Page 1

BVE80

BVPS80

BVP80

BVP80, BVPS80 & BVE80 Series

Pneumatically & Electrically Actuated

Barstock Ball Valves

Page 2

2

Page 3

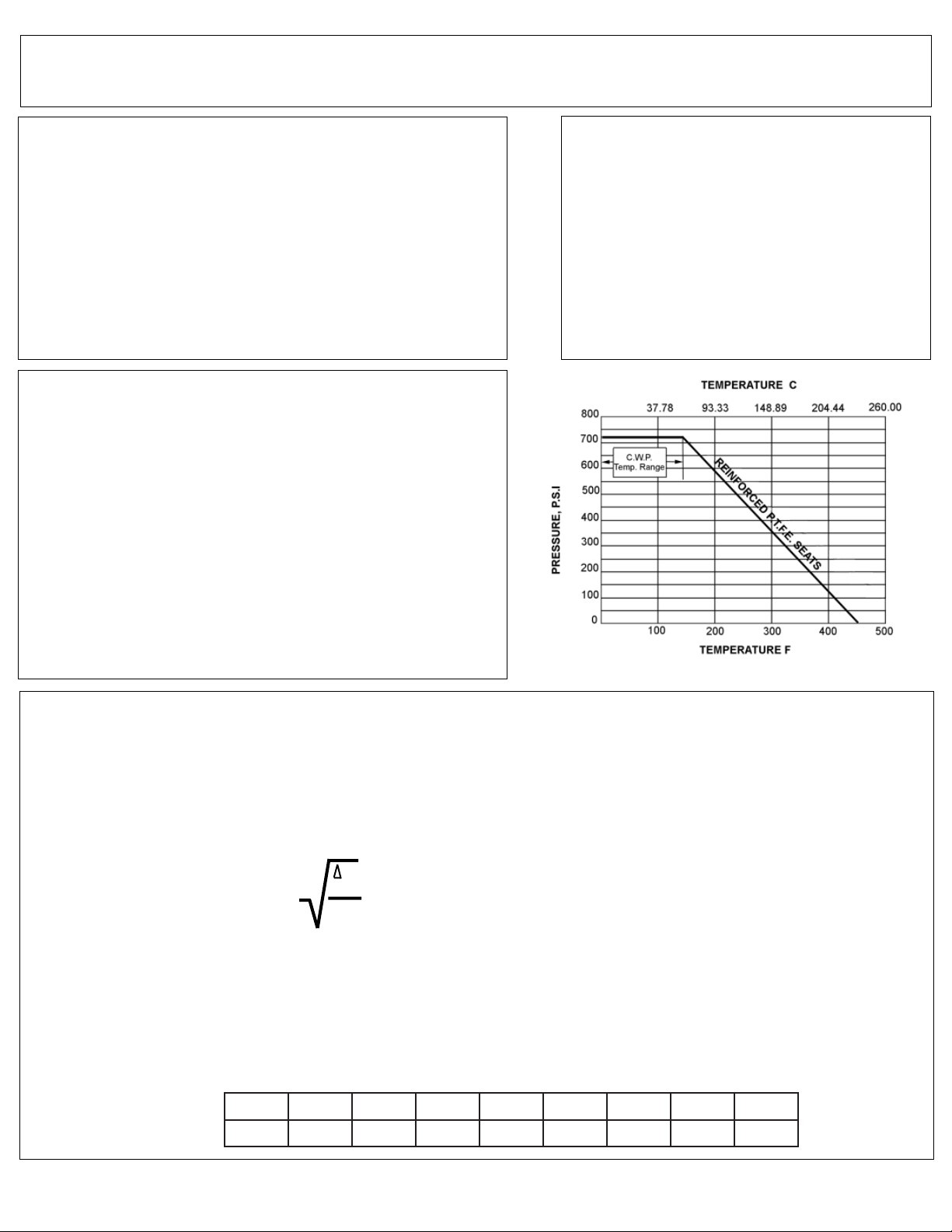

Ball Valve - RATINGS

TEMPERATURE: -50 F to 450 F

(also see Pressure Temperature Chart)

PRESSURE: 720 p.s.i. C.W.P. (Cold Working Pressure

to 150 F)

(also see Pressure Temperature Chart)

VACUUM: 20 Micron

SATURATED STEAM: 150 p.s.i.

BVP80, BVPS80 & BVE80 Series Ball Valves

Ball Valve - MATERIALS OF CONSTRUCTION

BODY: Brass - ASTM B-16, or 316 Stainless Steel -

ASTM A276

BALL AND STEM: 316 Stainless Steel

SEATS AND STEM SEAL: Glass Reinforced P.T.F.E.

