Page 1

NEMA 4X NoN-MEtAllic

PolycArboNAtE ENclosurEs

AMP Series

Electrical Junction

Boxes

l Suited for Higher Temperatures

or Corrosive Environments

l Protect Controls and Components

Indoor or Outdoors

l UL 94 Flammability Rating

l UV Stabilized for Outdoor Use

l Molded-in Hinge with Stainless

Steel Hinge Pin

l Solid or Clear Cover with Screw

or Latch Closures

l Optional Sub-Panels Available

l Molded-in Bosses for Direct

Mounting of DIN Rail

l Raised Cover with Additional

Depth for Optional Front Panel

l Factory Installed Mounting

Flanges or Polycarbonate

Mounting Feet Included

AMP664F, enclosure

with screw closure

and factory installed

mounting feet, shown

smaller than actual size.

AMP series non-metallic polycarbonate

enclosures are designed to insulate and

protect electrical controls and components

in both indoor and outdoor applications

and are especially well suited for higher

temperatures and corrosive environments.

These NEMA 4X and IP66 plastic junction

boxes feature raised covers with a variety

of screw or latching options that allow you

to provide the level of security or ease of

access needed for each application. Hinged

models are constructed with a stainless

steel hinge pin and padlocking latches are

available in stainless steel or non-corrosive

plastic snap latches.

The AMP series enclosure are well suitable

for mild acid conditions such as aluminum

chloride, boric acid, calcium chloride, sea

water, sodium nitrate and zinc chloride.

OM-AM series plastic enclosures are

available with the added feature of a raised

cover. The cover adds an additional 22 mm

(0.88") of depth to accommodate meters and

controllers, switches and other devices, and

can be used with the optional front panel

for maximum configuration within a single

enclosure.

AMP1206CCNLF,

enclosure with

clear cover, shown

with aluminum sub-

panel OM-PLA120,

and front panel kit

OM-HFPP120.

SPECIFICATIONS

Standards: UL50, UL50E, UL508A and

UL706C

UL Types: 1, 2, 3, 4, 4x, 12 and 13

CSA-C22: No. 14

CAN/CSA-C22: No.94

CSA Types: 1, 2, 3, 3R, 4 4X, 12 and 13

NEMA Types: 1, 2, 3, 3R, 4, 4X, 12 and 13

IEC 60529: Type IP66

CONSTRUCTION

Materials: Injection molded

polycarbonate thermoplastic

Temperature Rating: -35 to 130°C

(-31 to 266°F)

