Page 1

Solid State Relays

High Reliability, Vdc Input/

Vac Output, Vac Input/Vac Output

SSRL240AC10

SSRL Series

shown actual size.

U Current Ratings to 100 A

U Multi-Million Cycle Life

U Compatible with

Temperature Controllers

U Solid-State, SCR Design

U Zero Voltage Switching

U Control AC Lines

to 660 Vac

U AC and DC Control

Signal Models

U LED Input Status Indicator

U Thermal Conductive

Pad Included

The SSRL Series solid state relays

are used to control large resistance

heaters in conjunction with

temperature controllers. Solid state

relays are SPST, normally open

switching devices with no moving

parts, capable of millions of cycles

of operation. By applying a control

signal, an SSR switches “on” the

AC load current, just as the moving

contacts do on a mechanical

contactor. Three-phase loads can

be controlled using 2 or 3 SSR’s.

Use 3 SSR’s for “Y” or “star”

3-phase loads using a neutral line.

Two SSR’s will control “delta” loads

with no neutral line. Three solid

state relays are also used when

there is no neutral load to provide

redundancy and extra assurance

of control.

“Switching” takes place at the

0 voltage crossover point of the

alternating current cycle. Because of

this, no appreciable electrical noise

is generated, making SSR’s ideal

for environments where there are

apparatuses susceptible to RFI.

