance generation will abort the generation.

• Providing any different type of setting with the [ZERO CLR] and [NEXT ENTER] keys when the

generation function is either TC, RTD, FRQ, or PULSE will change the function to DCV.

Output Limiter

If the load current when generating a voltage of 1 or 10 V range or the load voltage

when generating a current of 20 mA range exceeds the maximum value in the

specifications, the protective limiter turns output off. To recover the output, correct the

load to a normal state and press the [SOURCE ON] key to turn output on.

Current sinking function

This allows drawing the specified value of the current from an external voltage source

in the direction of the Hi terminal.

Generation

CA100

Ix: Specified value of current

Hi

Lo

Ix

To use the function follow the procedure below:

1 Turn off the external power supply (up to 28 V).

2 Connect the external power supply to the output terminal on the instrument.

3 Select [DCA] using the [FUNCTION] key, set the polarity to "-" using [+/-], and

specify the output value.

4 Turn on the external power supply and press the [SOURCE ON] key to turn on

output.

Note

• The current-generation function of the CA100 may result in an unstable output if the CA100 is

connected to a positioner or electro-pneumatic converter having a large input inductance

component. Make sure the input inductance component of the equipment to be connected is no

greater than 100 µH.

• If the equipment’s input inductance component is unknown, connect the CA100 to the equipment

as shown below, and measure the generated current. If the reading does not stabilize or an

accuracy error results at that point, the input inductance component is likely to be greater than

100µH.

CA100

SOURCE

(DC mA)

MEASURE

(DC mA)

Hi

Lo

Lo

mA

Hi

Lo

Input source:

Equipment such as a

converter

• If the equipment’s input inductance component is too large, connect a 200-Ω resistor and a 1-µF

capacitor to the CA100’s output, as shown below. This setup makes it possible to connect an input

having an inductance component of up to 3 H to the CA100.

(This RC circuitry is available as an accessory part numbered 990 20.)

25

Page 27

(99020)

SOURCE

CA100

Note however that this additional circuitry reevaluates the CA100’s response specification as noted

below.

Response: 1 sec (at load resistances no greater than 2 kΩ)

Do not use this circuitry for purposes other than current generation; otherwise, it can produce

measurement errors.

(DC mA)

MEASURE

(DC mA)

R: 200 Ω ±10%, 1/4 W

C: 1 µF ±10%, 50 V

(Equivalent to the 533M5002105K resistor from Matsuo Electric)

Hi

Lo

Lo

mA

Hi

R

C

Lo

Thermocouple, Resistance Temperature Detector

This generates thermo-electric power corresponding to the temperature of thermocouple

(TC) or resistance corresponding to the temperature of resistance temperature detector

(RTD) from the output terminal.

1 Press [FUNCTION] on the SOURCE side and align to [TC] or [RTD].

2 Press [RANGE] on the SOURCE side to select TC type.

Type TC/RTD Type Display Temperature Range

TC

K

Input source:

Equipment such as a

converter

˚C

-200.0 to +1372.0˚C

E

J

T

N

B

R

RTD

* RTD : The specifications are compatible with both IEC 751-1983 and IEC 751-1995.

TC : The specifications are compatible with both IEC 584-1-1989 and IEC 584-1-1995.

To switch the standard, refer to page 21.

Pt100 ˚C -200 to +850˚C

˚C

˚C

˚C

˚C

˚C

˚C

-250.0 to +1000.0˚C

-210.0 to +1200.0˚C

-250.0 to +400.0˚C

-200.0 to +1300.0˚C

+400 to +1820˚C

-40 to +1767˚C

3 To change the polarity, press the [+/-] key.

Selecting "-" places a leading minus sign (-) before figures, while selecting "+"

places no leading sign.

4 Specify the temperature.

• Using [ ] or [ ] (for initial setting)

Press [ ] or [ ] to specify the output value from the rightmost digit.

To reset the value to zero, press the [ZERO CLR] key.

• Using the numeric keypad (refer to page 21)

Enter a temperature value using the numeric keypad and the decimal point key

(where applicable), and press the [NEXT ENTER] key. The figure flickers when

entering a value.

When entering decimals, press the decimal point key first and then the

appropriate key or keys on the numeric keypad.

If a value out of the generation range is specified, an error occurs. In this case,

press [ZERO CLR] to reset to the previous value, and reenter a new value.

5 Press the [SOURCE ON] key to start generation.

[ON] is displayed.