Hinge: Molded hinge with stainless steel pin

Color: Light gray – RAL#7035

Cover Seal: Closed cell neoprene, in

continuous tongue and grove channel

Internal Mounting: #10-32 threaded brass

inserts for sub-panel, plastic bosses for

DIN rail for #10 sheet metal screws

Page 2

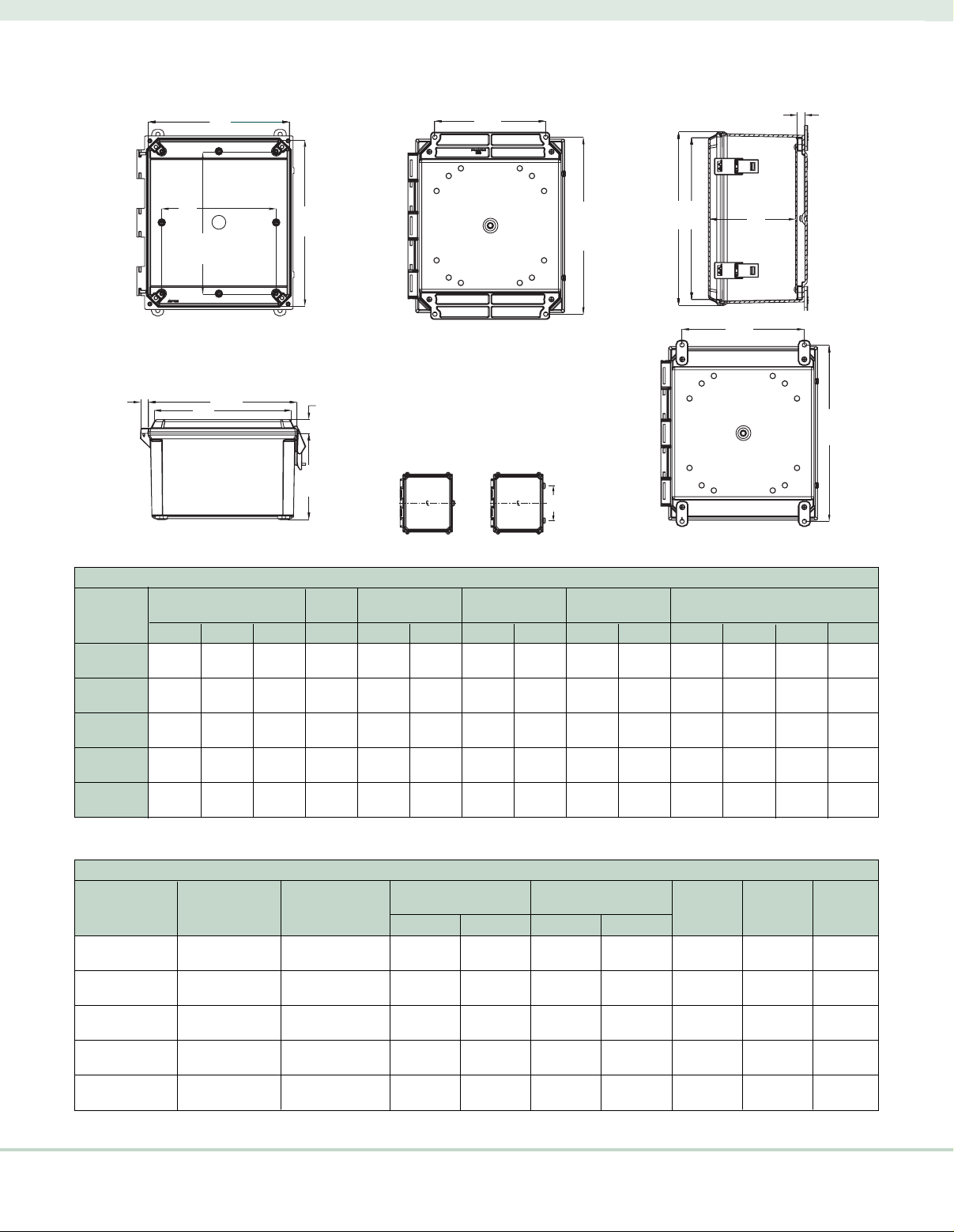

J

I

FLANGE MOUNT

J

H

I

FLANGE MOUNT

15 mm

(0.58)

B

F

U

M

J

I

J

FLANGE MOUNT

15 mm

(0.58)

F

U

M

J

H

L

I

NOTE: COVER REMOVED FOR CLARITY

LATCH LOCATIONS

FOR USE ON

6 x 6 x 4

8 x 6 x 4

10 x 8 x 4

FOR USE ON

12 x 10 x 6 D = 191 mm (7.50)

14 x 12 x 6 D = 203 mm (8.00)

FLANGE MOUNT

15 mm

(0.58)

B

A

Z

S

F

U

M

J

H

L

D

I

15 mm

(0.58)

Z

A

I

U

M

F

S

NOTE: COVER REMOVED FOR CLARITY

14 mm

(0.57)

W

K

22 mm

(0.87)

FLANGE MOUNT

LATCH LOCATIONS

FOR USE ON

6 x 6 x 4

8 x 6 x 4

10 x 8 x 4

FOR USE ON

12 x 10 x 6 D = 191 mm (7.50)

14 x 12 x 6 D = 203 mm (8.00)

L

C

D

FOOT MOUNT

DIMENSIONS: mm (in)

BOX SIZE USABLE PANEL BOSS FLANGE MOUNT FOOT MOUNT

INSIDE DIMENSIONS DEPTH CENTERS CENTERS CENTERS COVER SIZE

A B C F S Z J I H L K M W U

AMP664 151 156 101 106 108 108 102 173 125 171 150 144 171 165

(5.93) (6.16) (3.98) (4.18) (4.25) (4.25) (4.00) (6.81) (4.91) (6.75) (5.89) (5.67) (6.72) (6.50)

