Page 1

N.C.

N.C.

DATA B (QUAD)

DATA A ONLY

COMMON

+5 to +28VDC1

2

3

4

5

6

76.2 (3)

RIGHT SIDE VIEW (COVER REMOVED)

REMOVE THIS SIDE

COVER TO EXPOSE

TERMINAL STRIP

1/2" NPT

CONDUIT

THD

TOP VIEW

FRONT VIEW

BOTTOM VIEW

76.2 (3)

152.4 (6)

76.2

(3)

.375 DIA. SHAFT

.75 LONG, 303

STAINLESS STEEL

1/4"-20 THD, 1/2" DEEP ON 2 (50.8)

DIA. BOLT CIRCLE 4 HOLE

PATTERN, FRONT AND BOTTOM

IndustrIal duty

DISC

SLOTTED

SHAFT

LED

PHOTO XISTOR

1.5K

COMMON

DATA A

+VDC

PULSE

SHAPING

AMPLIFIER

SINGLE CHANNEL

(ORDER SEPARATELY)

CABLE & CONNECTOR ASSY

REF.

DISC

SLOTTED

SHAFT

LED

PHOTO XISTOR

1.5K

COMMON

DATA A

+VDC

PULSE

SHAPING

AMPLIFIER

SINGLE CHANNEL

(ORDER SEPARATELY)

CABLE & CONNECTOR ASSY

SHAFT

LED

PHOTO XISTOR

1.5K

COMMON

DATA A

+VDC

PULSE

SHAPING

AMPLIFIER

SINGLE CHANNEL

(ORDER SEPARATELY)