To stop the output, press [SOURCE ON] again.

[OFF] is displayed.

26

Page 28

Note

RJC sensor

With RJC sensor Without RJC sensor

20˚C (798 µV)

813 µV

Generated

voltage

CA100

40˚C

CA100

1611 µV

Generated

voltage

Set temperature

40˚C

Set temperature

• When outputting, if you change the generation function or generation range, output turns off

automatically.

• The generation of RTD-use signals in this instrument employs an "active impedance" scheme in

order to provide a dummy resistance. This scheme generates a DC voltage appropriate for the

current being measured that is supplied by a resistance meter such as a multimeter. The scheme,

therefore, can generate correct DC voltages only when the value of the supplied current being

measured is 1 to 5 mA. Note that connecting a low-impedance device (e.g., a voltage source,

capacitor, or resistor) to the output during resistance generation may cause oscillation.

• In the case of generating RTD-use signals, it takes 10 ms in a 500-Ω range (refer to the

specifications for other ranges) for the instrument-detected resistance measurement current to

settle within the given accuracy range. This means that the connecting time must be no less than

10 ms where a device that operates by electrically switching its signal input circuit is used.

Reference Junction Compensation

Use a reference junction compensation (RJC) sensor (optional) to calibrate a

thermometer containing built-in RJC without using an external 0°C reference junction

chamber.

1 Connect an RJC sensor to the RJC sensor input connector.

When connecting, insert the connector until its upper locking hook snaps into place.

To disconnect the connector, press the hook lightly down to release the lock and

pull it.

Generation

Locking hook

Sensor lead

Note

• Do not pull the sensor lead with the connector locked.

2 Connecting the sensor automatically activates the INT RJC state and thermo-

electric power is output with reference to the temperature detected by the RJC

sensor. [INT RJC] is displayed at this time. (For reference temperature

measurement accuracy using an RJC sensor, refer to the section "Specifications" on

page 52.)

• The thermo-electric power when an RJC sensor is connected can be achieved by

subtracting the thermo-electric power detected by an RJC sensor from the thermoelectric power without an RJC sensor.

27

Page 29

• Compensating the output voltage using the temperature detected with the RJC sensor

is executed on a sampling rate of approximately 10-second intervals. It means that

there is a delay of up to 10 seconds before the first compensation starts.

• To perform accurate measurement, leave the instrument for a certain time (5 min. at

room temperature) before starting the measurement.

Be sure to disconnect the RJC sensor from the instrument when no

reference junction compensation is required.

Frequency, Pulse Signal

This generates frequencies and pulse signals at specified values via the output terminal.

CAUTION

Frequency

Voltage (0 to 10 V)

signal

Frequency (1 Hz to 50 kHz)

Pulse signal

Voltage (0 to 10 V)

Frequency (1 Hz to 50 kHz)

: One pulse

Number of generated pulses

(1 to 60000 cycles)

1 To generate frequencies, press [FUNCTION] on the SOURCE side to align with

[FRQ]. [ Hz] is displayed. Jump to step 4.

To generate pulse signals, align with [PULSE]. [ CYCLES] appears. Go to

step 2.

2 Specify the number of pulses to generate between 1 and 60,000.

• Using [ ] or [ ] (for initial setting)

Press [ ] or [ ] to specify the number of pulses to be output.

To reset the value to zero, press [ZERO CLR].

• Using the numeric keypad (refer to page 21)

Enter the number of pulses to generate using the numeric keypad, and press the

[NEXT ENTER] key. The figure flickers when entering a value. If a value out

of the range of 1 to 60,000 is specified, an error occurs. In this case, press

[ZERO CLR] to reset to the previous value, and reenter a new value.

3 Press [NEXT ENTER].

[ Hz] is displayed.

4 Press [RANGE] on the SOURCE side to select the voltage frequency range.

28

Type Frequency Range Display Setting Range

FRQ/ 100 Hz Hz 1.0 to 110.0 Hz

PULSE

1000 Hz Hz 90 to 1100 Hz

10 kHz kHz 0.9 to 11.0 kHz

50 kHz kHz 9 to 50 kHz

Page 30

5 Specify the voltage frequency to generate.

• Using [ ] or [ ]

Press [ ] or [ ] to specify the voltage frequency to generate from the rightmost

digit. To reset the value to zero, press [ZERO CLR].

• Using the numeric keypad

Enter a voltage frequency to generate using the numeric keypad and the decimal

point key (if applicable), and press the [NEXT ENTER] key. The figure flickers

when entering a value.