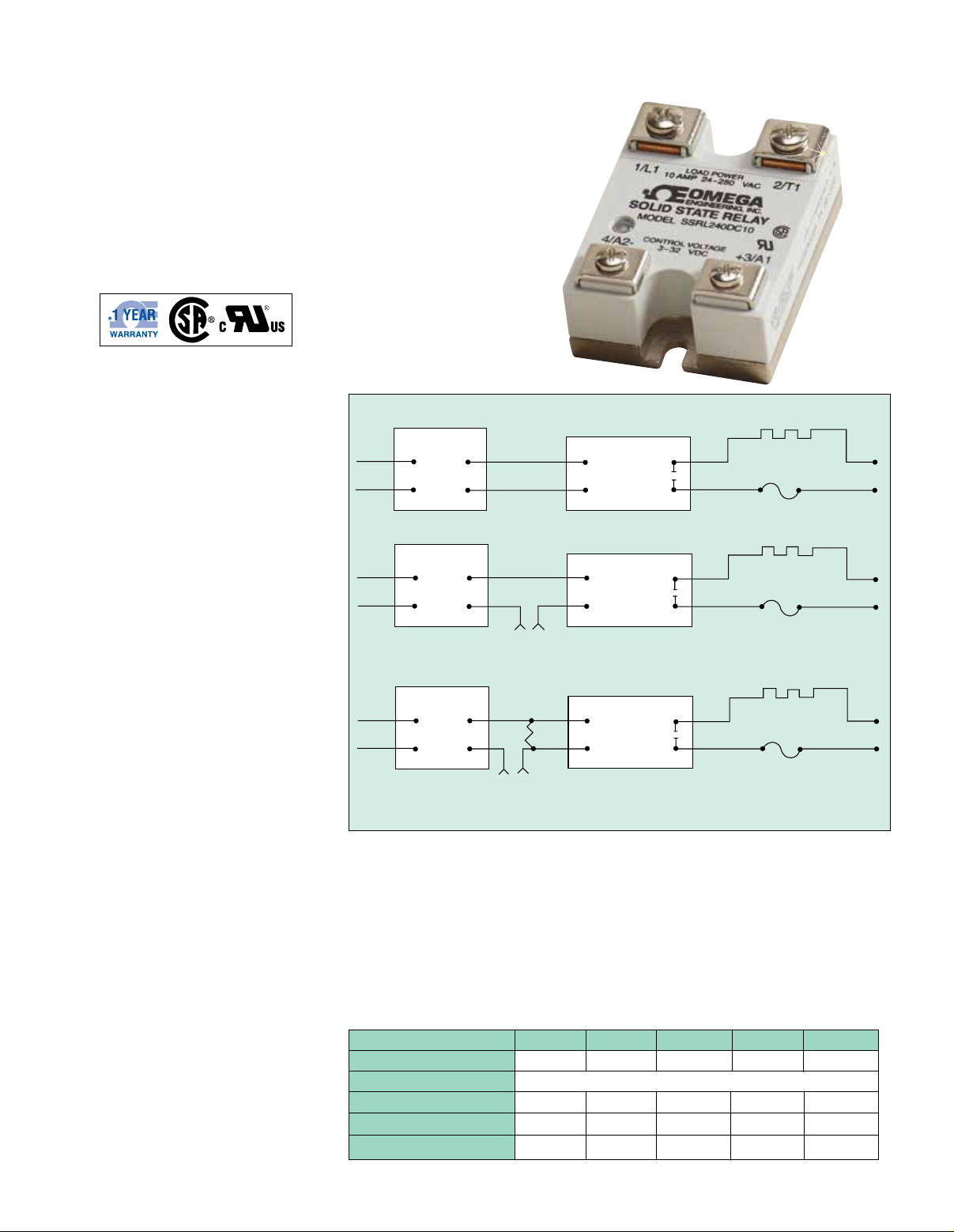

AC output SSR used with temperature controller with DC voltage SSR driver output

Temperature

Controller

Vac

AC output SSR used with temperature controller with mechanical relay output

Temperature

Controller

Vac

AC output SSR used with temperature controller with triac output

Temperature

Controller

Vac

Control

Side

0 or 5 Vdc,

Typically

Control

Side

Vac

Driving

SSR

Control Side

Load

Resistor

Vac

Driving

SSR

4

3

4

3

4

3

DC Input

SSR

AC Input

SSR

AC Input

SSR

Load

Side

1

2

Load

Side

1

2

Load

Side

1

2

Heater

Fast Blow

Fuse

Heater

Fast Blow

Fuse

Heater

Fast Blow

Fuse

Vac

Vac

Vac

Typical Applications

Common Specifications

Operating Temperature: -20 to 80°C

(-5 to 175°F)

Storage Temperature: -40 to 80°C

Capacitance: 8 pF, input to output (max)

Line Frequency Range: 47 to 63 Hz

Turn-On Time: 20 ms, AC; 05 cycle, DC

Turn-Off Time: 30 ms, AC; 05 cycle, DC

(-40 to 175°F)

Isolation: 4000 Vrms, input to output;