AMP864 202 156 101 106 159 108 102 224 125 222 150 195 171 216

(7.94) (6.16) (3.98) (4.18) (6.25) (4.25) (4.00) (8.81) (4.91) (8.75) (5.89) (7.67) (6.72) (8.50)

AMP1084 252 207 101 106 210 159 152 273 175 273 200 246 221 267

(9.93) (8.16) (3.98) (4.18) (8.25) (6.25) (6.00) (10.75) (6.91) (10.75) (7.89) (9.67) (8.72) (10.50)

AMP1206 303 258 152 157 260 210 203 324 224 323 251 296 272 318

(11.93) (10.16) (5.98) (6.18) (10.25) (8.25) (8.00) (12.75) (8.82) (12.75) (9.89) (11.67) (10.72) (12.50)

AMP1426 354 309 152 157 311 260 254 373 275 373 302 347 323 368

(13.93) (12.16) (5.98) (6.18) (12.25) (10.25) (10.00) (14.68) (10.82) (14.75) (11.89) (13.67) (12.72) (14.50)

Nomimal wall thickness 3.7 mm (0.14")

DIMENSIONS: mm (in)

WITH ALUMINUM WITHOUT

SUB-PANEL SUB-PANEL

MODEL NO. SUB-PANEL FRONT PANEL A-MIN A-MAX B-MIN B-MAX C D-MIN D-MAX*

AMP664 AMP-PLA66 OM-HFPP66

(1.71) (3.21) (2.39) (3.89) (0.58) (0.88) (2.38)

AMP864 AMP-PLA86 OM-HFPP86

(1.71) (3.21) (2.39) (3.89) (0.58) (0.88) (2.38)

(1.71) (3.21) (2.39) (3.89) (0.58) (0.88) (2.38)

AMP1206 AMP-PLA120 OM-HFPP120

(3.71) (5.21) (4.39) (5.89) (0.58) (0.88) (2.38)

AMP1426 AMP-PLA142 OM-HFPP142

(3.71) (5.21) (4.39) (5.89) (0.58) (0.88) (2.38)

Note: Aluminum sub-panels are 2.54 mm (0.100") thick, steel sub-panels are 1.91 mm (0.75") thick.

* Front panel stops can be installed from the edge of the box to 1.5" deep into the box.

AMP1084 AMP-PLA108 OM-HFPP108

2

43 82 62 99 15 22 60

43 82 62 99 15 22 60

43 82 62 99 15 22 60

94 132 112 150 15 22 60

94 132 112 150 15 22 60

Page 3

Adjustable front

panel support.

Closures

Detail of plastic

latch front panel.

• Lift-off cover with four screws

• Molded-in hinge with two screws

• Molded-in hinge with padlocking SS snap latch

• Molded-in hinge with padlocking plastic snap latch

Solid cover with 4 screws.

ACCESSORIES TO ORDER VISIT omega.com/amp for Pricing and Details

MODEL NO, DESCRIPTION

SCE-6P6 Carbon steel sub-panel for 6 x 6 enclosure - painted white

SCE-8P6 Carbon steel sub-panel for 8 x 6 enclosure - painted white

SCE-10P8 Carbon steel sub-panel for 10 x 8 enclosure - painted white

SCE-12P10 Carbon steel sub-panel for 12 x 10 enclosure - painted white

SCE-14P12 Carbon steel sub-panel for 14 x 12 enclosure - painted white

AMP-PLA66 Aluminum sub-panel for 6 x 6 enclosure

AMP-PLA86 Aluminum sub-panel for 8 x 6 enclosure

AMP-PLA108 Aluminum sub-panel for 10 x 8 enclosure

AMP-PLA120 Aluminum sub-panel for 12 x 10 enclosure

AMP-PLA142 Aluminum sub-panel for 14 x 12 enclosure

OM-HFPP66 Hinged front panel kit for 6 x 6 enclosure

OM-HFPP86 Hinged front panel kit for 8 x 6 enclosure

OM-HFPP108 Hinged front panel kit for 10 x 8 enclosure

OM-HFPP120 Hinged front panel kit for 12 x 10 enclosure

OM-HFPP142 Hinged front panel kit for 14 x 12 enclosure

Solid cover with SS latch.