CABLE & CONNECTOR ASSY

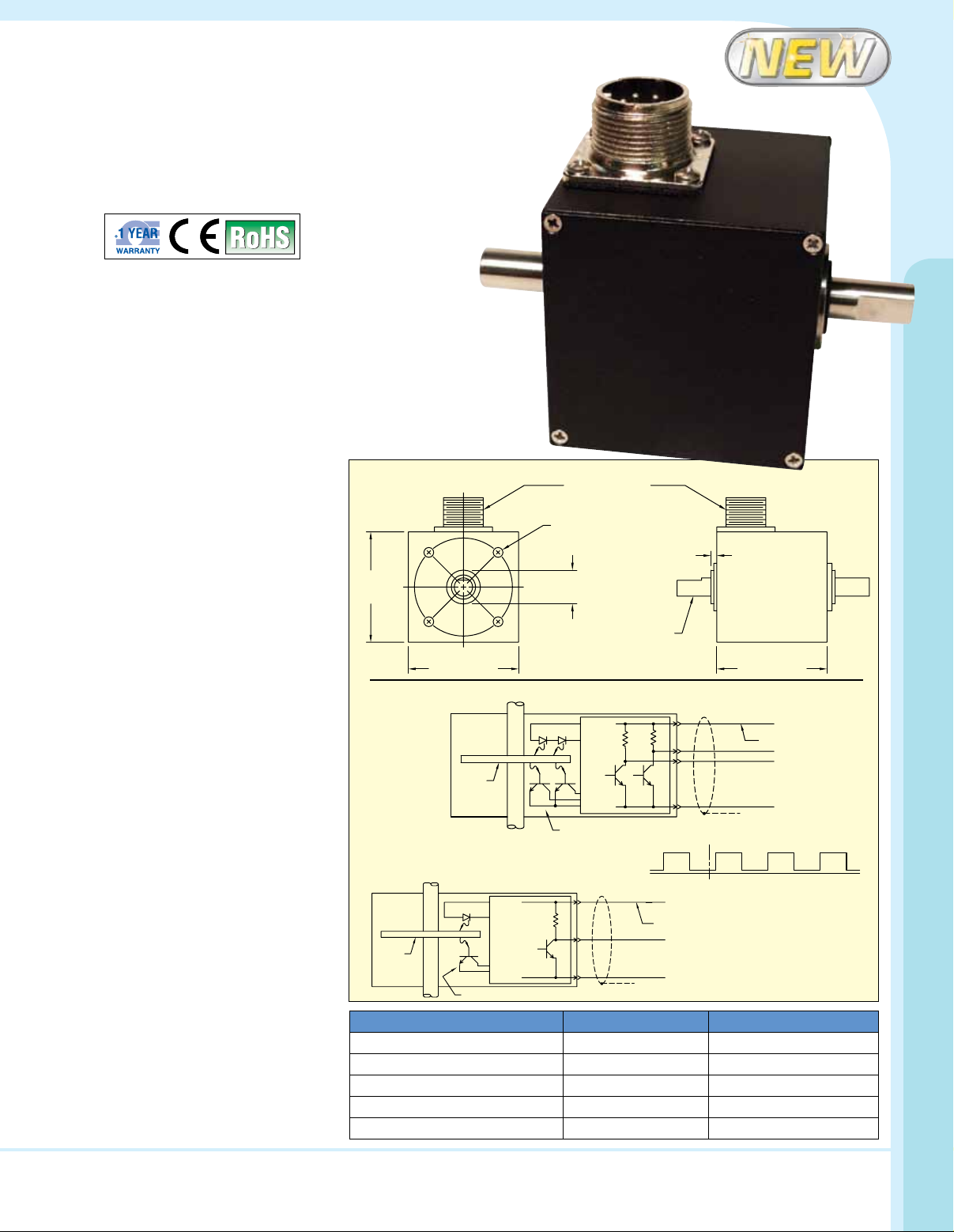

rotary EncodEr

shaft EncodErs

ZB Series

• Single Channel or Quadrature

Output Models

• Current Sinking, 250 mA Maximum

• 4.75 to 28 Vdc Supply Voltage

• Up to 1000 PPR for High

Resolution Precision Counting or

Speed Measurement

• 6000 RPM Shaft Speed

• Conversion Bracket for Length

Sensor Measurement

AU-ZBG01002 industrial duty

encoder, 100 ppr with 6-pin MS

connector, shown smaller than

actual size.

Dimensions: mm (inch)

Drives and Motors

MS TYPE CONNECTOR

The ZB Series shaft encoders are general

duty industrial rotary pulse generators. The

AU-ZBG models are for single channel sensing

for counting, one directional measuring or

speed applications. The AU-ZBH models

are for quadrature applications, allowing for

counting up and down along with speed and

direction measurements. A conversion bracket

is available to easily convert this encoder

into a length measuring sensor. They can be

direct-coupled to a machine shaft by means

of a flexible-bellows, spring, or rubber sleeve

type coupling that allows for axial and radial

misalignment. They can also be coupled with

light instrument timing-belts. Timing-belt

drives also allow convenient gear-up or geardown speed ratio changes that can be useful

for obtaining non-standard PPR rates.

SPECIFICATIONS

ELECTRICAL

Supply Voltage: 4.75 to 28 Vdc @ 80 mA

maximum from 0 to 85°C (32 to 185°F)

4.75 to 24 Vdc @ 80 mA maximum from

0 to 100°C (32 to 212°F)

Output: Current sinking, 250 mA

maximum current per output

ZBG (Single Channel): 250 mA maximum

ZBH (Quadrature): 250 mA maximum

current per output (quad. phase

relationship is 90° ±22.5 electrical

degrees)

Maximum Frequency: 1000 ppr, 20 KHz

Connections: 6-pin MS style

connector (male) (MIL-C-5015)

6-32 THD .25" DEEP ON

2 (50.8) DIA. BOLT CIRCLE

57.15

(2.25)

52.2

51.75

Electrical connections

SLOTTED

DISC

(BOTH SHAFT ENDS & BOTTOM)

24.7 MAX.

(0.974)

9.5 (0.375) DIA. SHAFT

19 (0.750) LONG, BOTH ENDS

)(

QUADRATURE

LED'S

SHAFT

DUAL

CHANNEL

PULSE

SHAPING

AMP.

PHOTO XISTOR'S

1.5K

1.5K

REF.

2.41

(0.095)

)(

52.2

51.75

+VDC

CABLE & CONNECTOR ASSY

(ORDER SEPARATELY)

DATA A

DATA B

COMMON

FUNCTION 6-PIN MS CONN CABLE WIRE COLOR

+Vdc

COMMON

DATA A

DATA B (if applicable, quad)

NO CONNECTION

A RED

B BLACK

C WHITE

D GREEN

E —

1

Page 2

SINGLE WHEEL

74.4 (2.93)

DUAL WHEEL 101.6 (4)

(0.85)

21.6

SINGLE SHAFT UNITS

THIS WHEEL AND SHAFT

OMITTED ON

CAUTION: Downward tension

on signal cable can cause

wheel(s) to lift. Make sure

cable is clamped to

machine frame near

encoder and allow slack.

NOTE: The weight at the

Length Sensor unit

provides sufficient traction

for accurate operation

when mounted as shown,

with arm angle from

horizontal not exceeding

±30°, and with hinge clamp

toward the far extreme of

the extension arm.

