Page 1

RESISTANCE WIRE FOR TEMPERATURE

COMPENSATION AND ZERO BALANCE

To Order Visit omega.com/bridge_completion_resistors_res for Pricing and Details

MODEL NO. FUNCTION MATERIAL Ω/FT TEMP COEFF. SPOOL LENGTH

SGB-36 Zero and span temp comp. Balco 19.7 0.45%/°C 500'

SGC-36 Zero and span temp comp. Copper 0.415 0.39%/°C 500'

SGM-36 Zero balance Manganin 15.2 0.002%/°C 200'

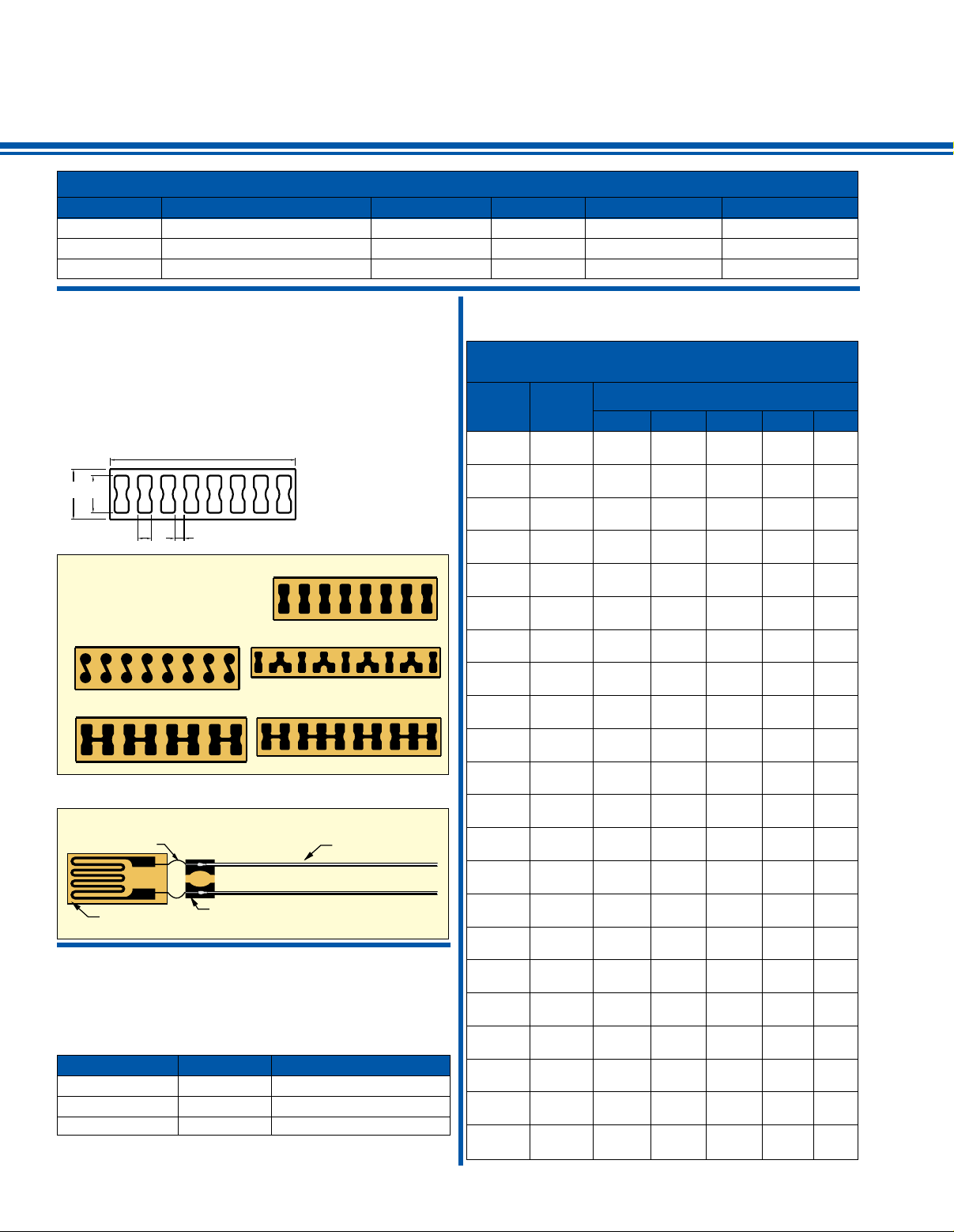

BONDABLE TERMINAL PADS

Terminal pads serve 2 main purposes. First, they act

as intermediate points for attaching ribbon leads of

thin-gage wire to heavier instrumentation wires. Second,

they give stress relief to strain gage systems. When the

heavy instrumentation wire moves, the terminal pad protects

the strain gage. Carrier is polyimide with a thickness of

0.075 mm (0.003"). Minimum bending radius is 2 mm (0.079").