When entering decimals, press the decimal point key first and then the

appropriate key or keys on the numeric keypad.

If a value out of the voltage frequency range is specified, an error occurs. In this

case, press [ZERO CLR] to reset to the previous value, and reenter a new value.

6 Press [NEXT ENTER].

[ V] is displayed.

7 Specify a voltage to generate between 0 and 10 V.

• Using [ ] or [ ]

Press [ ] or [ ] to specify the voltage to generate from the rightmost digit. To

reset the value to zero, press [ZERO CLR].

• Using the numeric keypad

Enter a voltage generated using the numeric keypad and the decimal point key,

and press the [NEXT ENTER] key. The figure flickers when entering a value.

When entering decimals, press the decimal point key first and then the

appropriate key or keys on the numeric keypad.

If a value out of the 10 V range is specified, an error occurs. In this case, press

[ZERO CLR] to reset to the previous value, and reenter a new value.

8 Press the [SOURCE ON] key to start generation.

[ON] is displayed.

To stop the generation, press [SOURCE ON] again.

[OFF] is displayed.

Generation

Note

• When outputting, if you change the generation function or generation range, output turns off

automatically.

29

Page 31

Measurement

Connecting the Input Terminal

Connection Precautions

• To prevent electrical shock, a protective grounding connection

must be made before connecting the measurement lead.

• Always turn off the power supply to the object being measured

before connecting it to the instrument. Never connect or

disconnect the measurement lead wires from the object while

power is being supplied to it; otherwise, a serious accident may

result.

• Make sure that you do not connect a current circuit to the voltage

input terminal or vice versa. An incorrect connection may cause

damage not only to the circuit or equipment under test and to

this instrument, but may also injure the operator.

• Be sure to use the attached measuring lead.

• The maximum allowable potential difference is 42 Vpeak and

Cat II for every I/O and ground terminal. However, the maximum

allowable potential difference between the negative 24 V OUT

terminal and the ground is 18 Vpeak. Never apply a voltage

exceeding this tolerance, or else the measured target circuit or

equipment may be damaged and the operator injured.

WARNING

Connecting

CAUTION

• Do not apply a voltage exceeding the permitted maximum input

voltage, or else the instrument may be damaged.

Permitted maximum input voltage: 42 V DC

• Do not apply a current exceeding the permitted maximum input

current, or the built-in current input circuit’s protective fuse may

burn out. If it does, replace the fuse with a new one. For

replacing fuses, refer to page 50.

Permitted maximum input current: 120 mA DC

1 Insert the plug of the measurement lead to the input terminal of the instrument.

2 Pinch the output terminals on the target device with the clips on the other side of the

lead.

For measuring DC voltage or resistance

MEASURE

mA

FUSE

250V F 125mA

120mA MAX

Hi

42V MAX

Lo

Measured

object

30

Page 32

For measuring DC current

MEASURE

mA

FUSE

250V F 125mA

120mA MAX

Hi

42V MAX

Lo

Measured

object

Measuring the DC Voltage, DC Current, and Resistance

1 Press the [MEASURE ON] key.

2 Press the [FUNCTION] key on the MEASURE side to align with the [DCV],

[DCA], or [Ω] that you want.

3 Press the [RANGE] key on the MEASURE side to select the measuring range.

Type Measuring Range Display

DCV 35 V

V

Measurement

DCA 100 mA

Ω

The measured result is displayed. The displayed value is updated every second.

Note

• Any data value being measured that exceeds the 120% of the measuring range will result in

overrange. The display then indicates [

range used).

• If no measured data are present immediately after the MEASURE key is turned on or if the

measurement function or range is switched to change the data on the display, the reading changes

to [

• When you switch the MEASURE key from the off to on, the instrument begins measurement with

the settings given immediately before the key was turned off.

• Providing any different type of setting with the [ZERO CLR] and [NEXT ENTER] keys during

measurement will abort measurement.

Display Holding On and Off

This determines whether the updating of displayed measured data is halted.

1 Press the [HOLD] key. "HOLD" is displayed.

2 To disable the display holding, press [HOLD] again. "HOLD" disappears from the

display.

].

5 V

500 mV

20 mA

50 kΩ

5 kΩ

500 Ω

V

mV

mA

mA

kΩ

kΩ

Ω

] (the position of the decimal point depends on the

Note

• The "HOLD" state only stops the updating of the display, but allows the instrument to continue

sampling data. This means that the measured data are updated through the communication

interface even during the "HOLD" state.