(Teflon )

Ball Valve - CONNECTION / STYLE

SIZES

Pipe / N.P.T.F. 1/4” - 2”

Dryseal National Pipe Taper)

(

Ball Valve - FLOW CHARACTERISTICS

The approximate flow rate through a valve can be calculated as follows:

P

Q = Cv

G

where; Q = flow rate in gallons (U.S. Std.) per minute

Note: The values derived from the flow equation are for estimating purposes only. Product variances or

systemic factors may alter actual performance.

Cv = valve constant

P = pressure drop across the valve in pounds per square inch

G = specific gravity of the media of relative to water

eziS4/18/32/14/31 4/1-12/1-12

vC5.55.5821236428021

3

Page 4

BVP80 & BVPS80 Series Pneumatic Actuators

BVP80 & BVPS80 Pneumatic Actuators - MATERIALS OF CONSTRUCTION

BODY: Aluminium with Teflon Imprenated Hard Anodized (PolyLube) Sufaces

EXTERNAL HARDWARE: (Pinion Shaft, Driver, End Caps) 300 Series Stainless Steel

SPRING MODULES: Zytel Housing, 300 Stainless Hardware

EXTERNAL TRIM: 300 Series Stainless Steel

PILOT VALVE

SPOOL: 18-8 Stainless Steel SEALS: Niltrile / Viton

HARDWARE: 18-8 Stainless Steel COIL / BODY: GF Nylon / GF Zytel

BVP80 & BVPS80 Pneumatic Actuators - RATINGS / SPECIFICATIONS

TEMPERATURE: -20 F to 350 F

AIR SUPPLY: 50 - 125 psi air. Sufficient air delivery must be available at the actuator to ensure dependable

operation. The following precautions should be observed: Air supply should be clean and free of moisture.

When dirty or wet air is a problem; a filter / separator should be specified; these units are most effective when

installed as closely as possible to the actuator. A filter, when used, should permit a minimum flow of 4 scfm at an

upstream pressure of 60 psi. Eliminate severe restrictions to air flow (certain solenoid valves & fittings). The

most restricted passage must have an area no smaller than .012 inches square, the area of 1/8” diameter

orifice. If more than a single actuator is to be supplied by an individual pilot, the minimum passage requirement

applies per actuator.

TUBING: For short runs up to 5 feet 5/32” I.D. is suitable, 1/4” I.D. will serve up to 30 feet. For longer runs,

use 3/8” I.D. or larger.

DUTY CYCLE: 100% CYCLE TIME: (To Open or Close) Approximately 1/2 to 1 second*

* - Dependent upon actuator model, air pressure and delivery

AIR SUPPLY CONNECTION: 1/8” NPT

ELECTRICAL CONNECTION: Mini-DIN by Wire Strain Relief

ELECTRIC: Standard 120VAC Coil;

Wattage: 5

Class: F Continuous Duty

Protection: IP65 (with connector) Dust-tight, Water Resistant

BVP80 & BVPS80 Pneumatic Actuators- MAINTENANCE

Omega BVP70 & BVPS70 Series Pneumatic Actuators are designed to be maintenance free and normally are

replaced vs. repaired.

4

Page 5

BVE80 Series Electric Actuators

BVE80 Electric Actuator- MATERIALS OF CONSTRUCTION

ENCLOSURE: Dupont FR50 Cover, Teflon Coated Cast Aluminum Base

SHAFT: 18-8 Stainless Steel

EXTERNAL TRIM: 300 Series Stainless Steel

RATINGS / SPECIFICATIONS

TEMPERATURE: 40 F to 150 F

MOTOR: Reversing, Brushless, Capacitor-Run with Auto-Reset Thermal Overload Protection.

GEAR TRAIN: Permanently Lubricated, Maintenance Free

POWER: 120VAC 50/60 Hz Single Phase

PORTS: (2) 1/2” N.P.T. Conduit

CYCLE TIME: 6 Seconds

DUTY CYCLE: 1/4” - 1” Sizes;100% 1-1/4” - 2” Sizes; 75%

OVERRIDE: Manual - Fold Out Lever Handle

MANUAL OVERRIDE OPERATION

The push-button manual override system allows the user to easily disengage the electric drive gear train for

manual operation of the actuator. All external power must be off prior to using the manual override feature. The

actuator manual override handle can be used in the closed or open (lever extended) position to provide additional leverage. To open the handle, pinch the Lever Release Buttons and pull up. Press down the manual

override button (atop the center) and turn the handle to manually open or close the actuated valve assembly. To

reengage the drive train, release the override button and turn the handle until the manual override button ‘clicks’

signaling the re-engagement of the drive train. The manual override lever handle can then be closed.