Clear cover with plastic

latch and front panel.

Page 4

To Order Visit omega.com/amp for Pricing and Details

MODEL NO. SIZE: INCHES COVER CLOSURE

AMP664F 6 H x 6 W x 4 D Solid 4 Screws

AMP664HF 6 H x 6 W x 4 D Solid Hinge with 2 screws

AMP664CCF 6 H x 6 W x 4 D Clear 4 Screws

AMP664CCHF 6 H x 6 W x 4 D Clear Hinge with 2 screws

AMP664NLF 6 H x 6 W x 4 D Solid Plastic Snap Latch

AMP664LF 6 H x 6 W x 4 D Solid SS Snap Latch

AMP664CCNLF 6 H x 6 W x 4 D Clear Plastic Snap Latch

AMP664CCLF 6 H x 6 W x 4 D Clear SS Snap Latch

AMP864F 8 H x 6 W x 4 D Solid 4 Screws

AMP864HF 8 H x 6 W x 4 D Solid Hinge with 2 screws

AMP864CCF 8 H x 6 W x 4 D Clear 4 Screws

AMP864CCHF 8 H x 6 W x 4 D Clear Hinge with 2 screws

AMP864NLF 8 H x 6 W x 4 D Solid Plastic Snap Latch

AMP864LF 8 H x 6 W x 4 D Solid SS Snap Latch

AMP864CCNLF 8 H x 6 W x 4 D Clear Plastic Snap Latch

AMP864CCLF 8 H x 6 W x 4 D Clear SS Snap Latch

AMP1084F 10 H x 8 W x 4 D Solid 4 Screws

AMP1084HF 10 H x 8 W x 4 D Solid Hinge with 2 screws

AMP1084CCF 10 H x 8 W x 4 D Clear 4 Screws

AMP1084CCHF 10 H x 8 W x 4 D Clear Hinge with 2 screws

AMP1084NLF 10 H x 8 W x 4 D Solid Plastic Snap Latch

AMP1084LF 10 H x 8 W x 4 D Solid SS Snap Latch

AMP1084CCNLF 10 H x 8 W x 4 D Clear Plastic Snap Latch

AMP1084CCLF 10 H x 8 W x 4 D Clear SS Snap Latch

AMP1206F 12 H x 10 W x 6 D Solid 4 Screws

AMP1206HF 12 H x 10 W x 6 D Solid Hinge with 2 screws

AMP1206CCF 12 H x 10 W x 6 D Clear 4 Screws

AMP1206NLF 12 H x 10 W x 6 D Solid Plastic Snap Latch

AMP1206CCHF 12 H x 10 W x 6 D Clear Hinge with 2 screws

AMP1206LF 12 H x 10 W x 6 D Solid SS Snap Latch

AMP1206CCNLF 12 H x 10 W x 6 D Clear Plastic Snap Latch

AMP1206CCLF 12 H x 10 W x 6 D Clear SS Snap Latch

AMP1426F 14 H x 12 W x 6 D Solid 4 Screws

AMP1426HF 14 H x 12 W x 6 D Solid Hinge with 2 screws

AMP1426CCF 14 H x 12 W x 6 D Clear 4 Screws

AMP1426CCHF 14 H x 12 W x 6 D Clear Hinge with 2 screws

AMP1426NLF 14 H x 12 W x 6 D Solid Plastic Snap Latch

AMP1426LF 14 H x 12 W x 6 D Solid SS Snap Latch

AMP1426CCNLF 14 H x 12 W x 6 D Clear Plastic Snap Latch

AMP1426CCLF 14 H x 12 W x 6 D Clear SS Snap Latch

Ordering Example: AMP664HF, solid cover enclosure with hinge and 2 screw closure.

AMP1206CCFL, clear cover enclosure with stainless steel snap latches, AMP-PLA120,

aluminum sub-panel for 12x10" enclosure.

4

Loading...

Loading...