• Holding the display is not allowed if the communication mode is “talk-only” or the “printer”mode.

(See page 39.)

31

Page 33

24 V DC Power Supply

Connecting the Output Terminal

Connection Precautions

The permitted maximum potential difference is 42 Vpeak and Cat II

for every I/O and earth terminal. However, the permitted maximum

potential difference between the negative 24 V OUT terminal and

the ground is 18 Vpeak. Never apply a voltage exceeding this

tolerance, or the measured object circuit or equipment may be

damaged and the operator injured.

• Do not apply a voltage to the 24 V DC output terminal externally,

or else the instrument may be damaged.

• If the 24 V DC output terminal is short-circuited or the load

current exceeds the range (24 to 30 mA), an error is displayed

and the 24 V DC power supply is turned off. In this case, remove

the cause of the short circuit or the overload completely and then

turn the 24 V DC power supply back on. Note that an overload

cannot be detected for the first 5 seconds or so after turning on

the 24 V DC power supply.

• When using batteries, continuous running of the instrument with

the load current of the 24 V DC power supply at more than 20

mA shortens the operable time extremely.

WARNING

CAUTION

Connecting

1 Insert the plug of the measurement lead into the 24 V DC output terminal of the

2 Pinch the 24 V DC terminals on the target device with the clips on the other side of

24V OUT

22mA MAX

Turning Output On and Off

1 Press the [24 V OUT].

2 To stop the 24 V DC power supply, press [24 V OUT] again.

Note

• If the 24 V DC power supply becomes overloaded, the power supply turns off automatically. To

32

instrument.

the lead.

Supplied

object

[24 V OUT] appears on the screen and the 24 V DC power is supplied from the

output terminal.

[24 V OUT] disappears from the display.

continue supplying 24 V DC power, remove the cause of the overload and then press the [24 V

OUT] key again.

Page 34

Using the RS-232-C Interface

RS-232-C Interface Functions

Reception Function

Allows you to make the same settings (except for on and off of the power supply and

those related to communication) as those which can be made using the keys on the front

panel. This function allows the instrument to receive a request for the output of a

generated set-up value, measured value, panel set-up information and error codes.

Transmission Function

Allows the instrument to output a generated set-up value and measured value at a

specified cycle. The panel set-up information and status byte can also be output. In

addition, error codes which occurred can be output.

Note

• During the talk-only or printer mode (when the printer is connected), only output of the generated

set-up value and measured value at a specified cycle is available.

• When using any source other than an AC power supply, the power supply to the circuit for the RS232-C is turned off to increase the operating time available with batteries or the like. Turn on the

power supply as necessary. (See page 37.)

Specifications

24 V DC Power Supply

WARNING

When connecting the RS-232-C cable to the connector, make

sure the power switch of the instrument is turned OFF. Connect

the RS-232-C connector to the remote instrument with the cable

before starting the RS-232-C communication.

Electrical characteristics: Conforms to EIA RS-232-C.

Connection: Point-to-point

Communications: Full-duplex

Synchronization: Start-stop system

Baud Rate: 150, 300, 600, 1200, 2400, 4800 and 9600

Start Bit: 1 bit (fixed)

Data Length: 7 or 8 bits

Parity: Even, odd or no parity

Stop Bit: 1 or 2 bits

Connector: DELC-J9PAF-13L6 (JAE or equivalent)

Hardware Handshaking: User can select whether RS and CS signals will always be

true, or be used for control.

Software Handshaking: User can select whether to control only transmission or both

transmission and reception using X-on and X-off signals.

X-on (ASCII 11H)

X-off (ASCII 13H)

Receiver Buffer Size: 256 bytes

Using the RS-232-C Interface

33

Page 35

Connecting the RS-232-C Interface Cable

Computer

This

instrument

RS [ready for reception of request to send]

SD [Send data]

RD [Received data]

CS [clear to send ready]

When connecting this instrument to a personal computer, make sure that the

handshaking, transmission rate and data format selected for the instrument match those

selected for the computer. For details, refer to the following pages. Use an interface

cable that is shielded and meets the instrument's specifications requirements.

Connectors and Signals

2 1 3 4 5

6 7 8 9

RS-232-C connector

Note: The instrument side is provided with a male D-Sub 9 pin.