2500 Vrms input/output to ground

Output Specifications for Vac and Vdc Input Models

Specifications 10 Amp 25 Amp 50 Amp 75 Amp 100 Amp

Max On-State Current 10 A 25 A 50 A 75 A 100 A

Min On-State Current 100 mA

Max 1-Cycle Surge 150 A 300 A 750 A 1000 A 1200 A

Max 1 sec Surge 30 A 75 A 150 A 225 A 300 A

12T (60 Hz), A2sec 416 937 2458 5000 6000

P-111

Page 2

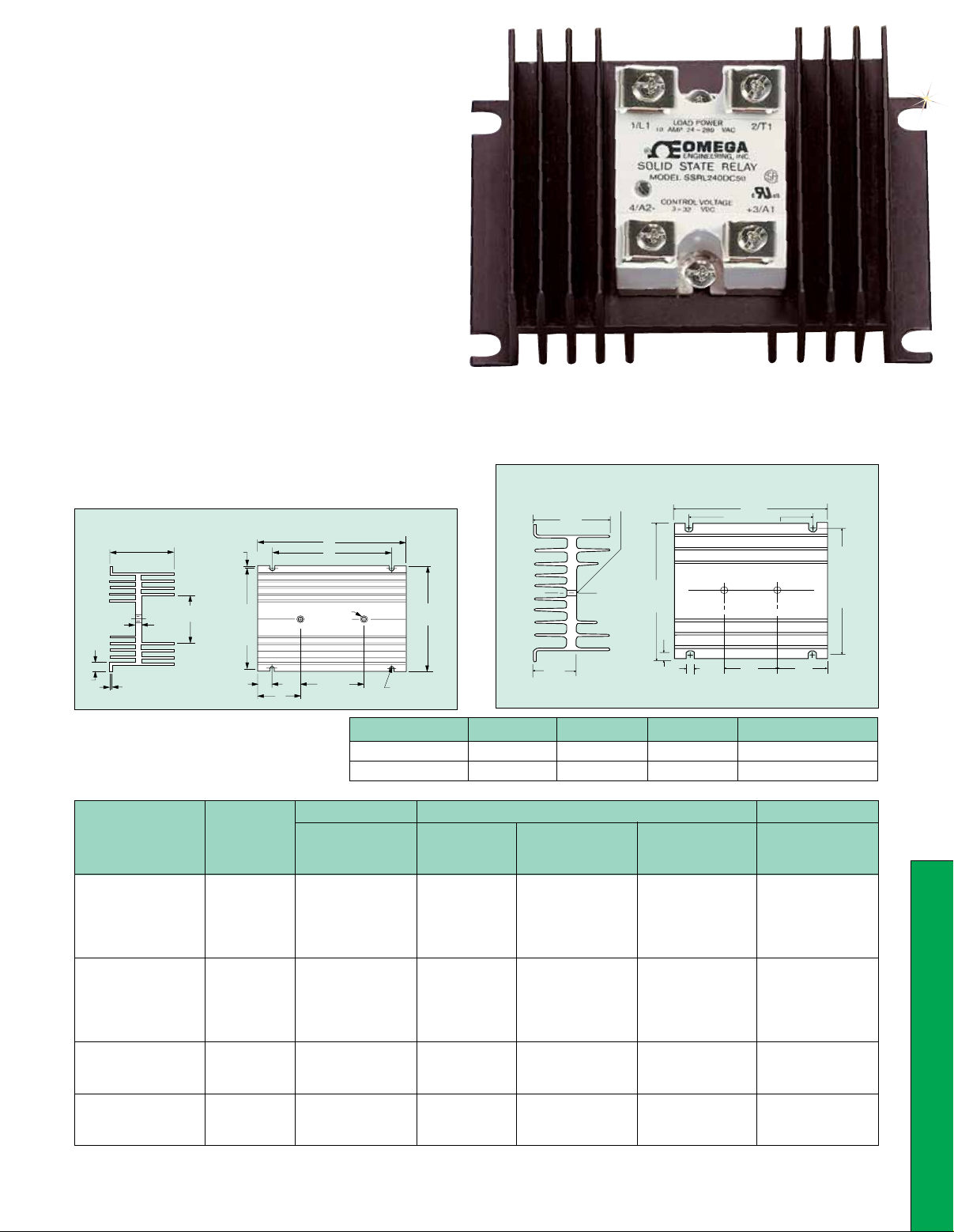

These SSR’s are of the twin SCR type, inherently

50.8 (2.000) 4.241

(0.167)

5.08

(0.200)

1.5748

(0.062)

112.17

(4.416)

6.35

(0.250)

C

47.625

(1.875)

A

B

120.65

(4.750)

3.175

(0.125)

R

8-32 TH'D

2 Places

50.8

(2.000)

more reliable and capable of higher overloads before

failure than triacs. Heat is developed in a solid state

relay due to the nominal voltage drop across the

switching device. To dissipate the heat, an SSR must

be mounted on a finned heat sink or aluminum plate.

An SSR should be located where the ambient temperature

is relatively low, since the current switching rating is

lowered as the temperature increases. Another SSR

characteristic is a small leakage current across the

output when the relay is open. Because of this, a

voltage will always exist on the load side of the device

In comparing SSR’s with mechanical contactors, the

SSR has a cycle life many times that of a comparably

priced contactor. However, SSR’s are more prone

to failure due to overload and improper initial wiring.

Solid state relays can fail, contact closed, on overload

circuits. It is essential that a properly rated, fast

blowing I

2

T fuse be installed to protect the load circuit

Finned heat sinks are anodized fabrications that come

complete with tapped mounting holes and screws.

See thermal rating curves and ordering instructions for

proper selection.

All SSRL series relays come with a thermally conductive

pad mounted on the baseplate. This will significantly

improve the thermal conductivity between the heat sink

and SSR baseplate. It is also suggested that 10"/lb of

torque be used on the SSR mounting screws.

FHS-1 and FHS-2 Heat Sink

Dimensions:

mm (inch)

SSRL240DC50 solid state relay shown smaller than actual size with

FHS-2 heat sink. See P-114 for more information.

FHS Heat Sink Dimensions

and Specifications

FHS-6 Heat Sink

SSR MOUNTING HOLES (2) 8-32 THDS.