Maximum temperature is 220°C (428°F).

D

B

A

C

E

Terminal pad patterns,

shown larger than actual size.

BTPB

BTPD

BTP-5 shown

actual size.

BTP

BTPC

BTPE

TYPICAL STRAIN GAGE INSTALLATION

Ribbon Leads from Strain Gage

or User Supplied Fine Gage Wire (30 AWG)

See omega.com

Adhesive,

See omega.com

BTP Series Terminal Pads for Stress Relief

and Junction for Different-Gage Wires,

See Chart at Right

Instrumention Wire

20 to 28 AWG

See omega.com

BRIDGE COMPLETION RESISTORS

Accuracy: 0.1%

Temperature Compensation: 5 ppm; -20 to 80°C (-4 to 176°F)

Power:

MODEL NO. Ω MAX BRIDGE EXC.

RES-120 120 10 Vdc

RES-250 250 15 Vdc

RES-350 350 18 Vdc

Note: For strain gage accessories see omega.com

Ordering Example: RES-350, 350 Ω bridge completion resistor.

1

⁄4 W

BONDABLE TERMINAL PADS

To Order Visit omega.com/bridge_completion_resistors_res

for Pricing and Details

MODEL PER

NO. PACK A B C D E

BTP-1 70 1.8 2.6 0.7 9.9 0.6

(0.07) (0.1) (0.03) (0.39) (0.02)

BTP-2 60 2.4 3.4 0.9 13.2 0.8

(0.09) (0.13) (0.04) (0.52) (0.03)

BTP-3 50 3.2 4.5 1.2 17.6 1

(0.13) (0.18) (0.05) (0.69) (0.04)

BTP-4 30 4.8 6.5 1.8 24 1.2

(0.19) (0.26) (0.07) (0.94) (0.05)

BTP-5 20 6 8.5 2.3 32.4 1.8

(0.24) (0.33) (0.09) (1.28) (0.07)

BTP-6 10 9 11.8 3.4 41.4 1.8

(0.35) (0.46) (0.13) (1.63) (0.07)

BTPB-1 70 1.8 2.6 0.7 9.9 0.6

(0.07) (0.1) (0.03) (0.39) (0.02)

BTPB-2 60 2.4 3.4 0.9 13.2 0.8

(0.09) (0.13) (0.04) (0.52) (0.03)

BTPB-3 50 3.2 4.5 1.2 17.6 1

(0.13) (0.18) (0.05) (0.69) (0.04)

BTPB-4 30 4.8 6.5 1.8 24 1.2

(0.19) (0.26) (0.07) (0.94) (0.05)

BTPB-5 20 6 8.5 2.3 32.4 1.8

(0.24) (0.33) (0.09) (1.28) (0.07)

BTPB-6 10 9 11.8 3.4 41.4 1.8

(0.35) (0.46) (0.13) (1.63) (0.07)

BTPC-1 30 3.2 4.5 1.2 28.6 1

(0.13) (0.18) (0.05) (1.13) (0.04)

BTPC-2 25 3.8 5.4 1.4 34.3 1.2

(0.15) (0.21) (0.06) (1.35) (0.05)

BTPC-3 20 4.8 6.5 1.8 39 1.2

(0.19) (0.26) (0.07) (1.54) (0.05)

BTPC-4 15 6 8.5 2.3 52.7 1.8

(0.24) (0.33) (0.09) (2.07) (0.07)

BTPD-1 25 2.4 3.4 0.9 13.2 0.8

(0.09) (0.13) (0.04) (0.52) (0.03)

BTPD-2 25 3.2 4.5 1.2 17.6 1

(0.13) (0.18) (0.05) (0.69) (0.04)

BTPD-3 20 4.8 6.5 1.8 24 1.2

(0.19) (0.26) (0.07) (0.94) (0.05)

BTPE-1 25 2.4 3.4 0.9 16.5 0.8

(0.09) (0.13) (0.04) (0.65) (0.03)

BTPE-2 25 3.2 4.5 1.2 22 1

(0.13) (0.18) (0.05) (0.87) (0.04)

BTPE-3 20 4.8 6.5 1.8 30 1.2

(0.19) (0.26) (0.07) (1.18) (0.05)

E-63

STRIPS

DIMENSIONS mm (inch)

Loading...

Loading...