SINGLE WHEEL

74.4 (2.93)

DUAL WHEEL 101.6 (4)

(0.85)

21.6

SINGLE SHAFT UNITS

THIS WHEEL AND SHAFT

OMITTED ON

CAUTION: Downward tension

on signal cable can cause

wheel(s) to lift. Make sure

cable is clamped to

machine frame near

encoder and allow slack.

NOTE: The weight at the

Length Sensor unit

provides sufficient traction

for accurate operation

when mounted as shown,

with arm angle from

horizontal not exceeding

±30°, and with hinge clamp

toward the far extreme of

the extension arm.

SINGLE WHEEL

74.4 (2.93)

DUAL WHEEL 101.6 (4)

SINGLE SHAFT UNITS

THIS WHEEL AND SHAFT

OMITTED ON

22.4 (.88)

WHEEL

RADIUS

48.3

(1.9)

175.3 (6.9 )

CAUTION: Downward tension

on signal cable can cause

wheel(s) to lift. Make sure

cable is clamped to

machine frame near

encoder and allow slack.

NOTE: The weight at the

Length Sensor unit

provides sufficient traction

for accurate operation

when mounted as shown,

with arm angle from

horizontal not exceeding

±30°, and with hinge clamp

toward the far extreme of

the extension arm.

22.4

(0.88)

73.7

(2.9)

63.5 (2.5)

31.8

(1.25)

6.3 (0.25)

Lock washers (2) must be

installed between bolt heads

and top clamp piece.

E-clip retaining ring (2)

must be installed in slots.

SINGLE WHEEL

74.4 (2.93)

DUAL WHEEL 101.6 (4)

(0.85)

21.6

SINGLE SHAFT UNITS

THIS WHEEL AND SHAFT

OMITTED ON

22.4 (.88)

WHEEL

RADIUS

48.3

(1.9)

175.3 (6.9 )

CAUTION: Downward tension

on signal cable can cause

wheel(s) to lift. Make sure

cable is clamped to

machine frame near

encoder and allow slack.

NOTE: The weight at the

Length Sensor unit

provides sufficient traction

for accurate operation

when mounted as shown,

with arm angle from

horizontal not exceeding

±30°, and with hinge clamp

toward the far extreme of

the extension arm.

MECHANICAL

Maximum Shaft Speed: 6000 RPM

Shaft Diameter: 9.5 mm (0.375")

Radial Shaft Load: 18 kg (40 lbs) operating

Axial Shaft Load: 13.6 kg operating (30 lbs)

Starting Torque: ZBG and ZBH: 0.38 oz-in

(2.68 N-mm)

Moment Of Inertia: 6.5 x 10-6 oz-in-sec

2

Housing: Black non-corrosive finished

6063-T6 aluminum

Bearings: ABEC 3 double sealed ball bearings

Weight: 10 oz (283.5 g)

ENVIRONMENTAL

Operating Temperature: 0 to 100°C

(32 to 212°F) (see supply voltage on

previous page)

Storage Temperature: -25 to 85°C

(-13 to 185°F)

Humidity: 98% RH non-condensing

Vibration: 10 g @ 58 to 500 Hz

Shock: 50 g @ 11 msec duration

Note: NPN Transistor outputs have 1.5 KΩ

load resistors returned to supply for internal

feed back purposes. This does not interfere

with the ability to use these outputs as

conventional “Open-Collector” outputs as long

as the supply voltage for the ZB is supplied

by the indicator or control receiving its output

signal. The ZB’s internal load resistor also

allows the output to be used as a current

source, however, load current must be limited

to 1 mA maximum

Convert to Length Sensor

The length sensor conversion bracket, model

AU-LSCB1000, comes with a 3 m (10')

long, 4 wire shielded cable and a 6-pin MS

connector. The hinge clamp assembly–model

AU-LSAHC001, provides an easy method

for attachment and mounting of the rotary

encoder to be used as a length sensors with

the AU-LSCB1000 conversion bracket. This

can be used with one or two wheels as the

application requires.

Length Sensor

Measurement Accuracy

Factors which affect measurement accuracy

include measuring wheel accuracy and wear,

and material conditions. Ideally, materials

which are hard, thin and strong provide good

readings, conversely, soft, thick and elastic

materials can present problems in obtaining

true readings. The great majority of these

situations, where this effect is consistent, can

be compensated for by applying a multiplier

to the quadrature output pulse train so as to

obtain a corrected measurement. Counter

or Rate Indicators with “input scaling” can

compensate for measuring wheel wear and

material elastic and compliance errors.