66.5

(2.62)

C

L

120.7

(4.75)

Dimensions: mm (in)

139.7

(5.50)

114.3 (4.50)

C

L

12.7

(0.50)

115.8

(4.56)

CENTERS

(SCREWS)

#6

SSR240 Series

Electrical Specifications

Input-Control Signal Output

Control Control Control Max Peak

Signal Signal Signal Input Voltage*

Model No. Type Voltage Turn-On Turn-Off Current (60 s Max)

SSRL240AC10

SSRL240AC25 AC

SSRL240AC50 control 90 to 280 Vac 90 Vac 10 Vac 10 mA 800V

SSRL240AC75 signal

SSRL240AC100

SSRL240DC10

SSRL240DC25 DC

SSRL240DC50 control 3 to 32 Vdc 3 Vdc 1 Vdc 14 mA 800V

SSRL240DC75 signal

SSRL240DC100

SSRL660AC50 AC

SSRL660AC75 control 90 to 280 Vac 90 Vac 10 Vac 10 mA 1200V

SSRL660AC100 signal

SSRL660DC50 DC

SSRL660DC75 control 4 to 32 Vdc 4 Vdc 1 Vdc 14 mA 1200V

SSRL660DC100 signal

Transients above table value should be suppressed.

*

36.6

(1.44)

END VIEW

Model No. A B C Thermal Rating

5.6

(0.22)

(TYP.)

5.1

(0.20)

(TYP.)

47.5

(1.87)

TOP VIEW

FHS-1 3.00" 2.50" 0.56" 2°C/W

FHS-2 5.50" 5.00" 1.81" 1.2°C/W

P-112

46.0

(1.81)

P

Page 3

10.0

57

(2.250)

43

(1.700)

47

(1.850)

11

(0.480) SQ.

28

(1.100)

12

(0.470)

45

(1.750)

OUTPUT

8.0

6.0

4.0

2.0

LOAD CURENT (AMPERES)

0.0

20 30 40 50 60 70 80

SSR-10 AMP

3.0°C/W

AMBIENT TEMPERATURE (°C)

25.0

20.0

15.0

10.0

5.0

LOAD CURENT (AMPERES)

0.0

SSR-25 AMP

2.0°C/W

3.0°C/W

20 30 40 50 60 70 80

AMBIENT TEMPERATURE (°C)

1.5°C/W

1.0°C/W

50.0

40.0

30.0

20.0

10.0

LOAD CURENT (AMPERES)

0.0

SSR-50 AMP

1.0°C/W

1.5°C/W

2.0°C/W

20 30 40 50 60 70 80

AMBIENT TEMPERATURE (°C)

0.7°C/W

°C/W

0.5

75.0

60.0

45.0

30.0

15.0

LOAD CURENT (AMPERES)

0.0

7

(0.275)

INPUT

11

(0.450) SQ.

SSR-75 AMP

0.5

°

°

C/W

C/W

1.0

º

C/W

1.5

°

C/W

20 25 30 35 40 45 50 55 60 65 70 75 80

0.7

AMBIENT TEMPERATURE (°C)

57

(2.250)

43

(1.700)

47

(1.850)

12

(0.470)

(1.750)

28

(1.100)

11

(0.480) SQ.

45

OUTPUT

Dimensions:

mm (inch)

22

20

(0.870)

(0.785)

6

(0.250)

100.0

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

LOAD CURENT (AMPERES)

0.0

0510 15 20 25 30 35 40 45 50 55 60 65 70 75 80

1.0

°

C/W

0.7

°

0.5

C/W

AMBIENT TEMPERATURE (°C)

SSR-125 AMP

SSR-100 AMP

125.0

112.5

100.0

87.5

75.0

62.5

50.0

37.5

25.0

12.5

LOAD CURENT (AMPERES)

0.0

0510 15 20 25 30 35 40 45 50 55 60 65 70 75 80

1.0

°

C/W

0.7

°

C/W

0.5

°

C/W

0.4

AMBIENT TEMPERATURE (°C)

°

C/W

°

C/W

0.4

°

C/W

SSR240 Series Output-Vac Load Specifications

Nominal Nominal Maximum

AC Line Load Contact

Maximum Off-State Leakage

(25°C Maximum Ambient)