Lever Release Buttons

Manual Override Button

5

Page 6

BVP80, BVPS80 & BVE80 Series Installation Instructions

Ball Valve - INSTALLATION INSTRUCTIONS

The following serves as a guideline for those experienced in pipe joint makeup. Otherwise, services of a

certified pipe fitter should be utilized for installation.

1. Ensure that both the male pipe and female valve threads are free from dirt, debris and corrosion. Wire

brushing of the male pipe threads is recommended to ensure a good metal-to-metal joint.

2. Apply a good quality thread lubricant (pipe dope) on the male threads. Lubricant reduces friction when

pulling up the pipe joint. Note, thread lubricant is not intended to seal the joint and will not compensate for

poor quality male pipe or fitting threads.

3. Turn the female valve threads onto the male pipe threads by hand. Upon free engagement of the

threads, continue to turn the valve as far up as it will go (by hand). With the use of a wrench continue to

tighten the valve onto the pipe. The pipe joint seal should occur within 1 to 3 turns after wrenching begins.

Care should be taken not to exceed 3 turns in which damage to the threads can occur.

4. The pipe joint should be tested for leakage to ensure the pipe joint has been achieved.

Pneumatic Actuator - INSTALLATION INSTRUCTIONS

1. Attached air supply to 1/8” NPT air inlet on integral pilot / solenoid valve.

2. The coil is equipped with a DIN x Strain electrical connector. To wire the connector, remove the center

mounting screw and, with a small screwdriver, pry the inner element from the body of the connector to expose

the terminal blocks inside. Route the wire through the hub of the connector. Loosen the sealing nut and ensure

the wire insulation passes through the rubber grommet inside the hub. Affix the wires to the appropriate terminal block. Retighten sealing nut to secure the wire and provide a seal.

Electric Actuator - INSTALLATION INSTRUCTIONS

1. Unlatch and open the override handle to access the handle nut. Remove nut with 3/4” wrench.

2. Remove eight (8) socket head screws with 4mm hex wrench. Remove cover by pulling straight up.

3. Route the wire to be terminated through conduit hub and up through the access space to the terminal block.

Strip insulation back 1/4”, insert the stripped ends directly into the proper terminal clamps and tighten screws.

All internal connections are labeled in the diagram, see Page 7.

4. Attach grounding wire to green screw that is located on top of conduction bar.

5. Verify that cover o-ring is properly seated in groove. Replace cover and screws.

6

Page 7

BVP70, BVPS70 & BVE70 Series Installation Instructions

Electric Actuator - INSTALLATION INSTRUCTIONS (continued)

120AC Wiring Schematic

7

Page 8

BVP80, BVPS80 & BVE80 Series Maintenance Instructions

Actuator - MAINTENANCE

The BVP80, BVPS80 & BVE80 Series actuators are maintenance free.

& Dimensions

Ball Valve - MAINTENANCE

The BVP80, BVPS80 & BVE80 Series utilizes our self compensating stem seal design. This design automatically compensates for wear as well as thermal expansion and contraction resulting in a leak tight, maintenance free, service life.

Once the stem seal has worn beyond the compensation afforded by the Belleville springs adjustment of the

stem nut may enable valve to be returned to service. Holding the ‘flats’ of the stem, tighten the stem nut until

Belleville springs become fully compressed (flattened); the torque required to tighten the nut further increases

sharply when this point is reached. Do not tighten the stem nut beyond this point to avoid damage of the stem

seal.

BVP80 & BVPS80 Series Dimensions

evlaV

eziS

8/3&4/1

2/1 60.481.122.216.2

4/3 83.405.167.249.2

1 44.600.220.323.3

4/1-1

2 74.800.3-75.4

nruteRgnirpS

SPVB

ledoM-epyTrotautcA

AB 1BCDEFGHI

63.100.135.113.60.376.4

elbuoD

gnitcA

PVB

78.155.152.205.05.481.5

sehcnI,snoisnemiDetamixorppA

J

6769/68

88.3

23.00.3

95.7

01.157.4

00.181.222.2

21.254.307.3

KLMN

26.313.818.275.

82.501.1162.428.2/1-1 90.826.240.452.4

8

Page 9

BVE80 Series Dimensions

eziSevlaVABCDEFGHIJK

8/3&4/100.122.251.100.347.652.657.432.287.277.553.01

2/181.116.242.100.347.652.657.432.287.277.553.01

4/305.149.204.100.347.652.657.432.287.277.553.01

149.123.326.100.347.652.657.432.287.277.553.01

4/1-121.207.367.108.442.752.657.432.287.277.558.01

2/1-126.252.420.208.442.752.657.432.287.277.558.01

200.375.412.208.442.752.657.432.287.277.558.01

sehcnI-snoisnemiD

9

Page 10

10

Page 11

11

M-4189/0405

Loading...

Loading...