Wheels–

Maximum Wheel Speed is 600 RPM

“F” style wheels are made with a tan

polyurethane tread and are used for soft,

smooth materials such as paper, matting,

cardboard and fine weave textiles. The broad

width minimizes contact pressure and the tan

polyurethane tread minimizes marking.

2

86.4

(3.4)

50.8

(2.00)

73.7

(2.9)

(1.50)

31.8

(1.25)

63.5 (2.5)

4X Ø 7.9 (0.31)

38.1

19.0

(0.75)

WHEEL

RADIUS

114.3 (4.50)

144.8 (5.70)

19.0 (0.75)

Lock washers (2) must be

installed between bolt heads

and top clamp piece.

6.3 (0.25)

E-clip retaining ring (2)

must be installed in slots.

22.4

(0.88)

175.3 (6.9 )

48.3

(1.9)

21.6

(0.85)

SINGLE WHEEL

74.4 (2.93)

DUAL WHEEL 101.6 (4)

22.4 (.88)

Dimensions: mm (inch)

CAUTION: Downward tension

on signal cable can cause

wheel(s) to lift. Make sure

cable is clamped to

machine frame near

encoder and allow slack.

NOTE: The weight at the

Length Sensor unit

provides sufficient traction

OMITTED ON

SINGLE SHAFT UNITS

THIS WHEEL AND SHAFT

Length Sensors should be mounted so measuring

wheel(s) contact ribbon, strip or web as it passes over

a roller. As an alternative, wheel(s) can be driven by

roller surface next to material being measured.

for accurate operation

when mounted as shown,

with arm angle from

horizontal not exceeding

±30°, and with hinge clamp

toward the far extreme of

the extension arm.

Page 3

Diamond Knurled Aluminum

Tread

10-32 UNF

Set Screw

Alum.

Cast

-.000"

+.001"

Bore

(0.376)

9.6

25.4

(1)

The “K” style wheel is diamond knurled aluminum and used on rubber, course weave

fabrics, rough wood surfaces, foam and insulation.

Dimensions: mm (inch)

Tan, Smooth Polyurethane

Tread

10-32 UNF

9.6

(0.376)

Bore

+.001"

-.000"

Cast

Alum.

25.4

(1)

Set Screw

(0.376)

“F” style wheel has

polyurethane tread.

To Order Visit omega.com/zb_series for Pricing and Details

MODEL NO. DESCRIPTION

AU-ZBG01002

AU-ZBG10002

AU-ZBH01002

AU-ZBH10002

Single channel shaft encoder, 100 ppr

Single channel shaft encoder, 1000 ppr

Quadrature encoder shaft encoder, 100 ppr

Quadrature encoder shaft encoder, 1000 ppr

9.6

Bore

+.001"

-.000"

Cast

Alum.

25.4

(1)

“K” style wheel has knurled

aluminum tread.

Diamond Knurled Aluminum

Tread

10-32 UNF

Set Screw

Drives and Motors

ACCESSORIES

MODEL NO. DESCRIPTION

CCARPG01

CCARPG025

CCARPG050

AU-RPGFC002

AU-RPGFC003

AU-RPGFC004

AU-RPGFC005

AU-LSCB1000

AU-LSAHC001

AU-WF1000F

AU-WF1000K

AU-WM0400F

AU-WM0400K

Ordering Examples: AU-ZBG10002 single channel shaft encoder with 1000 ppr, CCARPG01, 6-pin MS connector with 3 m (10') cable,

and AU-RPGFC003, flexible shaf coupling, 0.375-0.375".

AU-ZBH10002 quadrature encoder with 1000 ppr, CCARPG01 3 m (10') cable with 6-pin MS connector, and AU-WF1000F 0.3 m (1')

circumference urethane measuring wheel.

6-pin MS connector with 3 m (10'), 22 AWG 4-conductor with drain, shielded cable

6-pin MS connector with 7.6 m (25'), 22 AWG 4-conductor with drain, shielded cable

6-pin MS connector with 15 m (50'), 22 AWG 4-conductor with drain, shielded cable

Flexible shaft coupling, 25 mm (1") long, 0.250 - 0.375"

Flexible shaft coupling, 25 mm (1") long, 0.375 - 0.375"

Flexible shaft coupling, 25 mm (1") long, 0.375 - 0.500"

Flexible shaft coupling, 25 mm (1") long, 0.375 - 6 mm

Length sensor conversion bracket

Hinge clamp assembly for sensor conversion bracket

0.3 m (1') circumference urethane measuring wheel

0.3 m (1’) circumference knurled measuring wheel

4

⁄10th meter circumference urethane measuring wheel

4

⁄10th meter circumference knurled measuring wheel

3

Loading...

Loading...