Model Number Voltage Current Voltage Drop 120 Vac 240 Vac 440 Vac

SSRL240AC10 10 A

SSRL240AC25 25 A

SSRL240AC50 24 to 280 Vac 50 A 1.6V 0.1 mA 0.1 mA N/A

SSRL240AC75 75 A

SSRL240AC100 100 A

SSRL240DC10 10 A

SSRL240DC25 25 A

SSRL240DC50 24 to 280 Vac 50 A 1.6V 0.1 mA 0.1 mA N/A

SSRL240DC75 75 A

SSRL240DC100 100 A

SSRL660AC50 50 A

SSRL660AC75 48 to 660 Vac 75 A 1.6V 0.25 mA 0.25 mA 0.25 mA

SSRL660AC100 100A

SSRL660DC50 50 A

SSRL660DC75 48 to 660 Vac 75 A 1.6V 0.25 mA 0.25 mA 0.25 mA

SSRL660DC100 100 A

P-113

Page 4

FB-1, FB-2,

and FB-3 fuse blocks

shown with KAX-25 fuses.

Fuses

To Order

Model No. Capacity Dimensions (Dia. x L)

KAX-10 10 A 14 x 51 mm (0.6 x 2")

KAX-25 25 A 14 x 51 mm (0.6 x 2")

KAX-30 30 A 14 x 51 mm (0.6 x 2")

KAX-50 50 A 21 x 81 mm (0.8 x 3.2")

KAX-70 70 A 31 x 92 mm (1.2 x 3.6")

KBH-50 50 A 18 x 81 mm (0.7 x 3.2")

KBH-70 70 A 19 x 92 mm (0.7 x 3.6")

Fuse Blocks

To Order

Model No. of

No. Fuses Compatible Fuses

FB-1 1 KAX-10, KAX-25, KAX-30

FB-2 2 KAX-10, KAX-25, KAX-30

FB-3 3 KAX-10, KAX-25, KAX-30

BS-101 1 KAX-50, KAX-70, KAX-100,

Shunt Resistors

for Controllers with AC SSR (Triac) Output

To Order

Model No.* Value

Visit omega.com/ssrl240_660 for Pricing

and Details

Visit omega.com/ssrl240_660 for Pricing

and Details

KBH (all models)

Visit omega.com/ssrl240_660 for Pricing

and Details

SSRR20-12 2000 Ω, 12 watts

SSRR20-50 2000 Ω, 50 watts

SSRR15-12 1500 Ω, 12 watts

SSRR15-50 1500 Ω, 50 watts

12 W versions for 120 V circuits; 50 W for 240 V.

*

All models shown smaller

than actual size.

BS-101 fuse blockshown

with KAX-50 fuse.

How to Order:

1) Select solid state relay based on type of control

signal (AC or DC) and current switching

requirements for resistive load.

2) Select fast blow (I2T) fuse and fuse block.

It is essential that a fuse be installed to protect

the load circuit.

3) Select required finned heat sink based on max

ambient temperature and thermal rating curve

on previous page.

To Order

Nominal

Model No. Description Rating

SSRL240AC10 10 A

SSRL240AC25 AC control 25 A

SSRL240AC50 signal 50 A

SSRL240AC75 (280 Vac line) 75 A

SSRL240AC100 100 A

SSRL240DC10 10 A

SSRL240DC25 DC control 25 A

SSRL240DC50 signal 50 A

SSRL240DC75 (280 Vac line) 75 A

SSRL240DC100 100 A

SSRL660AC50 AC control 50 A

SSRL660AC75 signal 75 A

SSRL660AC100 (660 Vac line) 100 A

SSRL660DC50 DC control 50 A

SSRL660DC75 signal 75 A

SSRL660DC100 (660 Vac line) 100 A

FHS-1 2°C/W

FHS-2 Finned heat sink 1.2°C/W

FHS-6 0.7°C/W

Accessory

Model No. Description

SSRL-DINRAIL-ADAPT DIN rail adaptor for 10 A

Comes complete with operator’s manual.

Note: All SSRL Series come with thermally conducting pad.

Reference SSR330 Series for additional heat sinks.

Ordering Examples: SSRL240DC25, solid state relay, FHS-2,

finned heat sink, KAX-25, fuse, and FB-1, fuse block.

SSRL240AC10, solid state relay, FHS-1, finned heat sink,

KAX-10, fuse, and FB-1, fuse block.

Visit omega.com/ssrl240_660 for Pricing

and Details

models only

P

P-114

Loading...

Loading...