2 RD (Received Data): Data received from personal computer

Signal direction: Input

3 SD (Send Data): Data transmitted to personal computer

Signal direction: Output

5 SG (Signal Ground): Ground for signals

7 RS (Request to Send): Signal used to handshake when receiving data from personal

computer

Signal direction: Output

8 CS (Clear to Send): Signal used to handshake when transmitting data from

personal computer

Signal direction: Input

Pins 1, 4, 6, and 9 are not used. Make sure, however, that pin 1 (Frame Ground) of the

counterpart is grounded.

Signal Direction

The figure below shows the direction of signals used by the RS-232-C interface.

34

Page 36

RS-232-C Standard Signals and their JIS and CCITT Abbreviations

Signals

Pin No.

Pin 9 connector

Abbreviation

RS-232-C

Name

CCITT

JIS

5

3

2

7

8

Pin 25 connector

7

2

3

4

5

AB (GND)

BA (TXD)

BB (RXD)

CA (RTS)

CB (CTS)

102 SG

103

104

105

106

SD

RD

RS

CS

Ground for signal

Send data

Clear to send

Received data

Request to send

RS-232-C Standard Signals

Notice on Connecting Printers

• Printers which support ESC/P commands can be used.

• When connecting a printer, refer to the printer specifications to ensure that a properly-

wired shielded cable is used.

• For details on the cable's pin assignments for connection to the CA100 calibrator,

refer to this information for an RS-232-C connector.

• Configure the baud rate, handshaking, and so on correctly, according to the

specifications of the printer being used.

Settings for Communication

The maintenance menu ([ZERO CLR] + [NEXT ENTER] keys) allows the setting of

communications functions.

Settings

Power source for communication

Turns the power supply to communications functions on and off. If this is disabled, no

communications function is available.

Using the RS-232-C Interface

35

Page 37

Communications modes

The following communications modes are available.

If the instrument continues providing output for more than two to three hours, it will

start delivering signals at an interval approximately one second longer than the preset

interval because of the characteristics of the internal clock.

Communication mode Description

Normal mode (nor) Allows operating normal communication functions.

Talk-only mode (tonLY) Outputs set generation value and measured value at specified interval (0*

Printer mode (Print) Outputs set generation value and measured value at specified interval (0*

* If 0 is specified for the interval, one data item is output whenever the [HOLD] key is pressed.

to 3,600 sec.).

to 3,600 sec.) via a printer.

Handshaking

To use an RS-232-C interface to transfer data between this instrument and a computer,

it is necessary to use certain procedures by mutual agreement to ensure the transfer of

data. These procedures are called "handshaking."

Various handshaking systems are available depending on the computers to be used; the

same handshaking system must be used for both the computer and this instrument.

There are four handshaking system combinations in this CA100 calibrator.

Handshaking System Combination (A circle indicates that the function is available.)

(Control method when sending data to computer)

Software

handshaking

Sending stops

when X-OFF

is received,

number

and sending

is resumed

when X-on is

Handshake mode selection

received.

0

1

2

3

Data send control

Hardware

handshaking

Sending stops when

CB (CTS) is false,

and sending is

resumed when CB

is true.

No

handshaking

(Control method when receiving data from computer)

Software

handshaking

X-OFF is sent when

the received data

buffer becomes

three quarters full,

and X-on is sent

when the received

data buffer becomes

one quarter full.

Data receiving control

Hardware

handshaking

CA (RTS) is set to false

when the received buffer

becomes three quarters

full, and is set to true

when the received data

buffer becomes one

quarter full.

Note

• The program for the personal computer must be designed in such a way that the receive buffers of

both this instrument and the personal computer never become full.

Precautions Regarding Data Receiving Control

When handshaking is used to control received data, data may still be sent from the

computer even if the free space in the receive buffer drops below 64 bytes. In this case,

after the received buffer is full, the excess data will be discarded, whether handshaking

is in use or not. Data storage to the buffer will begin again when there is free space in

the buffer.

No

handshaking

36

Page 38

Used

Circuit idle state

256 bytes

When handshaking is in use, reception of

data will stop when the free space in the

buffer drops to 64 bytes since data cannot

Used Free, 64 bytes

be passed to the main program fast

enough to keep up with transmission.

After the reception of data stops, data

continue to be passed to the internal

Free, 192 bytes

program. Reception of data starts again

when the free space in the buffer

increases to 192 bytes.

Whether handshaking is in use or not, if

the buffer becomes full, any additional

Used

received data are no longer stored and

are discarded.